Method for separating out single-size indium nanocubes by means of onion extracting solutions

A technology of nanocubes and extracting solution, which is applied in metal processing equipment, transportation and packaging, etc., can solve the problems of inability to achieve density gradient centrifugation of indium nanocubes, and achieve the effects of low cost, simple purification and high separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Implementation example:

[0023] (1) First, a 25 mg / L indium nanocube dispersion was prepared.

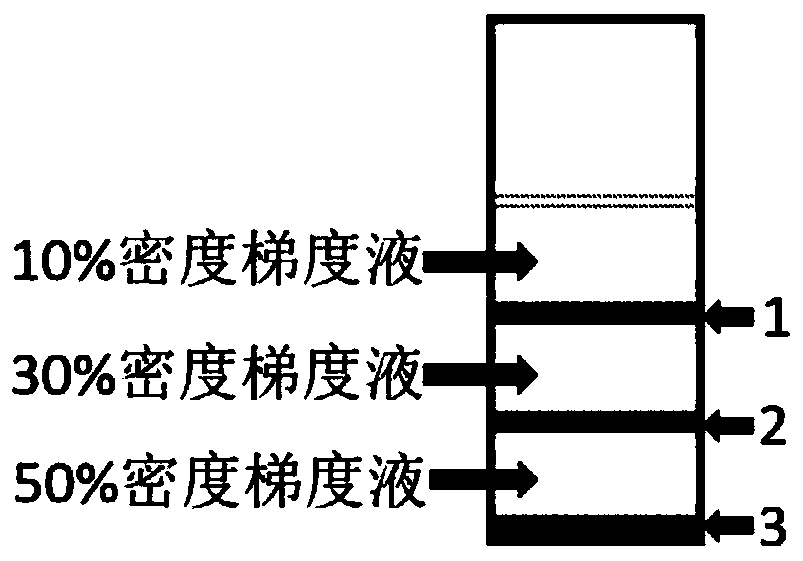

[0024] (2) Make a density gradient: use onion extract and water to prepare onion extracts with mass percentages of 50%, 30%, and 10%; starting from 50%, take 5 ml of the solution and gently add it to a centrifuge tube to prepare a gradient solution.

[0025] (3) Add 2.5 ml of the dispersion liquid of indium nanocubes to the gradient liquid.

[0026] (4) Centrifuge the liquid to be separated at 50,000 rpm for 4 hours at 25°C.

[0027] (5) After centrifugation, the indium nanocubes form 3 layers in the density gradient liquid, and the particle diameter of the indium nanocubes separated between the 10% onion extract solution and the 30% onion extract interface is 5.5 ± 1.0 nanometers, 30% onion The particle size of the indium nanocube separated between the interface of the extract and the 50% onion extract is 8.5±2.0 nm, and the particle size of the indium nanocube separated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com