Totally-closed indirect conductive snap safety socket and mating snap plug

A safety socket and matching plug technology, applied in the direction of connection, contact parts, base/shell, etc., can solve the problems of pollution, non-compliance with environmental protection and low carbon, arc sparks, etc., to reduce conductive metal materials, good safety protection, Avoid the effect of arc sparks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

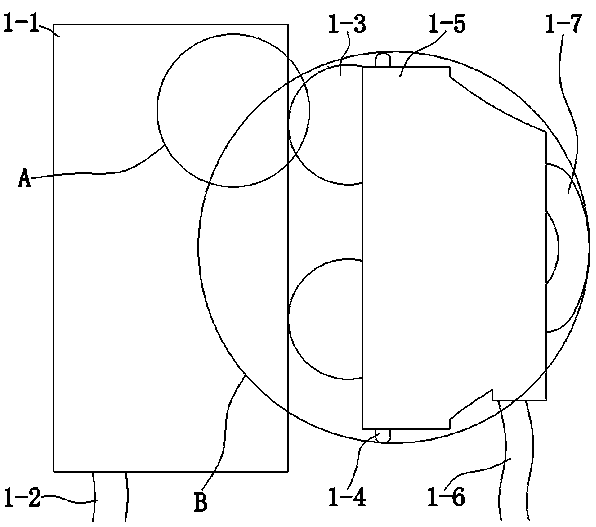

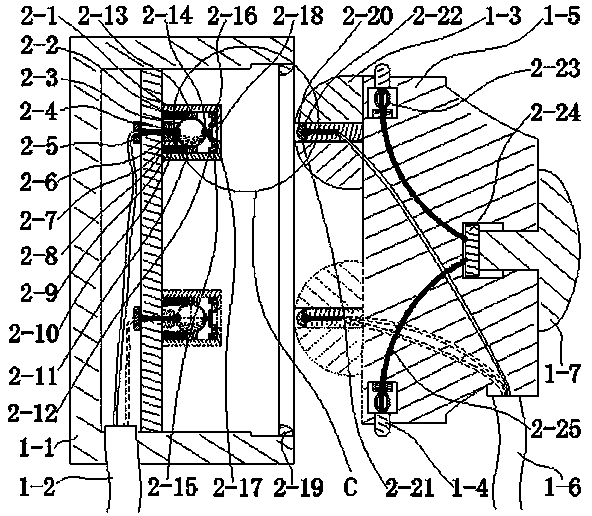

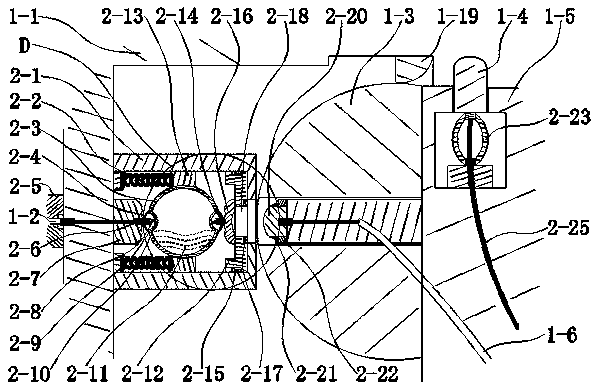

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12As shown, a fully enclosed indirect conduction buckle-type safety socket and a matching plug include an indirect conduction socket 1-1 and a matching buckle plug 1-5, and the indirect conduction socket 1-1 is plugged with a matching buckle plug 1 -5, in a fully enclosed state, connect to the power supply through indirect conduction through a fluid medium, characterized in that a functional tube 2-1 is set in the socket box of the indirect conduction socket 1-1, and the functional tube 2-1 is set as Three, fixedly installed on the partition in the socket box body; the medium conduction ball 2-3 and the movable sleeve 1-12 are arranged in the functional tube 2-1; the medium conduction ball 2-3 is a hollow spher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com