Suspension type electric hoist applicable for material transfer through soil removal port in top-down method

A technology of electric lifting and soil intake port, which is applied in the direction of load hanging components, support structures, track systems, etc., and can solve the problems of serious material accumulation on site, low material transfer efficiency, and low resource utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

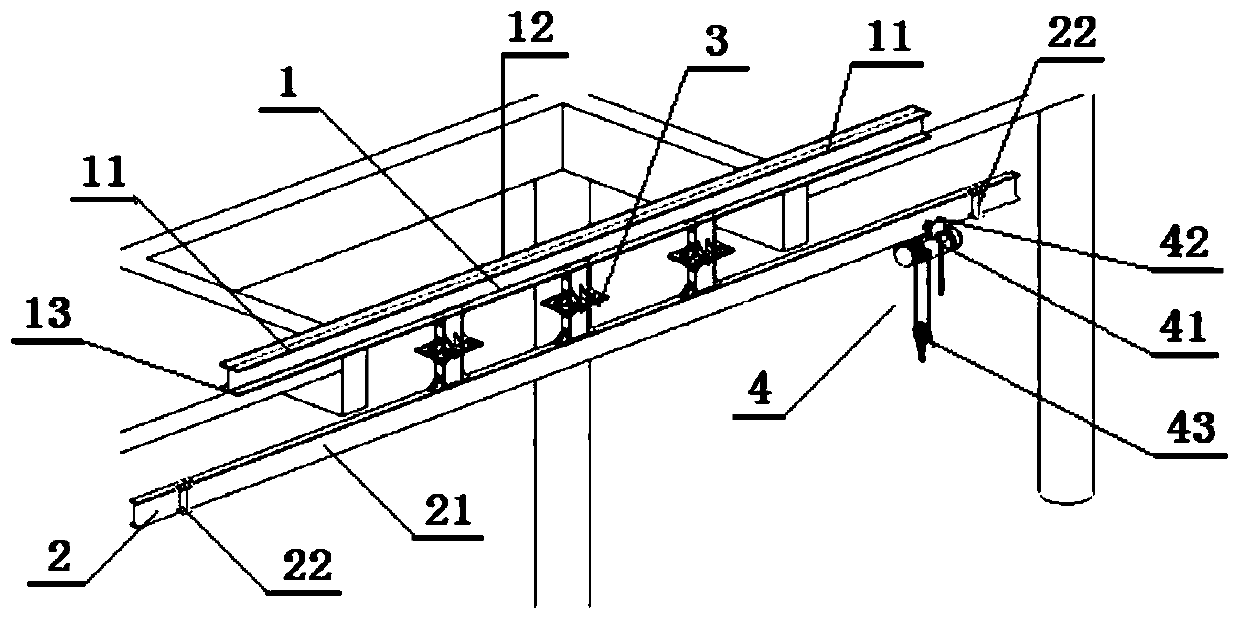

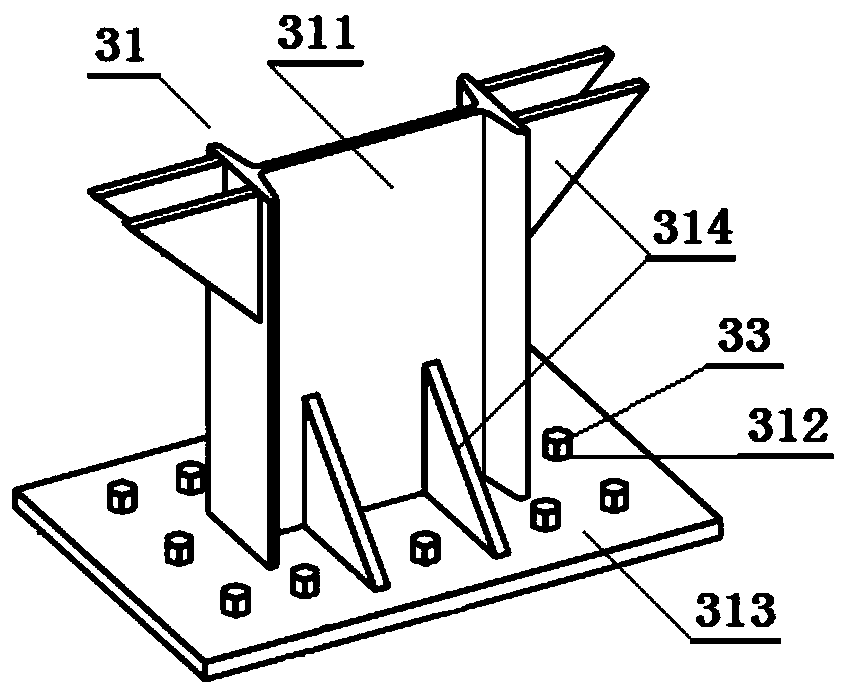

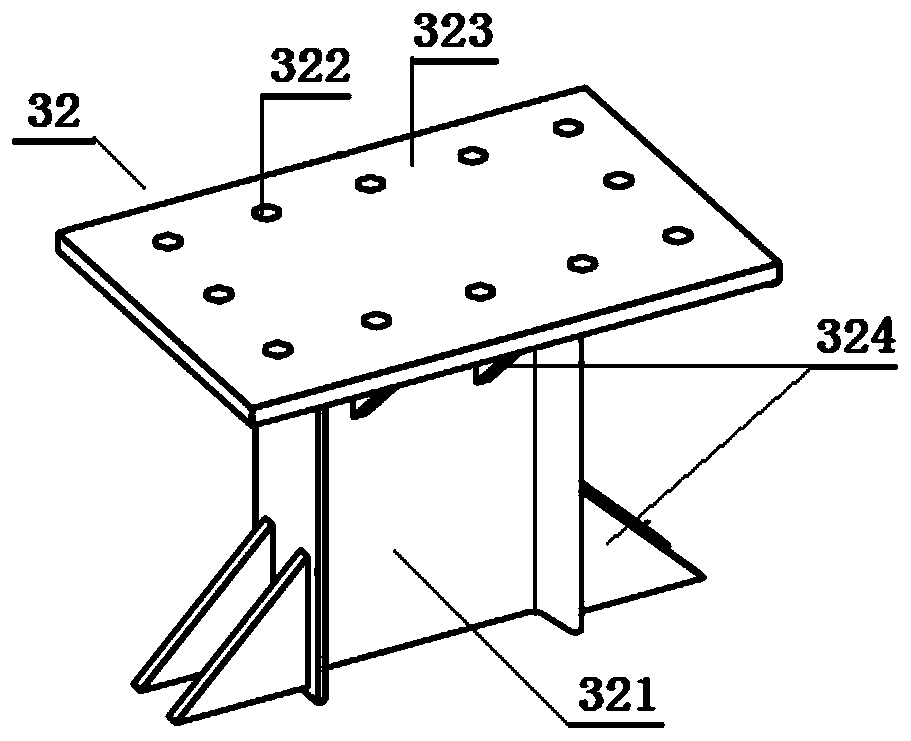

[0031] exist figure 1 , figure 2 , image 3 and Figure 4 Among them, the suspension type electric hoist suitable for transferring materials at the soil intake mouth of the present invention, the main body includes an upper suspension beam 1, a lower crane beam 2, several intermediate interconnecting members 3 and a movable electric hoisting mechanism 4, wherein :

[0032] The upper hanging beam 1 is made of 10-14 meters long hot-rolled I-beam, including the left and right shelving sections 11 that are limited and held on the floors on both sides of the soil borrowing mouth, and the middle suspension section that is suspended on the soil borrowing mouth. 12, and a supporting working surface 13 served by a side of the I-beam;

[0033] The lower crane girder 2 is made of 15-20 meters long hot-rolled I-beam, and is provided with a guide rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com