Water drive tank and water purifier

A water purifier and water flooding technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of occupying space, low safety factor, and practical utilization of water storage Insufficient efficiency and other problems, to achieve the effect of increasing the utilization rate of water storage space and reducing the risk of barrel explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

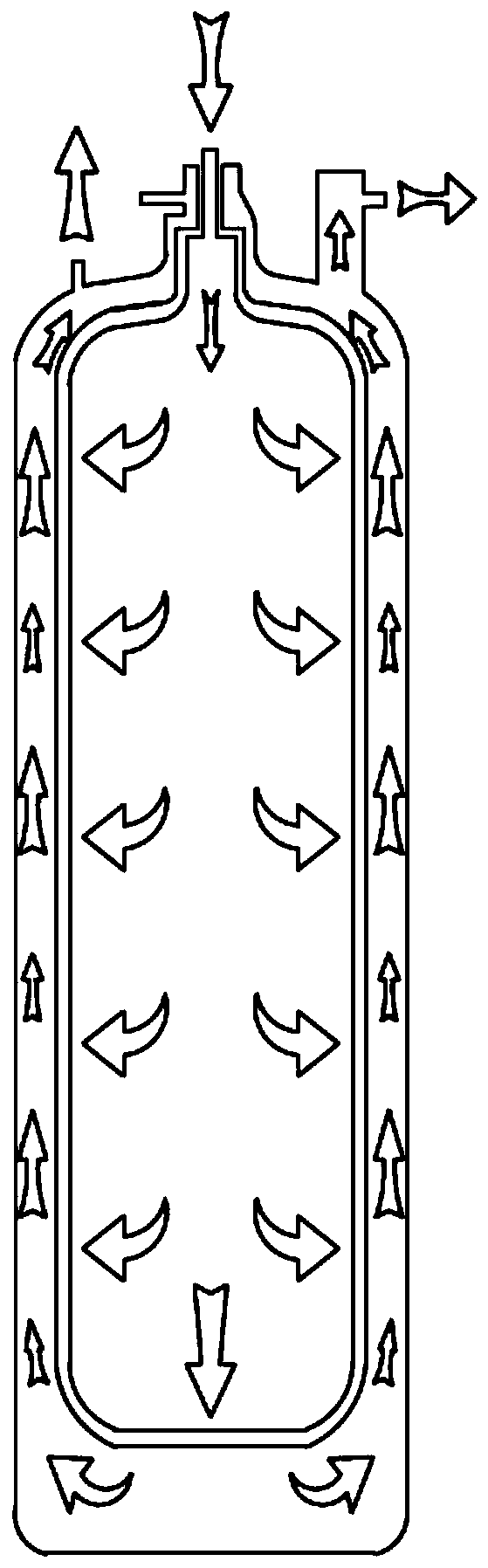

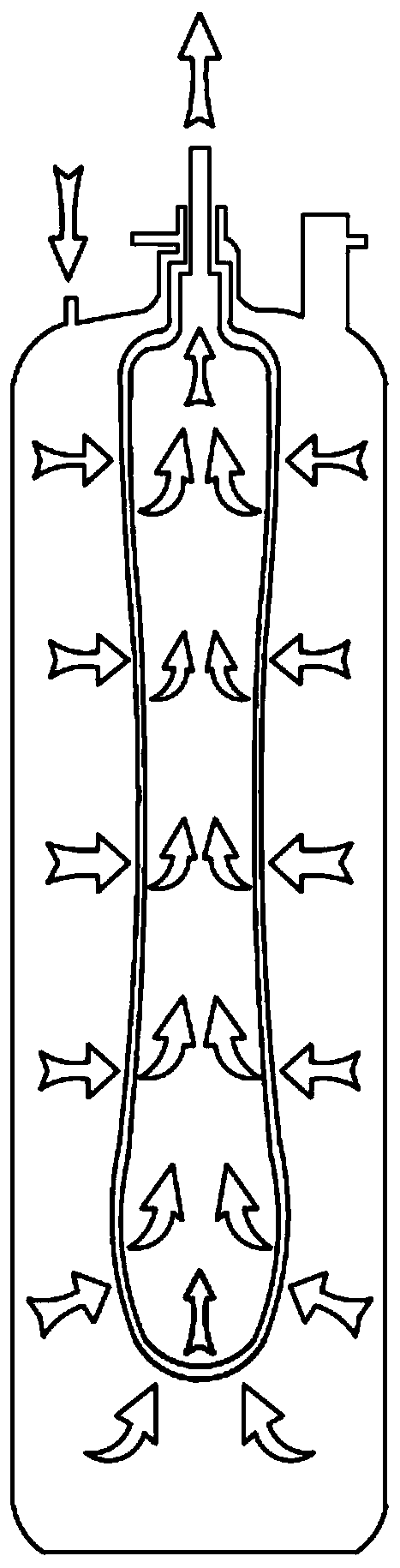

[0043] See attached figure 1 And attached figure 2 , The water flooding tank provided in Embodiment 1 of the present invention includes an inner tank and an outer tank. The inner tank is contained inside the outer tank, and a cavity is formed between the tank body of the inner tank and the tank body of the outer tank, and the inner tank and the cavity can communicate with the outside respectively. Water can exert a squeezing force between the inner tank and the cavity, wherein, when the water pressure inside the inner tank is greater than the water pressure in the cavity, the inner tank will When the volume of the cavity increases, the water in the cavity is squeezed out; when the water pressure inside the cavity is greater than the hydraulic pressure of the inner tank, the water in the cavity passes through the tank of the inner tank The body exerts a squeezing force to squeeze out the water inside the inner tank.

[0044] In the application process of the water flooding ...

Embodiment 2

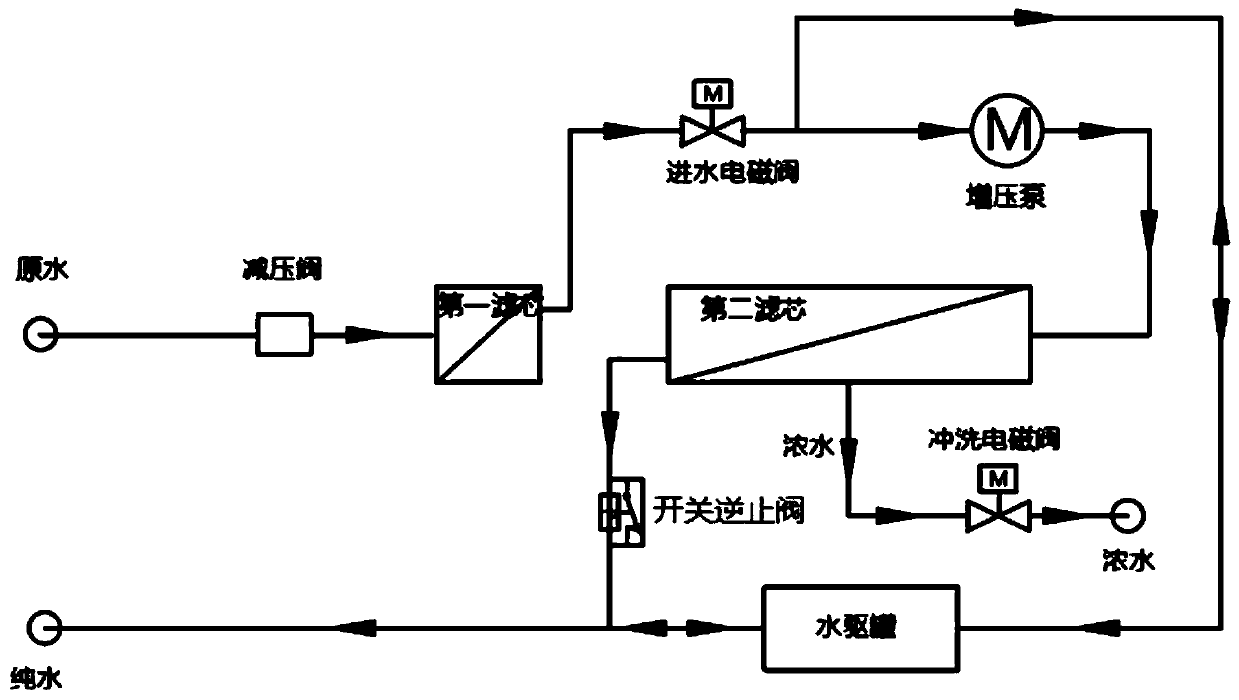

[0047] See attached image 3 , The water purifier provided by Embodiment 2 of the present invention includes a pressure reducing valve, a first filter element, a water inlet valve, a booster pump, a second filter element, a switch check valve, a flushing valve and the water flooding tank provided by the present invention. The booster pump, the retention port of the second filter element, and the check valve are connected in series to form a first series waterway; the water drive tank is connected in parallel with the first series waterway to form a parallel waterway; The pressure valve, the first filter element, the water inlet solenoid valve, and the parallel waterway are connected in series to form a water-making passage; the flushing valve is connected to the filtering port of the second filter element; raw water passes through the water-making The channel produces water and discharges the pure water through the water drive tank, and the filtered concentrated water is disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com