Method for calculating grinding output of MP-G type medium-speed coal mill

A technology of MP-G and coal pulverizer, which is applied in computing, instrumentation, electrical digital data processing, etc., can solve problems such as high concentration of NOx, grinding output not reaching the design value, and aggravated slagging in the furnace if the pulverized coal is too coarse. , to achieve the effects of reducing the concentration of NOx formation, improving the load carrying capacity, and alleviating the slagging of the furnace and boiler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Calculation of the grinding output of the MP-235G coal mill for Nalinhe coal.

[0035] Step 1: Provided by the owner to calculate the basic coal quality parameters of the coal sample: received basic moisture M t (%), received base ash A ar (%), Hastelloy Grinding Index HGI, at the same time determine the coal fineness R that needs to be ground 90 (%).

[0036] The Nalin River coal sample: M t = 14%, A ar =14.77%, HGI=68, R 90 = 20%;

[0037] Step 2: Calculate the grinding output B of the MP-G medium-speed coal pulverizer according to the power industry standard "Code for Design and Calculation of Coal Milling System in Thermal Power Plants" (DL / T5145-2012) M . The calculation method of the MP-G medium-speed coal mill is the same as that of the MPS coal mill, but the basic output of the coal mill is different.

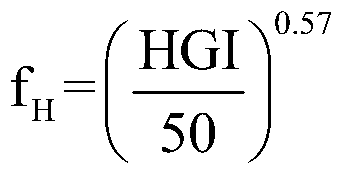

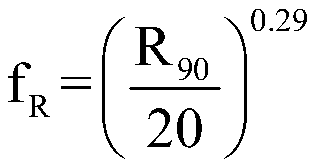

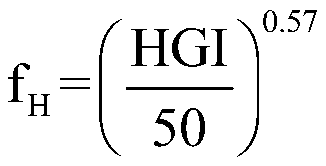

[0038] B M =B MO × f H × f R × f M × f A × f g × f e × f si

[0039] B M0 —The basic output of the coal mill, t / h, the value is det...

Embodiment 2

[0063] Example 2: Calculation of the grinding output of the MP-235G coal mill of Dongfanghong Coal.

[0064] Step 1: The owner provides the basic coal quality parameters for calculating the coal sample and receives the basic moisture content M t (%), received base ash A ar (%), Hastelloy Grinding Index HGI, at the same time determine the coal fineness R that needs to be ground 90 (%).

[0065] This Dongfanghong coal sample: M t =14.3%, A ar =8.54%, HGI=54, R 90 = 18%;

[0066] Step 2: Calculate the grinding output B of the MP-G medium-speed coal pulverizer according to the power industry standard "Code for Design and Calculation of Coal Milling System in Thermal Power Plants" (DL / T5145-2012) M . The calculation method of the MP-G medium-speed coal mill is the same as that of the MPS coal mill, but the basic output of the coal mill is different.

[0067] B M =B MO × f H × f R × f M × f A × f g × f e × f si

[0068] B M0 —The basic output of the coal mill, t / h...

Embodiment 3

[0092] Example 3: Calculation of the grinding output of the MP-235G pulverizer for coal blending in Yulin.

[0093] Step 1: The owner provides the basic coal quality parameters for calculating the coal sample and receives the basic moisture content M t (%), received base ash A ar (%), Hastelloy Grinding Index HGI, at the same time determine the coal fineness R that needs to be ground 90 (%).

[0094] This Dongfanghong coal sample: M t = 12.5%, A ar =25.00%, HGI=60, R 90 = 15%;

[0095] Step 2: Calculate the grinding output B of the MP-G medium-speed coal pulverizer according to the power industry standard "Code for Design and Calculation of Coal Milling System in Thermal Power Plants" (DL / T5145-2012) M . The calculation method of the MP-G medium-speed coal mill is the same as that of the MPS coal mill, but the basic output of the coal mill is different.

[0096] B M =B MO × f H × f R × f M × f A × f g × f e × f si

[0097] B M0 —The basic output of the coal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com