Wind speed online monitoring method

A technology of wind speed and air duct, which is applied in the field of primary and secondary wind monitoring in power plants, and can solve problems such as poor anti-blocking effect of pressure induction pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

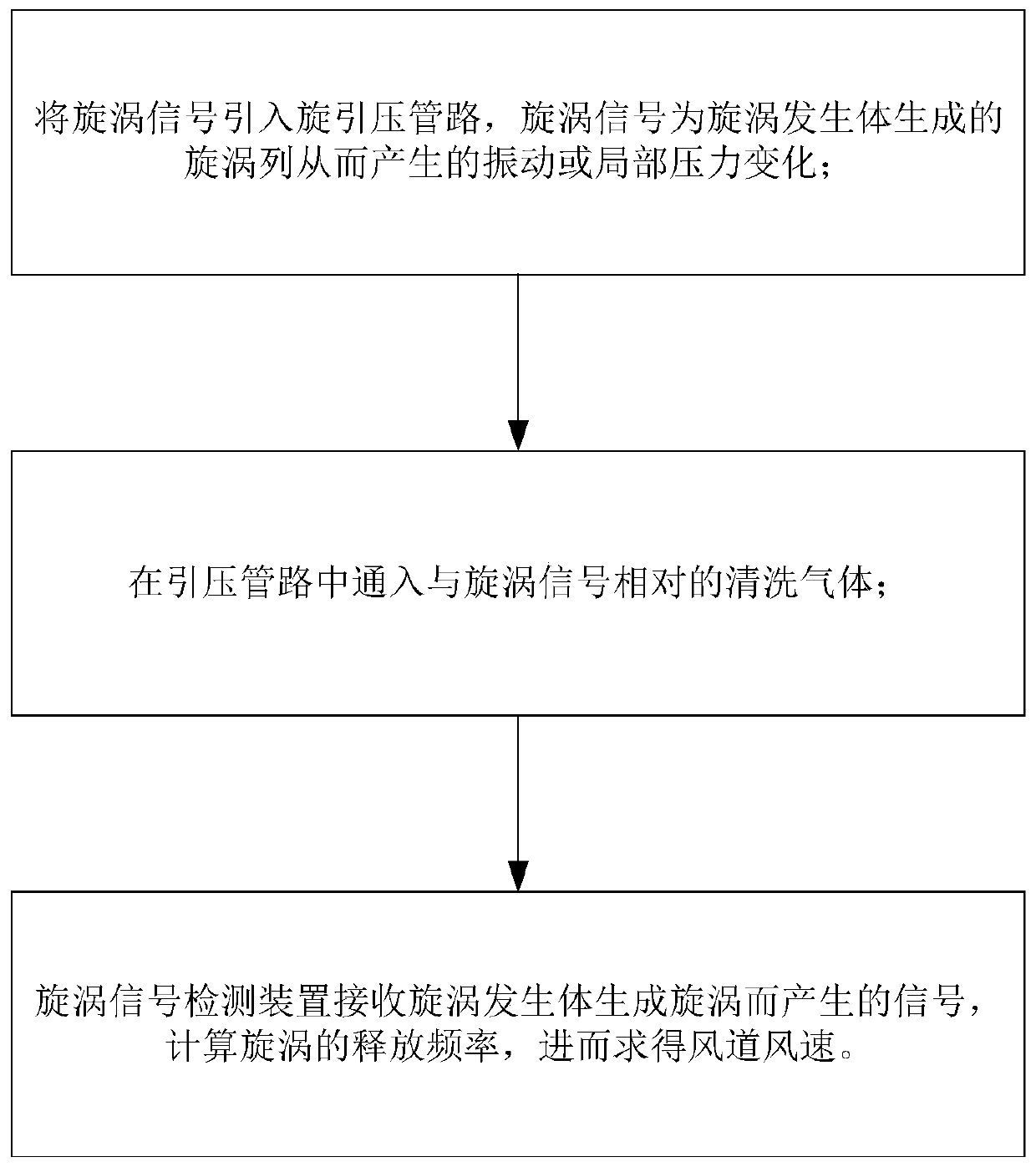

Method used

Image

Examples

Embodiment 1

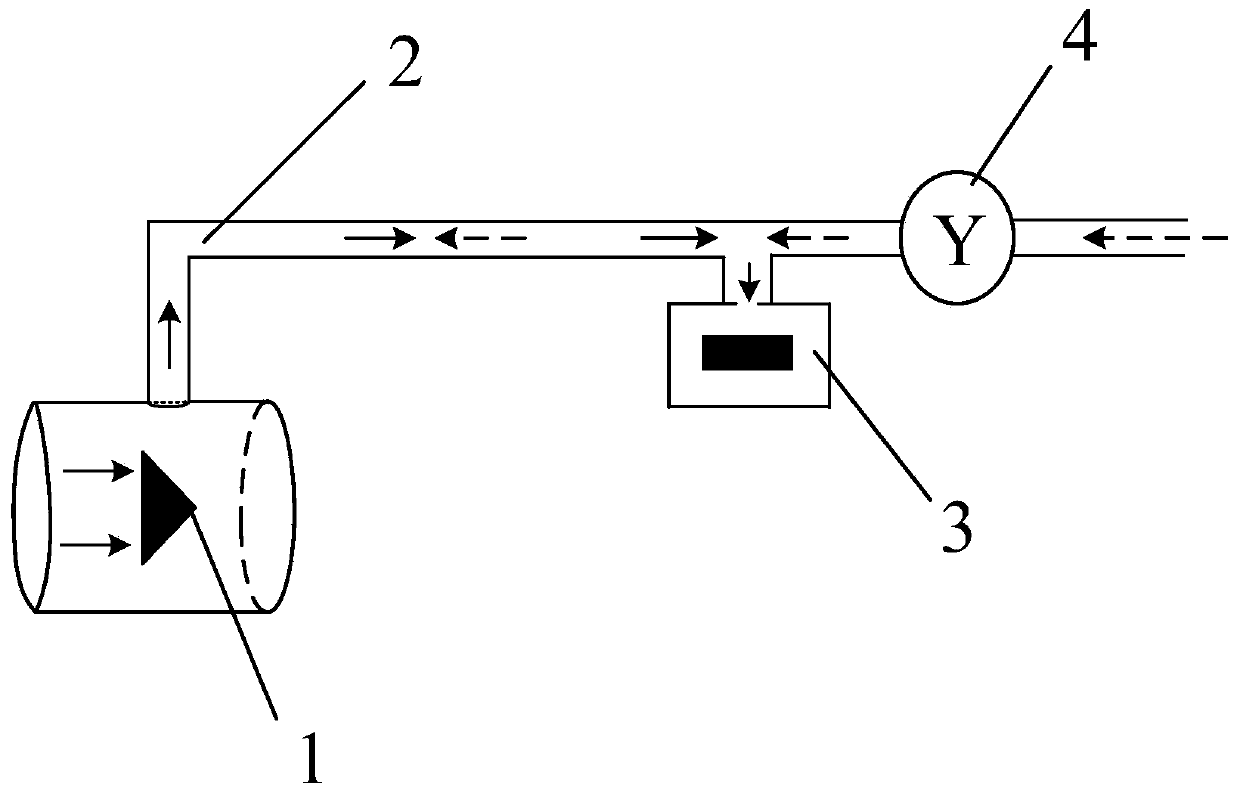

[0026] The wind speed online monitoring device applicable to this embodiment is such as figure 2 As shown, the probe air duct is included. In order to facilitate the measurement, the probe air duct is generally consistent with the extension direction of the air duct to be measured. The vortex generator 1 is set in the probe air duct, and a pressure pipe 2 is set on the probe air duct downstream of the vortex generator 1. The pressure pipe 2 is connected to the electret 3 (that is, the vortex signal detection element), and the pressure pipe The end is connected to the cleaning branch, and a pressure regulating valve 4 is provided on the cleaning branch.

[0027] During monitoring, according to the principle of Karman vortex street generation, a vortex train with a certain frequency will be generated downstream of the vortex generator 1. When the vortex is generated, the pressure near the vortex changes, and the pressure pipe 2 transmits the pressure change caused by the vortex tra...

Embodiment 2

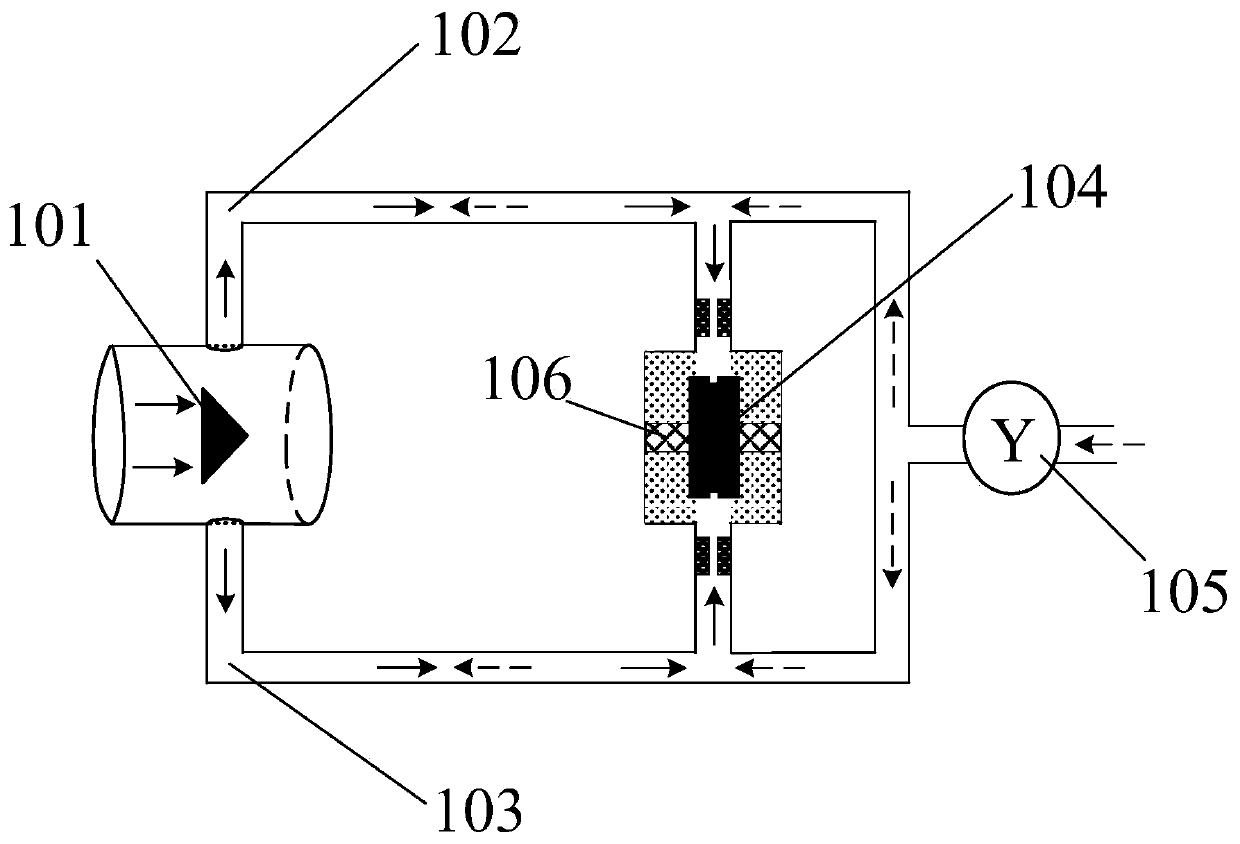

[0039] The difference between the second embodiment and the first embodiment is that the device in the second embodiment uses two pressure-inducing pipelines. When only one impulse pipeline is used, the signal waveform detected by the electret is poor. Therefore, two pressure pipes arranged symmetrically with respect to the electret are adopted. When using two pressure-inducing pipelines, the electret will not block the entire space in which it is located, so the electret is connected up and down, which can enhance the detected signal effect. The signals transmitted by the two pressure-inducing pipelines are alternating. This is because the vortex generated by the vortex generator is alternating, and vortexes are alternately generated to the two pressure-inducing pipelines.

[0040] The device applicable to the method of this embodiment is image 3 As shown, the first pressure pipe 102 and the second pressure pipe 103 are symmetrically opened on the wall of the probe air duct do...

Embodiment 3

[0043] The difference between this embodiment and the first embodiment is that in the first embodiment, the cleaning pipeline is connected to the end of the pressure-inducing pipeline; and in this embodiment, the cleaning pipeline is connected between the inlet end of the pressure-inducing pipeline and the vortex signal detection element . In other words, if the definition figure 2 The direction of the solid arrow is the downstream direction, so in this embodiment, the cleaning pipeline is upstream of the electret. In the first embodiment, the cleaning pipeline is downstream of the electret.

[0044] Such as Figure 4 As shown, a vortex generator 201 is provided in the probe air duct, and a pressure pipe 202 is opened on the probe air duct downstream of the vortex generator 201. The pressure pipe 202 has two branches, and the first branch is connected to the electret. 203. The second branch is connected to the outlet end of the pressure regulating valve 204 (that is, the clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com