A rail flaw detection signal generation and processing device

A signal generation and processing device technology, which is applied in the direction of processing detection response signals, measuring devices, instruments, etc., can solve the problems of misjudgment, damage detection accuracy and efficiency, etc., to reduce noise interference and improve damage recognition rate , the effect of reducing the misjudgment rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

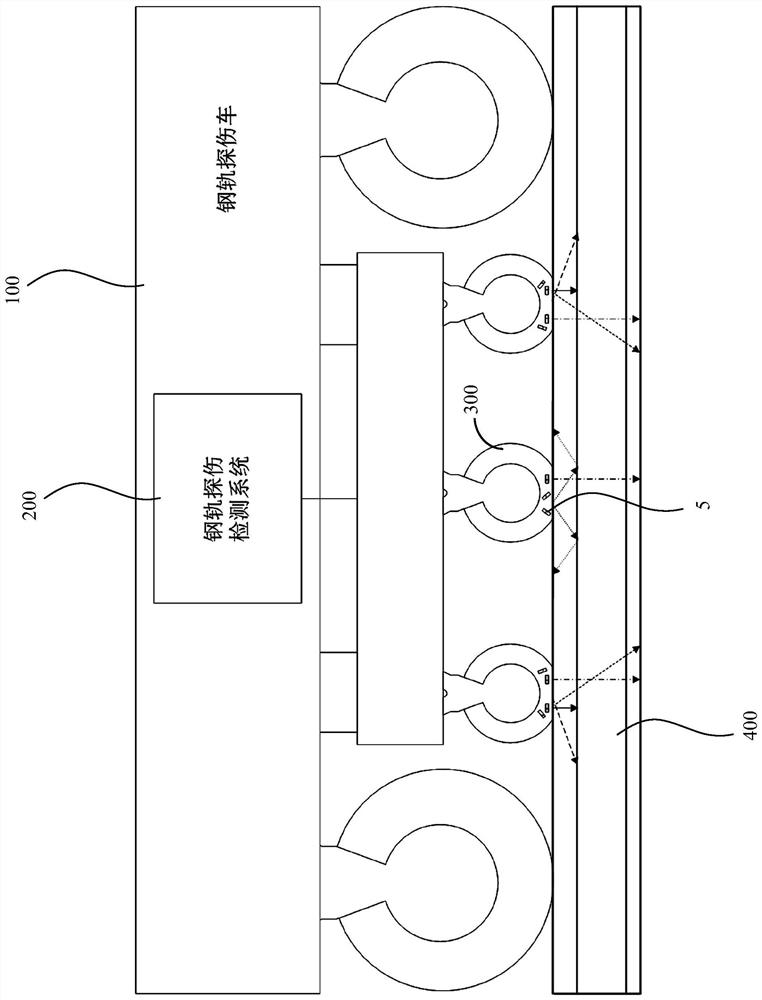

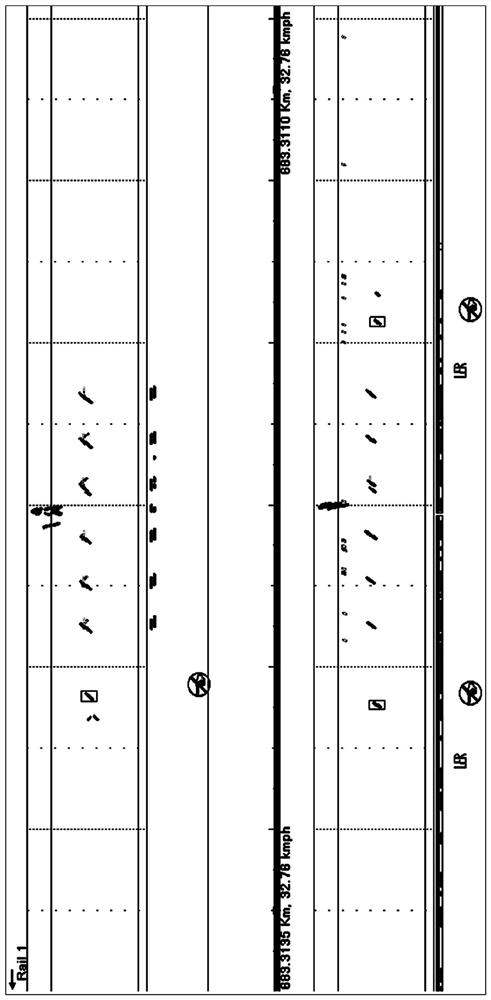

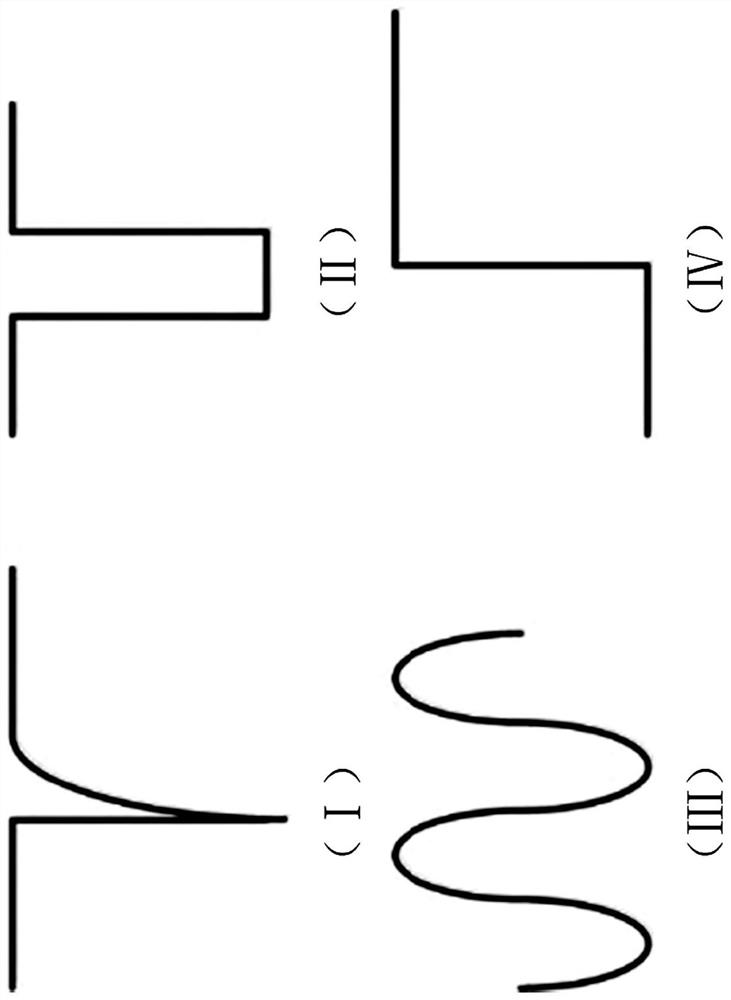

[0042] as attached Figure 5 As shown, an embodiment of a rail flaw detection signal generation and processing device specifically includes: a host computer parameter setting module 1, a real-time controller 2, a transmission pulse timing control module 3 and an ultrasonic excitation generation module 4. Set the pulse start time, transmission cycle and delay time of the high-voltage excitation signal of each channel through the host computer parameter setting module 1, and download them to the real-time controller 2. The real-time controller 2 generates corresponding control pulses through the bus control emission pulse sequence control module 3, and the control pulse controls the pulse number and the cycle of the ultrasonic excitation generation module 4 output high-voltage excitation signal, and the high-voltage excitation signal acts on the ultrasonic chip 5 (i.e. piezoelectric sensor) and generate an ultrasonic signal, which is incident on the rail 400. After the ultrason...

Embodiment 2

[0049] as attached Figure 9 As shown, an embodiment of a rail flaw detection signal generation and processing method based on the device described in Embodiment 1 specifically includes the following steps:

[0050] A) Set the pulse starting moment, the emission cycle and the delay time of the high-voltage excitation signal of each channel through the host computer parameter setting module 1, and download it to the real-time controller 2;

[0051] B) the real-time controller 2 generates corresponding control pulses through the bus control emission pulse sequence control module 3;

[0052] C) The emission pulse timing control module 3 controls the number and period of pulses of the high-voltage excitation signal output by the ultrasonic excitation generation module 4 by outputting control pulses;

[0053] D) The ultrasonic excitation generating module 4 outputs a high-voltage excitation signal to act on the ultrasonic chip 5 and generate an ultrasonic signal, which is incident...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com