Vertical mill system and method for producing oil well cement

An oil well cement and vertical mill technology, applied in the direction of grain processing, etc., can solve the problems of relatively strict performance requirements of cement, unable to meet the requirements of oilfield cementing use, etc., and achieve the effect of meeting the quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

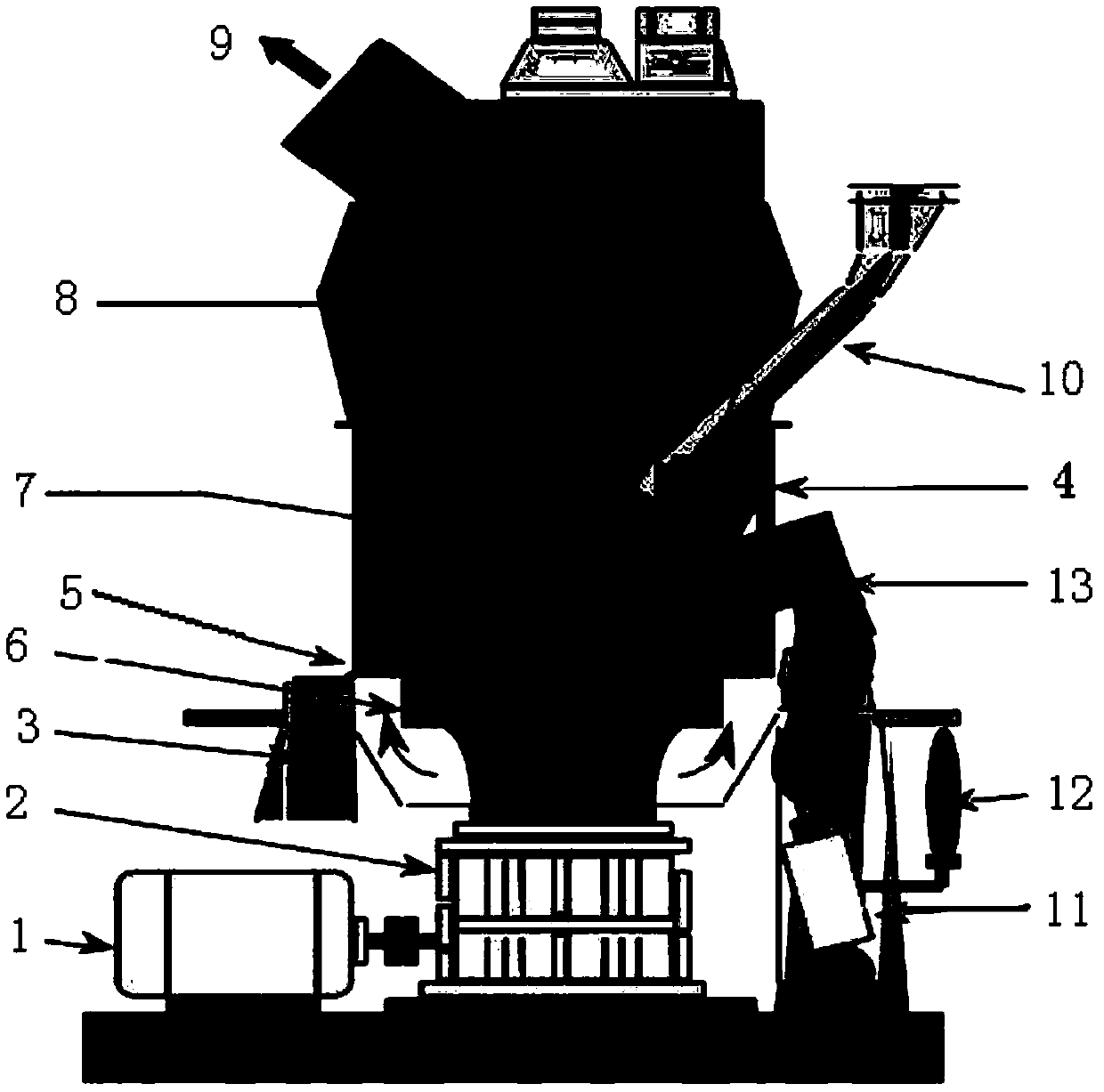

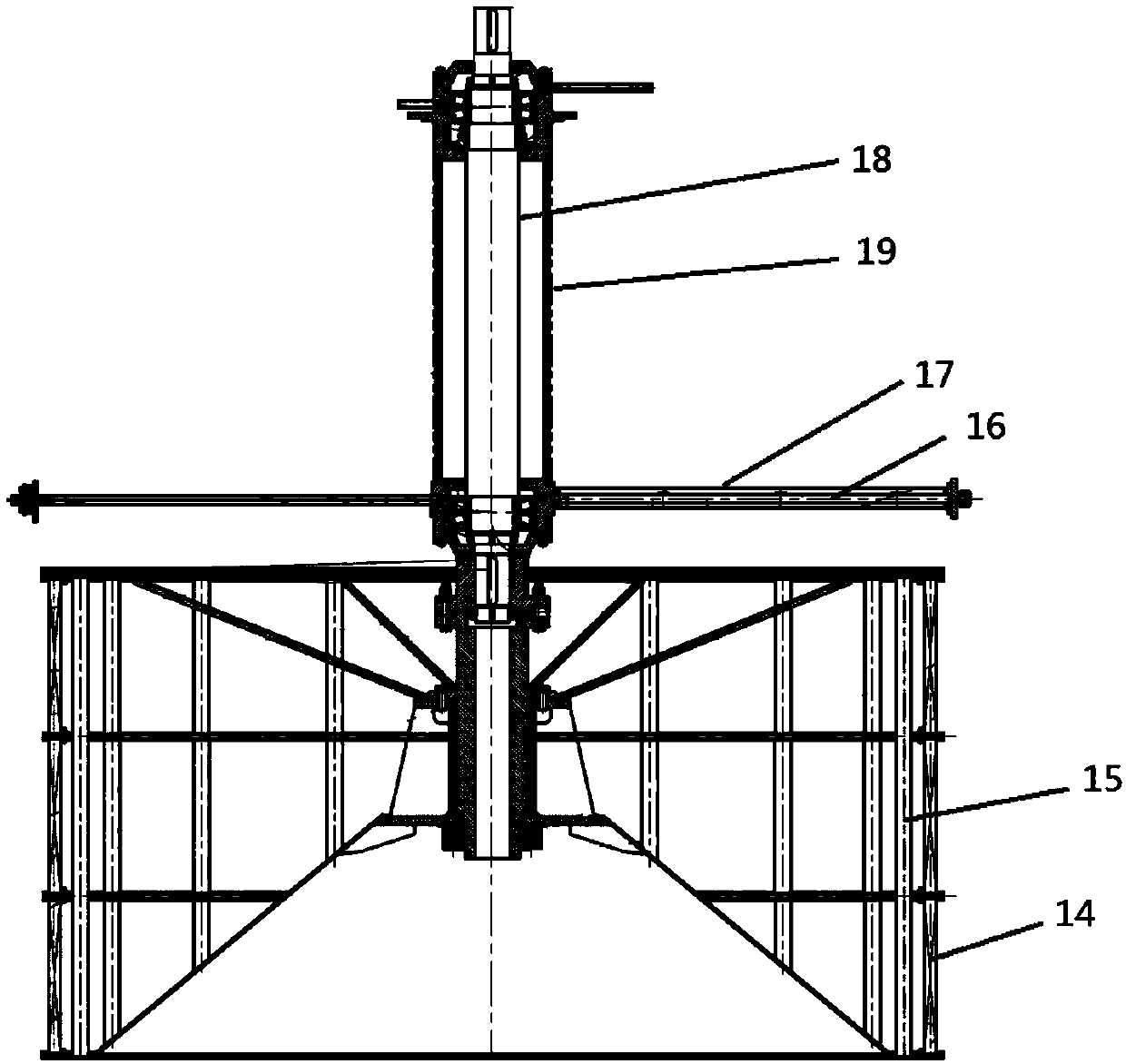

[0011] The following is attached Figure 1-Figure 2 The present invention is described in further detail.

[0012] as attached figure 1 , the present invention provides a vertical mill system for oil well cement production, including a motor 1, a reducer 2, a frame 3, a vertical mill shell 4, an air ring 5, a grinding disc 6, a grinding roller 7, a powder separator 8, Air outlet 9, feeding pipe 10, hydraulic cylinder 11, rocker arm 13. The vertical mill housing 1 is installed on the frame 3 and arranged on the upper part of the grinding disc 6; the grinding disc 6 is located at the bottom of the vertical mill housing 4 and above the reducer 2; the grinding roller 7 is installed through the rocker arm 13 on the side of the millstone 6; the powder selector 8 is installed on the top of the vertical mill housing 4; the motor 1 and the reducer 2 are connected to the millstone 6 through a transmission mechanism; side. The hydraulic cylinder 11 is connected to the grinding roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com