Separated axle needle type prepeller wind gauge for measuring cylinder vortex

An anemometer and separate technology, applied in the field of separate shaft needle blade anemometers, can solve the problems of unsuitable for accurate measurement, large interference of air flow resistance, insensitive response, etc., to improve the value of popularization and application, use and maintain Convenient, measure the effect of a wide speed range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

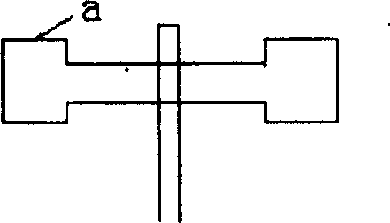

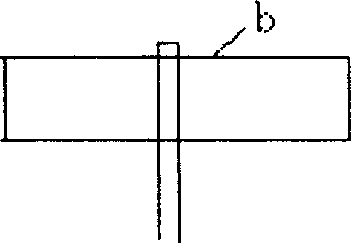

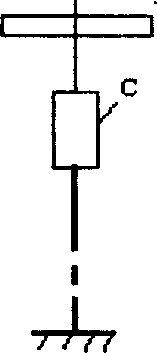

[0021] The separate pintle vane anemometer for measuring cylinder vortex according to the present invention will be described with reference to the accompanying drawings and embodiments.

[0022] The structure of the separated pintle vane anemometer for measuring the cylinder eddy current of the present invention is that a detachable bush 6 is arranged on the inner side of the anemometer body 1, and a circle is respectively arranged on both inner side surfaces of the anemometer body 1. Shaped shaft needle seat support 2, the midpoint of the thin support rod 7 fixed on it is fixed with adjustable shaft needle seat 3, the two tapered tips of the needle-shaped rotating shaft 4 with blade 5 and the adjustable shaft needle seat are installed 3; at least one through hole 9 facing the blade 5 is provided on the outside of the anemometer body 1, and a proximity sensor is inserted in the through hole 9, and the blade rotation signal is output through the proximity sensor in the through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com