Wind Energy Installation Comprising a Wind Speed Measuring System

a wind energy installation and measuring system technology, applied in the direction of liquid/fluent solid measurement, machines/engines, instruments, etc., can solve the problems of not being able to measure the speed of a single particle, not being able to adapt to the measurement of wind speed, and affecting the measurement effect of optical fiber, etc., to achieve the effect of not excessively consuming energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

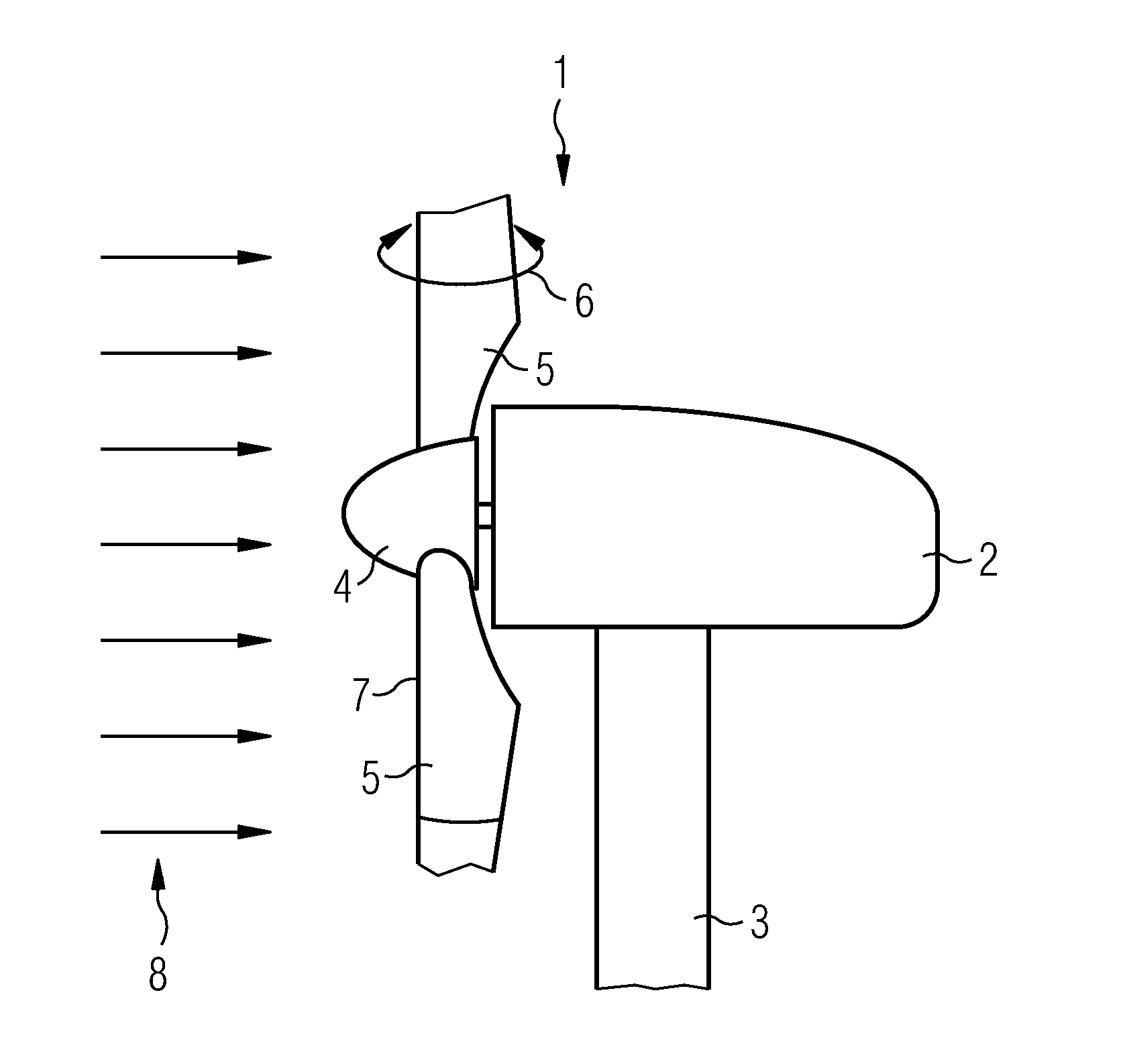

[0025]FIG. 1 shows schematically a wind energy installation 1 comprising a nacelle 2 which is mounted on top of a pylon 3 and which comprises a rotor 4 comprising at least one rotor blade 5. The embodiment of FIG. 1 shows two rotor blades 5. In order to tune the rotor blades 5 e.g. due to wind speed and wind direction the blades 5 are pivot-mounted within the rotor 4 as indicated by arrow 6.

[0026]In order to measure the wind speed of the wind 8 blowing at the vicinity of the installation 1 the installation 1 comprises at least one optical fiber 7 which allows to measure the wind speed by way of measurement of vibrations of the optical fiber 7 originated by vortex shedding.

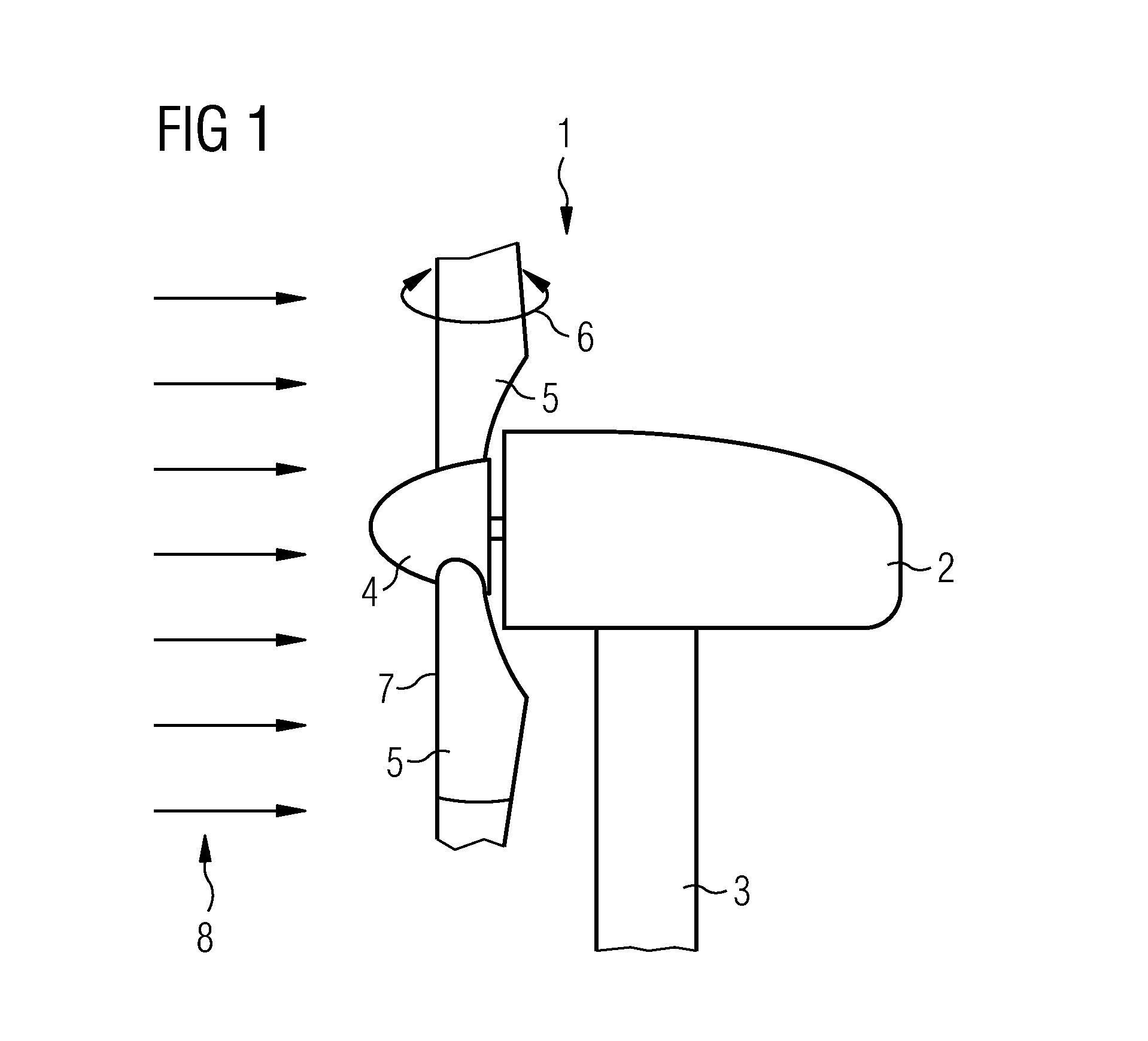

[0027]FIG. 2 shows an example of a cross-section of a rotor blade 5 which contains an optical fiber 7 at the leading edge 9 of the blade 5. The fiber 7 is located at the leading edge and is fixed at a certain distance from the leading edge such that the fiber 7 is able to vibrate due to vortex shedding.

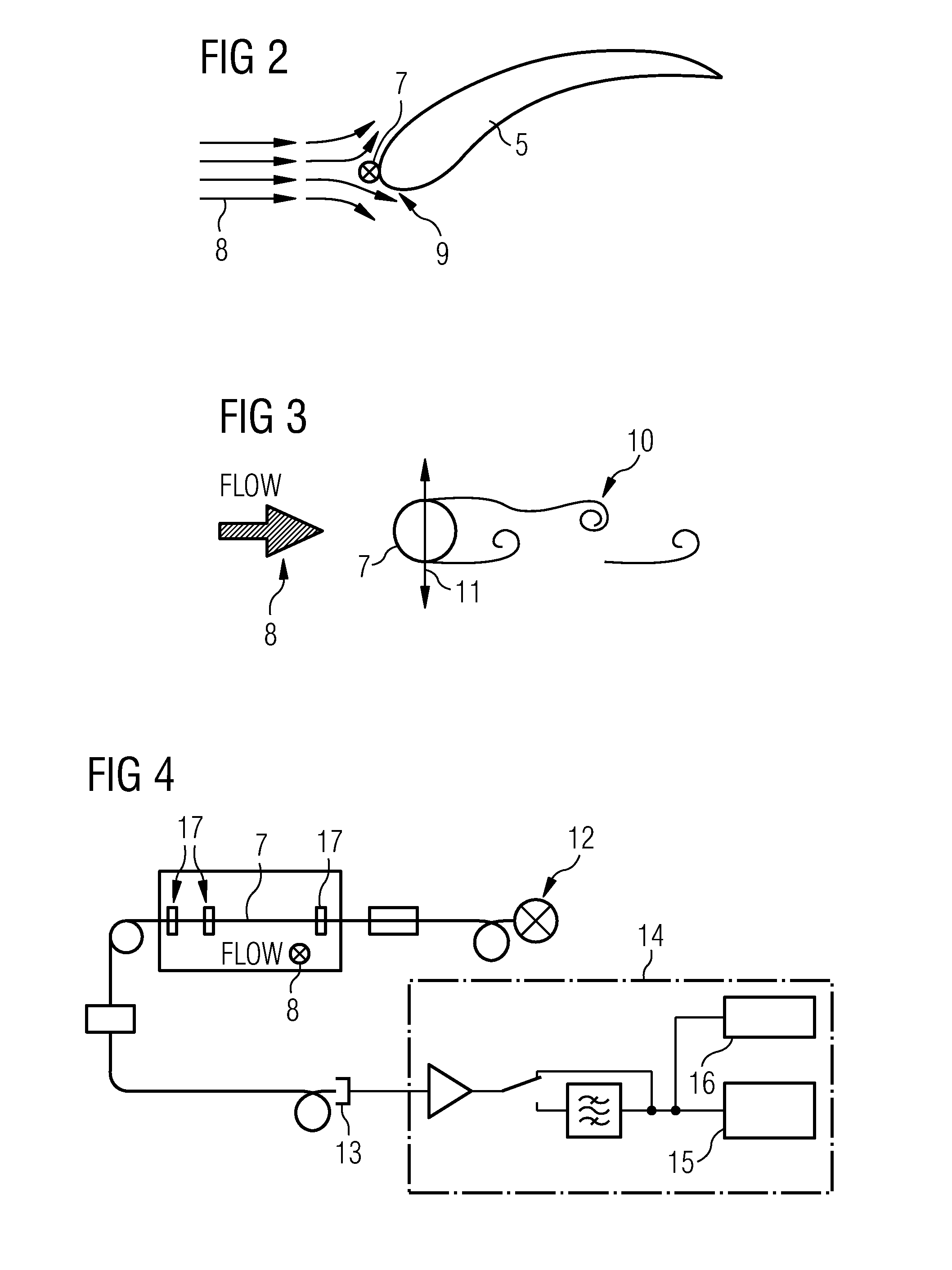

[0028]FIG. 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com