Method for calculating grinding output of ZGM type medium-speed coal mill

A calculation method and coal pulverizer technology, applied in calculation, instrumentation, electrical digital data processing, etc., can solve problems such as high concentration of NOx, aggravated slagging in the furnace if the coal powder is too coarse, and the grinding output cannot reach the design value. To achieve the effect of reducing the concentration of NOx and alleviating the slagging of the furnace and boiler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1: Calculation of the grinding output of the ZGM-123-N-I coal mill for Yulin coal blending.

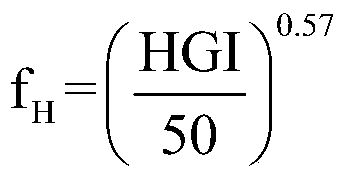

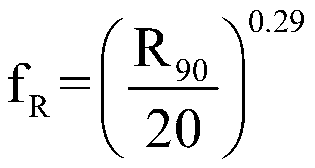

[0043] Step 1: Provided by the owner to calculate the basic coal quality parameters of the coal sample: received basic moisture M t (%), received base ash A ar (%) and Hastelloy Grindability Index HGI, at the same time determine the coal fineness R that needs to be ground 90 (%).

[0044] This time Yulin mixed coal: M t = 12.5%, A ar = 12.00%, HGI = 56, R 90 = 20%;

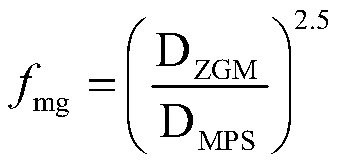

[0045] The second step: Calculate the grinding output B of the ZGM medium-speed coal mill according to the power industry standard "Design and Calculation Design Specifications for Coal Milling System in Thermal Power Plants" (DL / T5145-2012) M . The calculation method of the ZGM medium-speed coal mill is the same as that of the MPS coal mill, except that the ZGMG coal mill needs to modify the coefficient.

[0046] The calculation method of ZGMN and ZGMK coal mills is as follows:

[0047] B M =B M...

Embodiment 2

[0068] Example 2: Calculation of the grinding output of the ZGM-113-K-I coal mill for Yulin coal blending.

[0069] Step 1: Provided by the owner to calculate the basic coal quality parameters of the coal sample: received basic moisture M t (%), received base ash A ar (%) and Hastelloy Grindability Index HGI, at the same time determine the coal fineness R that needs to be ground 90 (%).

[0070] This time Yulin mixed coal: M t = 12.5%, A ar = 12.00%, HGI = 56, R 90 = 20%;

[0071] The second step: Calculate the grinding output B of the ZGM medium-speed coal mill according to the power industry standard "Design and Calculation Design Specifications for Coal Milling System in Thermal Power Plants" (DL / T5145-2012) M . The calculation method of the ZGM medium-speed coal mill is the same as that of the MPS coal mill, except that the ZGMG coal mill needs to modify the coefficient.

[0072] The calculation method of ZGMN and ZGMK coal mills is as follows:

[0073] B M =B M...

Embodiment 3

[0094] Example 3: Calculation of the grinding output of the ZGM-123-G-I coal mill for Yulin coal blending.

[0095] Step 1: Provided by the owner to calculate the basic coal quality parameters of the coal sample: received basic moisture M t (%), received base ash A ar (%) and Hastelloy Grindability Index HGI, at the same time determine the coal fineness R that needs to be ground 90 (%).

[0096] This time Yulin mixed coal: M t = 12.5%, A ar = 12.00%, HGI = 56, R 90 = 20%;

[0097] The second step: Calculate the grinding output B of the ZGM medium-speed coal mill according to the power industry standard "Design and Calculation Design Specifications for Coal Milling System in Thermal Power Plants" (DL / T5145-2012) M . The calculation method of the ZGM medium-speed coal mill is the same as that of the MPS coal mill, except that the ZGMG coal mill needs to modify the coefficient.

[0098] The calculation method of ZGMG coal mill is as follows:

[0099] B M =B MO × f H ×...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com