Patents

Literature

35results about "Fluid speed measurement using swirlflowmeter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

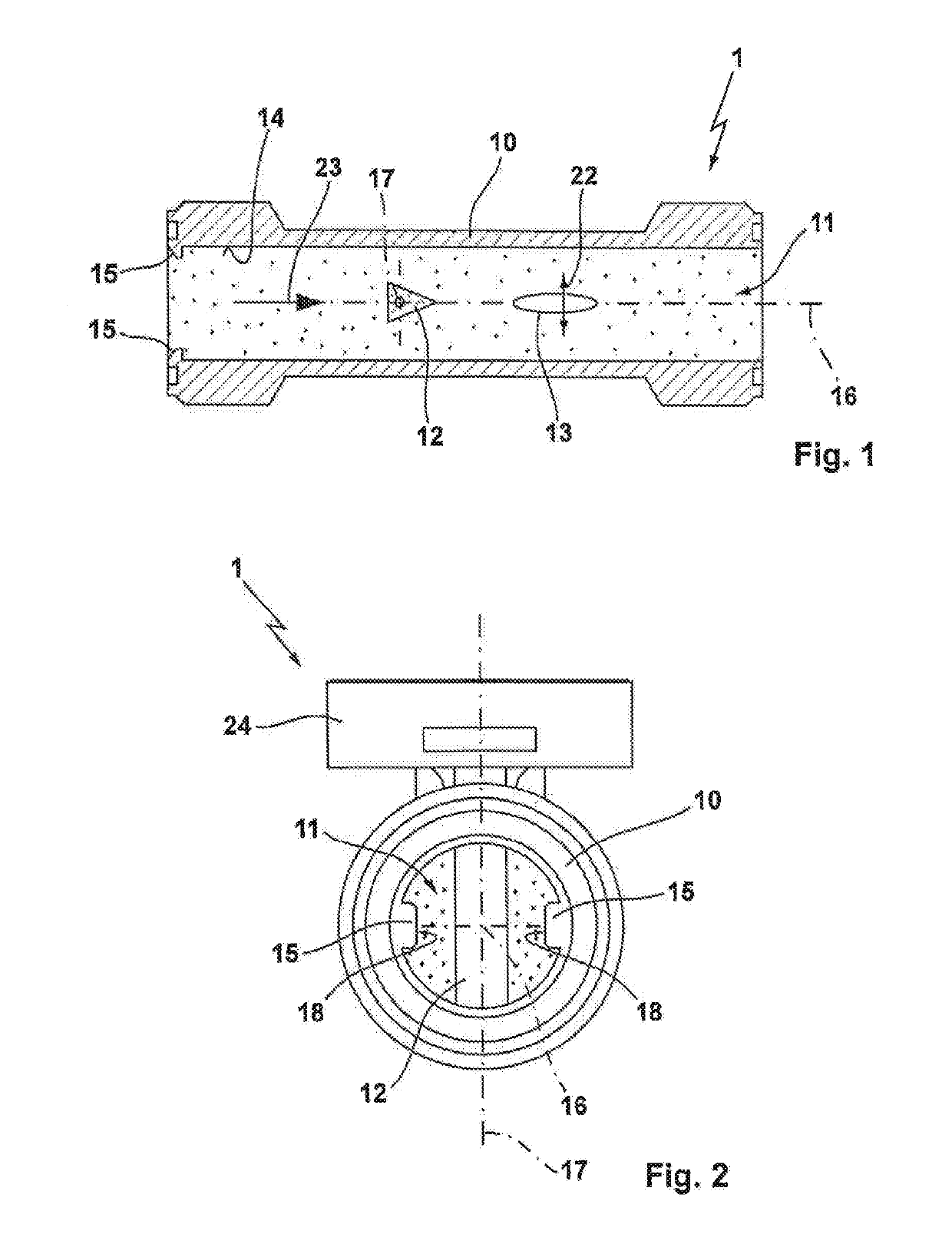

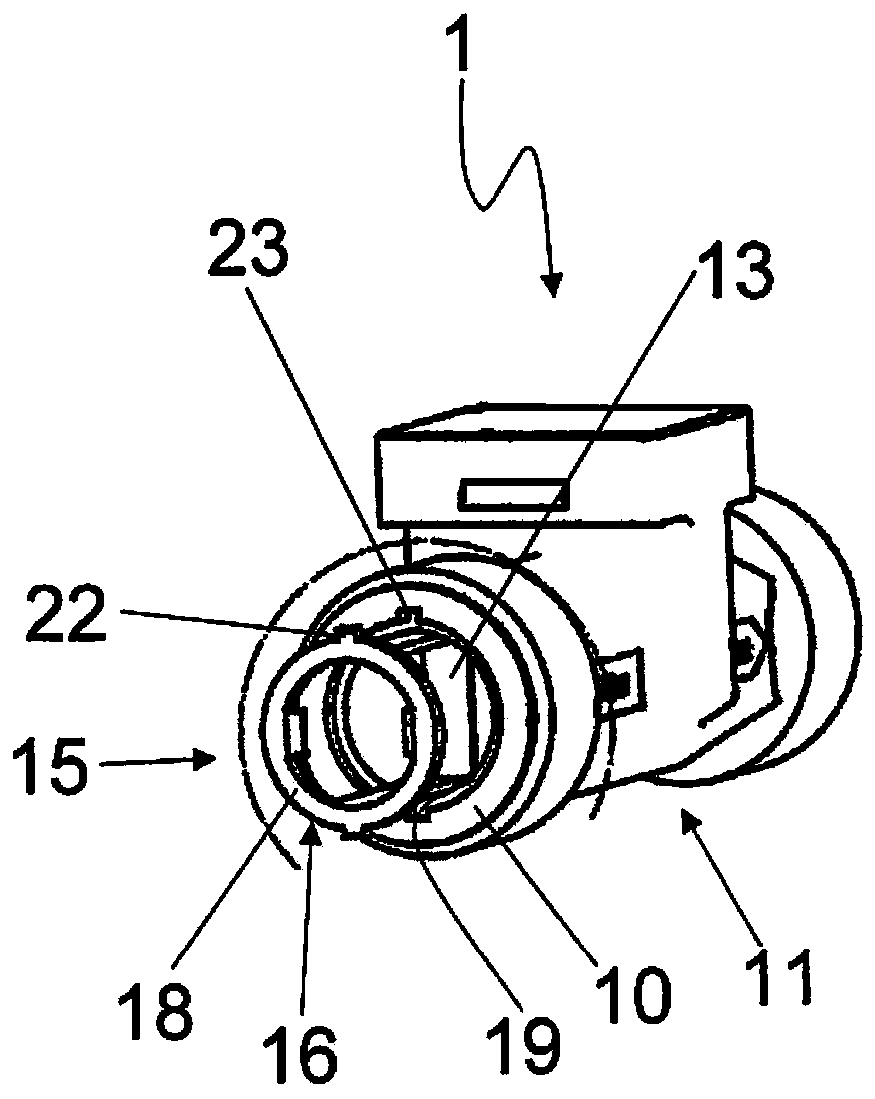

Resonant flow sensor and uses and production methods for the same

InactiveUS20110107829A1Easy to measureAerodynamic testingResonant frequencyEngineeringMethods of production

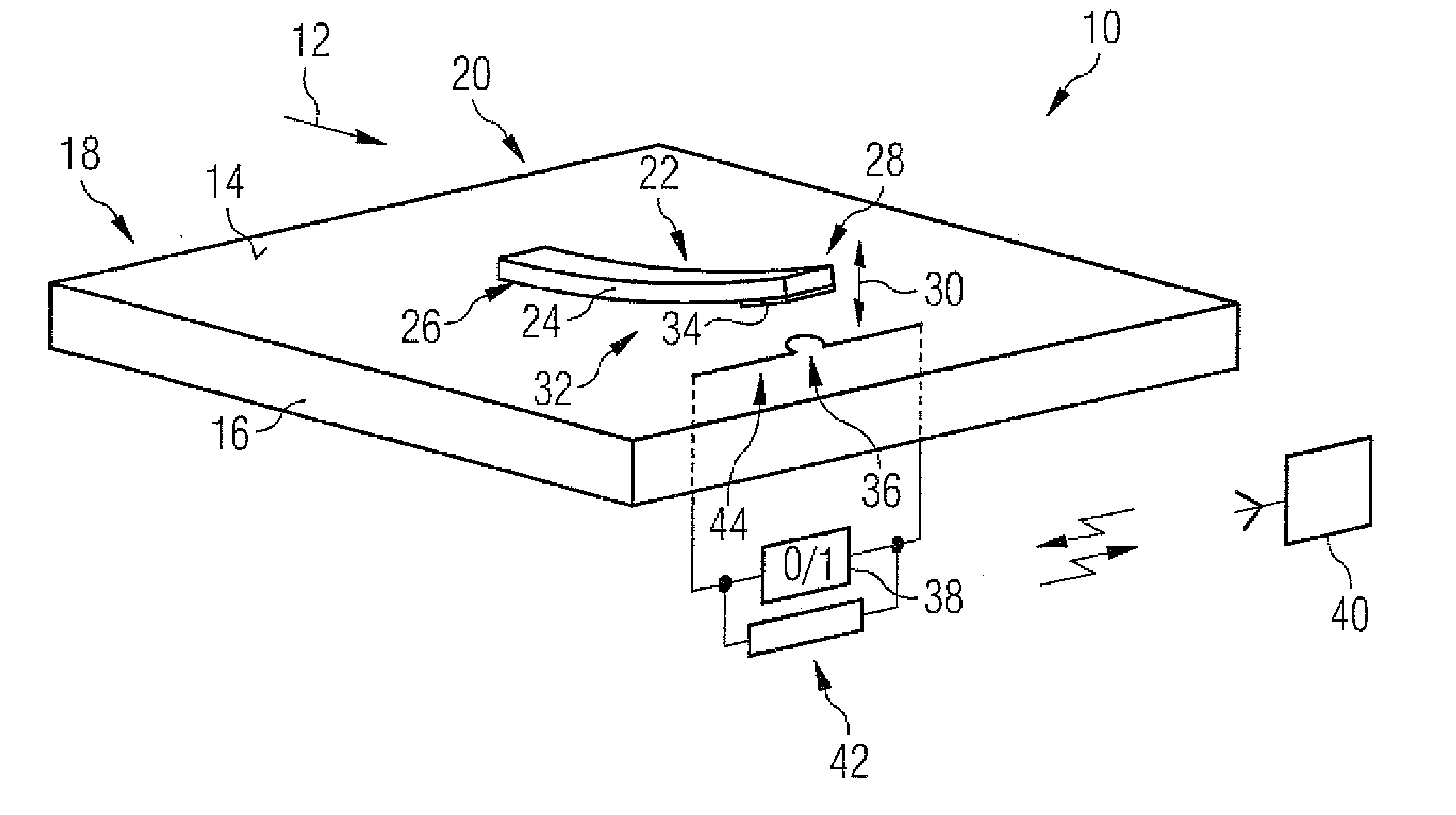

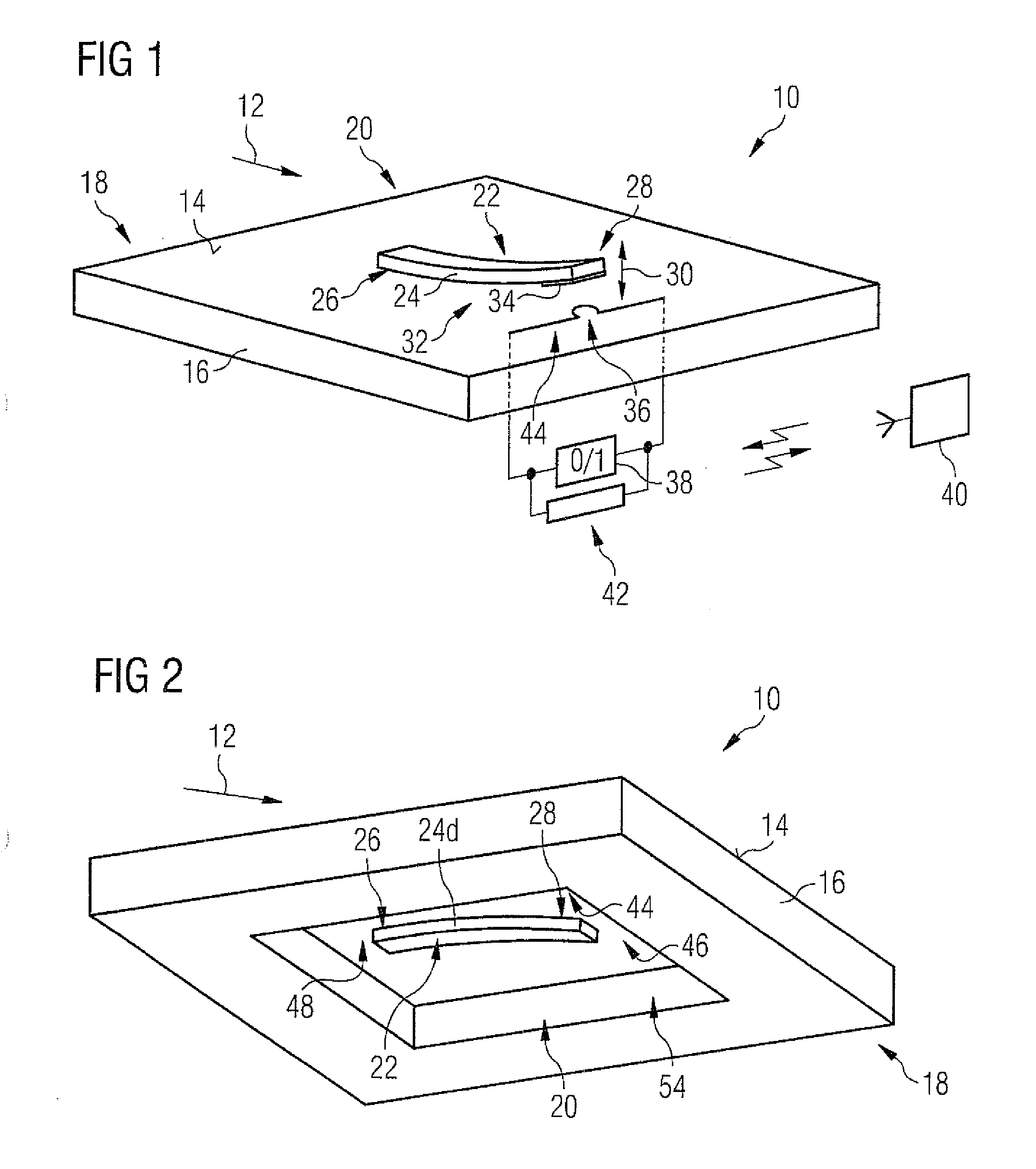

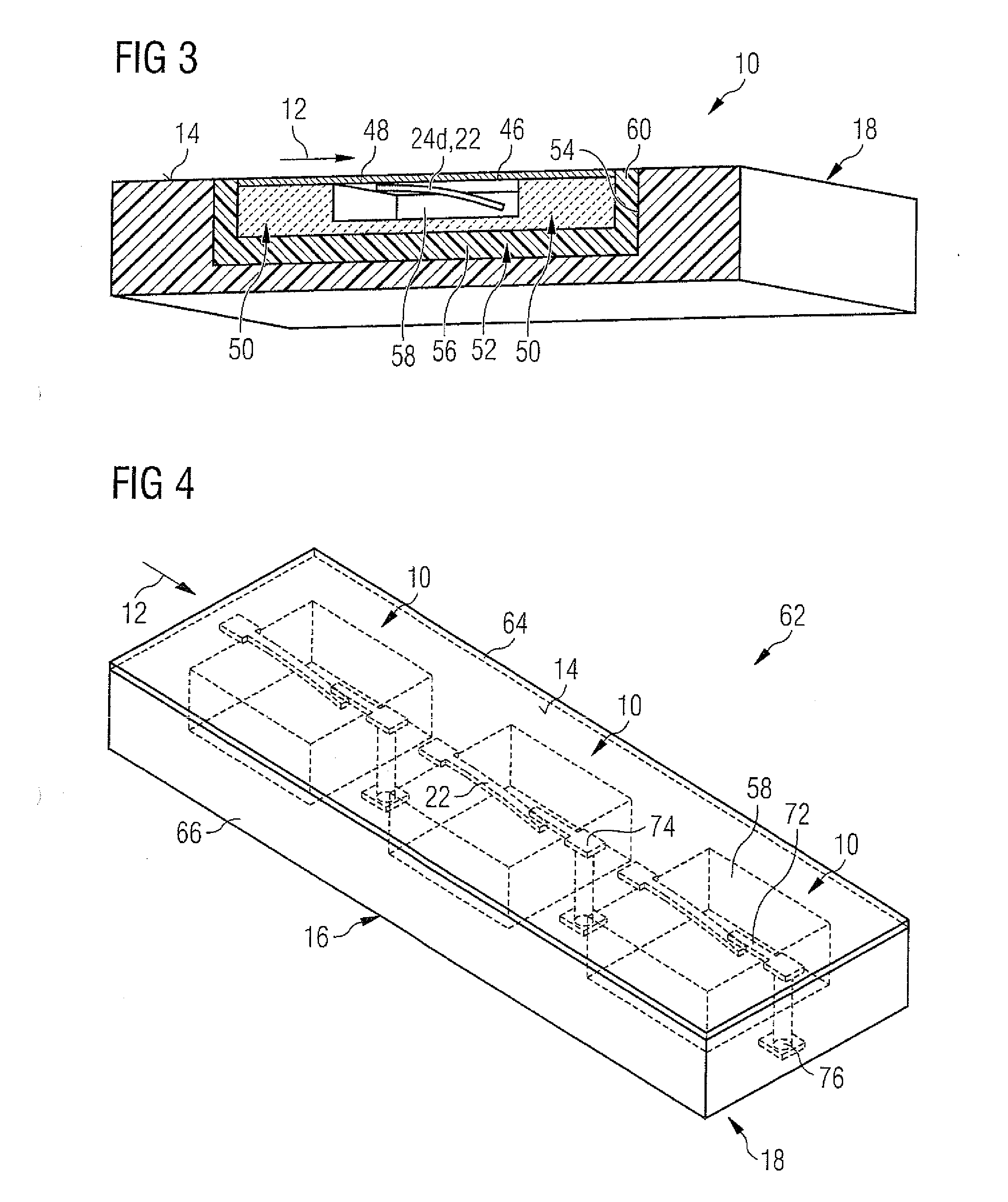

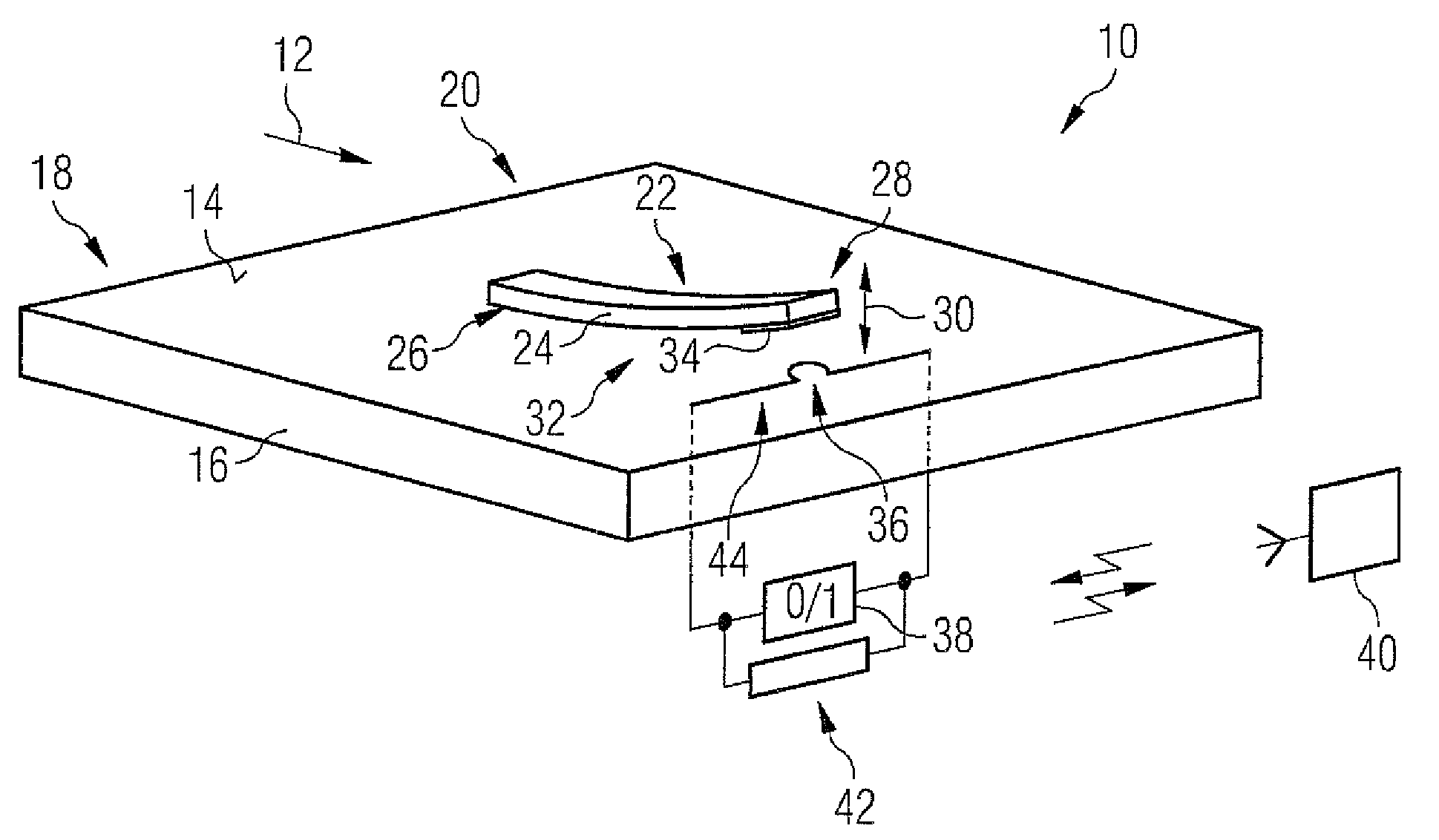

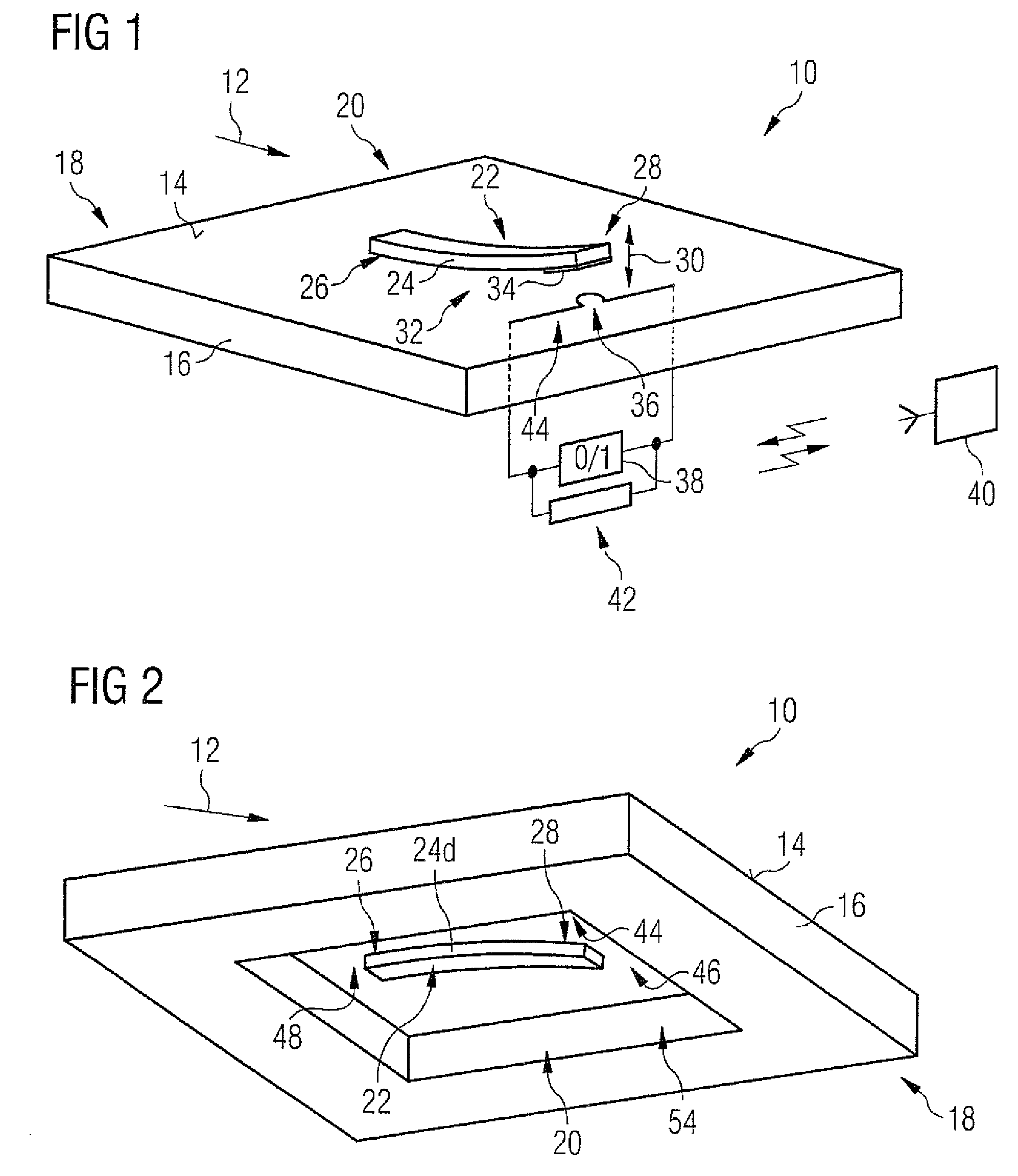

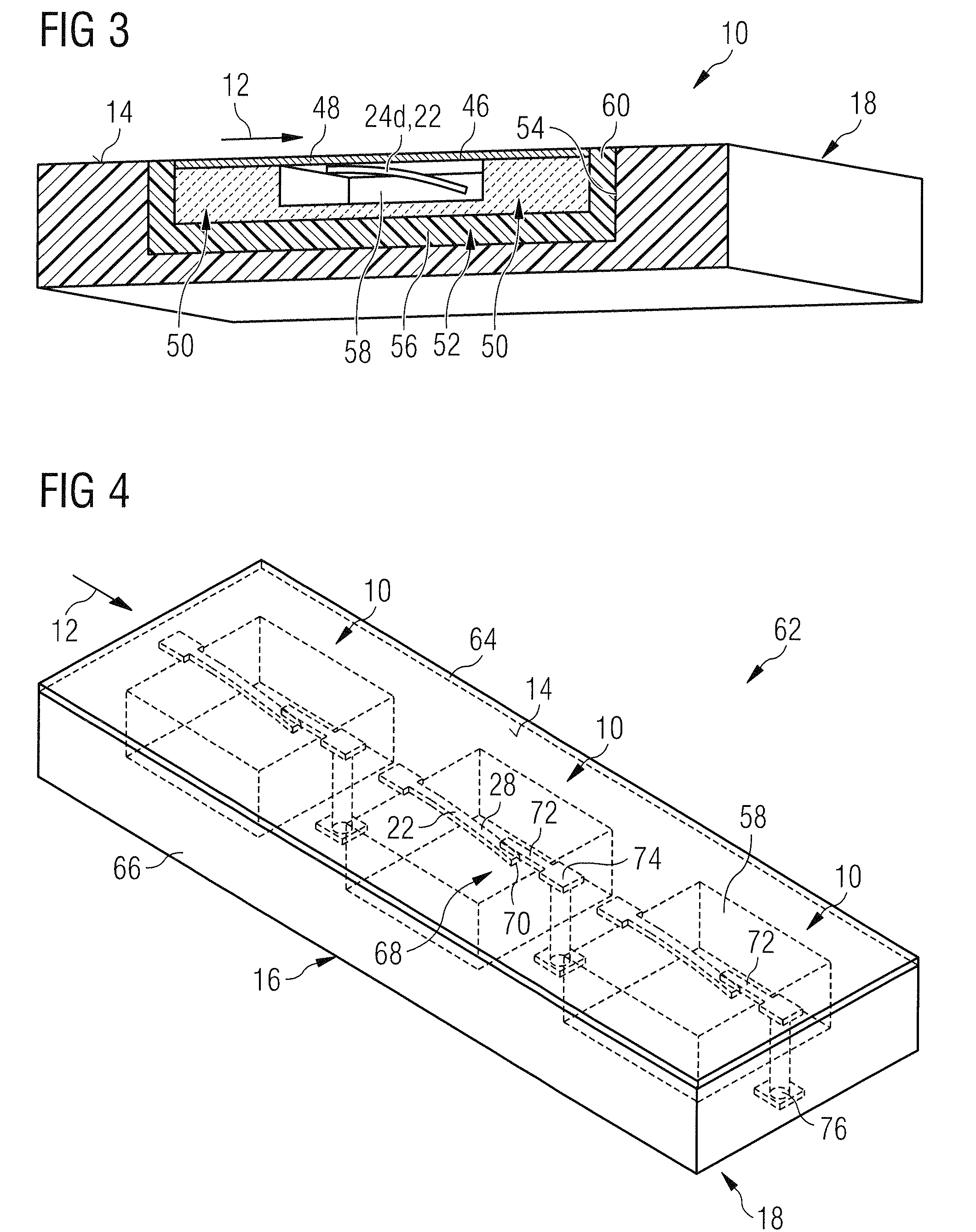

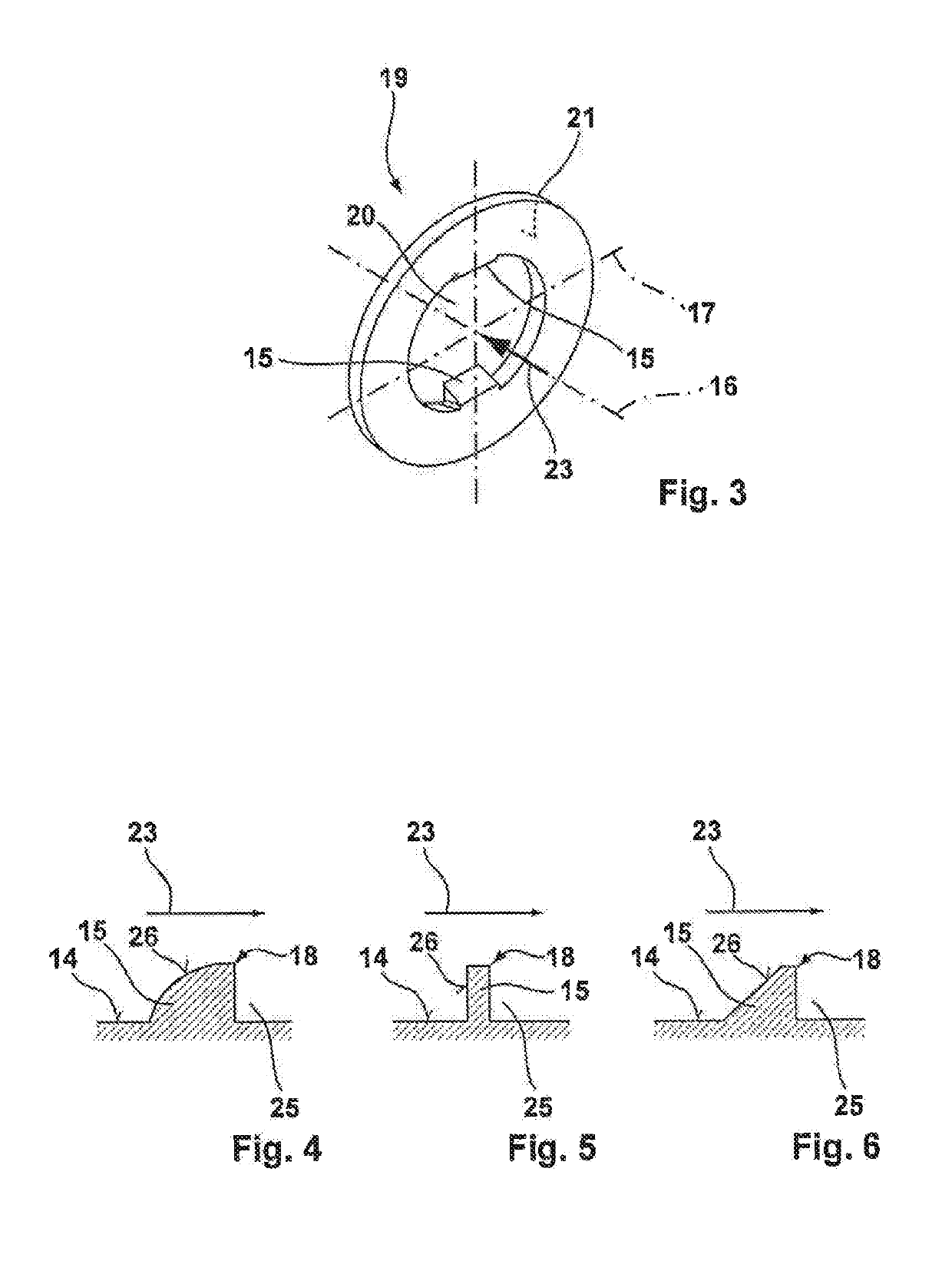

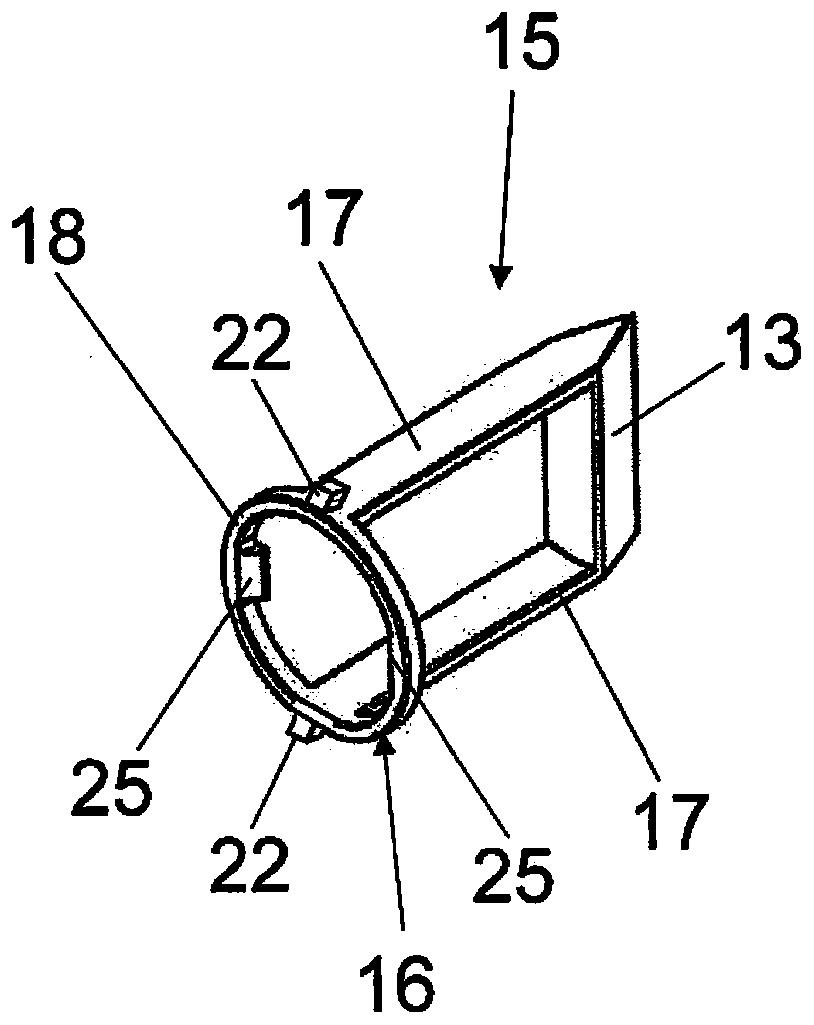

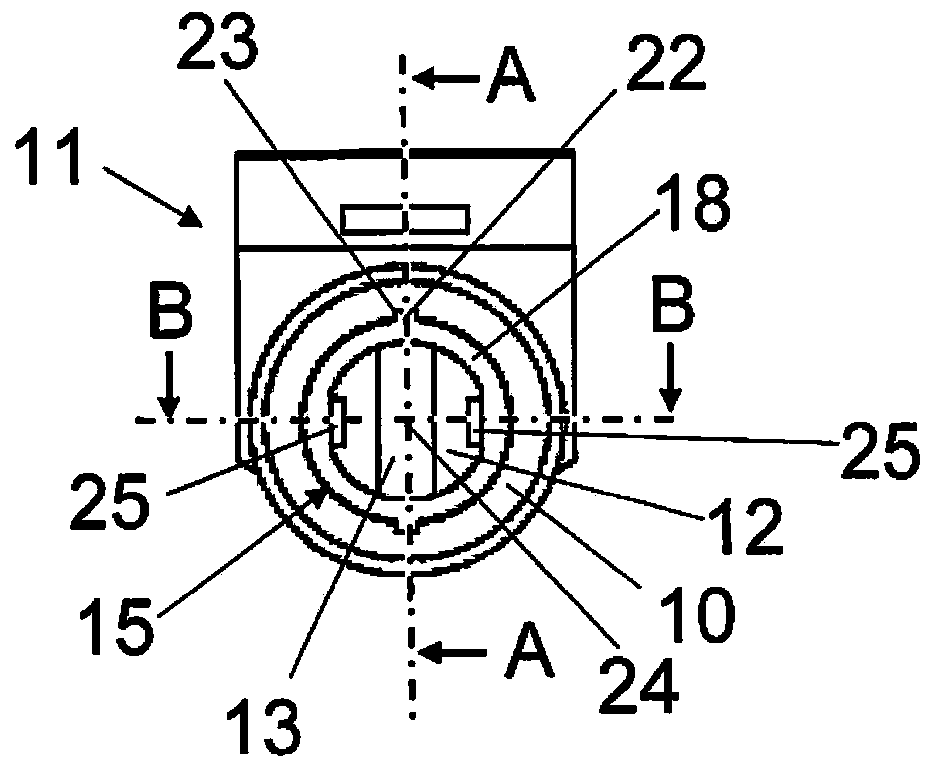

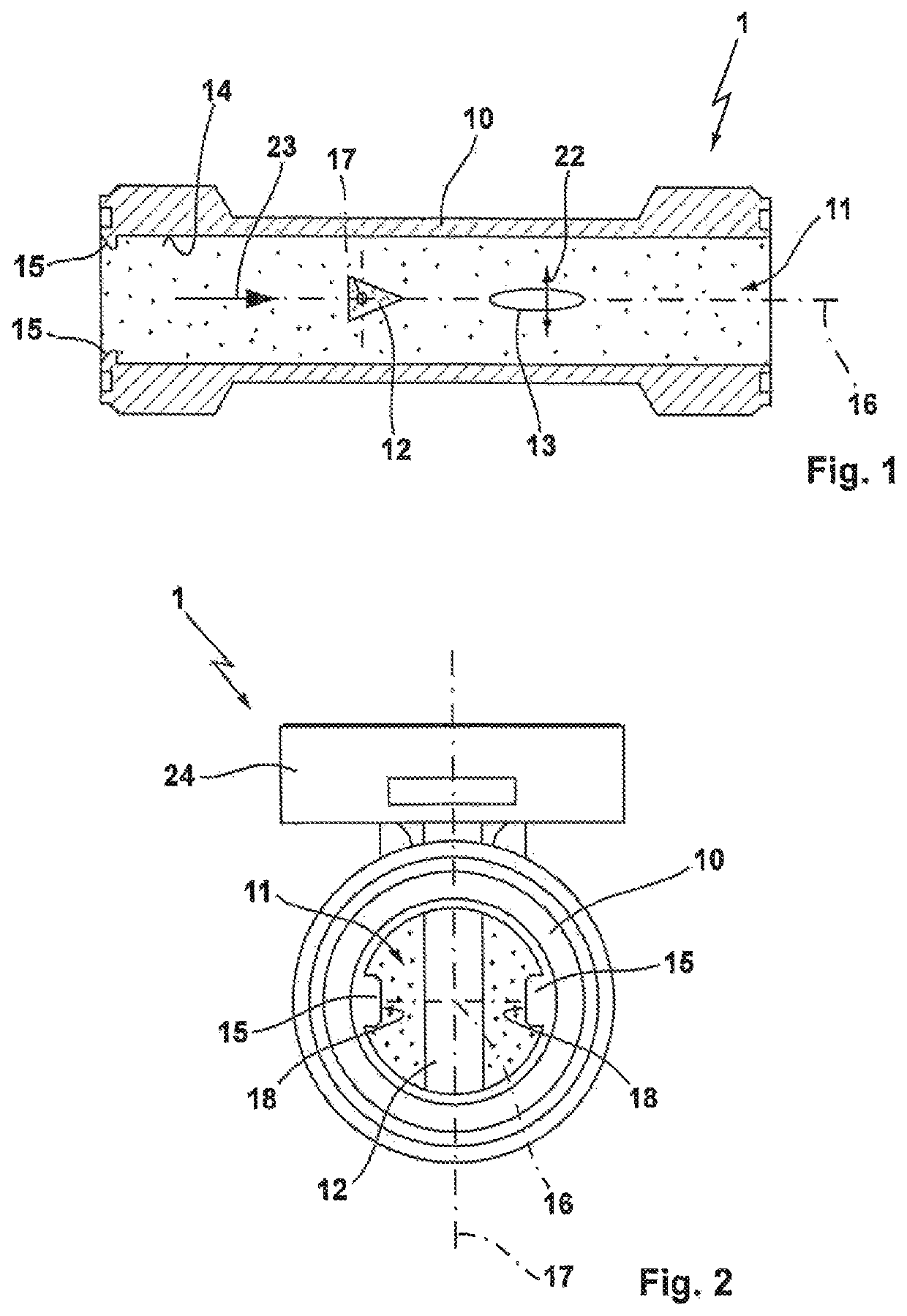

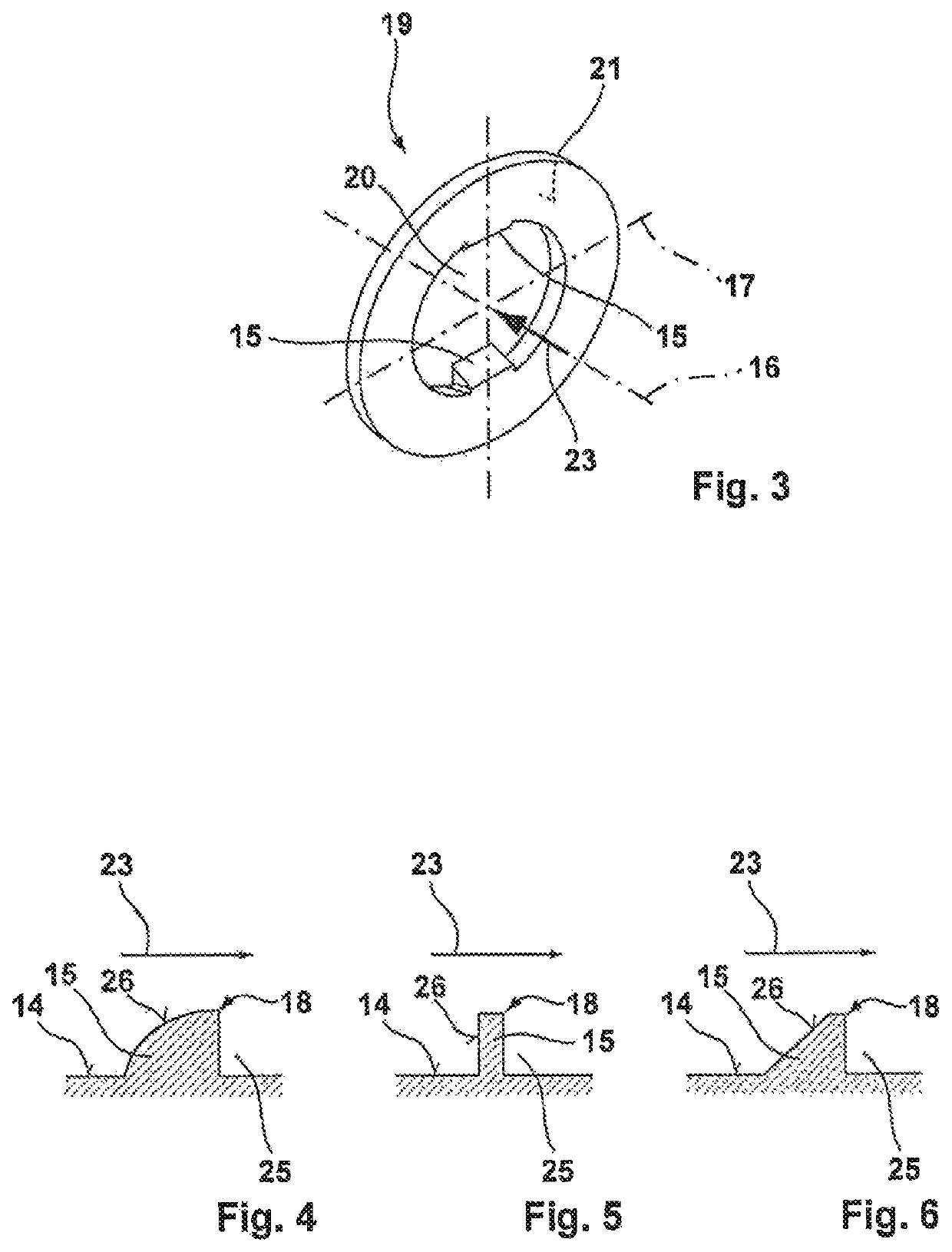

The invention relates to a flow state sensor (10) for detecting a flow state at a body (16) that may be impinged on by a flow (12). A flow state sensor (10) that is of a simple construction and that is simple to evaluate is characterised in accordance with the invention by at least one frequency detecting device (20) for detecting at least one predefined frequency characteristic of the flow state. The frequency detecting device (20) has at least one oscillation element (22; 22a, 22b, 22c) excitable to resonant oscillatory movement (30) by a flow (12) and having a resonant frequency or natural frequency adapted to the predefined frequency characteristic, especially corresponding to the predefined frequency characteristic. Uses of the flow state sensor (10) in a flow measuring device (62) and in a flow measuring method, and an advantageous production method for the flow state sensor (10) are also proposed.

Owner:AIRBUS OPERATIONS LTD +1

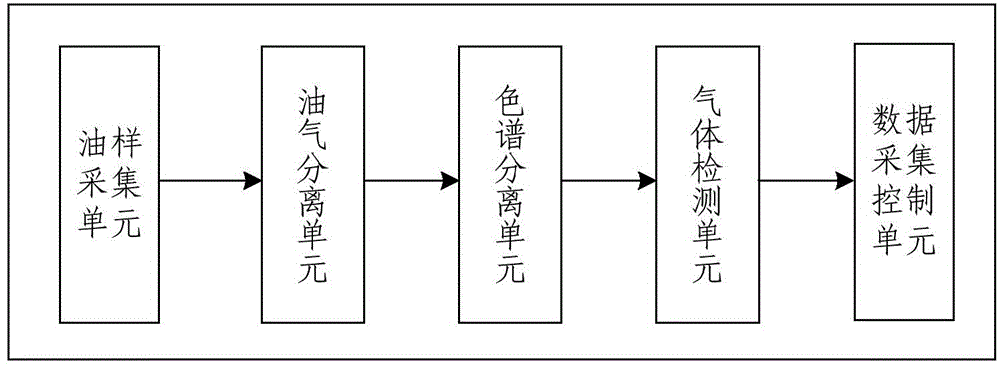

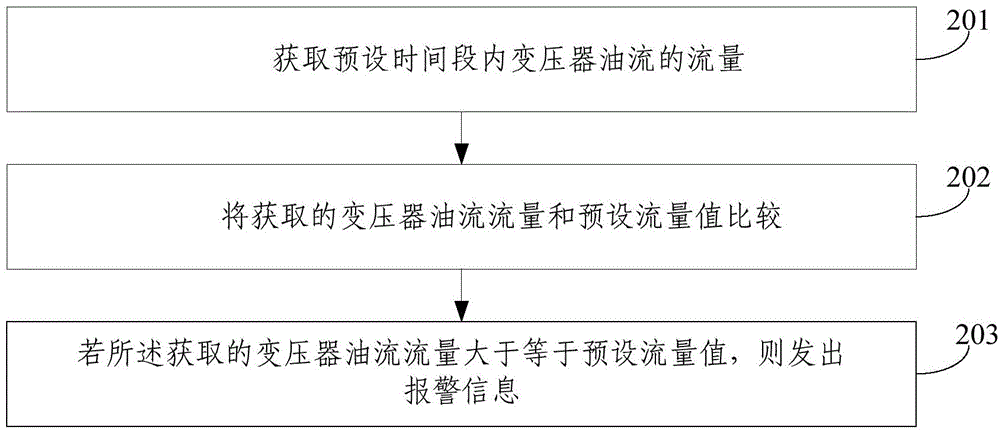

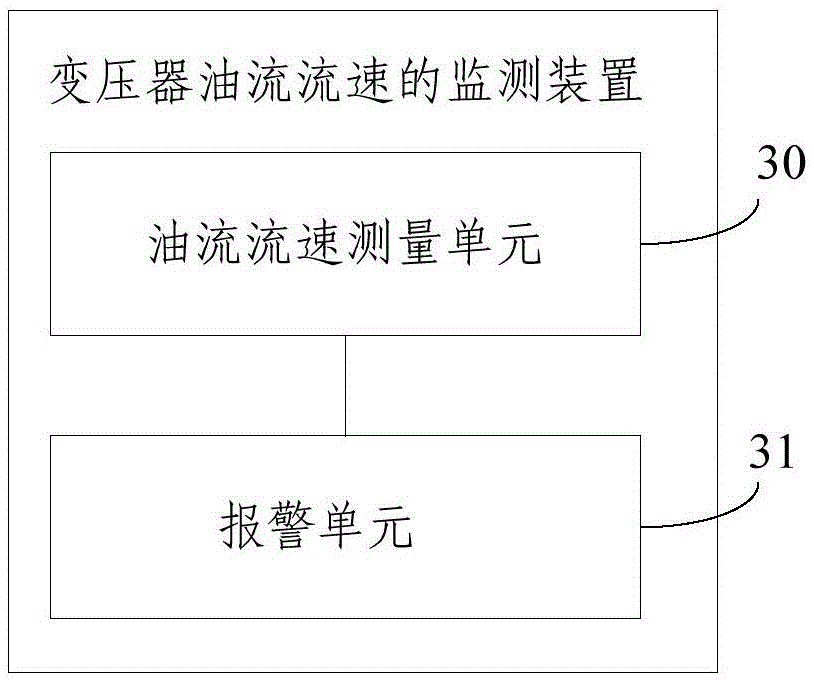

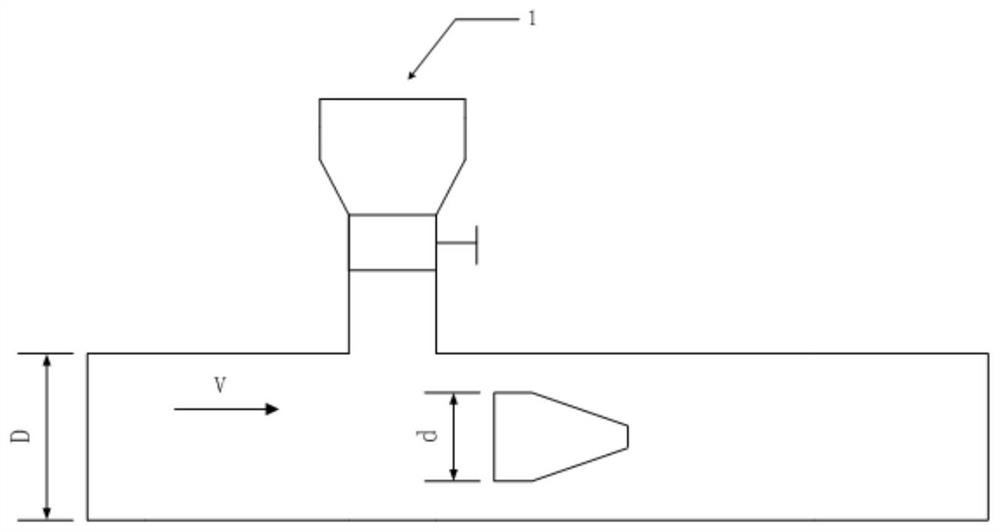

Monitoring method and device for flowing speed of transformer oil flow

InactiveCN105301281AImprove accuracyFluid speed measurement using swirlflowmeterTransformer oilStreamflow

The present invention provides a monitoring method and device for flowing speed of transformer oil flow. The monitoring method includes the steps as follows: acquiring the flow quantity of the transformer oil flow, comparing the acquired flow quantity of the transformer oil flow with the preset flow quantity, and giving warning information if the acquired flow quantity of the transformer oil flow is larger than the preset flow quantity. The monitoring method can realize fault early-warning for a transformer before a fault of the transformer occurs and improves early warning accuracy for the fault of the transformer.

Owner:ELECTRIC POWER RES INST STATE GRID SHANXI ELECTRIC POWER

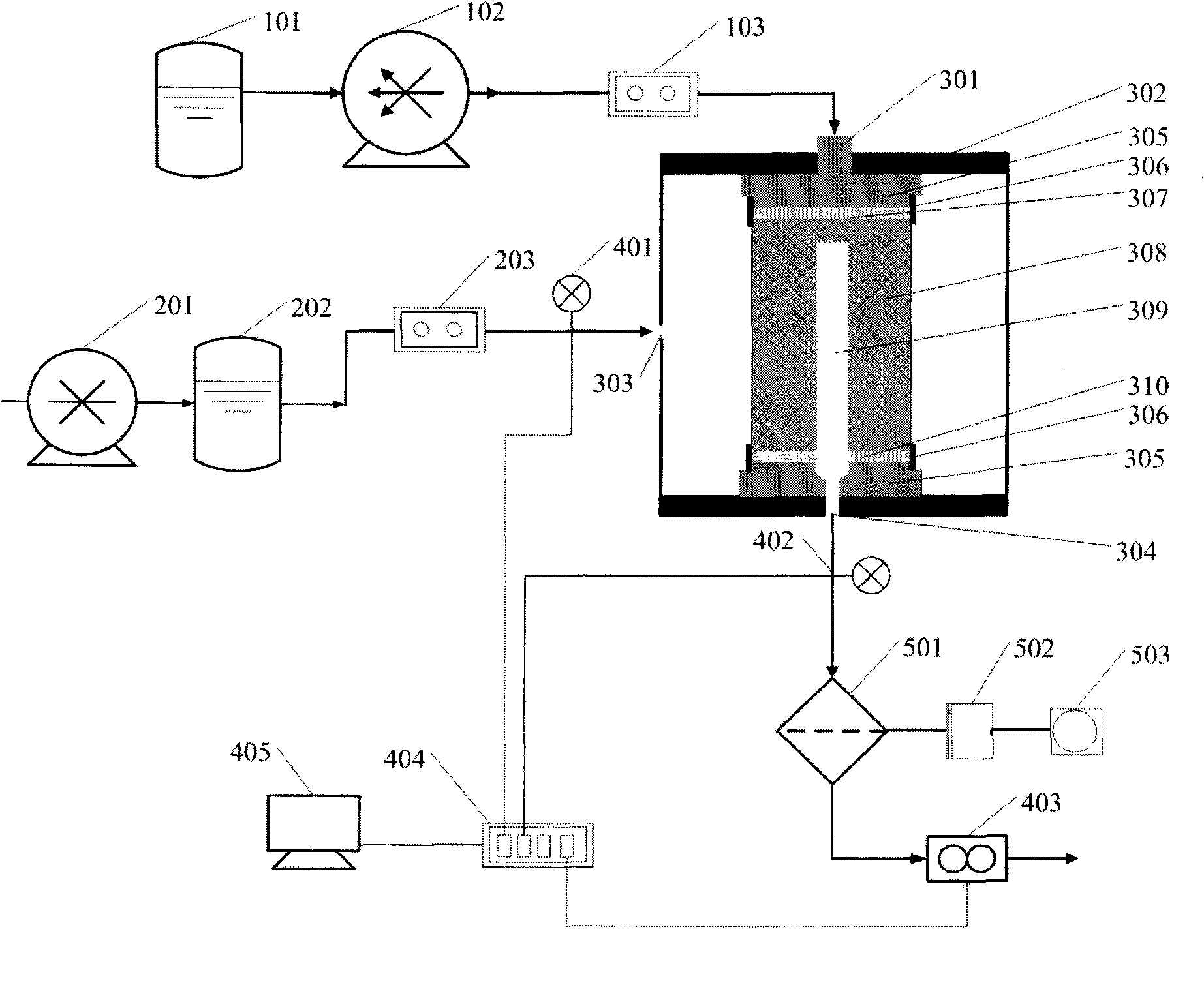

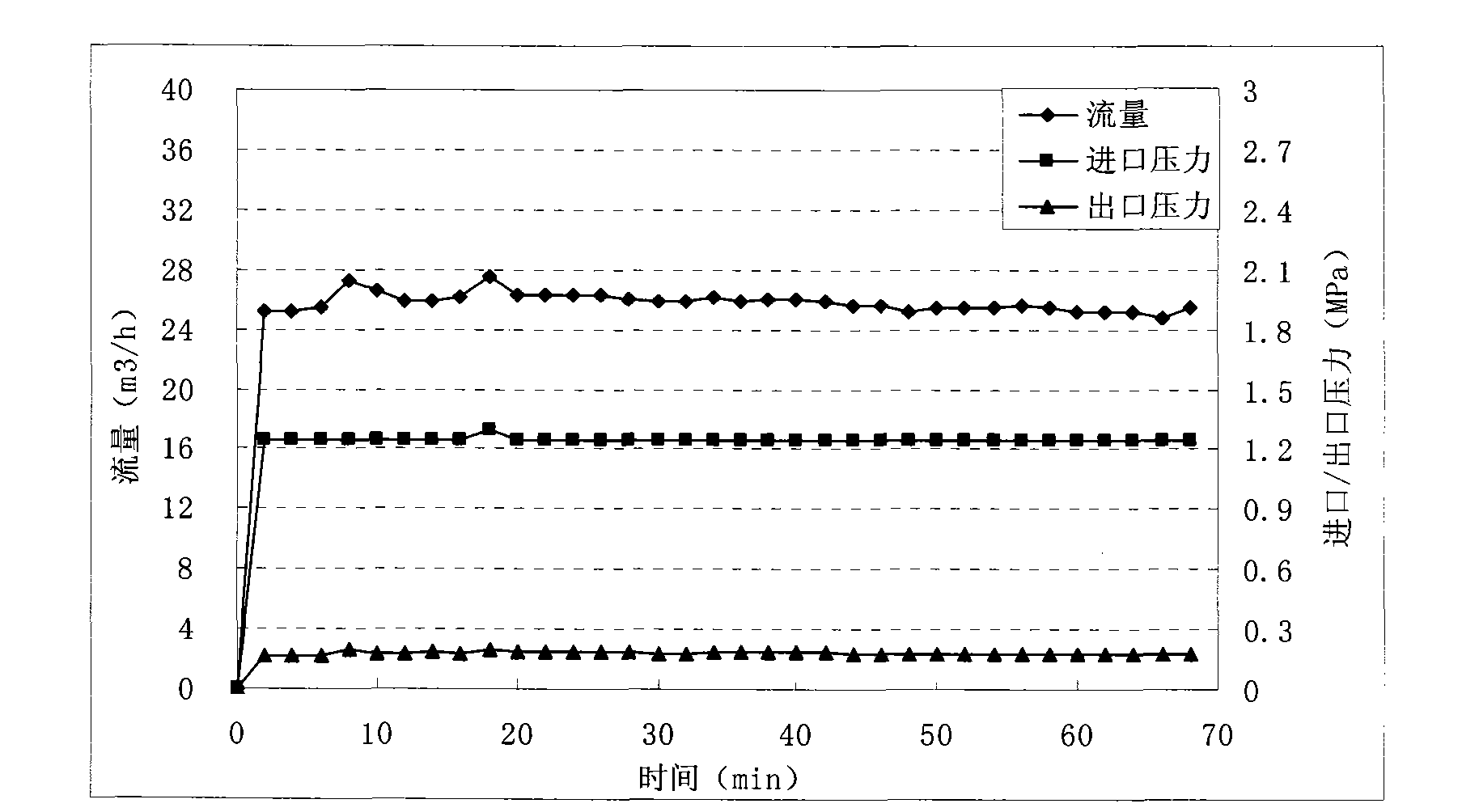

Device and method for detecting sanding critical flow velocity of gas well

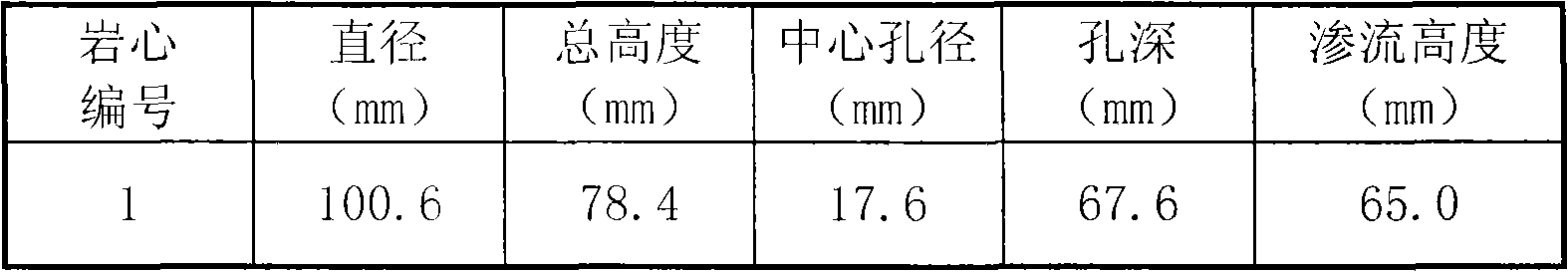

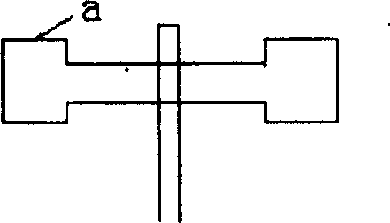

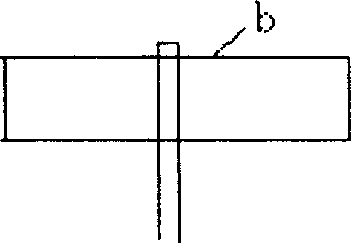

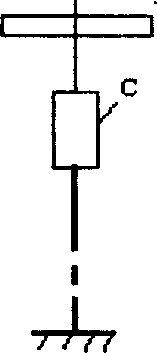

InactiveCN101915854ASolve the problem of sand critical velocityHydrodynamic testingFluid speed measurement using pressure differenceRock coreAxial compression

The invention provides a device and a method for detecting the sanding critical flow velocity of a gas well. The device consists of an axial compression system, a gas supply system, a simulation system, a measuring and acquiring system and a sand processing system. The method comprises the following steps of: providing different supply pressure for the simulation system simulating the production state of the gas well by using the gas supply system; measuring parameters such as inlet pressure, outlet pressure, gas flow rate, sand production volume after a certain experimental time and the like to obtain the sanding critical flow rate through a test result; and combining the sanding critical flow rate with the rock core size to solve the sanding critical flow velocity. Thus, the technology for determining the sanding critical flow velocity of the gas well on site is provided. By adopting the device and the method of the invention, as the experimental conditions are similar to the geological conditions of gas pools, the problem of detecting the sanding critical flow velocity under the condition of open hole completion of the gas well is solved accurately, conveniently and economically, and an experimental evidence is provided for directing on-site production of the gas pools.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

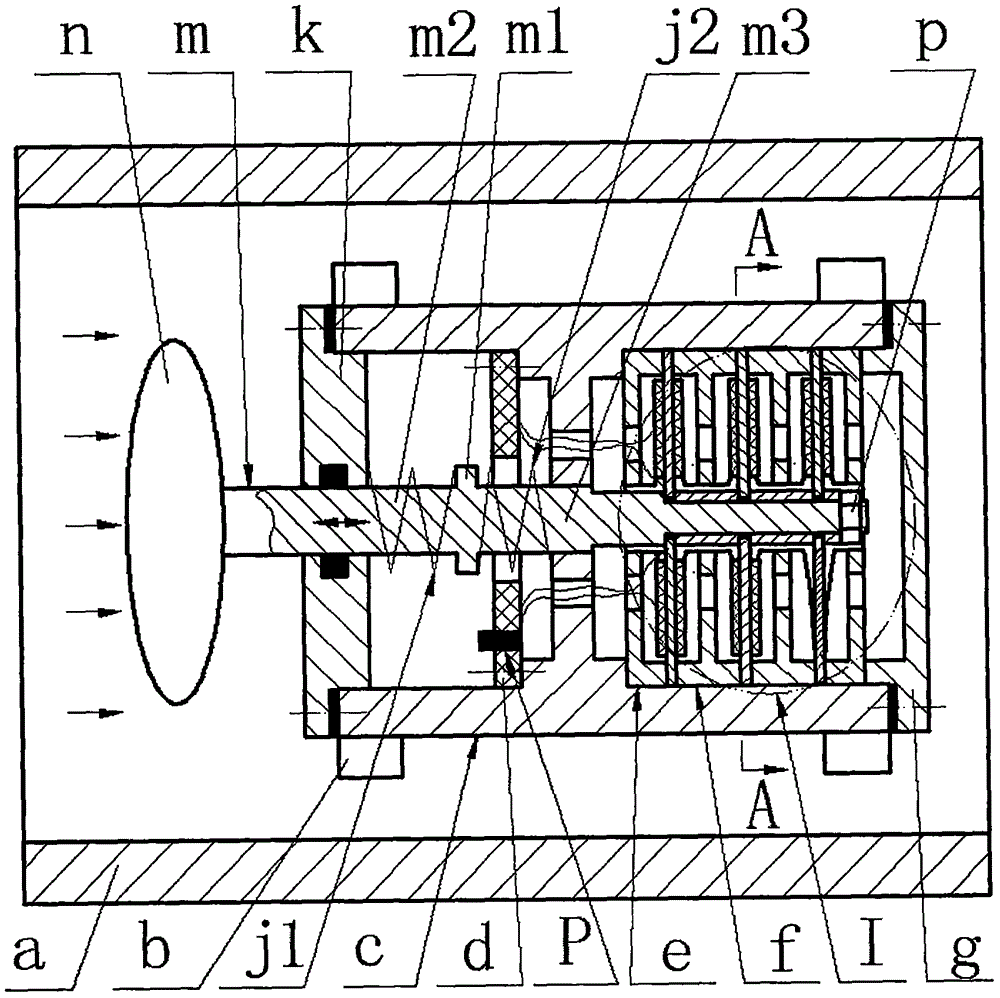

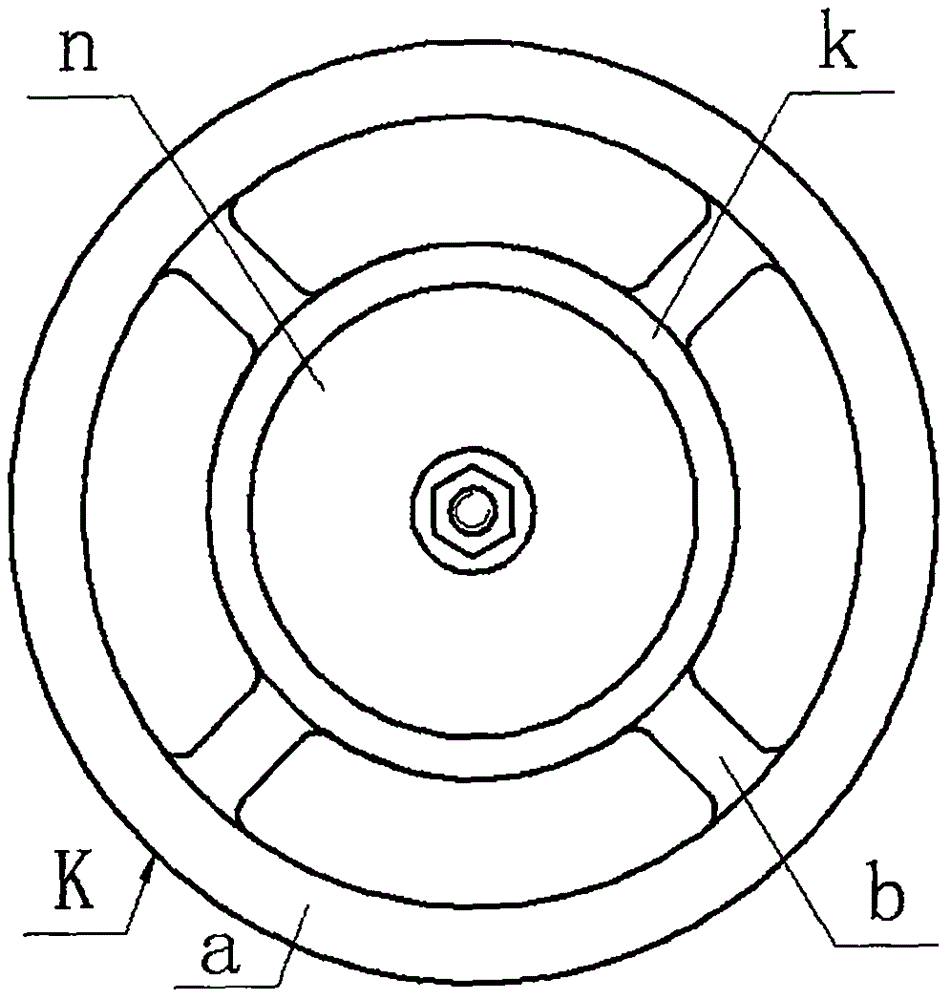

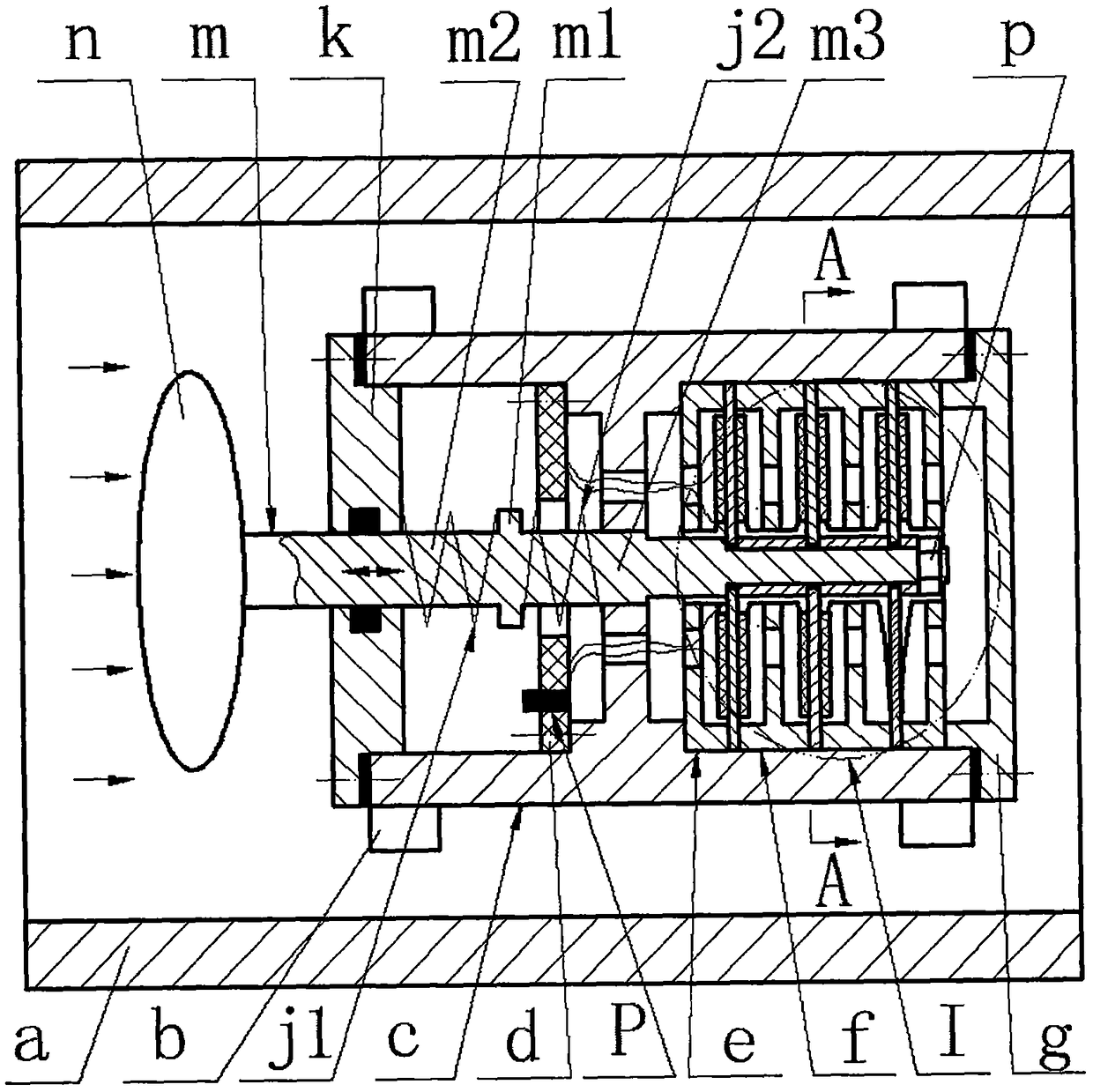

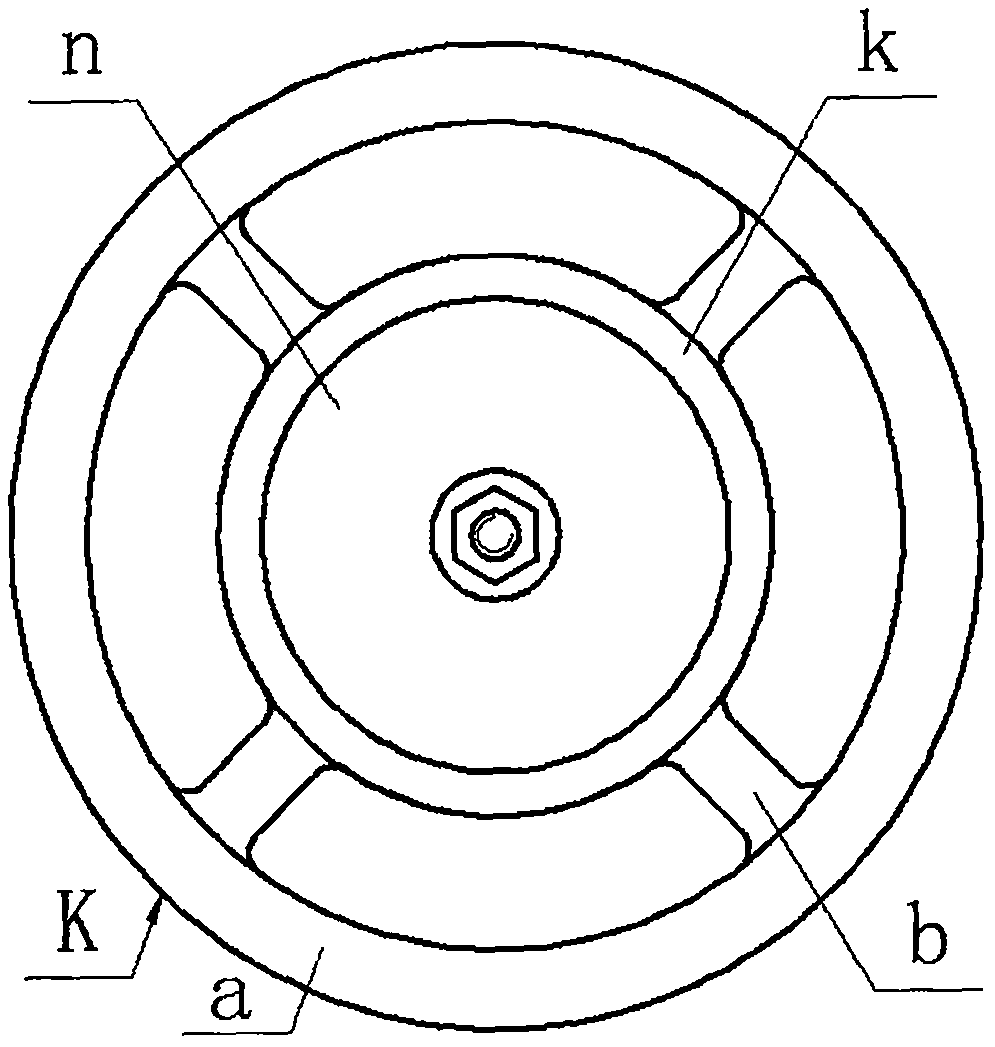

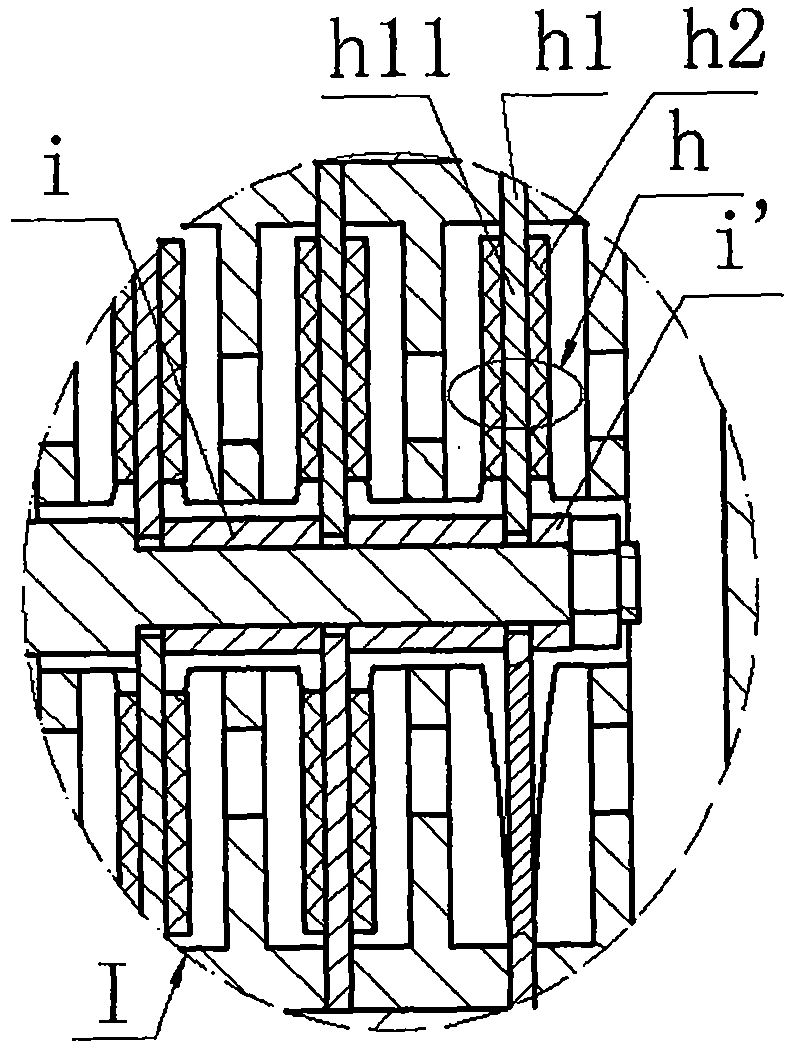

Separated axle needle type prepeller wind gauge for measuring cylinder vortex

InactiveCN1434298ACompact designSimple structureFluid speed measurement using swirlflowmeterProximity sensorEngineering

The invention provides a separate-type axial-needle blade anemoscope measuring the vortex of the cylinder tube, the knock-down bush set on the inner side of the anemoscope body, the brackets of the circular axial-needle stand respectively set on two end surfaces of the inner side of the anemoscope body, and the adjustable axial-needle stand fixed on the midpoint of the thin knighthead fixed on the brackets, and two subulate points of the needle rotary axis set with the blade cooperating with the adjustable axial-pin stand; at least one opened hole right facing the blade set on the outer side,the approach sensor inserted in the hole and the rotary signal of the blade is output by the approach sensor.

Owner:TIANJIN UNIV

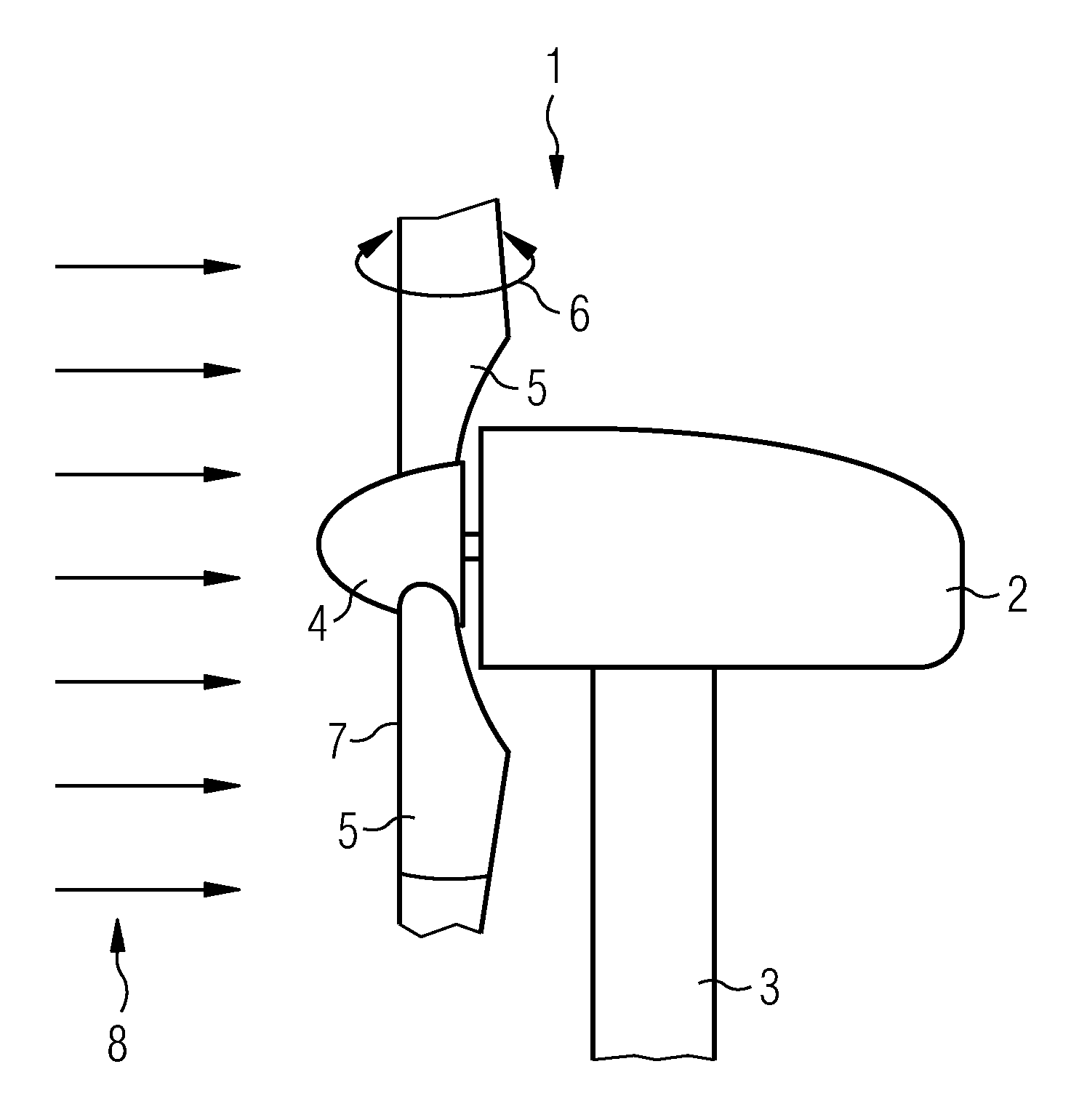

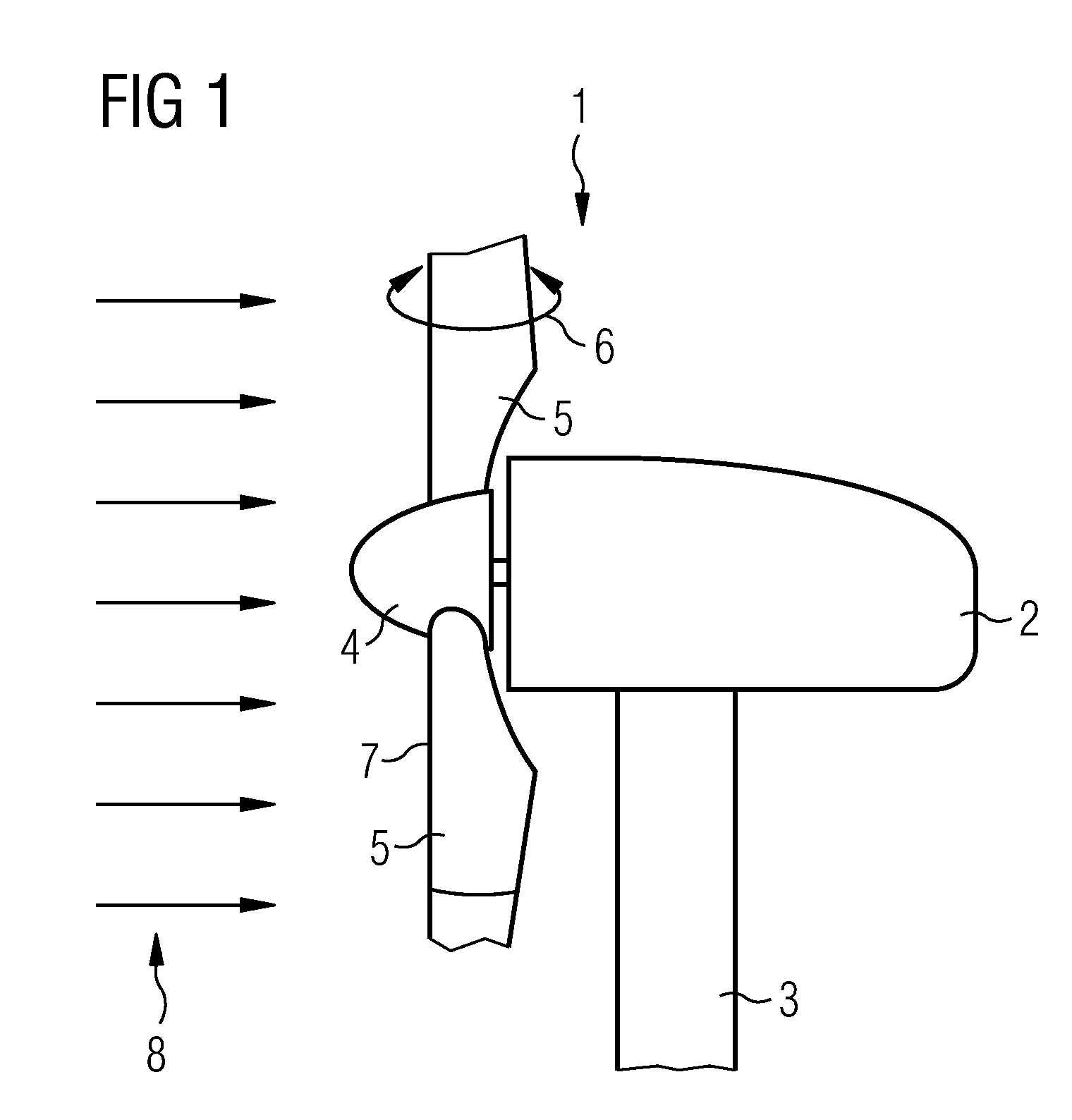

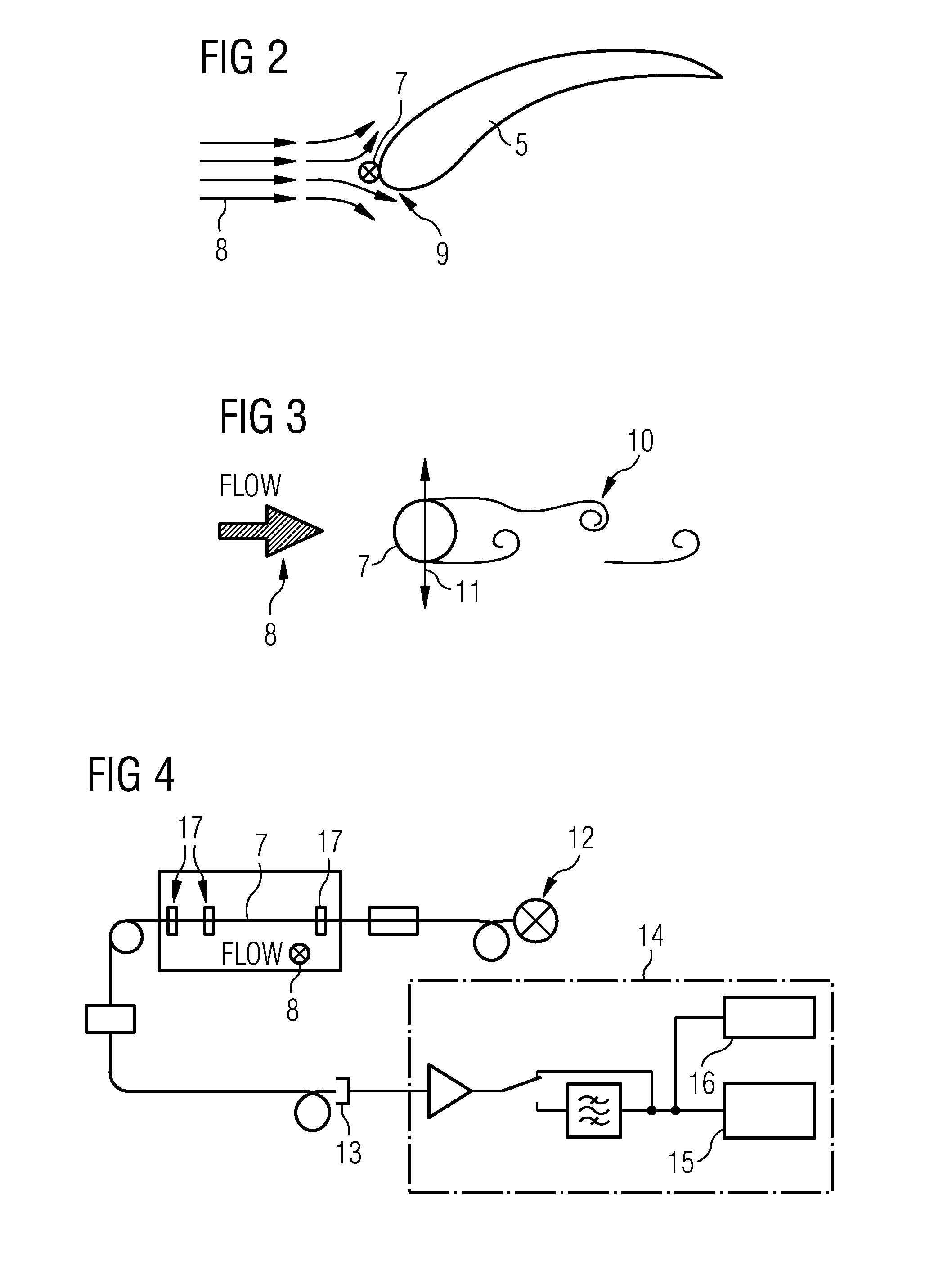

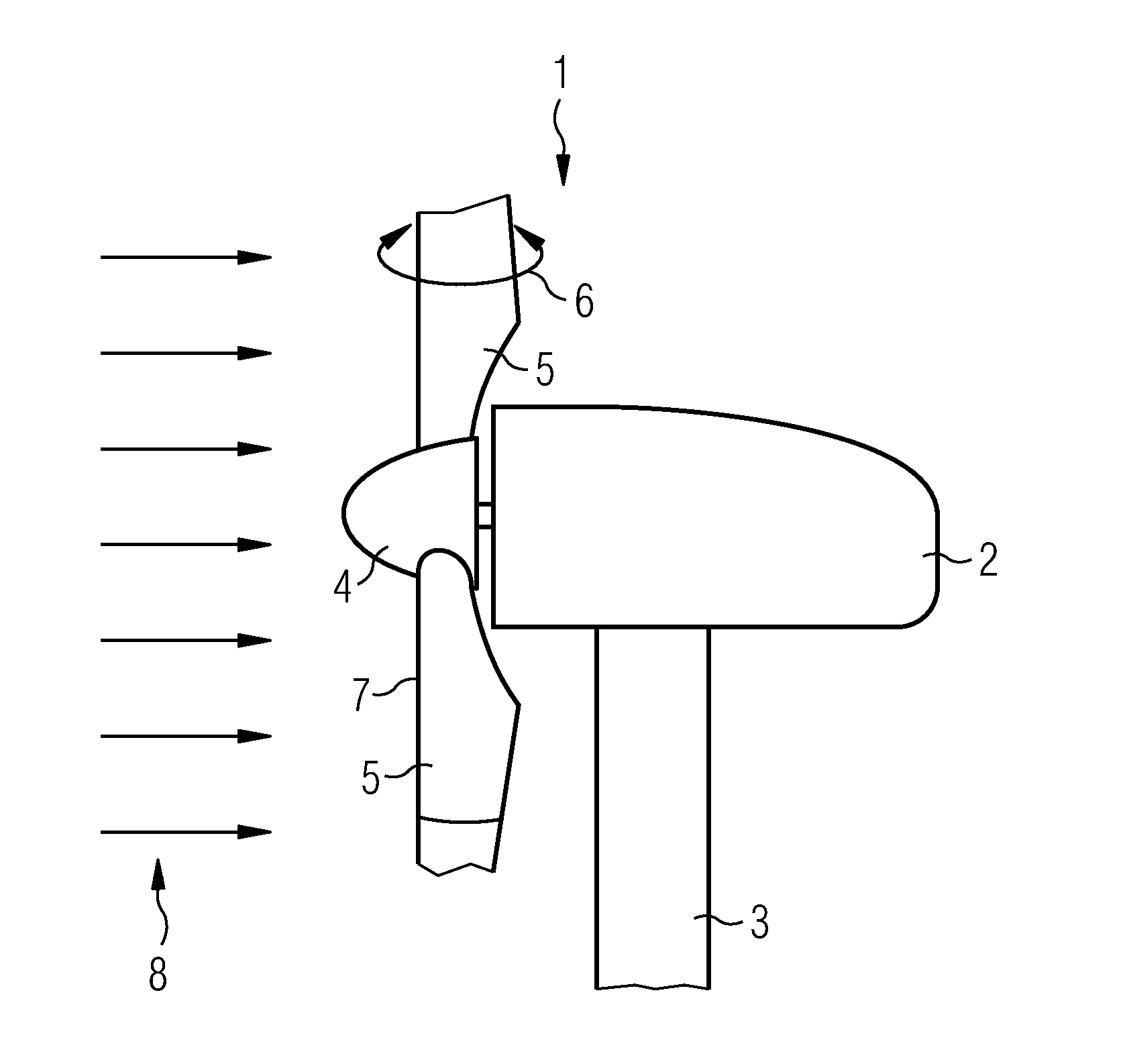

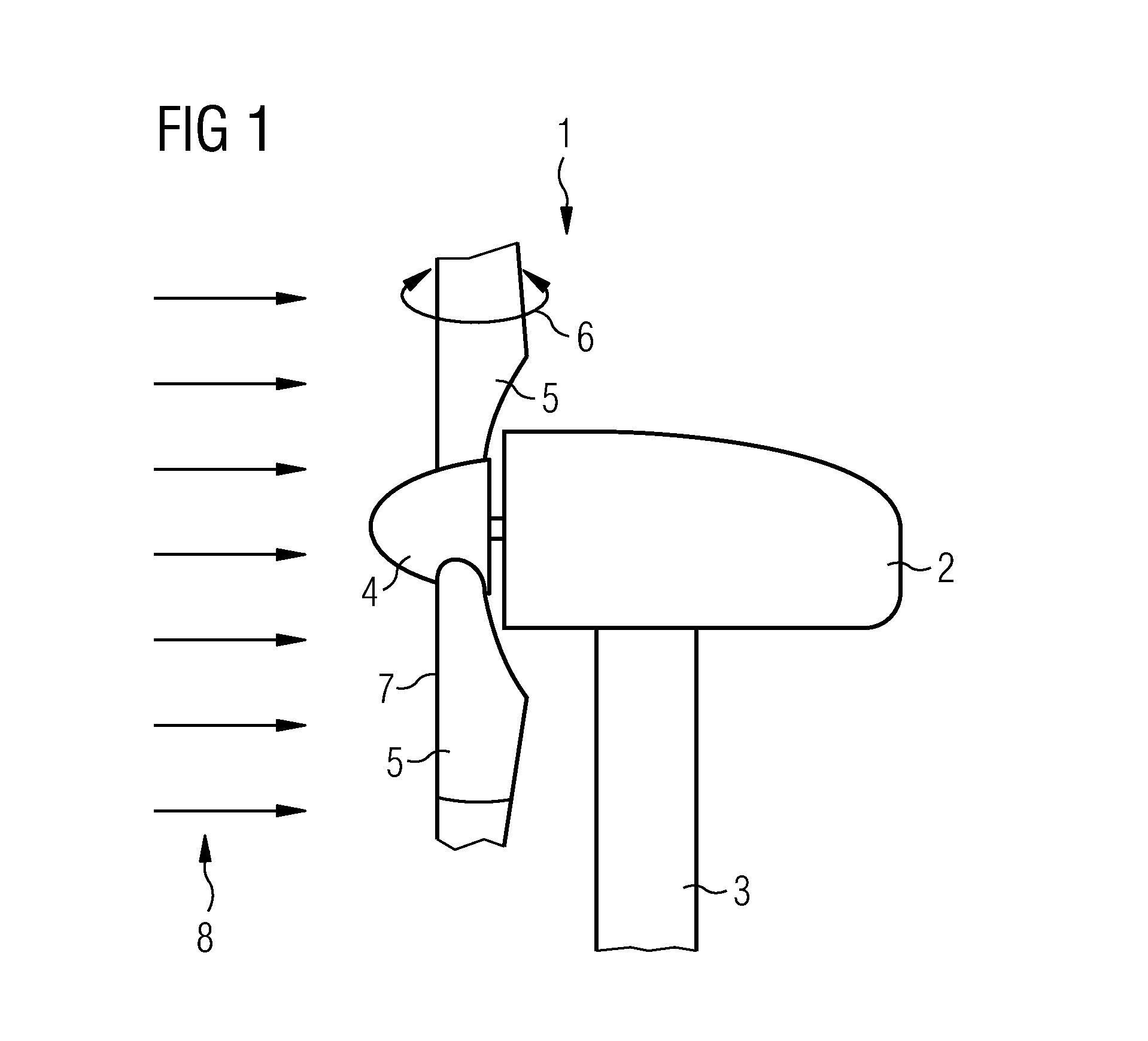

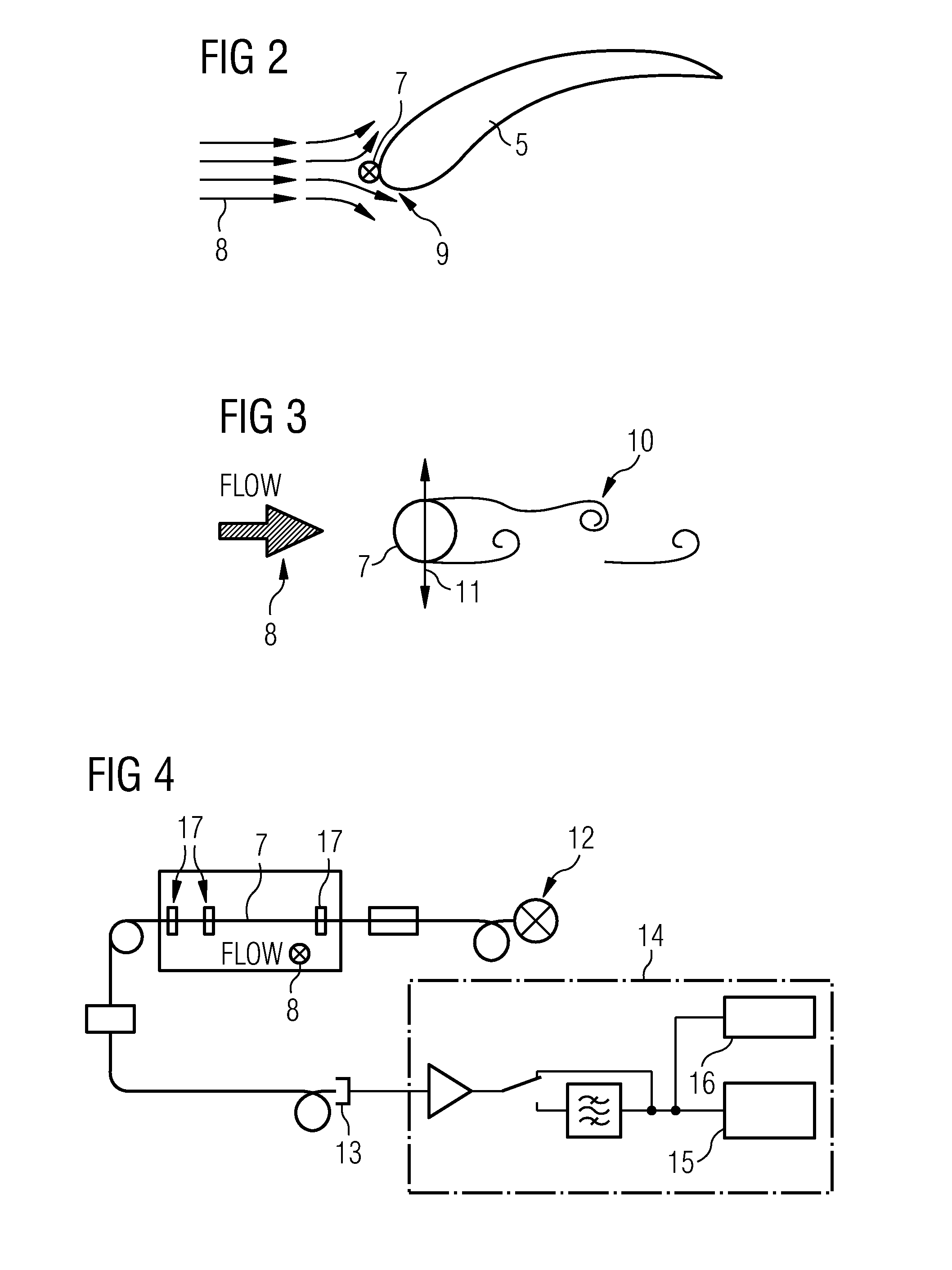

Wind energy installation comprising a wind speed measuring system

InactiveUS8381599B2Consume moreEngine fuctionsFluid speed measurement using swirlflowmeterEngineeringWind power

A wind energy installation is disclosed. The wind energy installation includes a rotor with at least one rotor blade. The wind energy installation includes at least one wind speed measuring system. The at least one wind speed measuring system optically measures the vibrations of an optical fiber due to vortex shedding.

Owner:SIEMENS AG

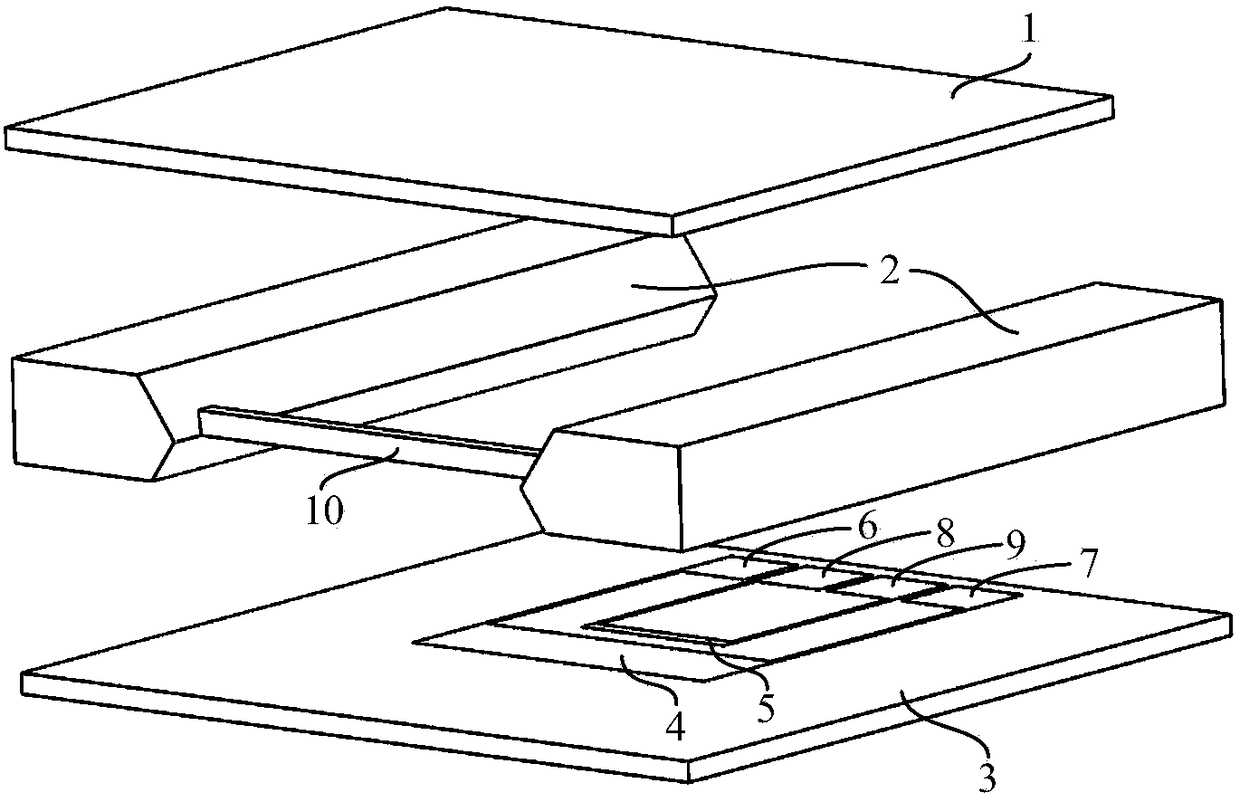

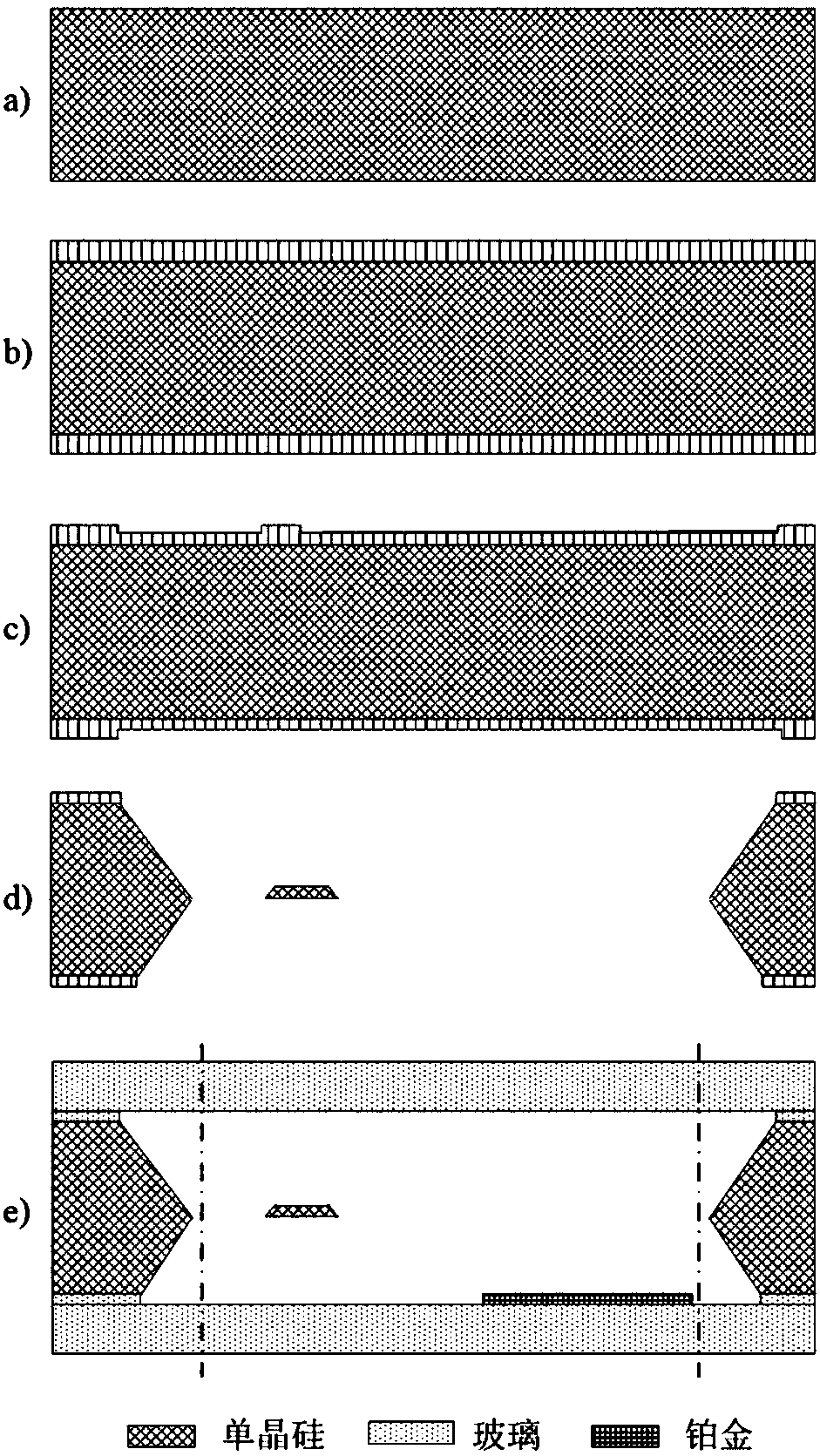

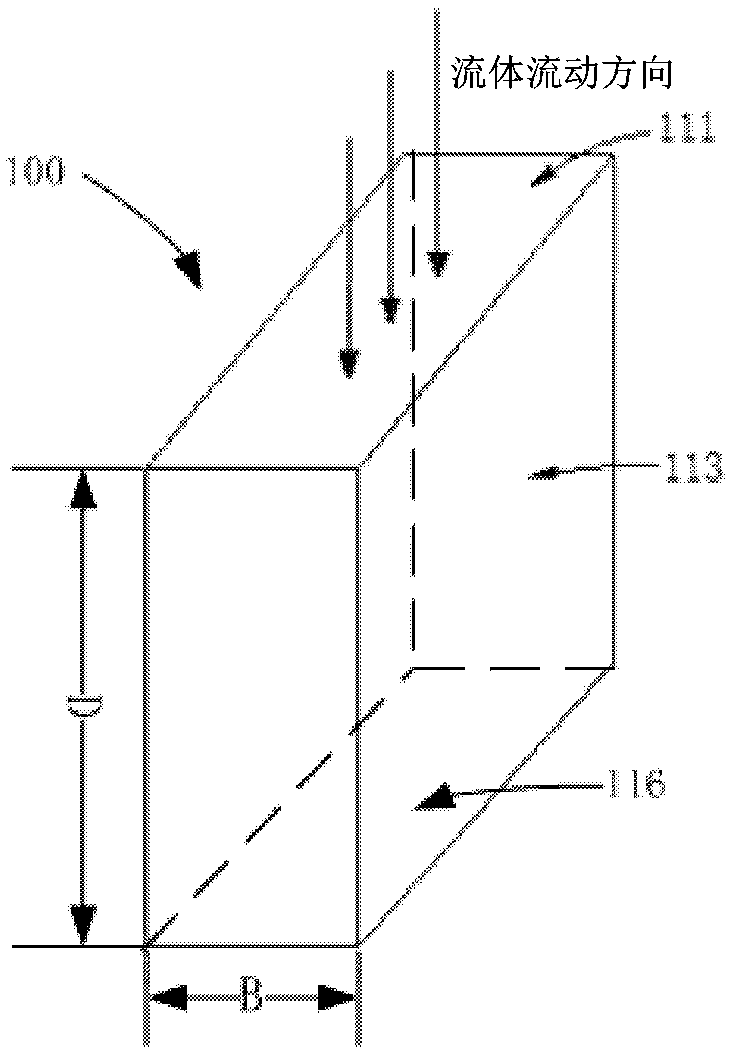

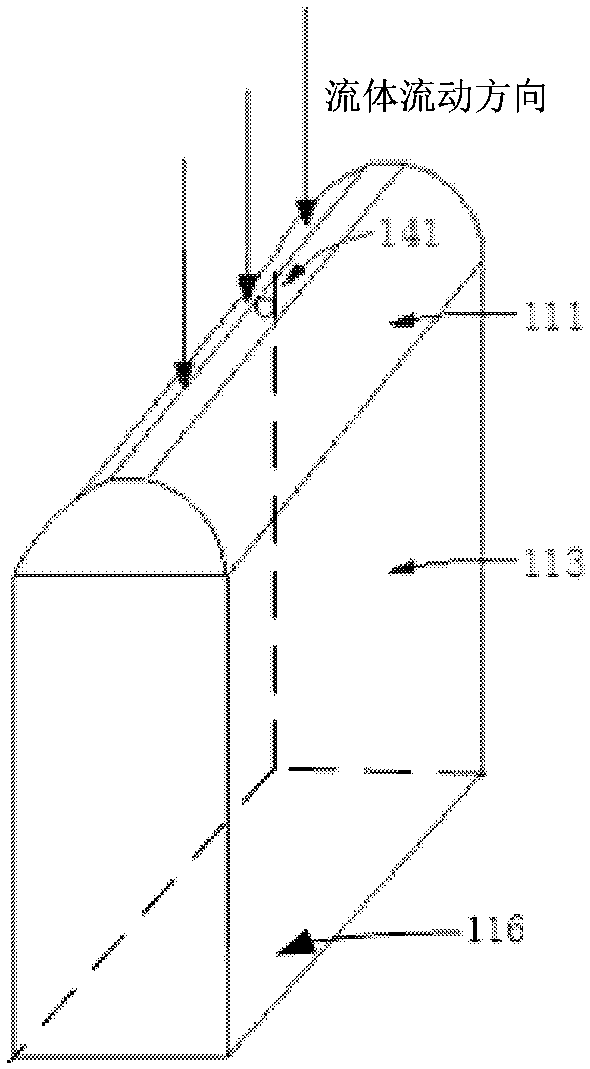

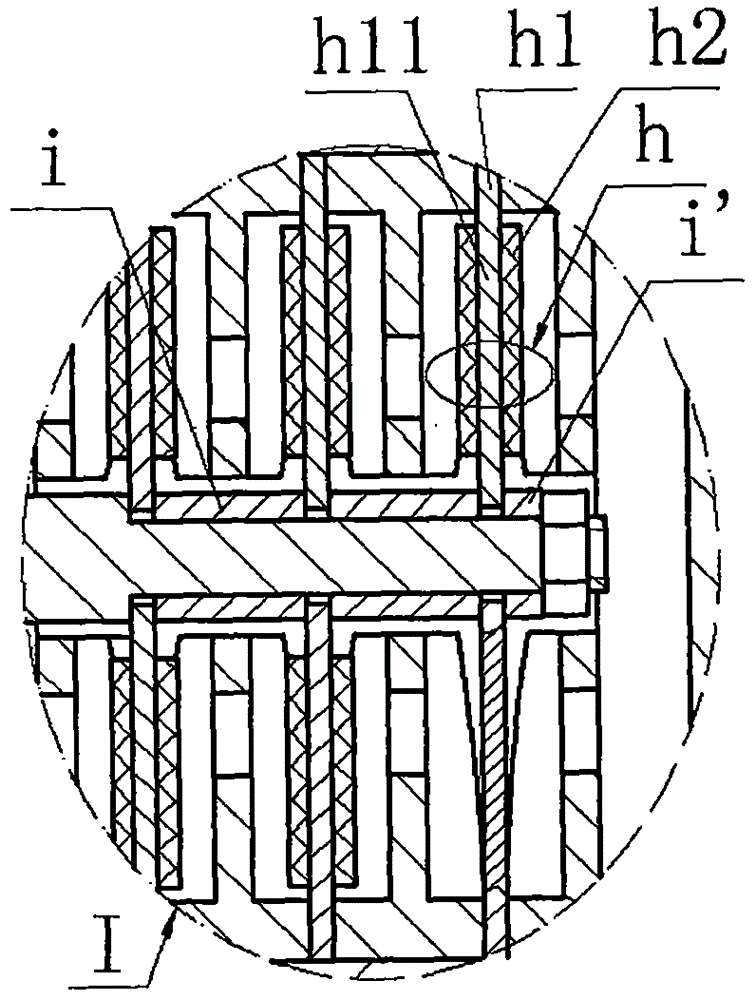

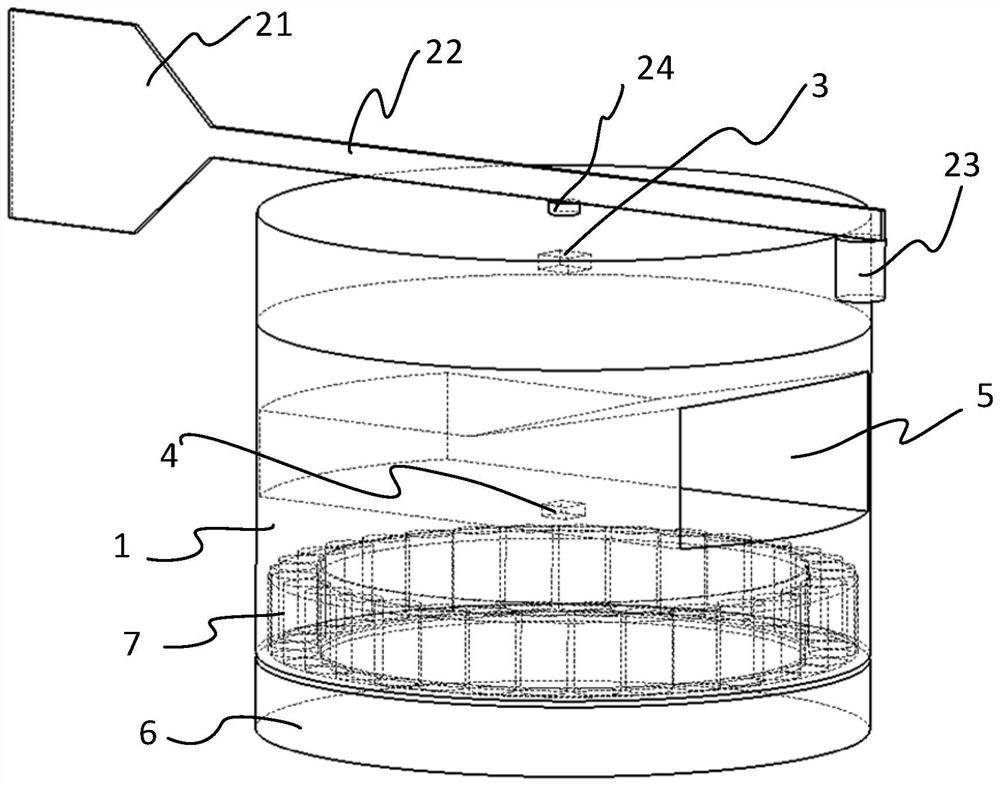

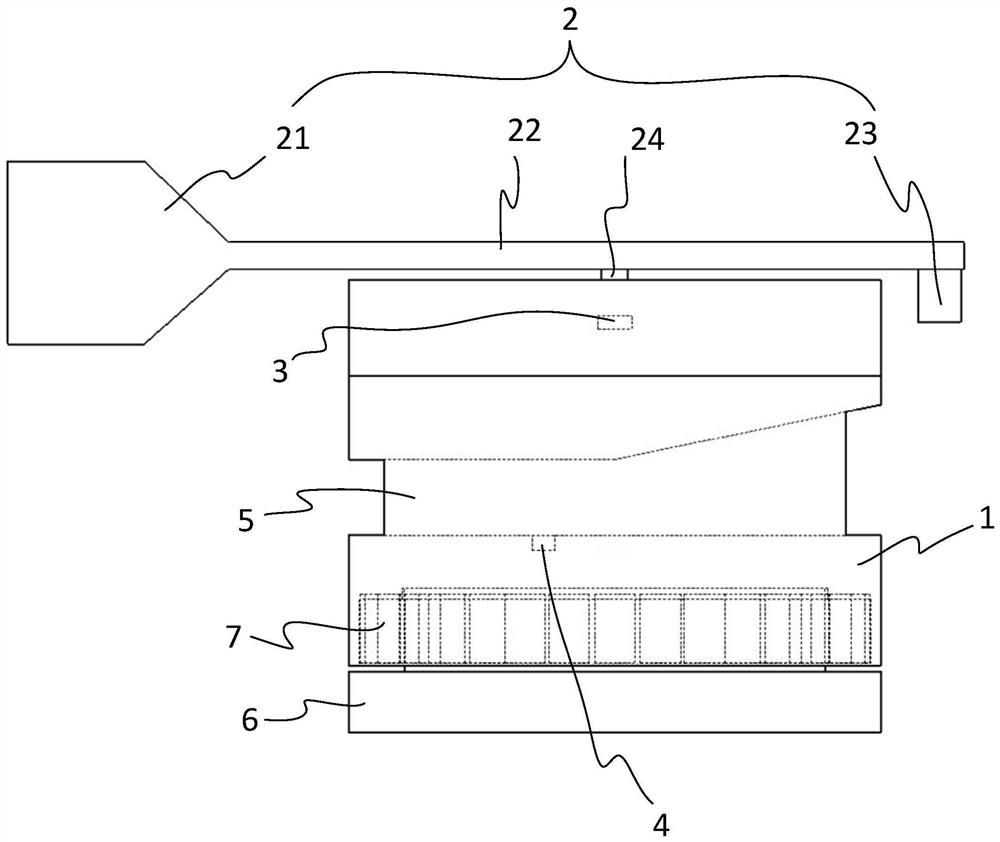

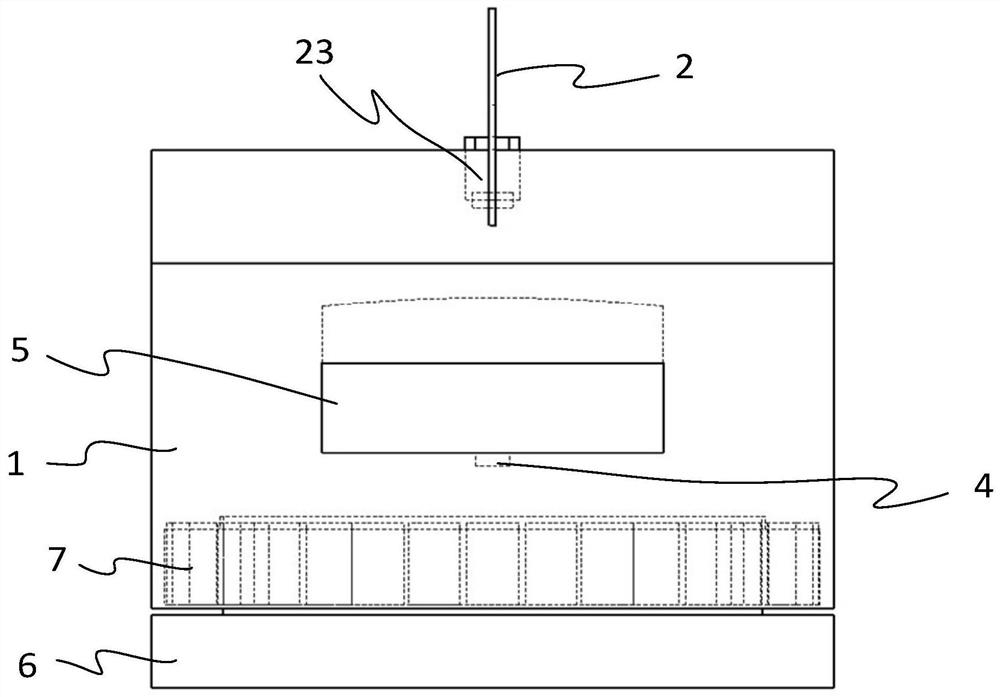

Dual-mode micro flowmeter and preparation method thereof

ActiveCN108593956ALarge measuring rangeReduce complexityFluid speed measurement using swirlflowmeterFluid speed measurement using thermal variablesElectrical resistance and conductanceDual mode

The invention discloses a dual-mode micro flowmeter and a preparation method thereof. The dual-mode micro flowmeter comprises an lower electrode plate, a middle electrode plate and an upper electrodeplate; the lower electrode plate is provided with a heat-sensitive film resistor I for flow rate detection and a heat-sensitive film resistor II for temperature compensation; the middle electrode plate is of an n-shaped structure, and a cross beam of the n-shaped structure is a micro vortex generator; the middle electrode plate is connected to the upper portion of the lower electrode plate; the upper electrode plate is connected to the upper portion of the middle electrode plate; the lower electrode plate, the middle electrode plate and the upper electrode plate are connected to form a micro flowmeter measuring cavity; flowing fluid is guided into the micro flowmeter measuring cavity through the lower electrode plate, the middle electrode plate and the upper electrode plate; the heat-sensitive film resistor I is heated through the galvanization of a lead electrode I connected with the heat-sensitive film resistor I and then detects heat loss caused by flowing; the heat-sensitive film resistor II is heated through the galvanization of a lead electrode II connected with the heat-sensitive film resistor II and detects the temperature in the flowing fluid; the micro vortex generator disturbs a flow field, so that periodic vortices occur in the micro flowmeter, and the flow rate in a pipe is obtained according to the separation frequency of the vortices.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

Resonant flow sensor and uses and production methods for the same

InactiveUS8733162B2Easy to measureVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesFlow transducerEngineering

The invention relates to a flow state sensor (10) for detecting a flow state at a body (16) that may be impinged on by a flow (12). A flow state sensor (10) that is of a simple construction and that is simple to evaluate is characterized in accordance with the invention by at least one frequency detecting device (20) for detecting at least one predefined frequency characteristic of the flow state. The frequency detecting device (20) has at least one oscillation element (22; 22a, 22b, 22c) excitable to resonant oscillatory movement (30) by a flow (12) and having a resonant frequency or natural frequency adapted to the predefined frequency characteristic, especially corresponding to the predefined frequency characteristic. Uses of the flow state sensor (10) in a flow measuring device (62) and in a flow measuring method, and an advantageous production method for the flow state sensor (10) are also proposed.

Owner:AIRBUS OPERATIONS LTD +1

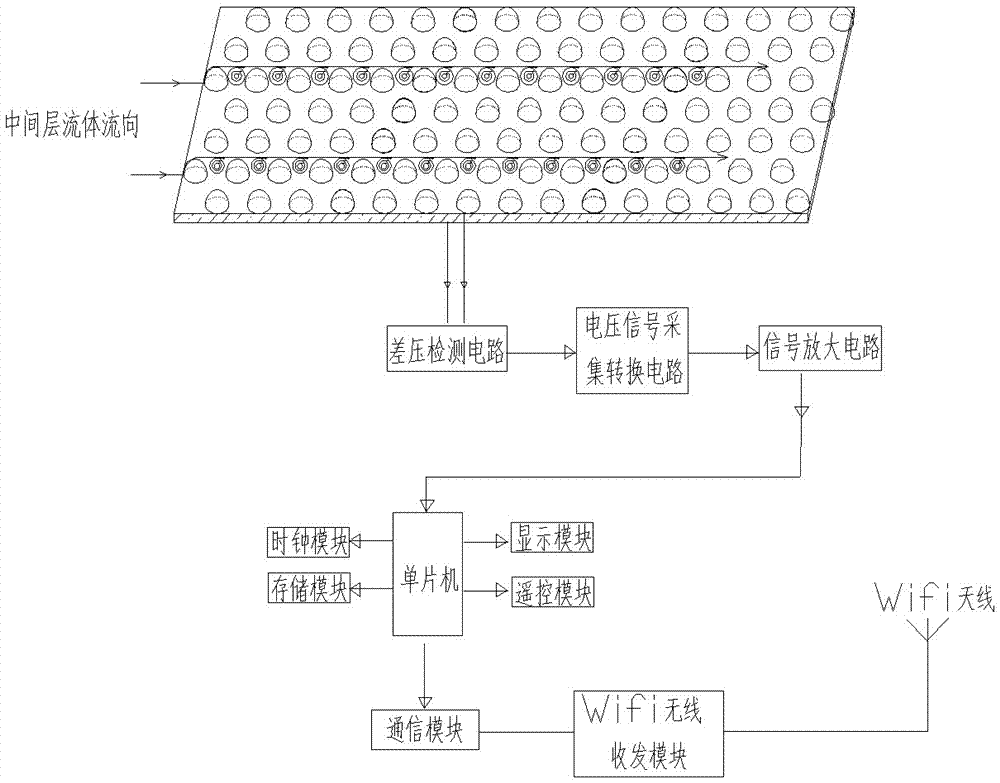

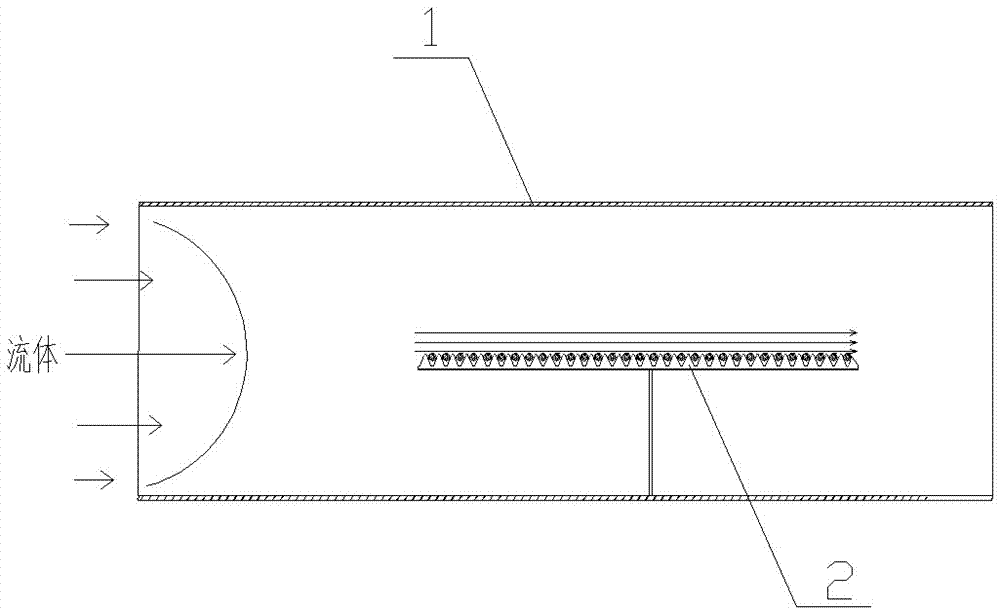

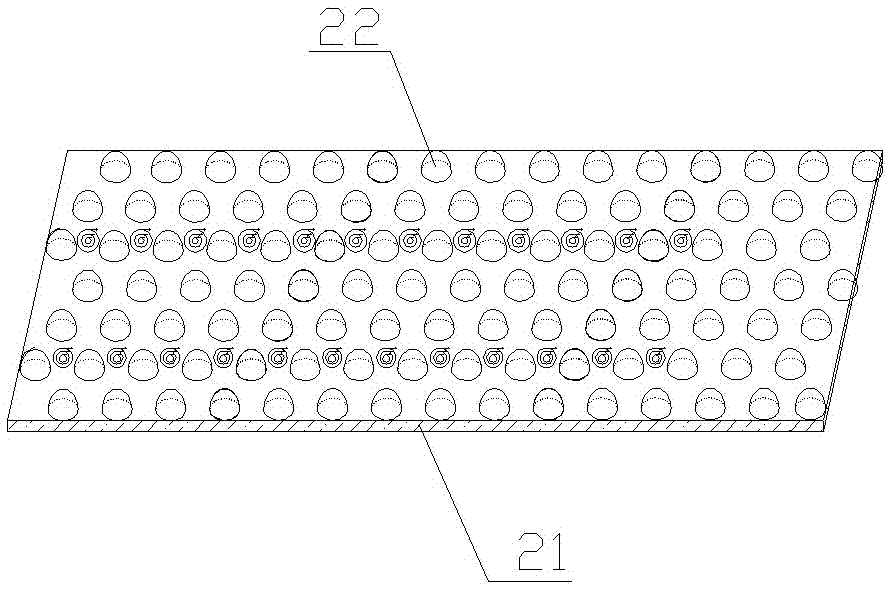

Wind speed on-line measurement system and test method

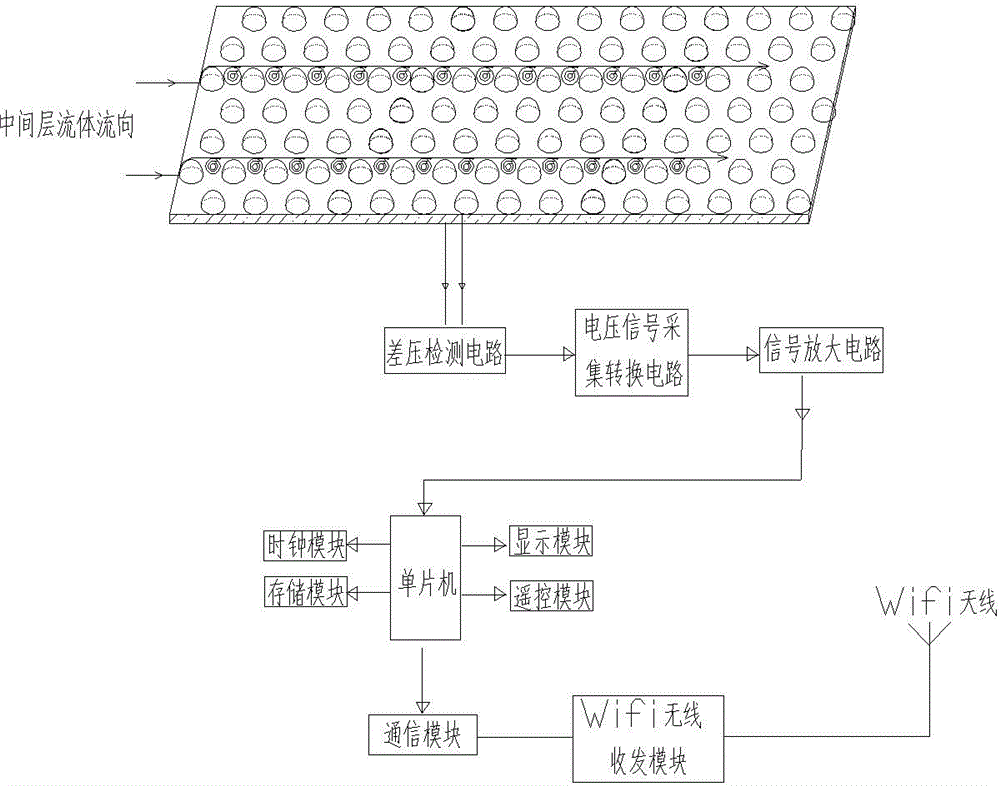

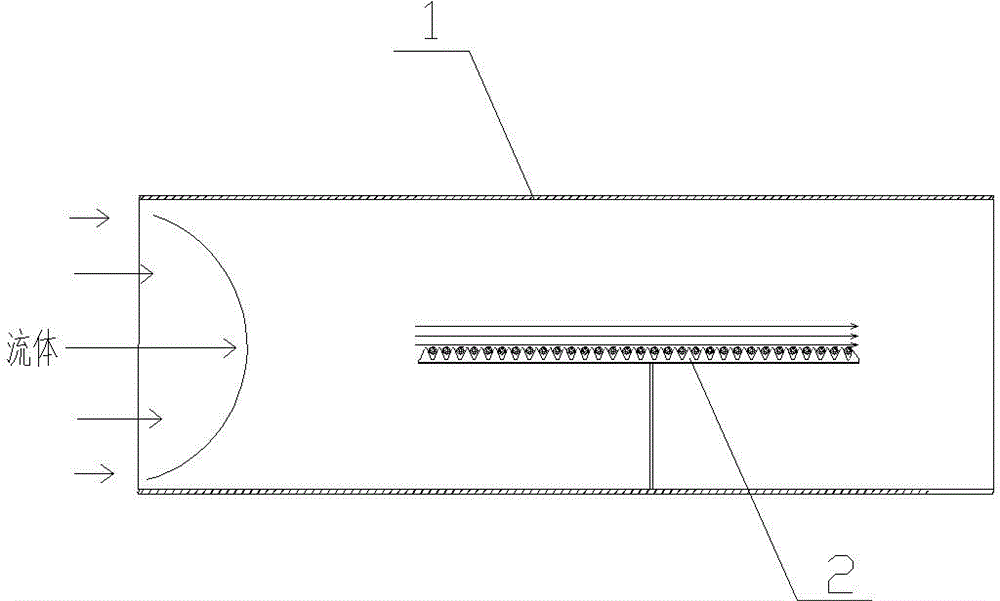

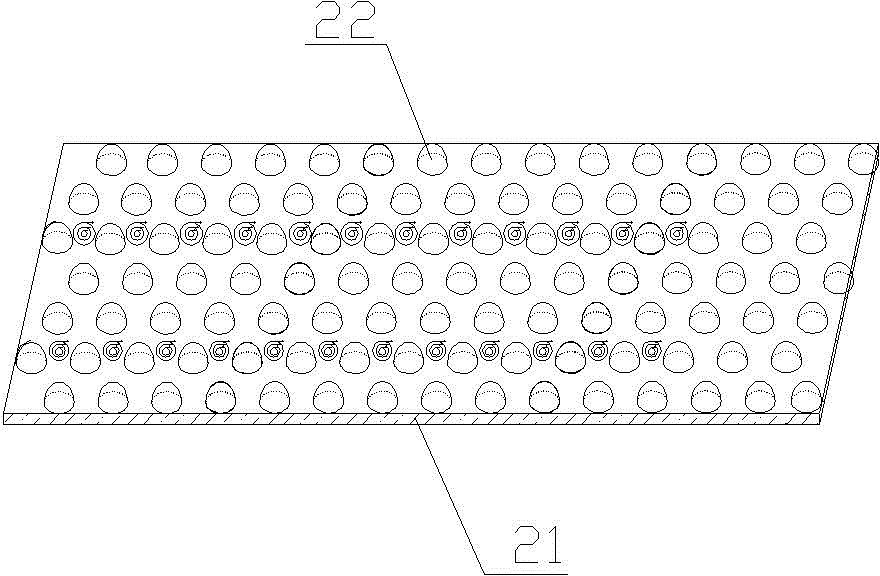

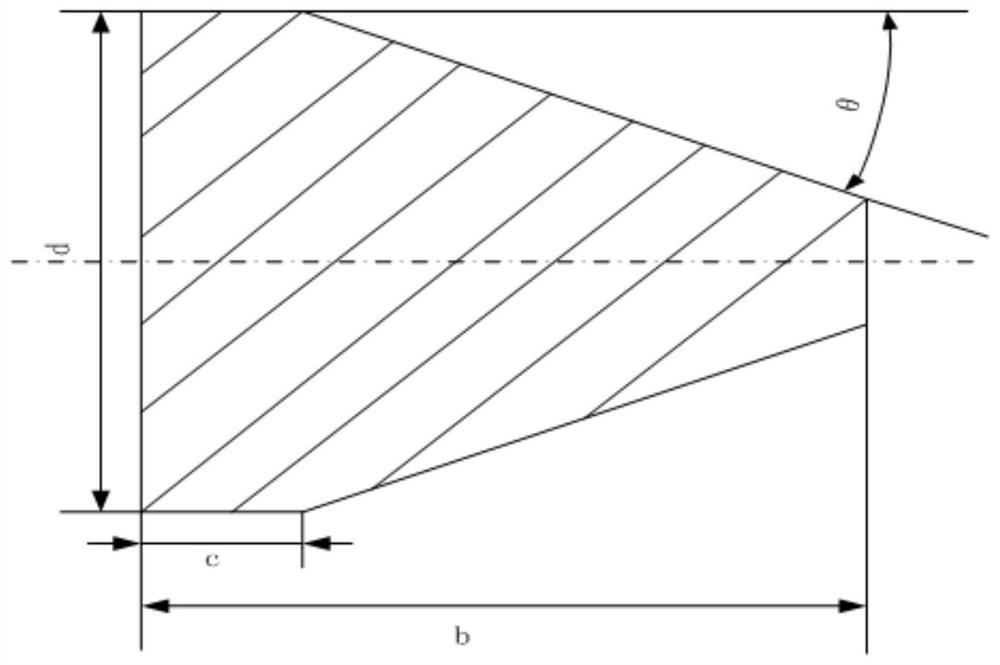

ActiveCN104833819AConsistent flow velocityConsistent actual flow velocityFluid speed measurement using swirlflowmeterMicrocontrollerMicrocomputer

The invention discloses a wind speed on-line measurement system and a test method. The measurement system includes a test pipeline, a monitoring board, a differential pressure detection circuit, a voltage signal acquisition and conversion circuit, a single-chip microcomputer, a communication module and a receiving terminal. The test method is as follows: 1) a measurement system is placed in a wind field; 2) wind speed measurement is performed through a detection plate, and wind speed signals are converted to voltage signals; 3) then voltage signal acquisition is performed through the differential pressure detection circuit, and voltage signals are transmitted to the single-chip microcomputer after passing through the voltage signal acquisition and conversion circuit; 4) the received voltage signals are reverted to wind speed after being processed through the single-chip microcomputer; and 5) the single-chip microcomputer sends wind speed signals to a receiving terminal through the communication module. The wind speed on-line measurement system provided is simple in structure, the test method is convenient to test, and low wind speed can be accurately measured.

Owner:CHONGQING MAS SCI & TECH CO LTD

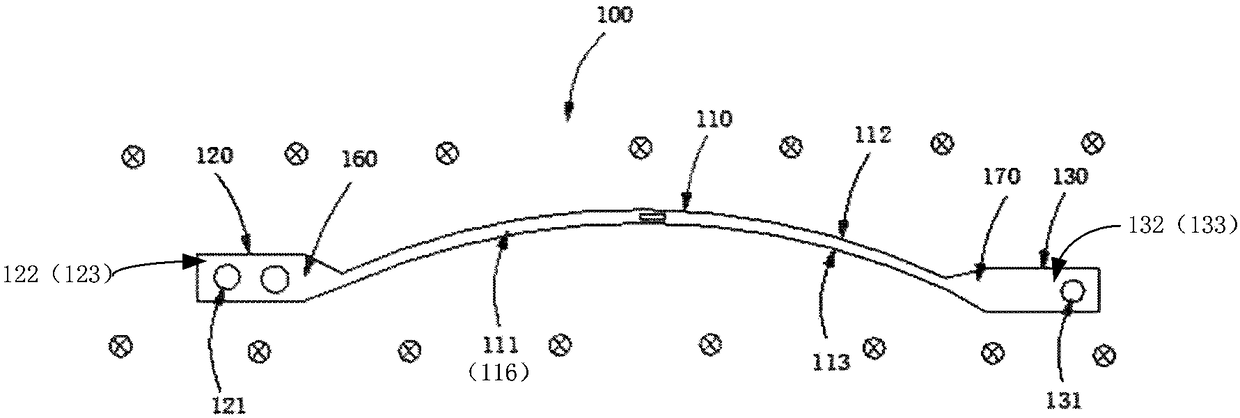

Electric connector, fluid state test device and fluid heat exchange system

ActiveCN108267261AAvoid destructionThermometer detailsThermometers using electric/magnetic elementsElectricityLongitudinal vibration

The invention discloses an electric connector, which comprises a main body part, a connection part, a first temperature sensing element and a second temperature sensing element, wherein the connectionpart is used for enabling the main body part to be electrically connected with a charged element arranged in a flow channel; the main body part comprises a first side surface and a second side surface parallel with the flow direction of the fluid; and the first temperature sensing element and the second temperature sensing element are arranged on mutually-opposite positions on the first side surface and the second side surface in an electrical insulation mode. The invention also discloses a fluid state test device with the electric connector and a fluid heat exchange system. According to theelectric connector, the fluid state test device and the fluid heat exchange system, in a condition of not influencing the fluid flow field, at least one purpose of measuring and monitoring the fluid velocity, measuring and monitoring the fluid pressure, measuring and monitoring the fluid resistance, measuring and monitoring the transverse vibration frequency of the electric connector and suppressing the longitudinal vibration and / or the transverse vibration of the electric connector can be realized.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

Wind Energy Installation Comprising a Wind Speed Measuring System

InactiveUS20110107846A1Without excessive energy consumptionConsume moreEngine fuctionsFluid speed measurement using swirlflowmeterEngineering

A wind energy installation is disclosed. The wind energy installation includes a rotor with at least one rotor blade. The wind energy installation includes at least one wind speed measuring system. The at least one wind speed measuring system optically measures the vibrations of an optical fiber due to vortex shedding.

Owner:SIEMENS AG

Intelligent pipeline flow velocity monitor

ActiveCN106018870ASimple structureReasonable structureFluid speed measurement using swirlflowmeterCantilevered beamLeft half

The invention relates to an intelligent pipeline flow velocity monitor, and belongs to the field of fluid monitoring. An inner tube in a pipeline is divided into a left cavity and a right cavity by a separator plate. The left cavity is internally provided with a circuit board, and the end portion thereof is equipped with a left end cover; left and right half shafts of a pin shaft are sleeved by a buffer spring and a balance spring respectively; the left half shaft extends out of the left end cover, and the end portion thereof is equipped with an exciter; the right half shaft extends into the right cavity from the separator plate; a right end cover enables two outer frames and at least one inner frame to be pressed in the right cavity; a metal substrate is pressed between the adjacent inner and outer frames and between the inner frames; a cantilever beam of each metal substrate is bonded with a piezoelectric wafer to form a piezoelectric vibrator, and the other end of the cantilever beam is fixed to the right half shaft; and one side of each outer frame and the two sides of each inner frame are provided with a limit surface and a sediment groove. The advantages are that power generation and flow velocity automatic measurement are realized synchronously through a coupling effect, and thus online monitoring of the flow velocity can be realized in a true sense; the monitor, configured along the length direction of the pipeline, is simple in structure and small in radial dimension, and can obtain required energy through the multiple piezoelectric vibrators easily; and each piezoelectric vibrator is reasonable in structure, large in generated energy and high in reliability.

Owner:高唐融知融智科技服务有限公司

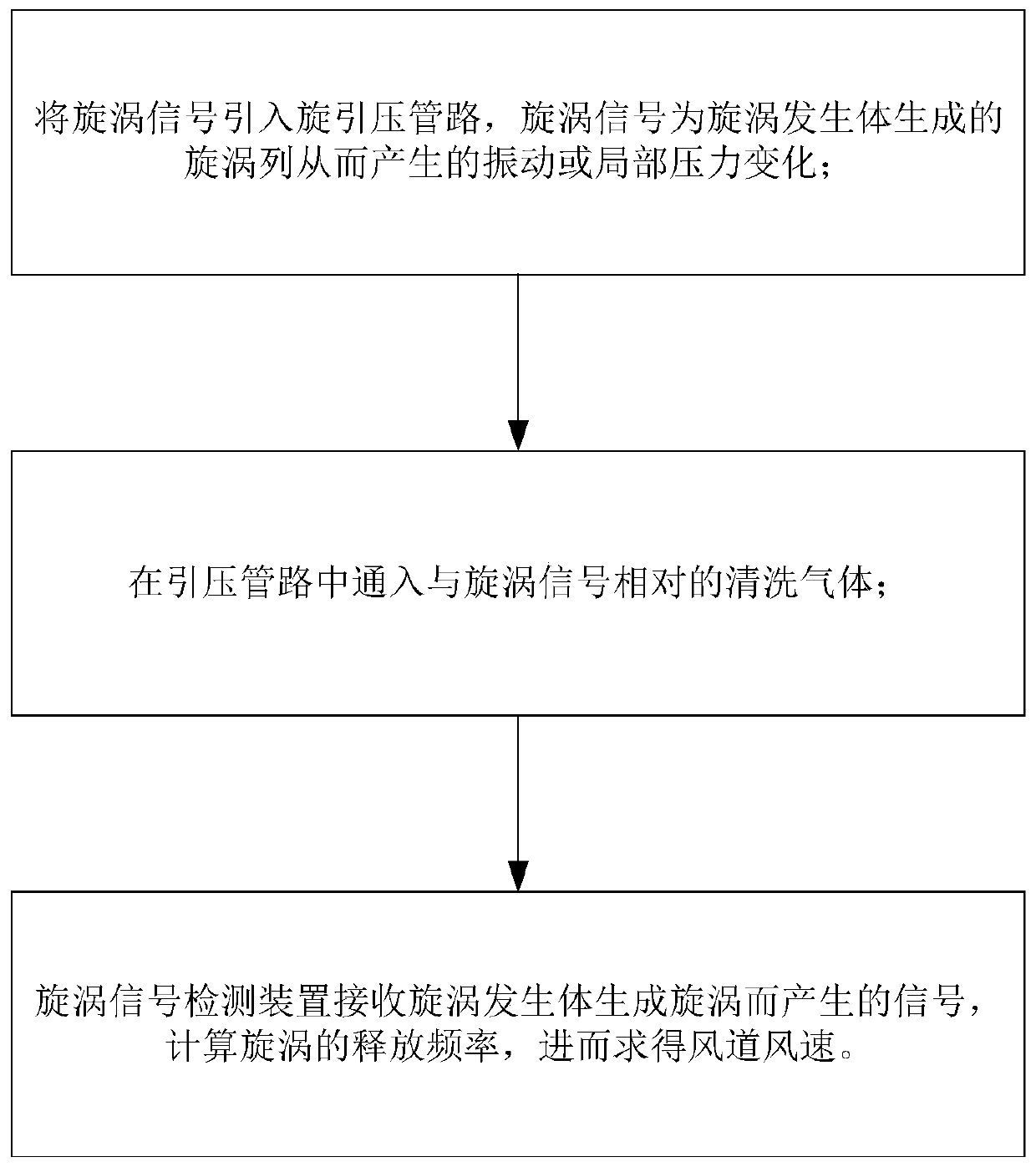

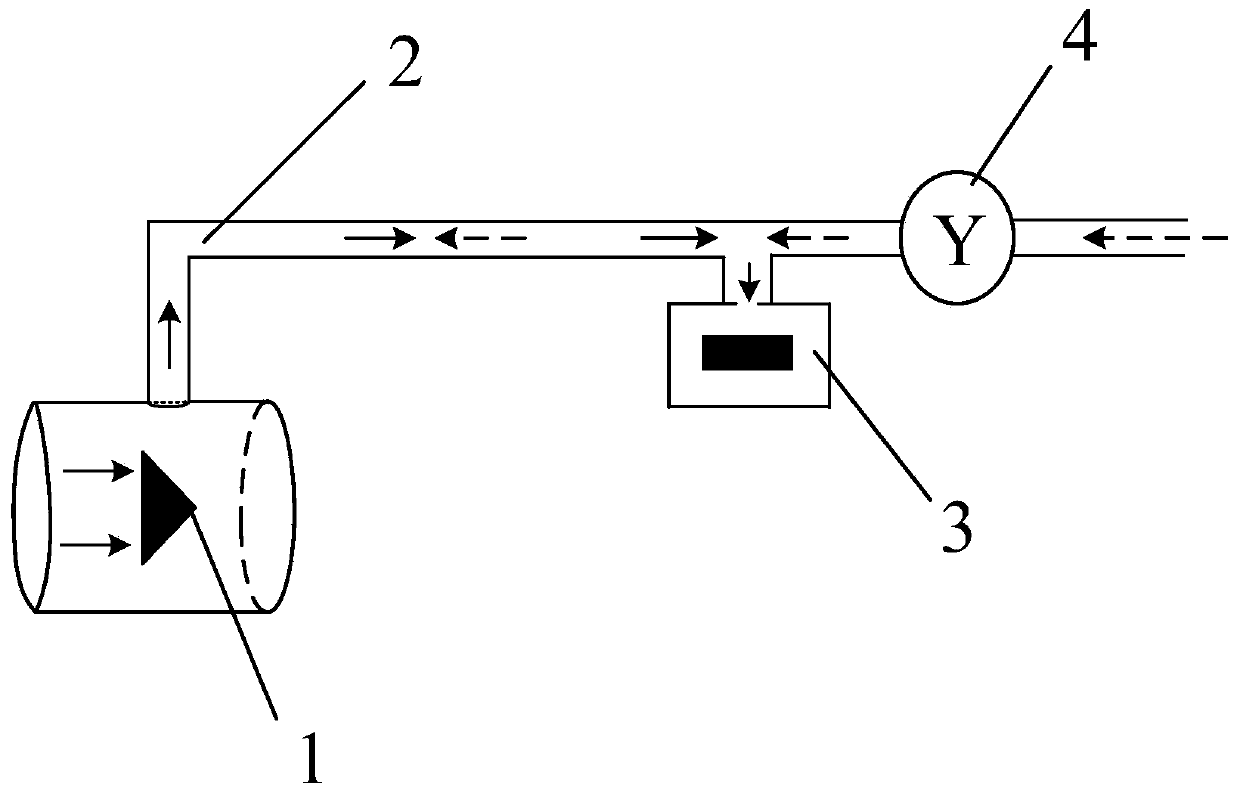

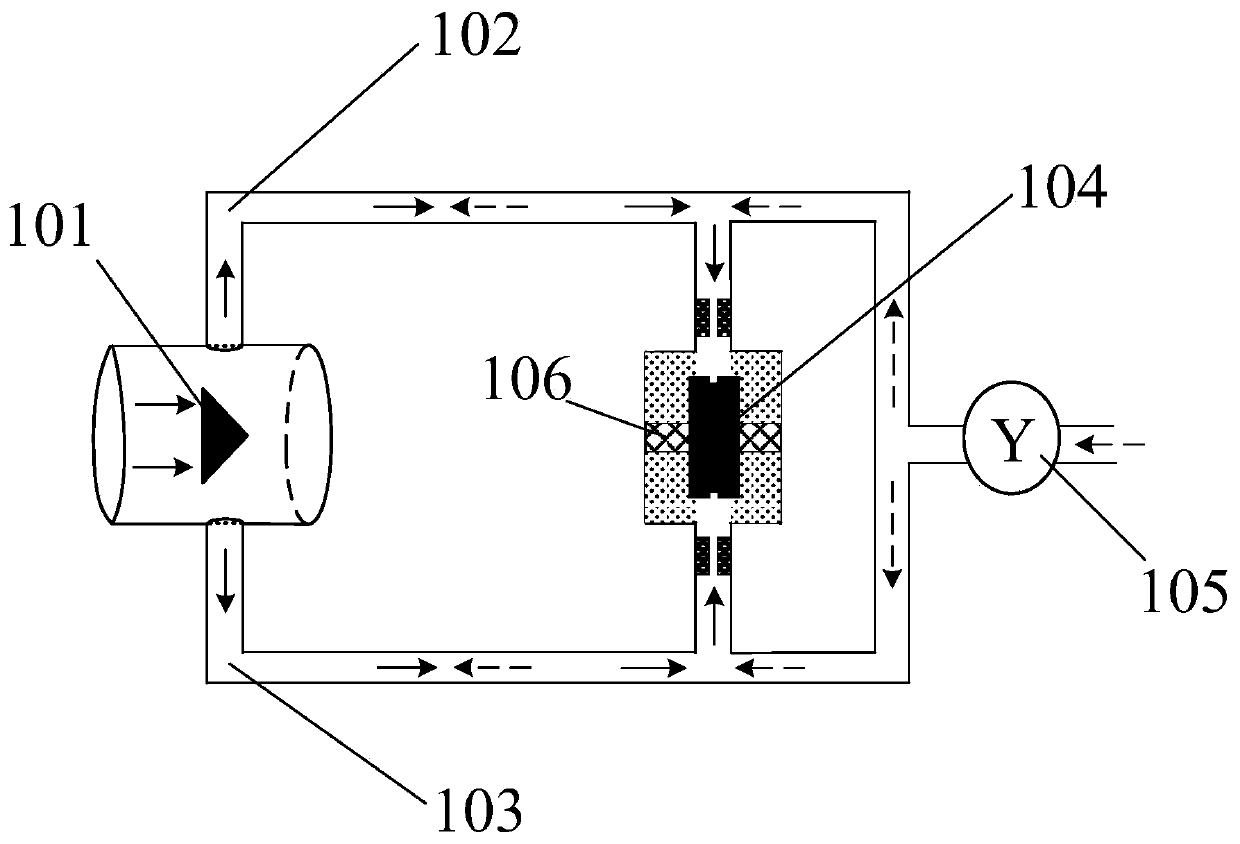

Wind speed online monitoring method

InactiveCN110596417AImprove anti-blocking effectDoes not affect transmissionFluid speed measurement using swirlflowmeterVolume meteringEngineeringHigh pressure

The invention relates to a wind speed online monitoring method. The method comprises the following steps: introducing a vortex signal into an impulse pipeline, wherein the vortex signal is the vibration or local pressure change produced by the vortex generated by a vortex generator; importing cleaning airflow opposite to the production of the vortex signal in the impulse pipeline, wherein a vortexsignal detection device receives the signal produced by the vortex generated by the vortex generator, computes release frequency of the vortex, and then obtains the wind flue speed. The cleaning airflow is added in the impulse pipeline while measuring the wind flue speed, the cleaning airflow is imported from a high-pressure gas source inlet, the high-pressure airflow is reduced to appropriate flow through a pressure-reducing valve. The measurement and cleaning can be synchronously performed, and the problem that the impulse pipeline is bad in anti-blocking effect due to the existing monitoring method is solved.

Owner:GL TECH CO LTD

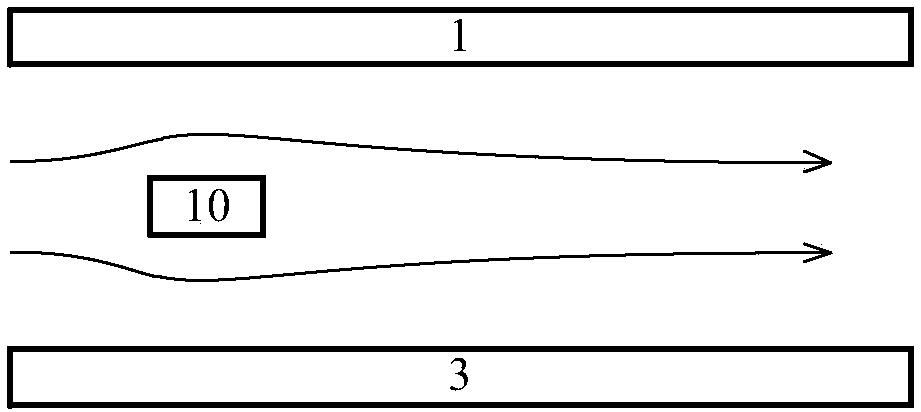

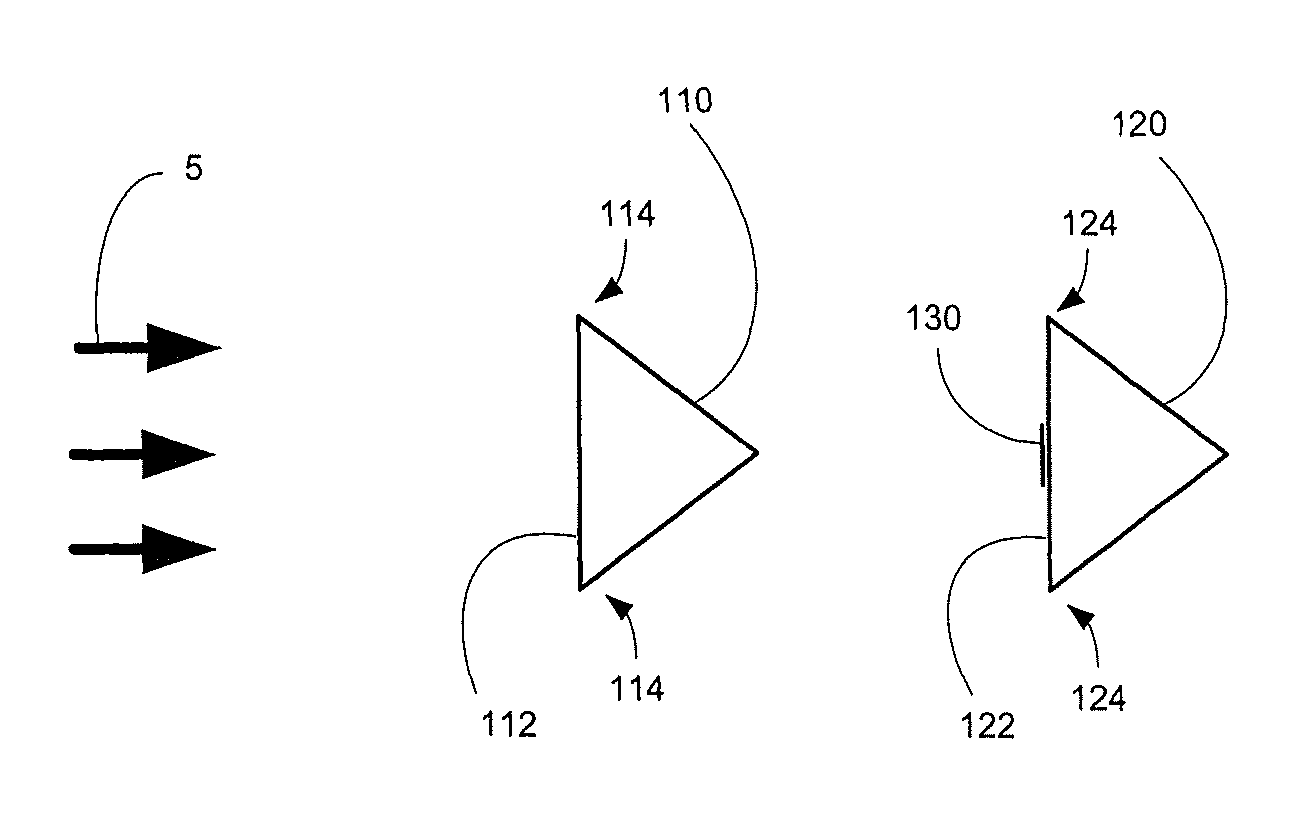

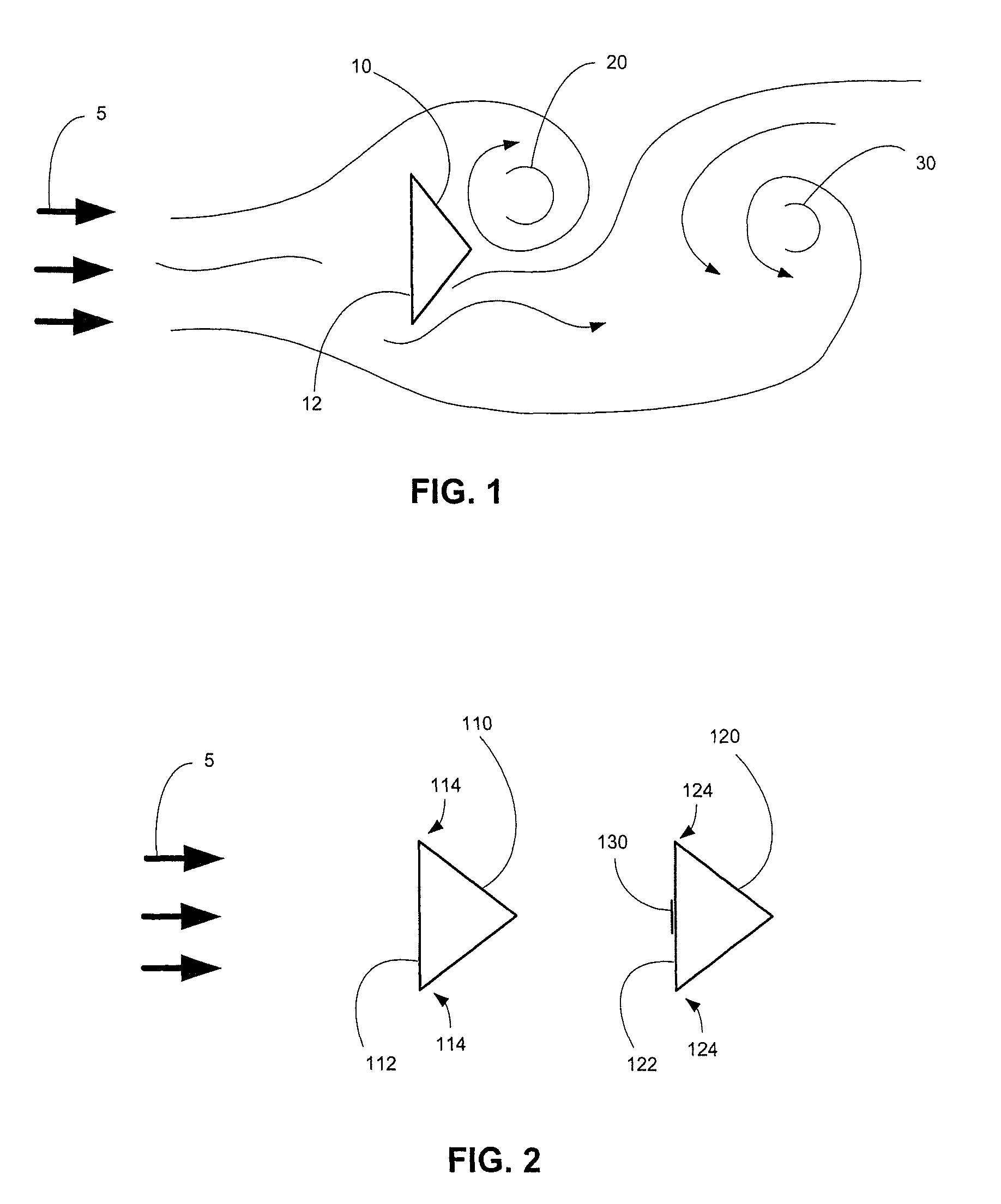

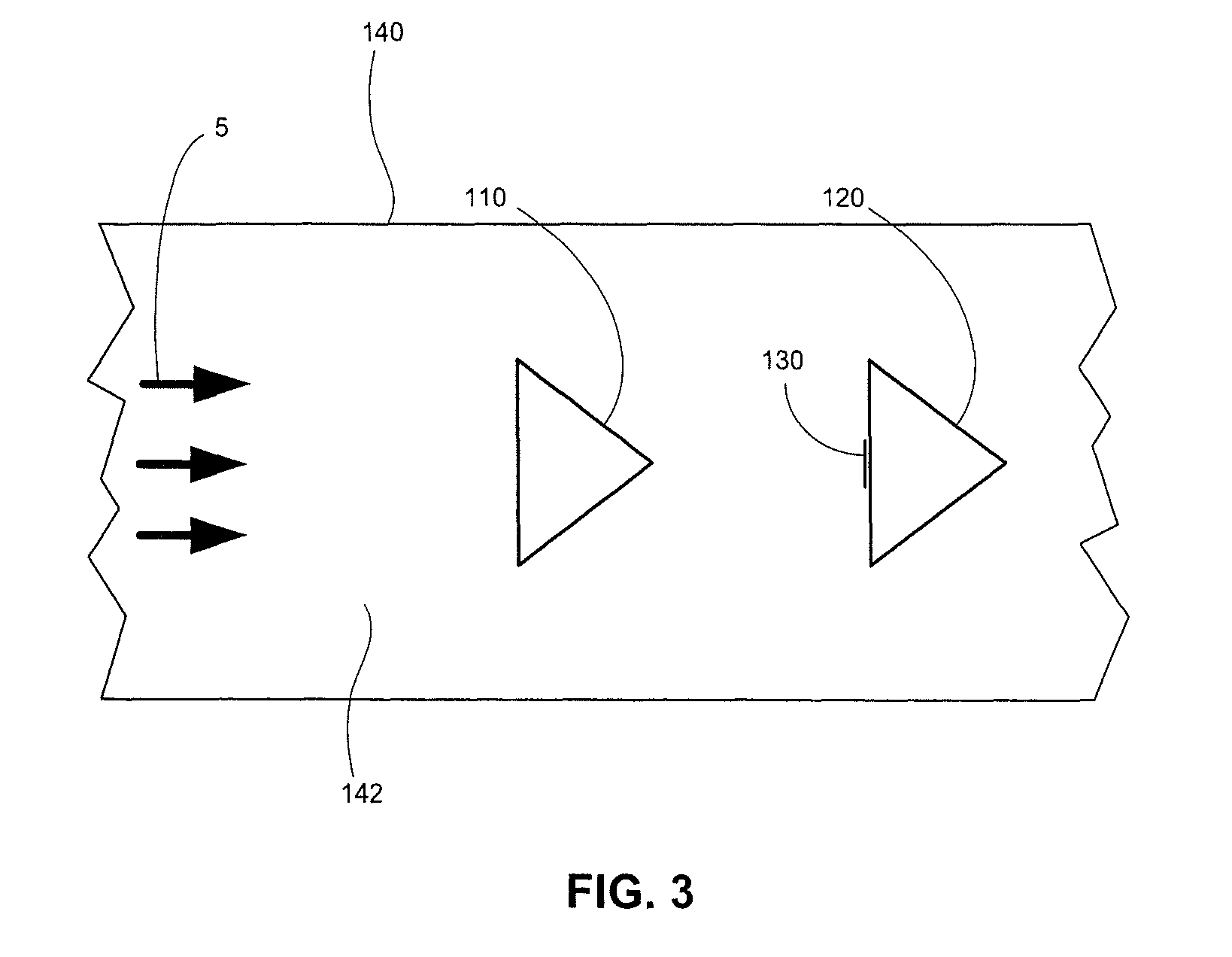

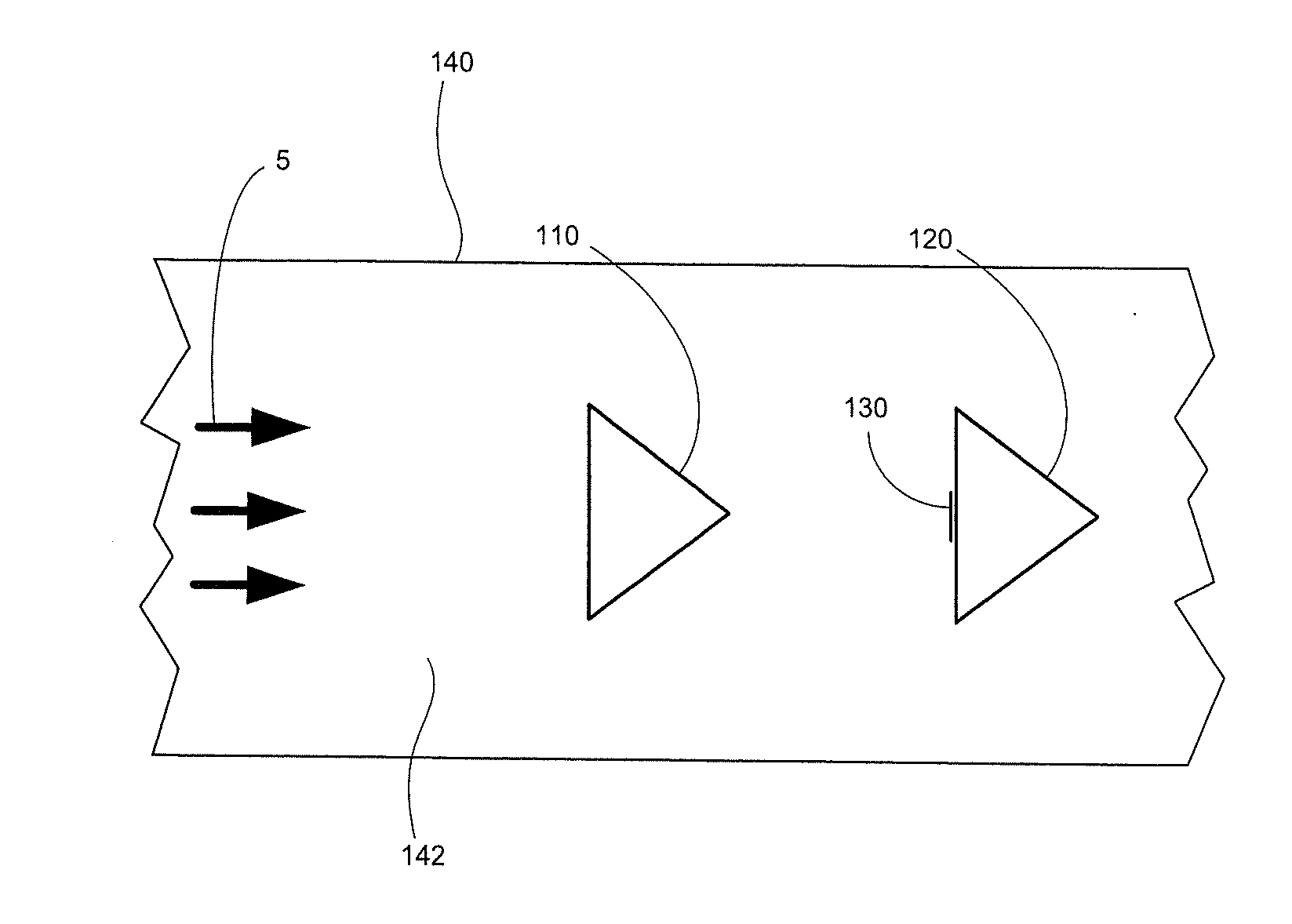

System and method for determining fluid speed

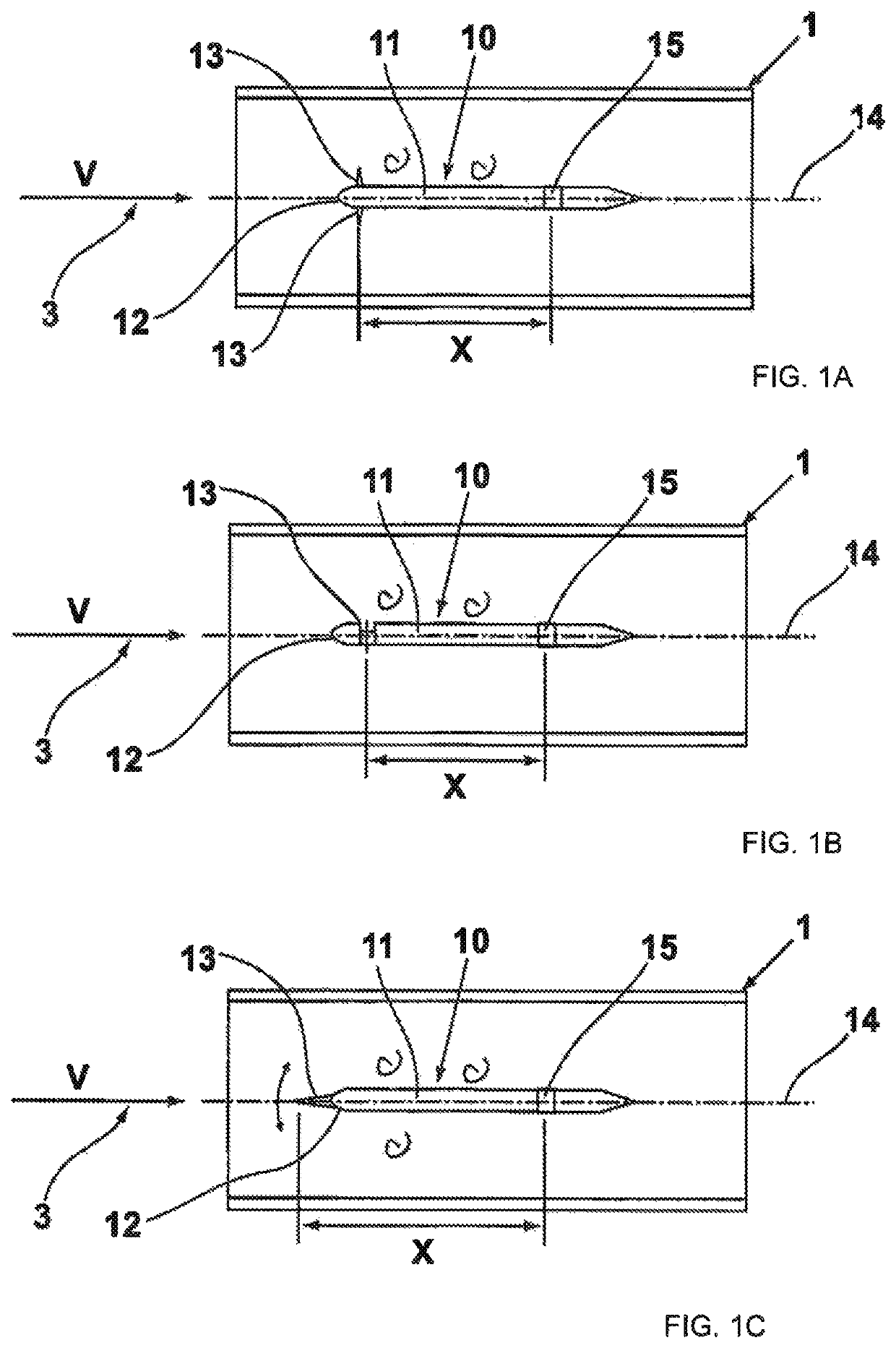

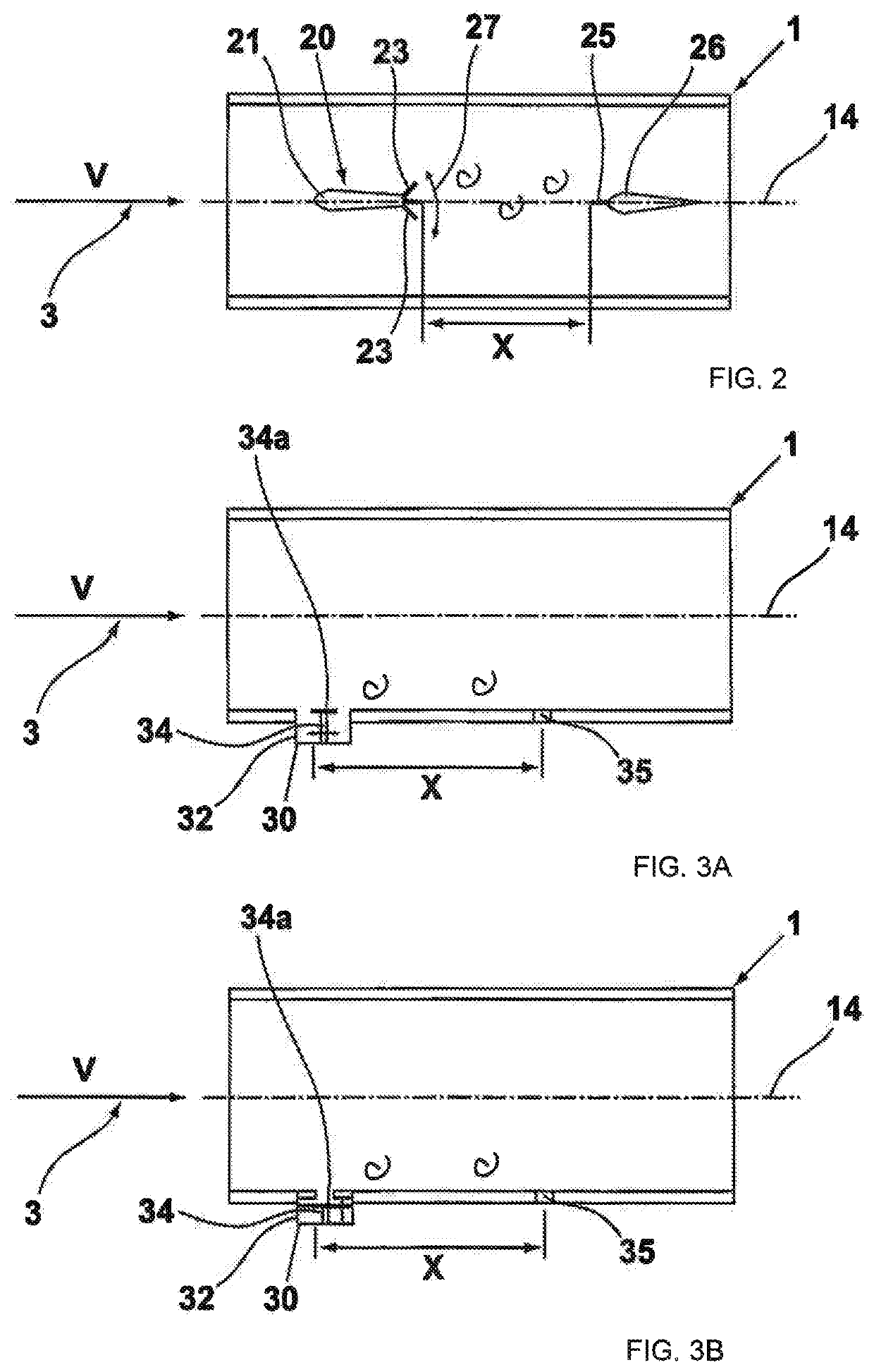

ActiveUS8925391B2Fluid speed measurement using swirlflowmeterVolume/mass flow by dynamic fluid flow effectSensor arrayEngineering

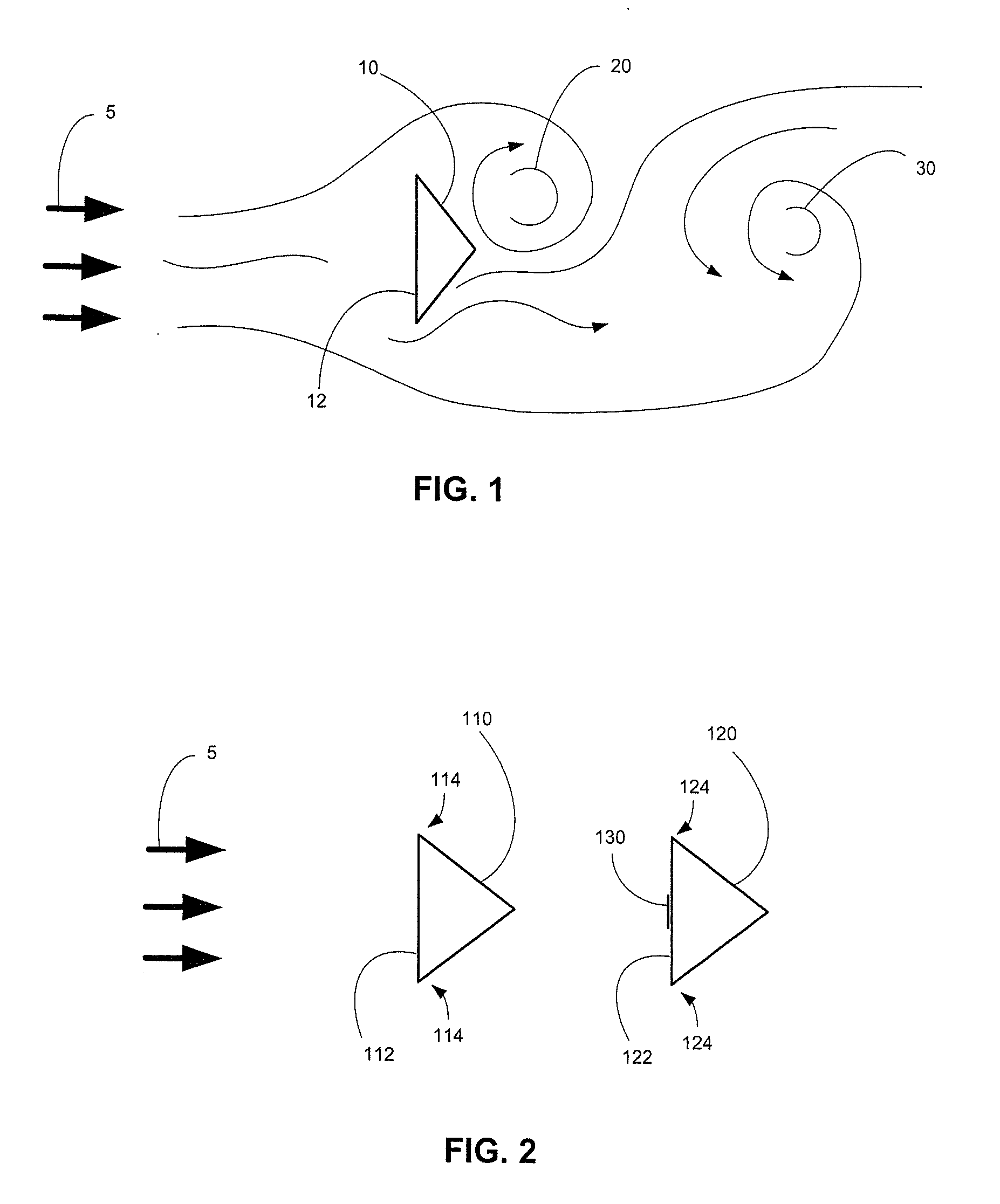

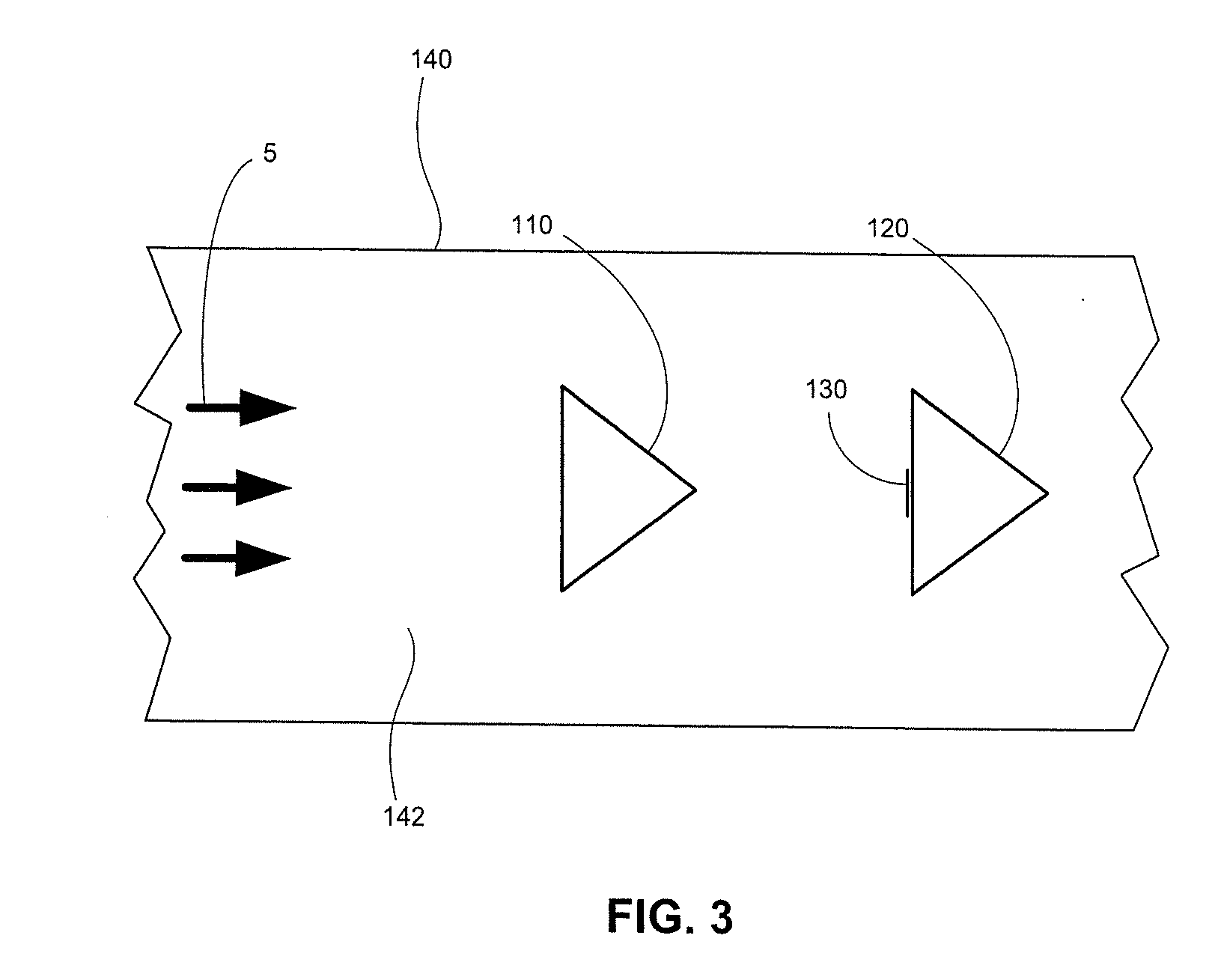

A flow speed sensor arrangement is provided for measuring a flow speed of a fluid stream relative to an object. The arrangement comprises a first obstructive body having a first forward facing surface and two lateral edges and a second obstructive body having a second forward facing surface. The second obstructive body is positioned in tandem relative to the first obstructive body so that the first and second forward facing surfaces face the same direction and so that when the first forward facing surface is presented to an incoming fluid stream, the first obstructive body is between the incoming fluid flow and the second obstructive body. A sensor array is disposed on the second forward facing surface. The first and second obstructive bodies are attachable to the object so that the first forward face is presented to an incoming fluid stream when the object is immersed in the fluid stream.

Owner:TAO OF SYST INTEGRATION

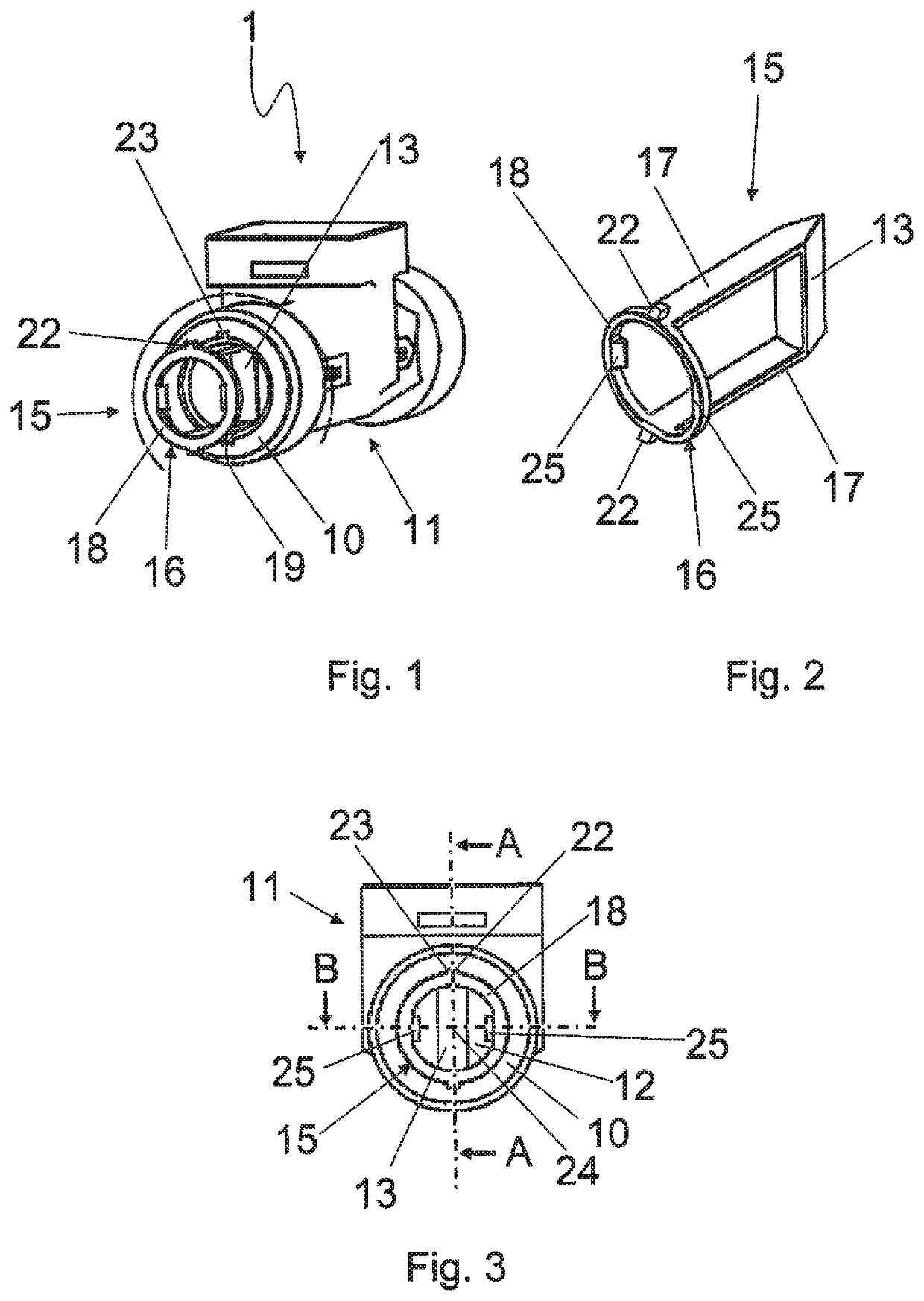

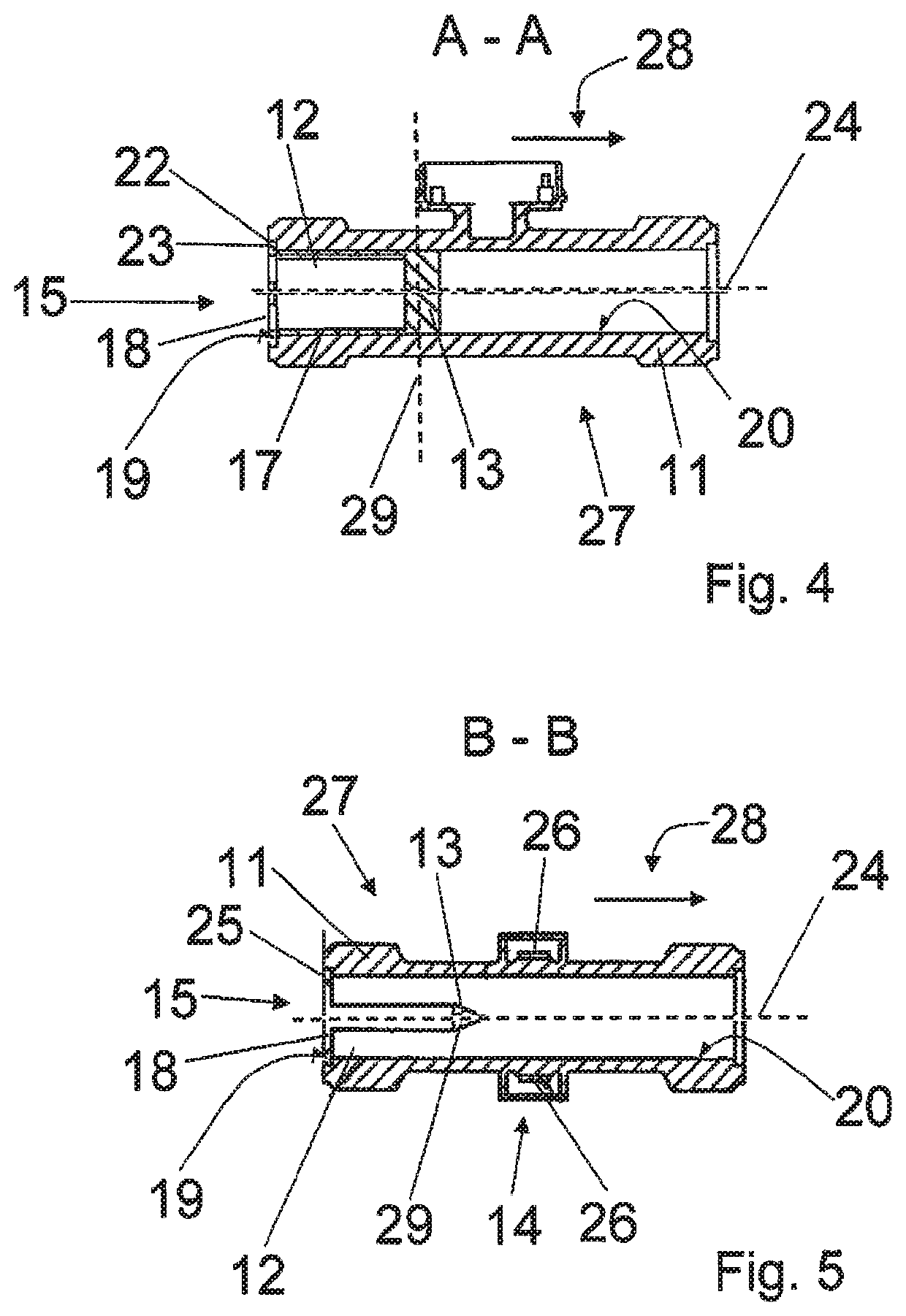

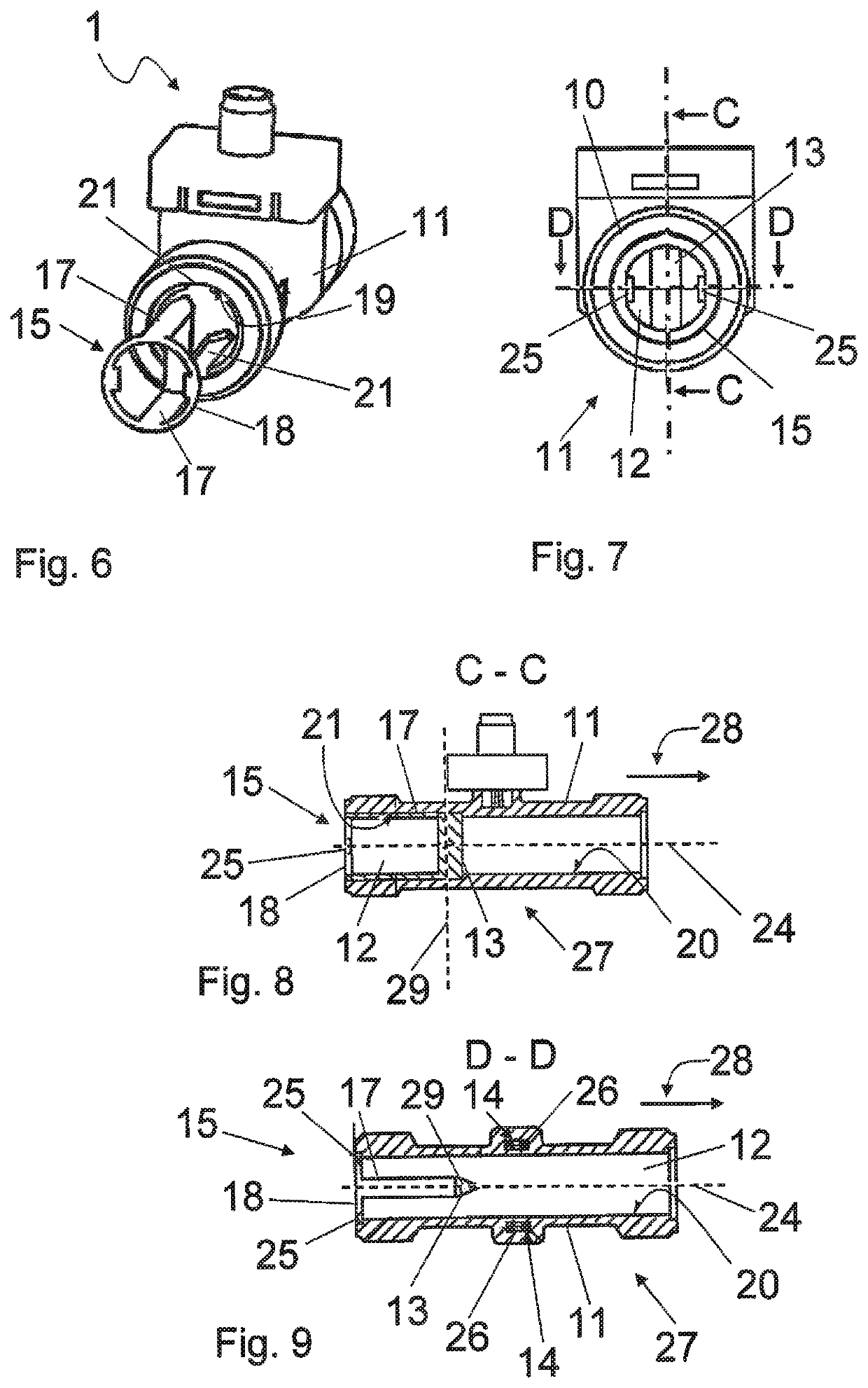

Flow meter

ActiveUS20190226888A1Easy to analyzeStrong loadFluid speed measurement using swirlflowmeterVolume/mass flow by dynamic fluid flow effectEngineering

Owner:SIKA DR SIEBERT & KÜHN GMBH & CO KG

Device for measuring flux by turbine method, the method and its uses

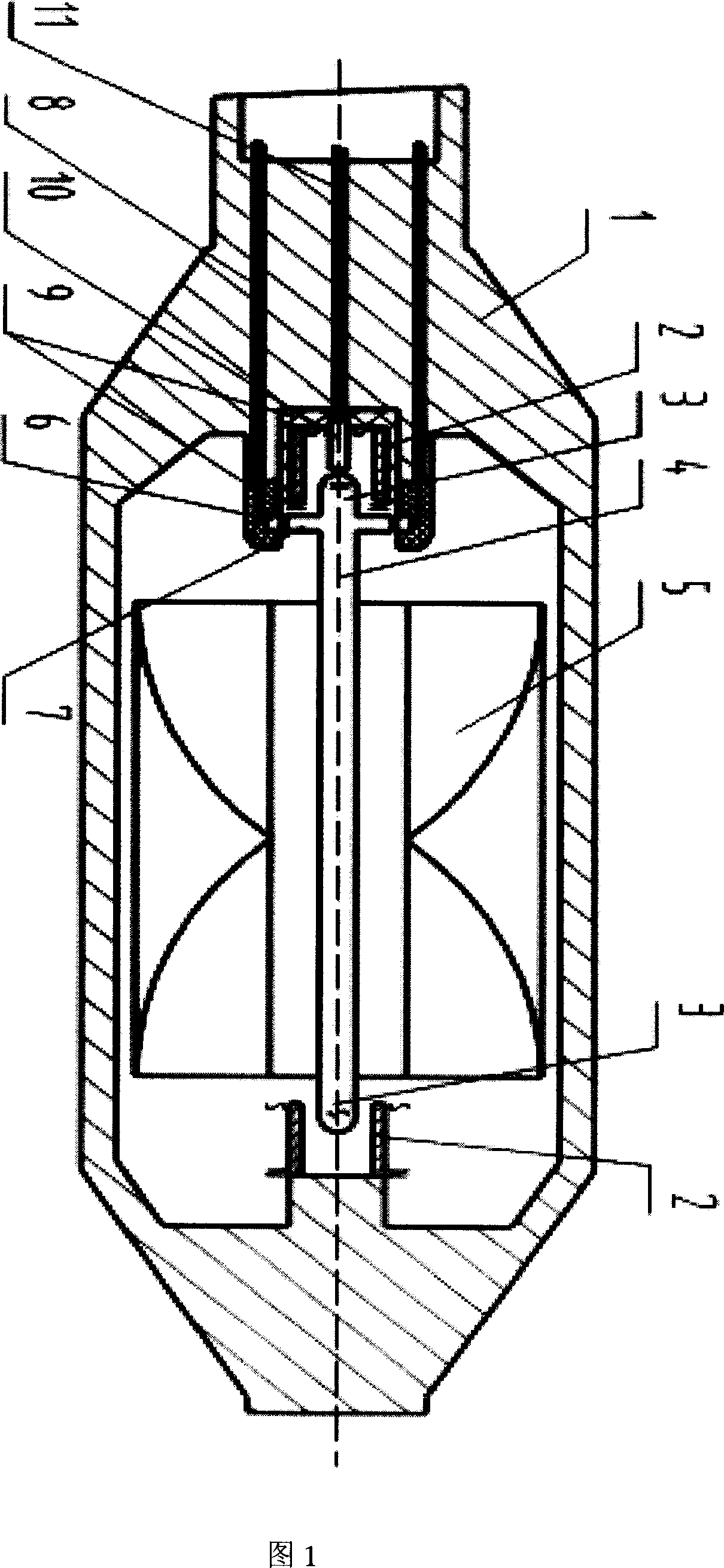

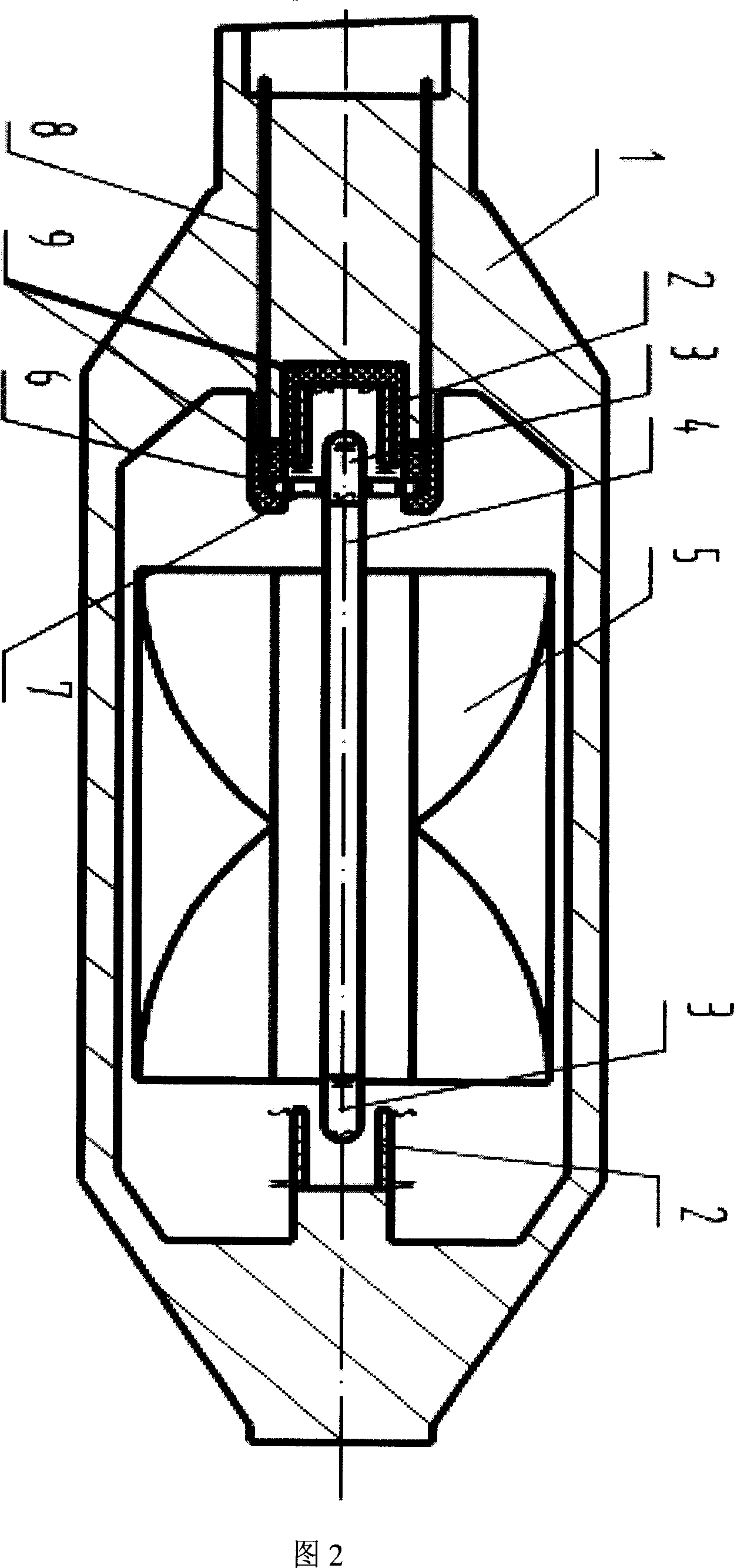

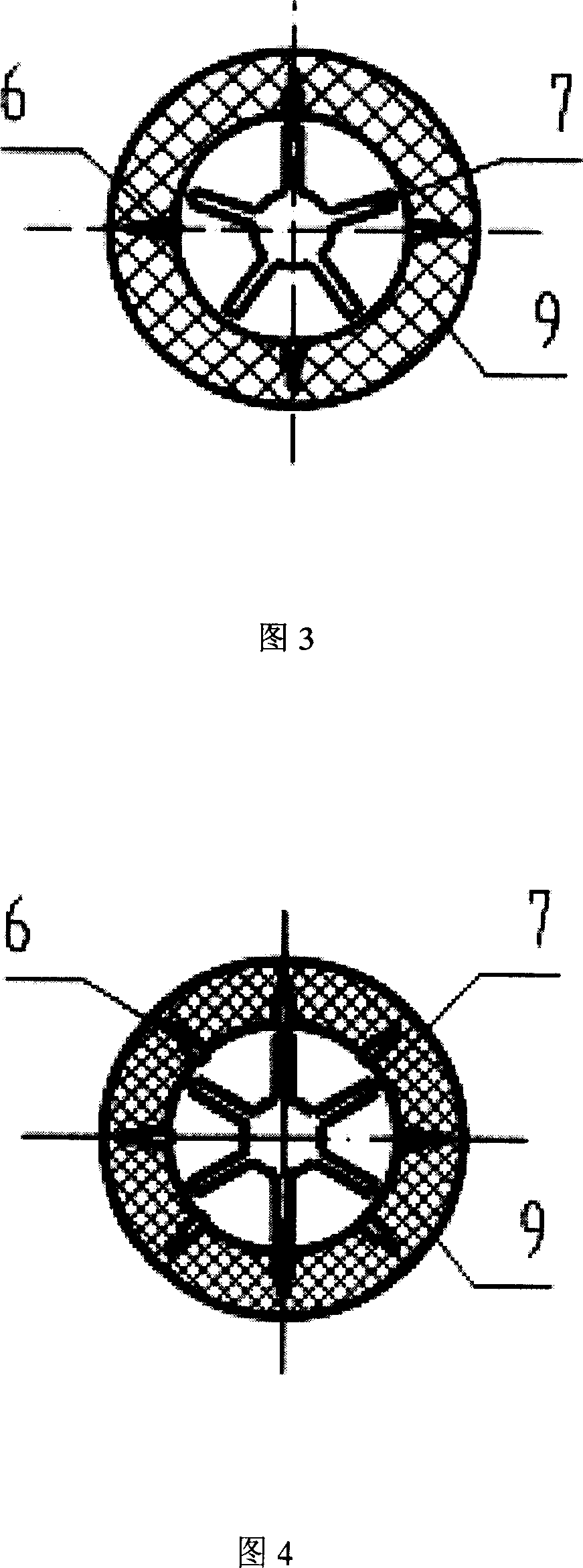

InactiveCN101101225AReduce frictionLow costFluid speed measurement using swirlflowmeterVolume/mass flow by dynamic fluid flow effectCapacitanceElectrical resistance and conductance

The invention relates to an equipment of turbine method to test the flux and its method, the equipment includes a turbine which reflects the flow velocity by the rotating velocity and the magnetic suspend bearing which supports the turbine, the turbine through the magnetic suspend bearing and the support of the equipment connected. Of which, on the support of the equipment installs a group measure electrode, on the turbine installs a group assistant electrode. Because of the turbine rotating lead the distance between the assistant electrode and the each measured electrode to change, further lead the resistance and capacitance between the each measured electrode and the assistant electrode to change, then further lead the resistance and capacitance of the each measured electrode also to change. The measured electrode connects to the test circuit, can test the rotating angle of the turbine through testing the resistance and capacitance between the measuring electrode.

Owner:BEIJING ZEBANON SCI & TECH +1

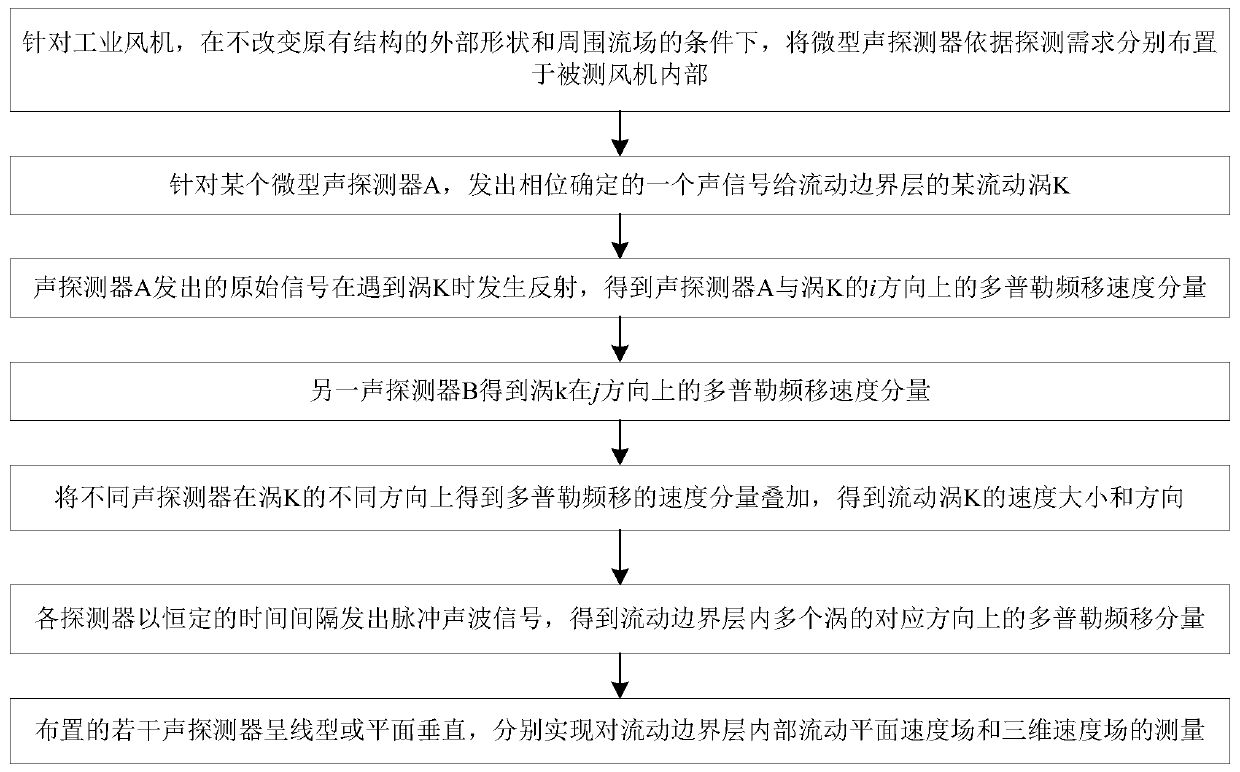

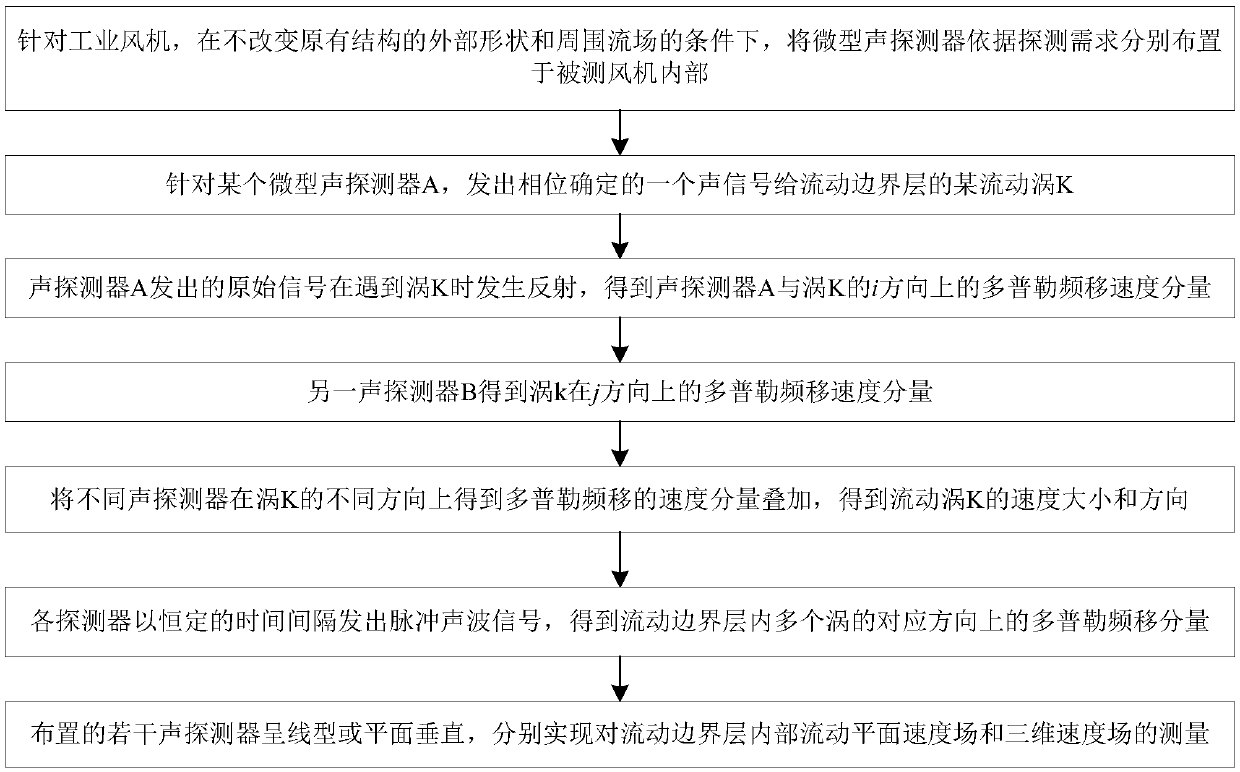

A method for flow measurement by non-extending miniature acoustic probes

ActiveCN108802423BAvoid secondary screeningLittle impact on flowFluid speed measurement using swirlflowmeterSound waveDoppler us

The invention discloses a method using a non-extension type miniature sound detectors to perform flow measurement and belongs to the field of hydrodynamics. The method is characterized in that the miniature sound detectors are arranged inside a to-be-measured fan; by one sound detector A, a phase-determined sound signal is transmitted to one flow vortex K of a flow boundary layer and is reflectedto obtain the Doppler frequency shift speed components of the A and the vortex K in the direction i; in the similar way, by another sound detector B, the Doppler frequency shift speed component of thevortex k in the direction j is obtained; the different speed components are overlapped to obtain the speed and direction of the vortex K; the detectors transmit the pulse sound wave signals at constant time intervals to obtain the Doppler frequency shift components of multiple vortexes in corresponding directions; the sound detectors are arranged in a linear or planar vertical manner to measure flow planar speed fields and three-dimensional speed fields inside the flow boundary layer. The method is fast in instantaneous response, small in error, low in resource consumption and worthy of popularization.

Owner:BEIHANG UNIV

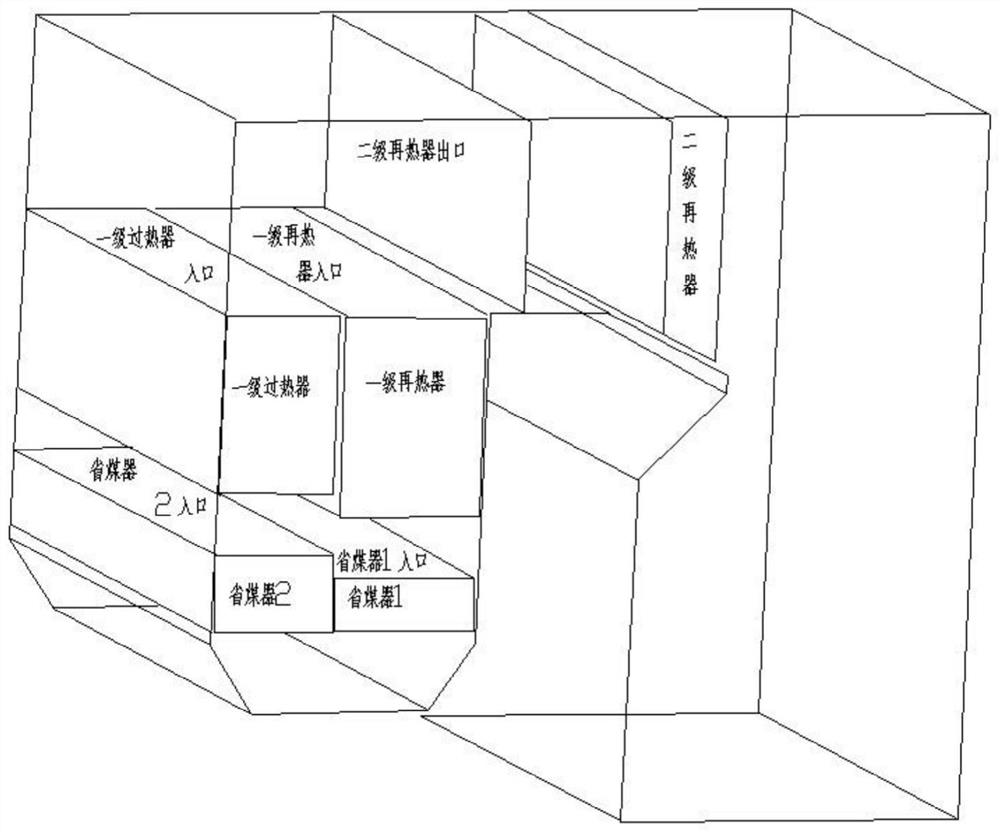

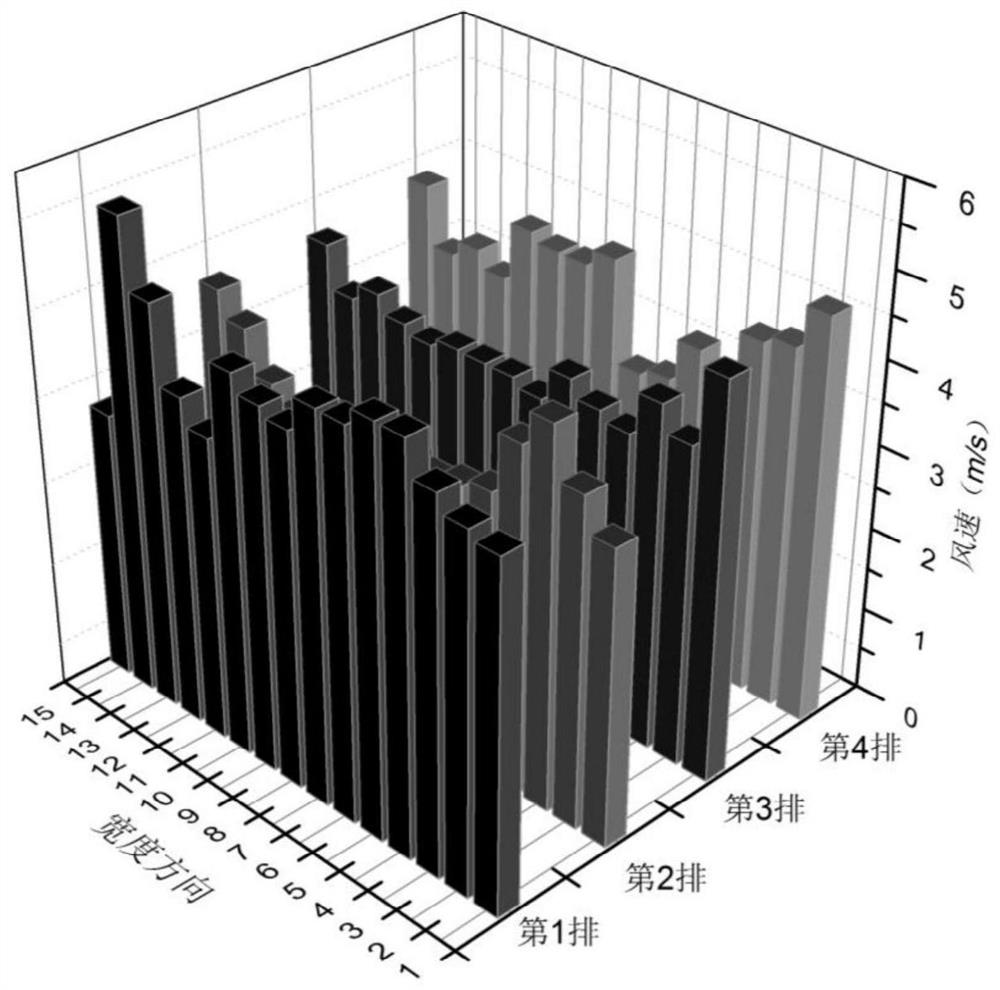

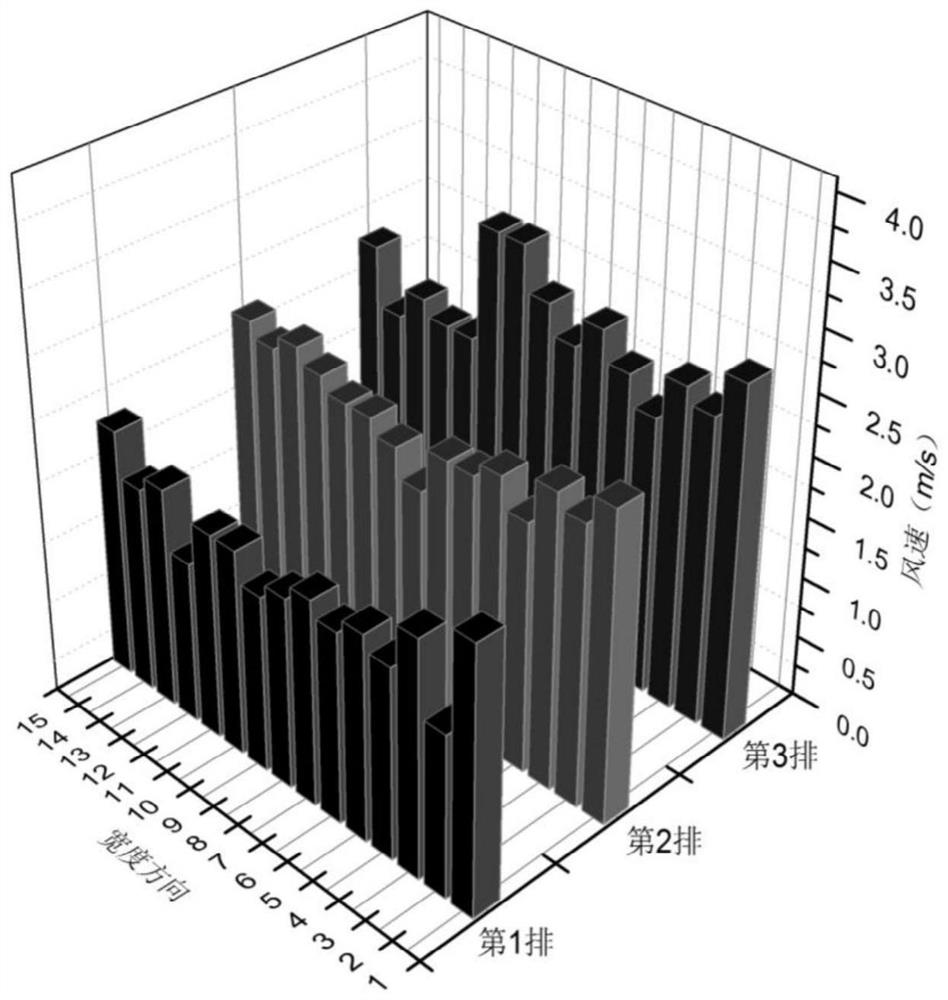

A method for diagnosis and prevention of soot blocking in flue gas channel at the tail of double tangentially fired boiler

ActiveCN110513717BPrevention and control of ashEasy to implementAir supply regulationFluid speed measurement using swirlflowmeterThermodynamicsCombustion

A method for diagnosing and preventing soot blockage in the flue gas channel at the tail of a double tangentially fired boiler. In a cold state, simulate the working condition of the hot state, and measure the section of the heating surface at the key position of the flue gas channel at the tail of the double tangentially fired boiler. Wind speed, compare whether the area with low wind speed is basically consistent with the ash accumulation area; if they are consistent, adjust the opening of the reheated flue gas baffle several times in the cold state and monitor the key positions described under each opening The cross-sectional wind speed of the heating surface, the opening of the reheated flue gas baffle at which the cross-sectional wind speed of the heating surface at the key position is the most uniform is the pre-adjusted opening; in the hot state, adjust the double tangential combustion Boiler parameters, when ensuring the normal operation of the double tangential combustion boiler, make the opening of the reheated flue gas baffle close to the preset opening. The method of the invention only needs to adjust the opening of the flue gas baffle to prevent and prevent ash blockage in the flue gas passage at the tail, and is easy to implement, low in cost and easy to control.

Owner:SUZHOU XIRE ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

An online wind speed measurement system and testing method

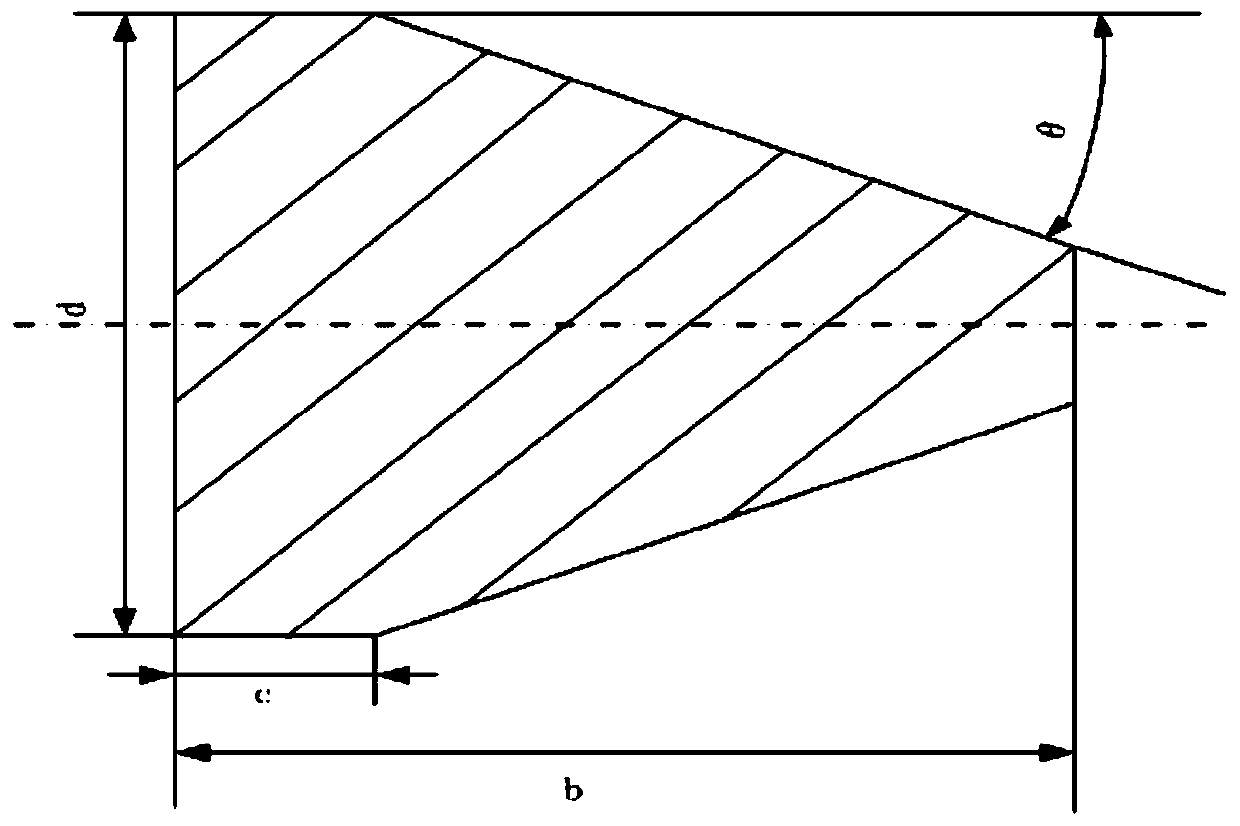

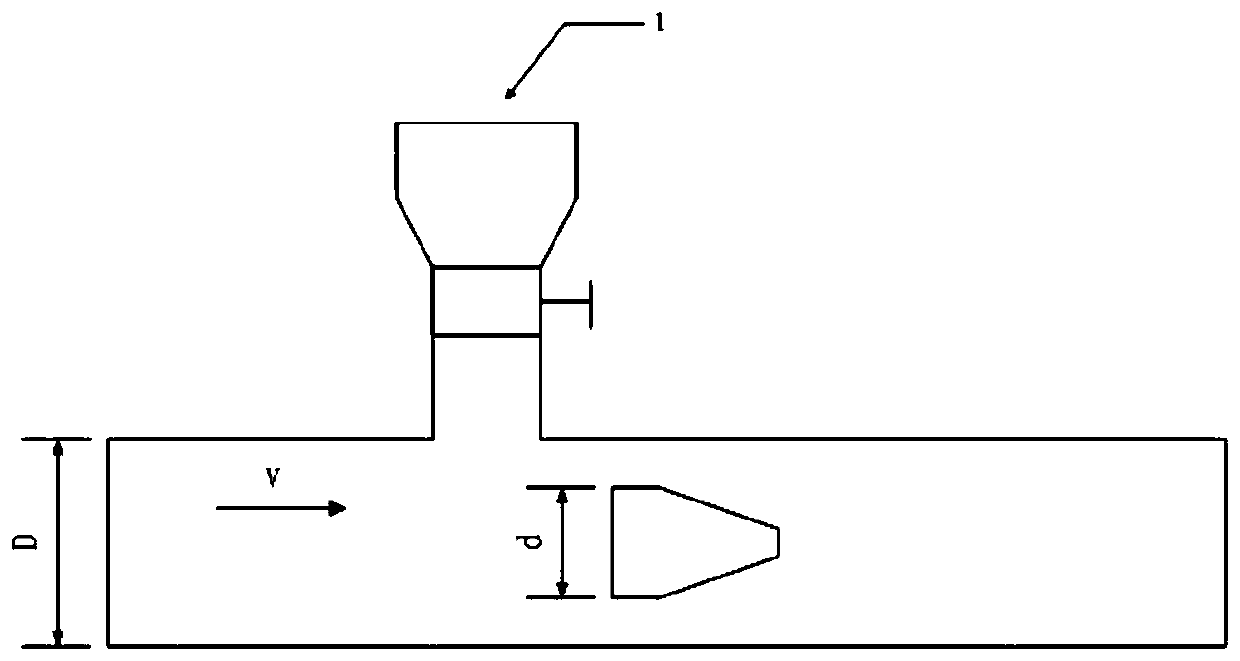

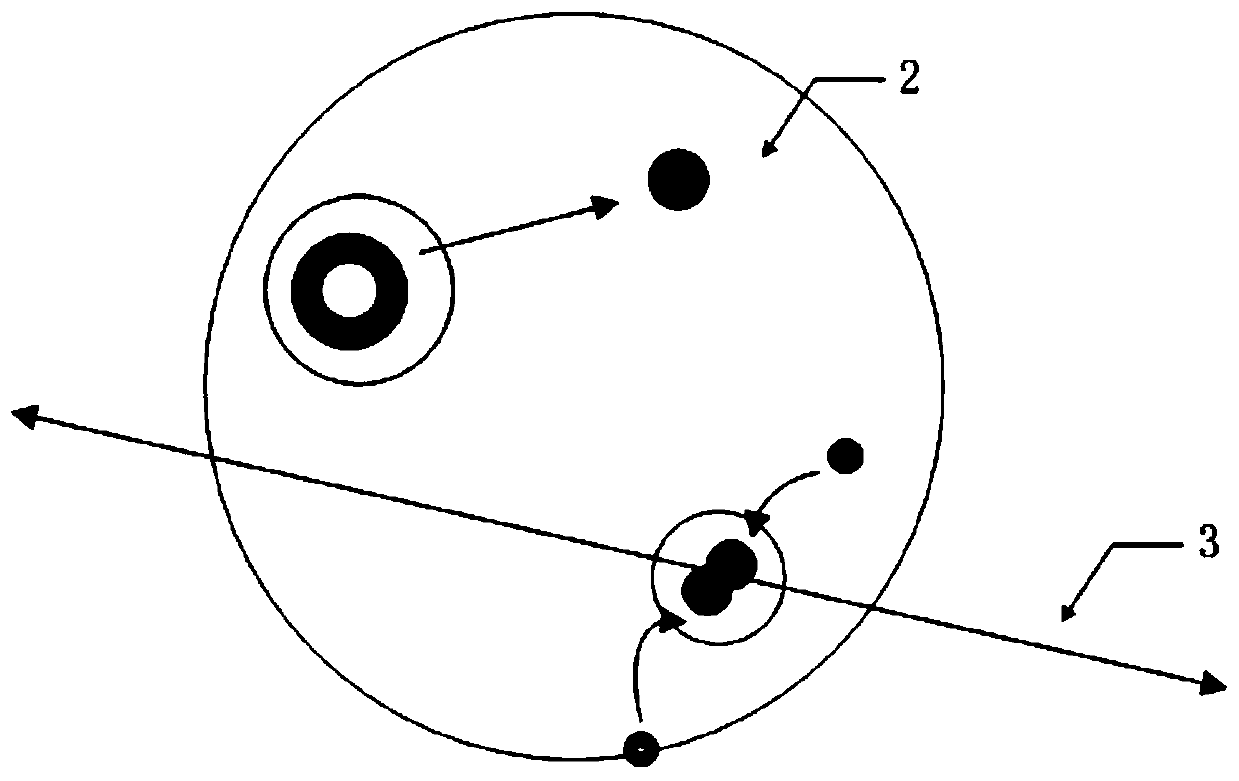

ActiveCN104833819BConsistent flow velocityConsistent actual flow velocityFluid speed measurement using swirlflowmeterMicrocontrollerDifferential pressure

The invention discloses an online wind speed measurement system and a test method. The measurement system includes a test pipeline, a monitoring board, a differential pressure detection circuit, a voltage signal acquisition conversion circuit, a single-chip microcomputer, a communication module, and a receiving terminal; the test method is as follows: 1) Place the measurement system in the wind field; 2) Measure the wind speed through the detection board, and convert the wind speed signal into a voltage signal; 3) Then collect the voltage signal through the differential pressure detection circuit, and transmit it after the voltage signal acquisition conversion circuit to the single-chip microcomputer; 4) process the received concave voltage signal through the single-chip microcomputer and restore it to wind speed; 5) the single-chip microcomputer sends the wind speed signal to the receiving terminal through the communication module. The invention has simple structure, convenient test and can accurately measure low wind speed.

Owner:CHONGQING MAS SCI & TECH CO LTD

Flow meter

ActiveCN110702176AEasy to replaceReduce flow lossFluid speed measurement using swirlflowmeterVolume/mass flow by dynamic fluid flow effectMechanicsFlange

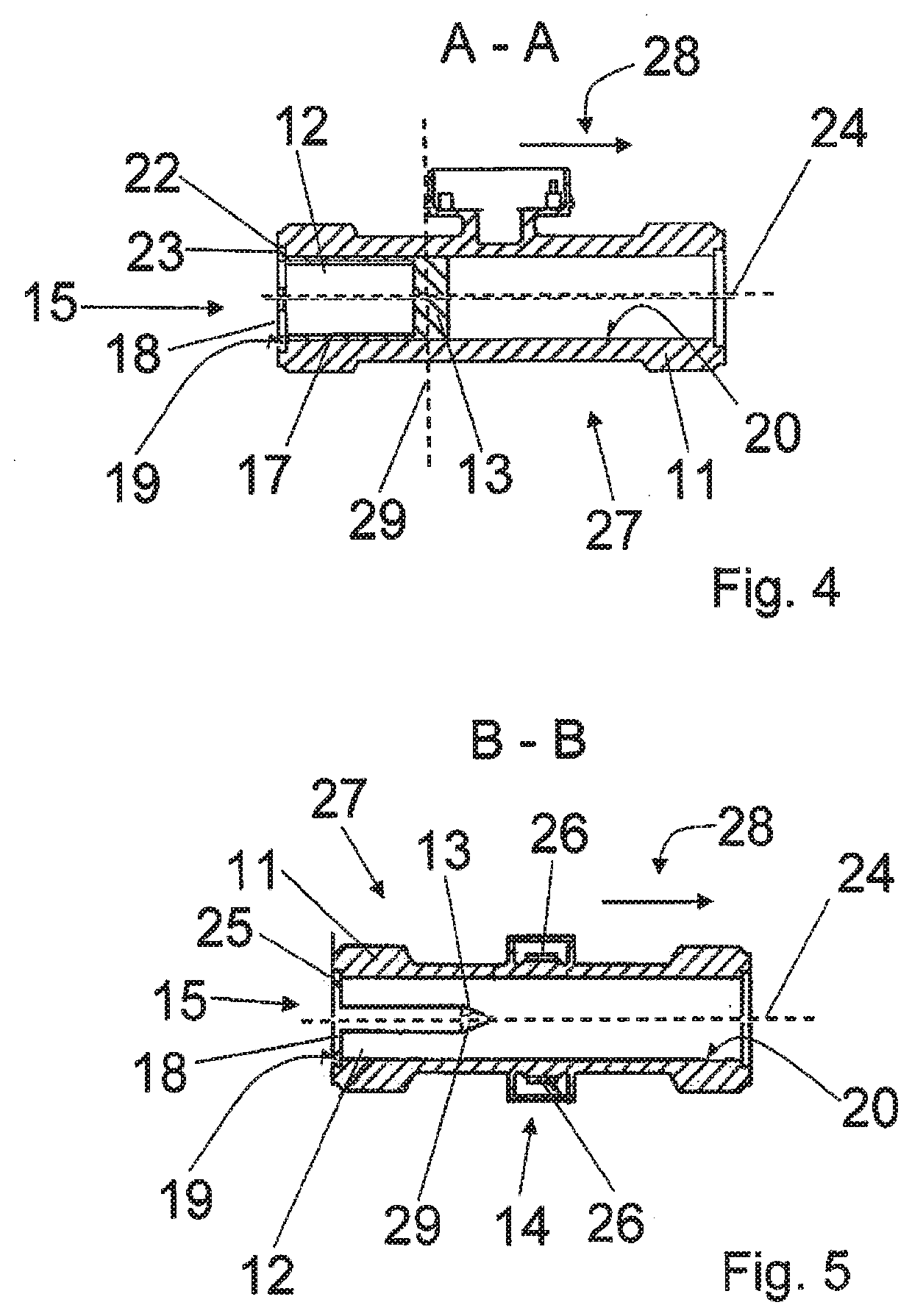

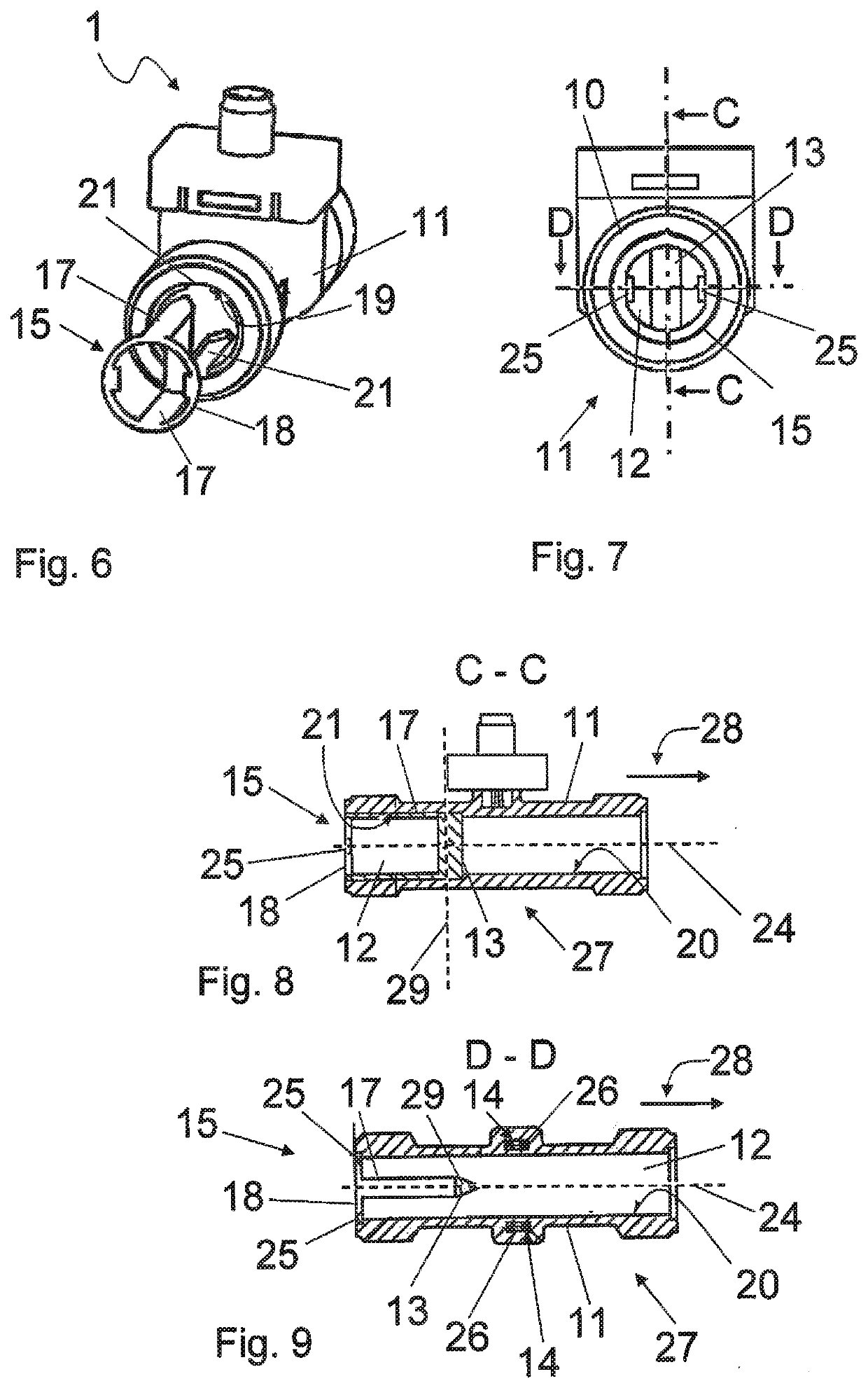

The invention relates to a flow meter for measuring the flow velocity of a fluid, and the flow meter includes a measurement tube that is axially bounded by at least one flange end and that forms a measurement space that can be flowed through by the fluid. At least one baffle is provided for generating interference in the flow, wherein the baffle is arranged in the measurement space. A detector fordetecting the interference is arranged downstream of the baffle. An insertion element is introduced into the measurement tube and has a base portion. The base portion is arranged in the flange end. The insertion element has brackets that adjoin the base portion and that project into the measurement space, with the baffle being formed and its position in the measurement space being held between the brackets.

Owner:SIKA DR SIEBERT & KÜHN GMBH & CO KG

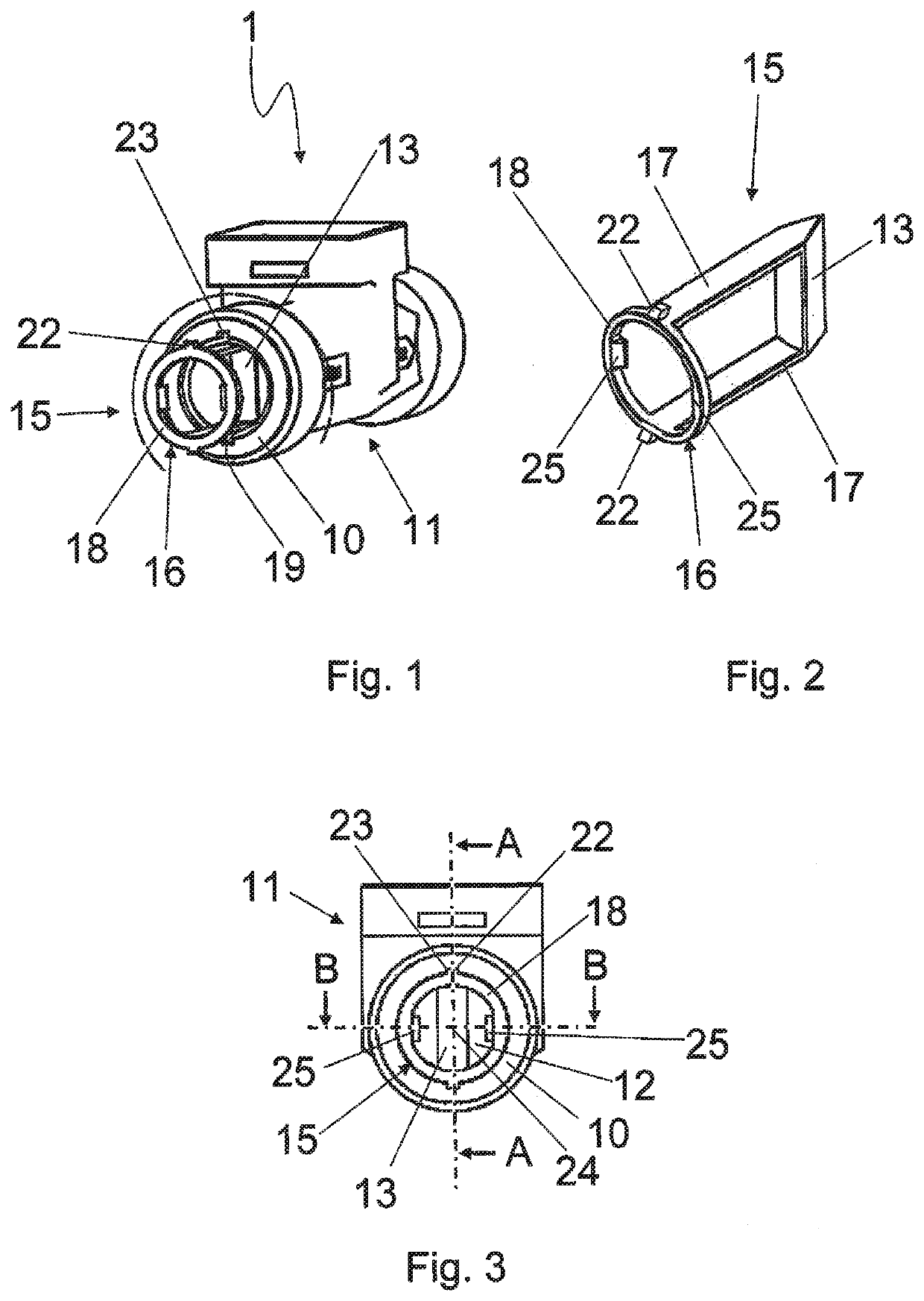

Device and method for determining the flow velocity of a fluid in a hollow body

ActiveUS10942049B2Varies in sizeFluid speed measurement using swirlflowmeterVolume/mass flow by dynamic fluid flow effectEngineeringMechanical engineering

Owner:SIKA DR SIEBERT & KÜHN GMBH & CO KG

Electrical connectors, fluid state testing devices and fluid heat exchange systems

ActiveCN108267261BAvoid destructionThermometer detailsThermometers using electric/magnetic elementsElectricityLongitudinal vibration

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

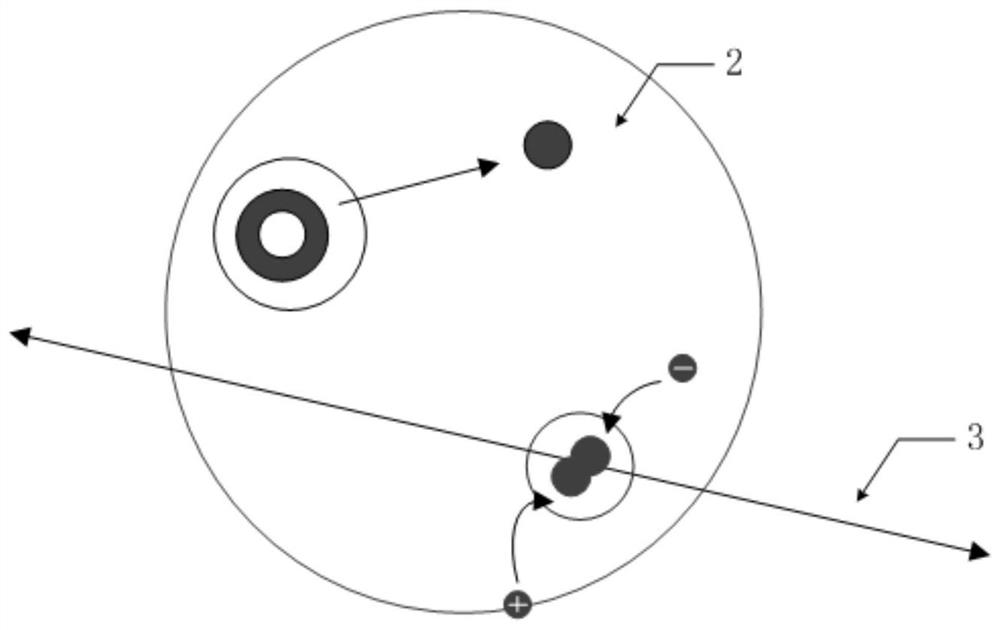

Liquid flow rate detection device and detection method based on positive electron technology and vortex street phenomenon

ActiveCN109782016AGood for monitoring sportsStrong penetrating powerFluid speed measurement using swirlflowmeterGamma photonPeak value

The invention discloses a liquid flow rate detection device and detection method based on positive electron technology and vortex street phenomenon. The detection method comprises the following steps:firstly injecting positive electron nuclide with activity into the liquid, and then injecting the liquid from an access pipe of a detection module, enabling the liquid to produce Kalman vertex streetphenomenon when flowing through a generating body through the vortex generating body, thereby forming the vortex; and then detecting the gamma photon produced by the positive photon decay of the nuclide by utilizing the gamma photon detection device, and obtaining the falling frequency of the vortex by utilizing the peak value and valley value of the detected gamma photon event number, thereby computing the flow rate passing through the pipeline by the liquid in the unit time. The gamma photon response line of the liquid for producing the Kalman vortex street phenomenon under a harsh environment (such as high temperature, high pressure, corrosion and impurity) can be real-time, nondestructively and online or in-place detected, thereby realizing the function of measuring the liquid flow rate in the measurement pipeline.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method using non-extension type miniature sound detectors to perform flow measurement

ActiveCN108802423AAvoid secondary screeningLittle impact on flowFluid speed measurement using swirlflowmeterResource consumptionSound wave

The invention discloses a method using a non-extension type miniature sound detectors to perform flow measurement and belongs to the field of hydrodynamics. The method is characterized in that the miniature sound detectors are arranged inside a to-be-measured fan; by one sound detector A, a phase-determined sound signal is transmitted to one flow vortex K of a flow boundary layer and is reflectedto obtain the Doppler frequency shift speed components of the A and the vortex K in the direction i; in the similar way, by another sound detector B, the Doppler frequency shift speed component of thevortex k in the direction j is obtained; the different speed components are overlapped to obtain the speed and direction of the vortex K; the detectors transmit the pulse sound wave signals at constant time intervals to obtain the Doppler frequency shift components of multiple vortexes in corresponding directions; the sound detectors are arranged in a linear or planar vertical manner to measure flow planar speed fields and three-dimensional speed fields inside the flow boundary layer. The method is fast in instantaneous response, small in error, low in resource consumption and worthy of popularization.

Owner:BEIHANG UNIV

An Intelligent Pipeline Velocity Monitor

ActiveCN106018870BSimple structureReasonable structureFluid speed measurement using swirlflowmeterCantilevered beamLeft half

Owner:高唐融知融智科技服务有限公司

Wind speed and direction detection device

PendingCN113075419AReduce volumeSimple shape and structureFluid speed measurement using swirlflowmeterIndication/recording movementFlow transducerAir velocity

The invention discloses a wind speed and direction detection device, relates to the technical field of wind speed and direction detection, and aims to solve the problems of inconvenience in carrying and low detection accuracy. The wind speed and direction detection device comprises a device body, a wind direction rod, a direction indicator and a flow sensor, an air duct which extends in the radial direction of the device body and penetrates through the device body is arranged in the device body, and the air duct is provided with an air inlet and an air outlet; the wind direction rod and the direction indicator are fixed on the device body, and the extension direction of the wind direction rod is parallel to the extension direction of the air duct; and the flow sensor is arranged in the air duct.

Owner:苏州容启传感器科技有限公司

Flow meter

ActiveUS11333536B2Simply replacedSmall flow lossFluid speed measurement using swirlflowmeterVolume/mass flow by dynamic fluid flow effectMechanical engineeringMechanics

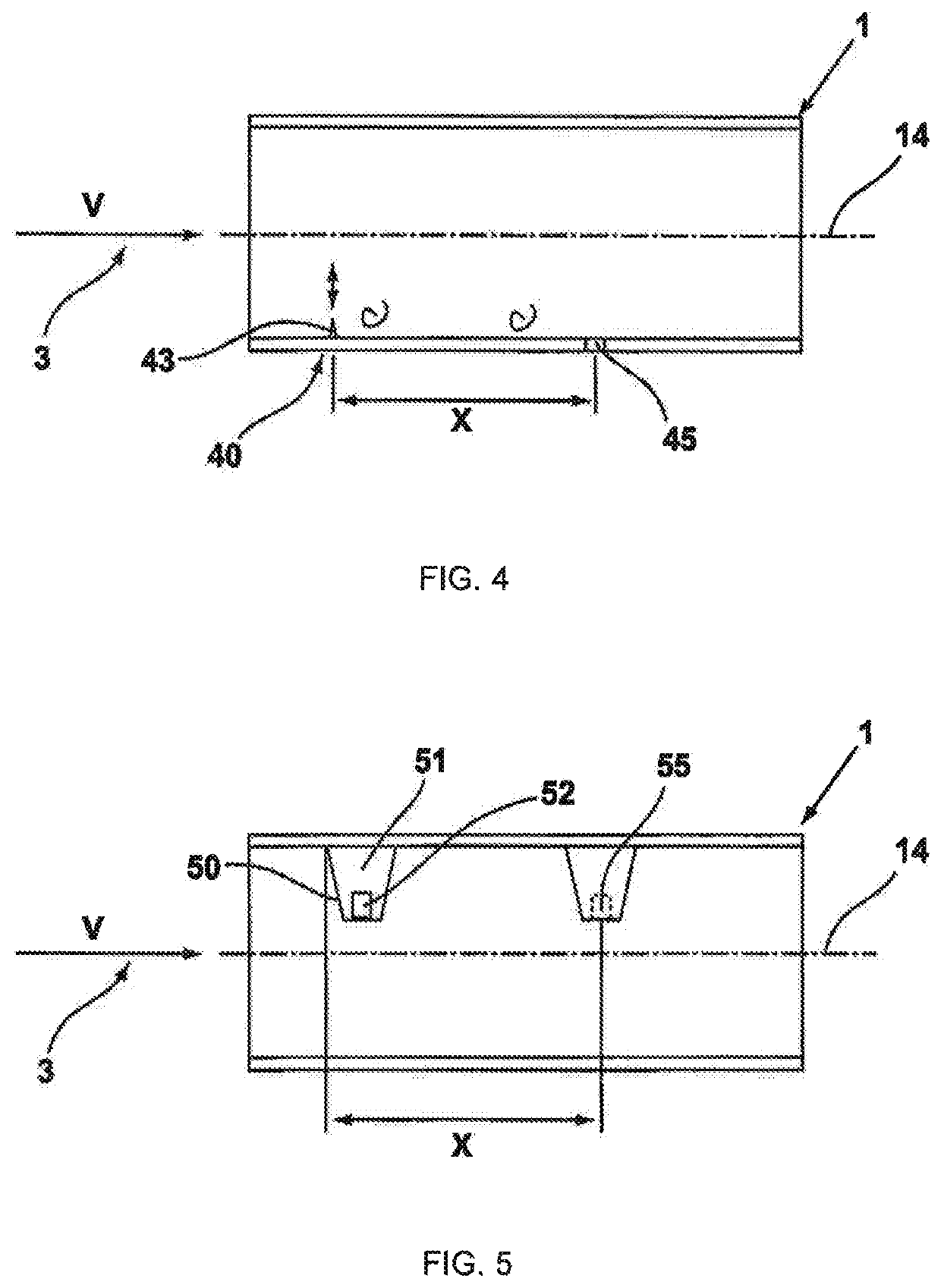

A flow meter for measuring the flow velocity of a fluid includes a measurement tube that is axially bounded by at least one flange end and that forms a measurement space that can be flowed through by the fluid. At least one baffle is provided for generating interference in the flow, wherein the baffle is arranged in the measurement space. A detector for detecting the interference is arranged downstream of the baffle. An insertion element is introduced into the measurement tube and has a base portion. The base portion is arranged in the flange end. The insertion element has brackets that adjoin the base portion and that project into the measurement space, with the baffle being formed and its position in the measurement space being held between the brackets.

Owner:SIKA DR SIEBERT & KÜHN GMBH & CO KG

Flow meter

ActiveUS20200018626A1Safely and reliably enable flow velocitySimply replacedFluid speed measurement using swirlflowmeterVolume/mass flow by dynamic fluid flow effectEngineeringMechanical engineering

A flow meter for measuring the flow velocity of a fluid includes a measurement tube that is axially bounded by at least one flange end and that forms a measurement space that can be flowed through by the fluid. At least one baffle is provided for generating interference in the flow, wherein the baffle is arranged in the measurement space. A detector for detecting the interference is arranged downstream of the baffle. An insertion element is introduced into the measurement tube and has a base portion. The base portion is arranged in the flange end. The insertion element has brackets that adjoin the base portion and that project into the measurement space, with the baffle being formed and its position in the measurement space being held between the brackets.

Owner:SIKA DR SIEBERT & KÜHN GMBH & CO KG

Flow meter

ActiveUS11274951B2Strong loadIncrease vortexFluid speed measurement using swirlflowmeterVolume/mass flow by dynamic fluid flow effectStream flowEngineering

Owner:SIKA DR SIEBERT & KÜHN GMBH & CO KG

A liquid flow velocity detection device and detection method based on positron technology and vortex street phenomenon

ActiveCN109782016BGood for monitoring sportsStrong penetrating powerFluid speed measurement using swirlflowmeterGamma photonNuclear engineering

The invention discloses a liquid flow velocity detection device and detection method based on positron technology and vortex street phenomenon. Firstly, the active positron nuclide is injected into the liquid, and then the liquid is injected from the access pipe of the detection component. The vortex generator causes the Kalman vortex street phenomenon to form when the liquid flows through the generator, forming a vortex, and then uses the gamma photon detection device to detect the gamma photons generated by the positron decay of the nuclide, and uses the number of gamma photon events detected The peak and valley changes of the vortex can get the shedding frequency of the vortex, so as to calculate the flow rate of the liquid through the pipeline per unit time. The invention can detect the gamma photon response line of the liquid that produces the Kalman vortex street phenomenon in a relatively harsh environment (such as high temperature, high pressure, corrosion, and impurities) in real time and non-destructively on-line or on-site, so as to realize the measurement of the flow rate of the liquid in the pipeline. Function.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

System and Method for Determining Fluid Speed

ActiveUS20130112008A1Fluid speed measurement using swirlflowmeterVolume/mass flow by dynamic fluid flow effectSensor arrayEngineering

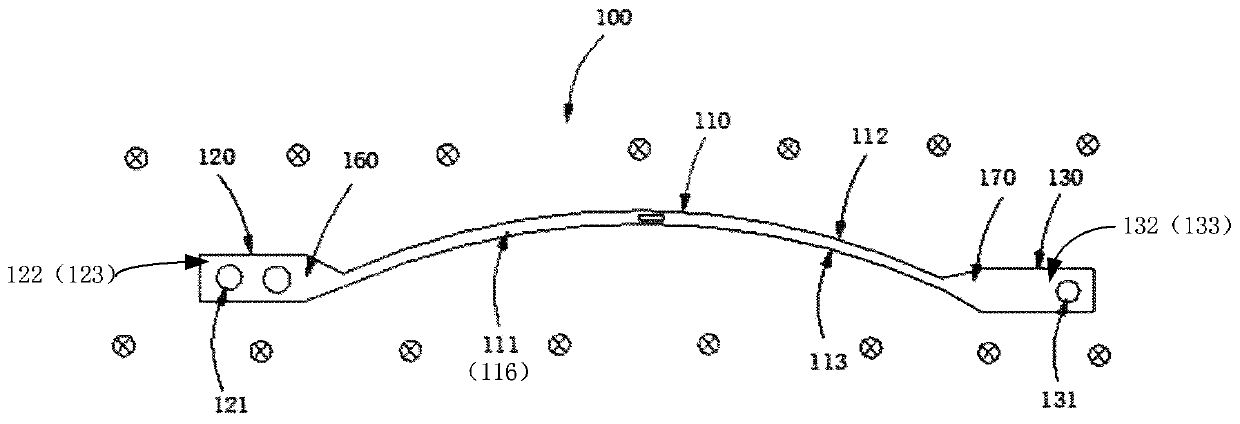

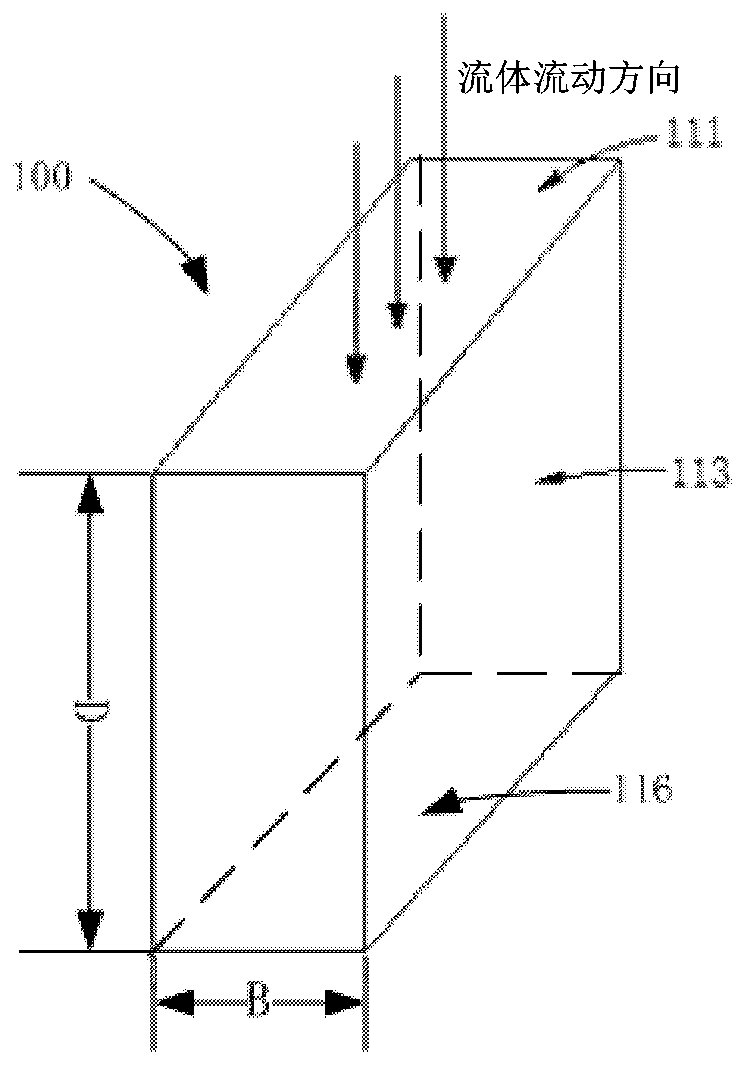

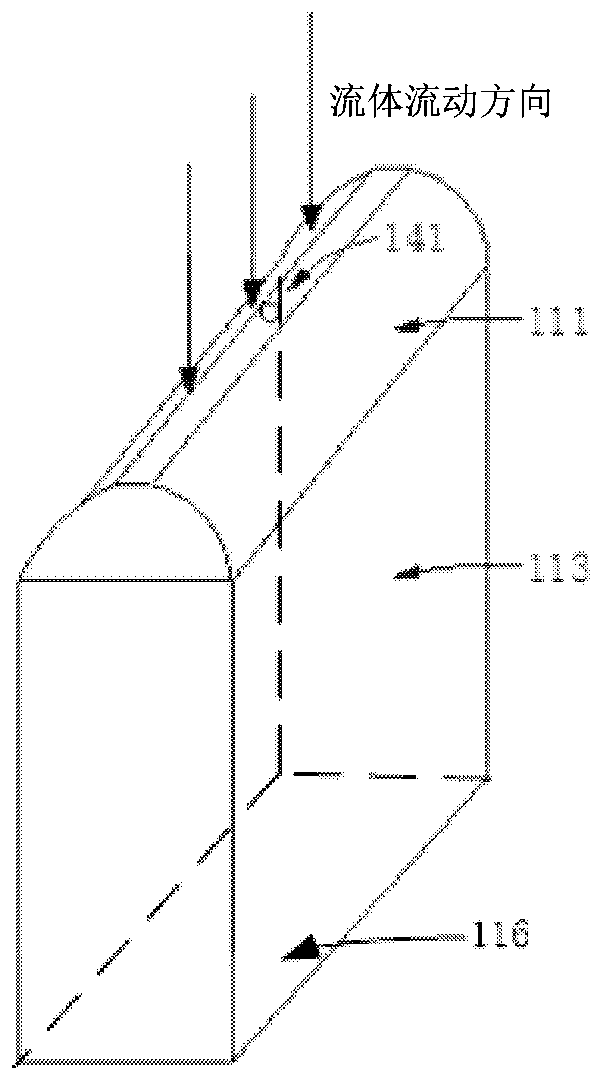

A flow speed sensor arrangement is provided for measuring a flow speed of a fluid stream relative to an object. The arrangement comprises a first obstructive body having a first forward facing surface and two lateral edges and a second obstructive body having a second forward facing surface. The second obstructive body is positioned in tandem relative to the first obstructive body so that the first and second forward facing surfaces face the same direction and so that when the first forward facing surface is presented to an incoming fluid stream, the first obstructive body is between the incoming fluid flow and the second obstructive body. A sensor array is disposed on the second forward facing surface. The first and second obstructive bodies are attachable to the object so that the first forward face is presented to an incoming fluid stream when the object is immersed in the fluid stream.

Owner:TAO OF SYST INTEGRATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com