Sample preparation process method

A process method and sample preparation technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of sample edge deformation, pollution, and inaccurate sample analysis results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

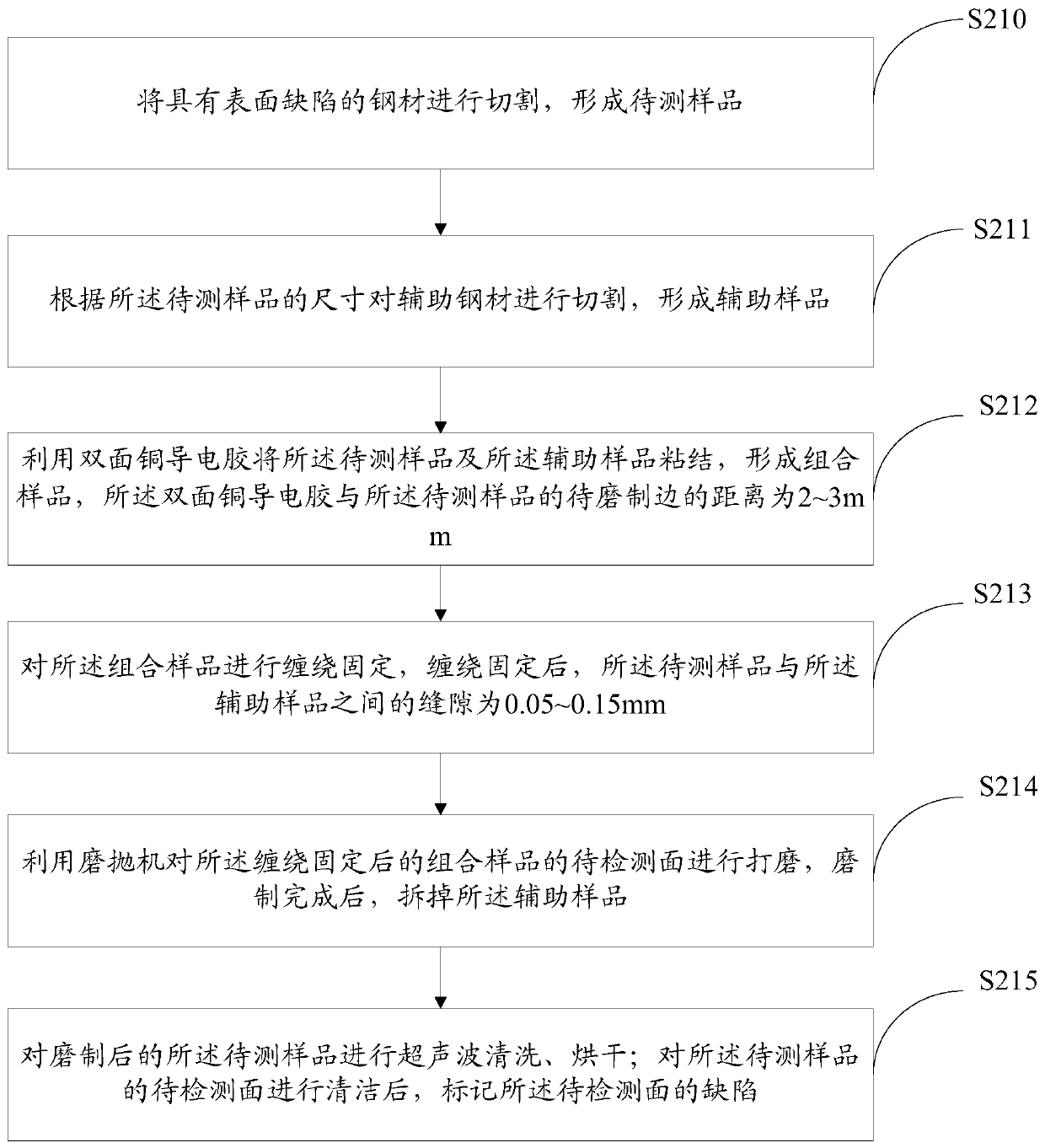

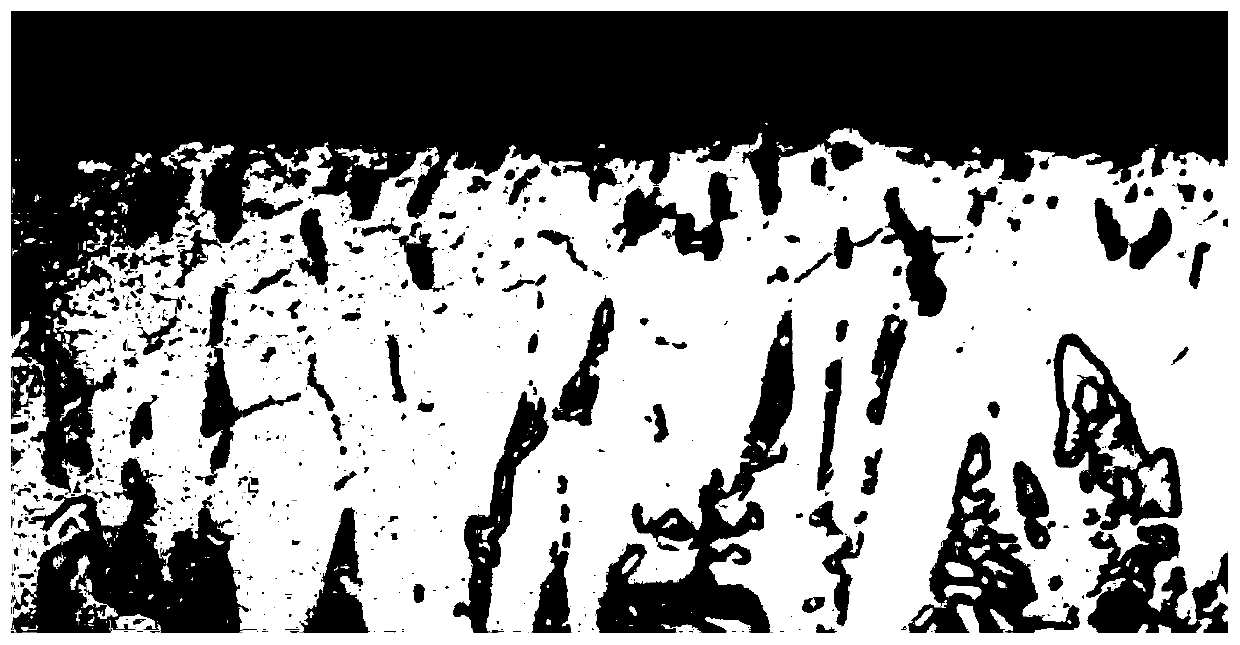

[0042] In order to solve the problem that the conventional sample preparation method in the prior art will cause deformation, damage or contamination of the sample edge, etc., resulting in inaccurate analysis results of the sample, and cannot provide objective and accurate data for process improvement and product quality improvement in actual production, Ultimately lead to the technical problem of not being able to ensure the quality of the product. The embodiment of the present invention provides a sample preparation process method. The method includes: cutting the steel with surface defects to form a sample to be tested; The steel is cut to form an auxiliary sample. The thickness of the auxiliary sample is 1-2mm, and the flatness of the auxiliary sample and the sample to be tested is kept consistent; The auxiliary sample is bonded to form a combined sample, and the distance between the double-sided copper conductive adhesive and the edge to be ground of the sample to be teste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com