Lower shell of aluminum alloy battery pack

An aluminum alloy and battery technology, applied in the direction of batteries, battery pack components, circuits, etc., can solve the problems of complex profile section, high manufacturing cost, short weld life, etc., and achieve long weld fatigue life, fewer parts, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

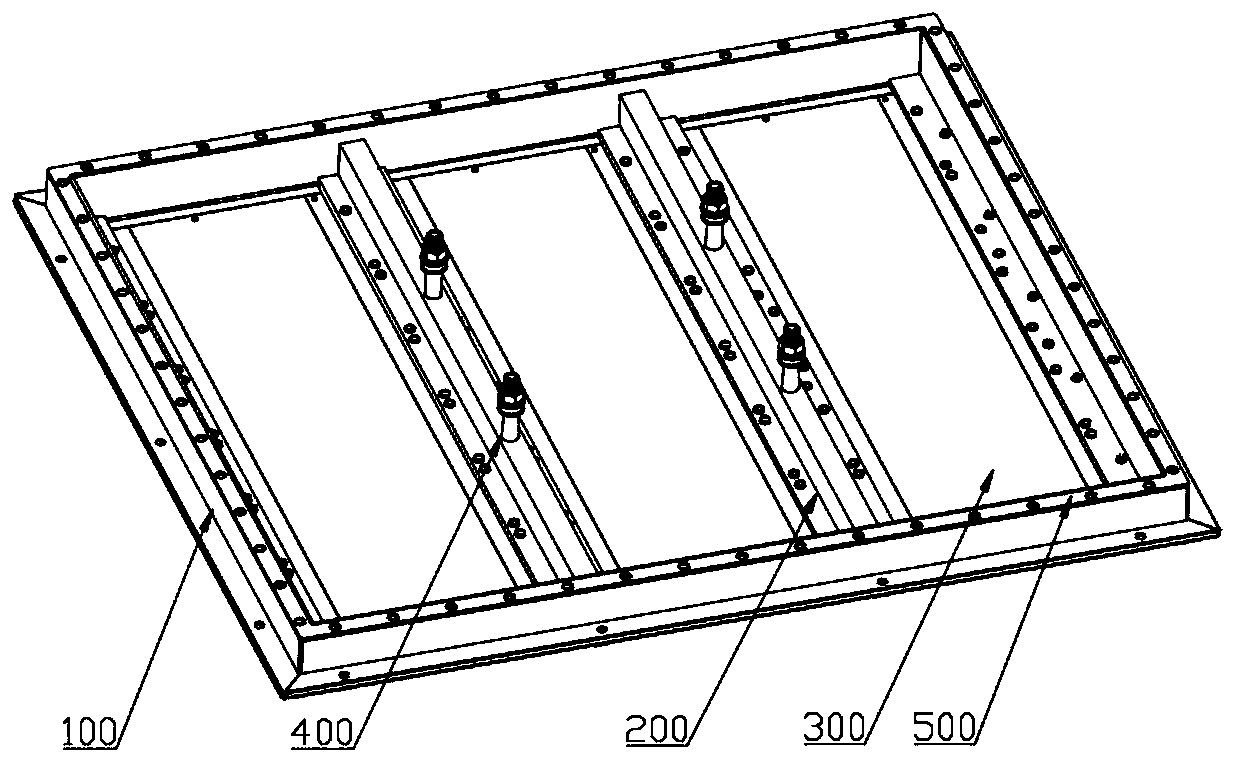

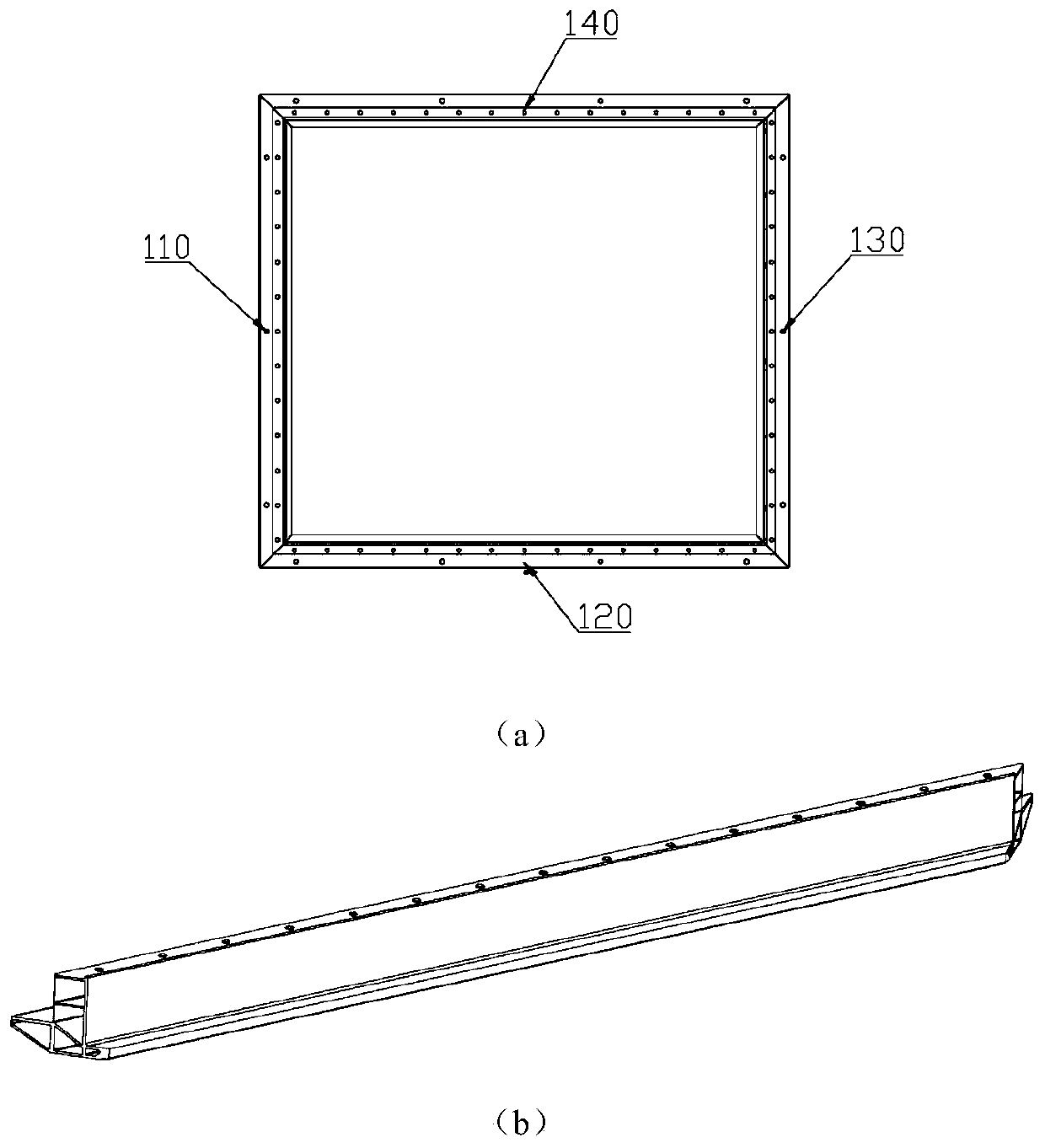

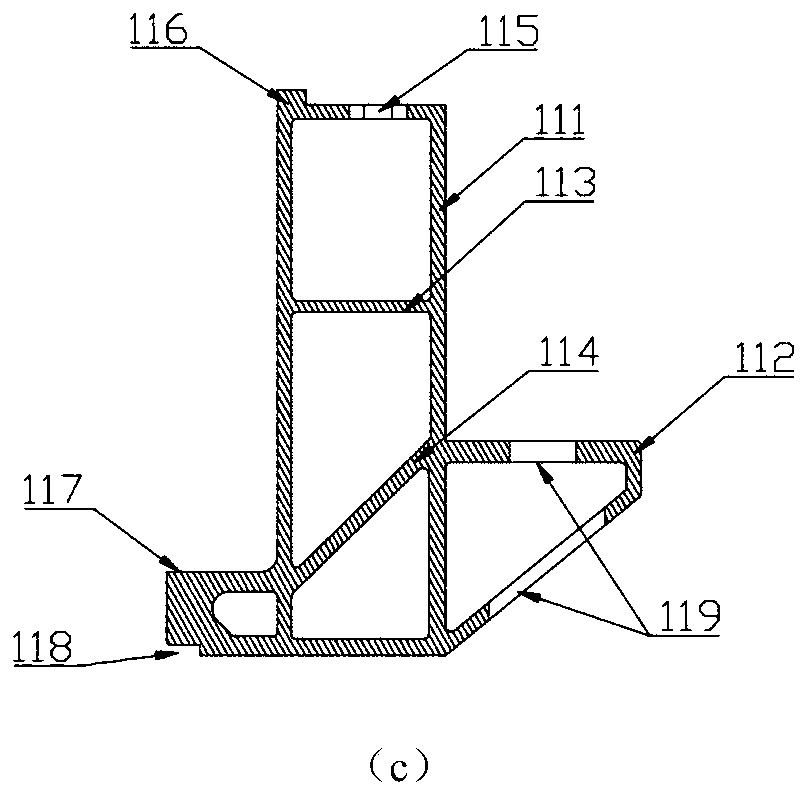

[0026] figure 1 It is an axonometric view of the lower casing of the aluminum alloy battery pack of the present invention, including four parts: frame structure 100, beam 200, floor 300 and middle lug 400; beam 200 and frame structure 100 are plugged through "male end, female end" and MIG The floor 300 is arranged between the beams, and fixed by friction stir welding and MIG welding; the middle lifting lug 400 passes through the beam 200 from bottom to top, and then fixed by MIG welding. Among them, by increasing the length of the side frame, the number of beams can be multiple, so as to meet the different needs of consumers for the cruising range, and flexibly install different numbers of battery modules to realize the platform and modular design and manufacture of batte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com