Green dynamic scheduling method for flexible production

A dynamic scheduling and flexible production technology, applied in control/regulation systems, comprehensive factory control, instruments, etc., can solve problems such as poor practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

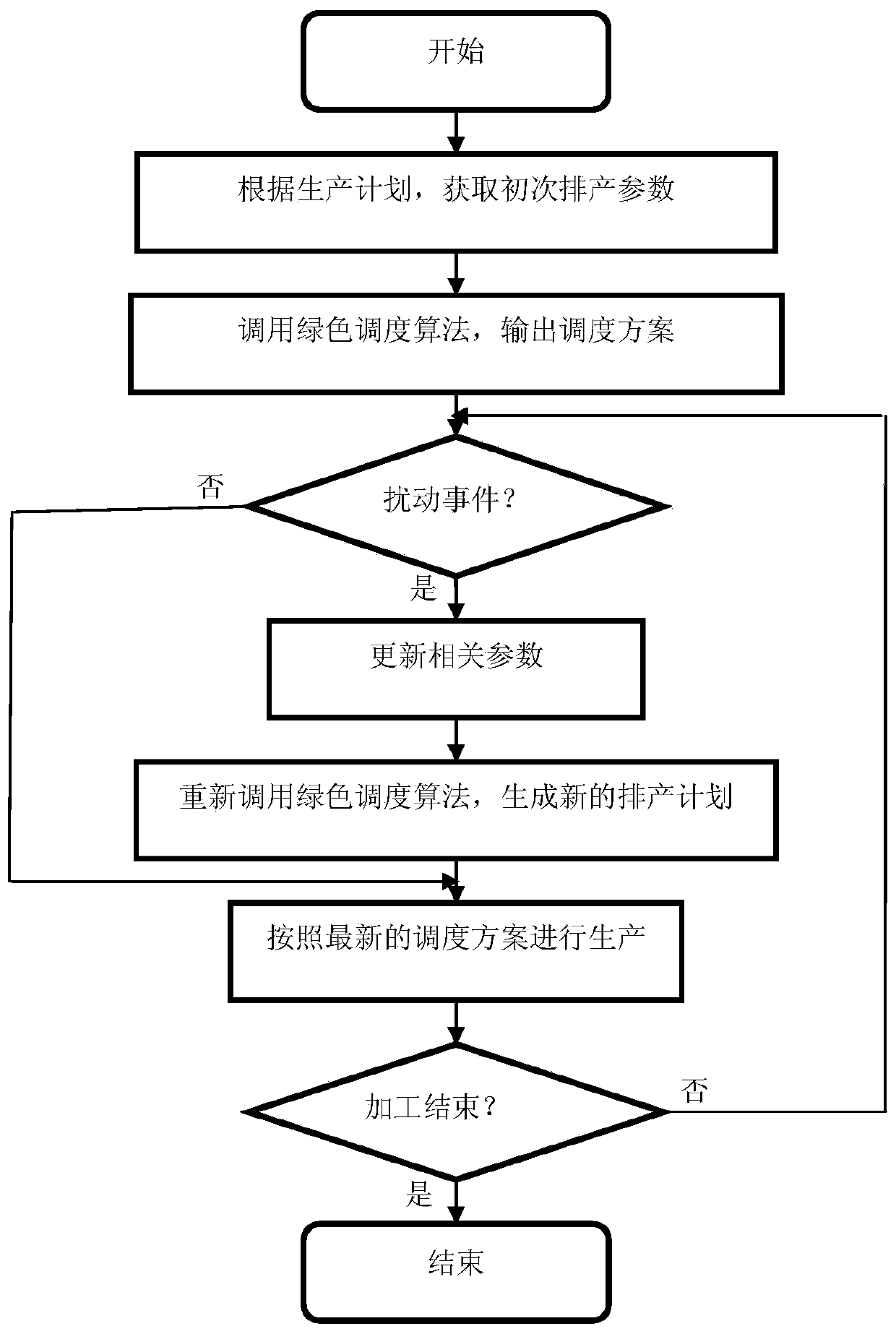

[0055] refer to Figure 1-2 . The specific steps of the green dynamic scheduling method for flexible production of the present invention are as follows:

[0056] Step 1. Release the production plan and obtain the initial data related to processing as calculation parameters.

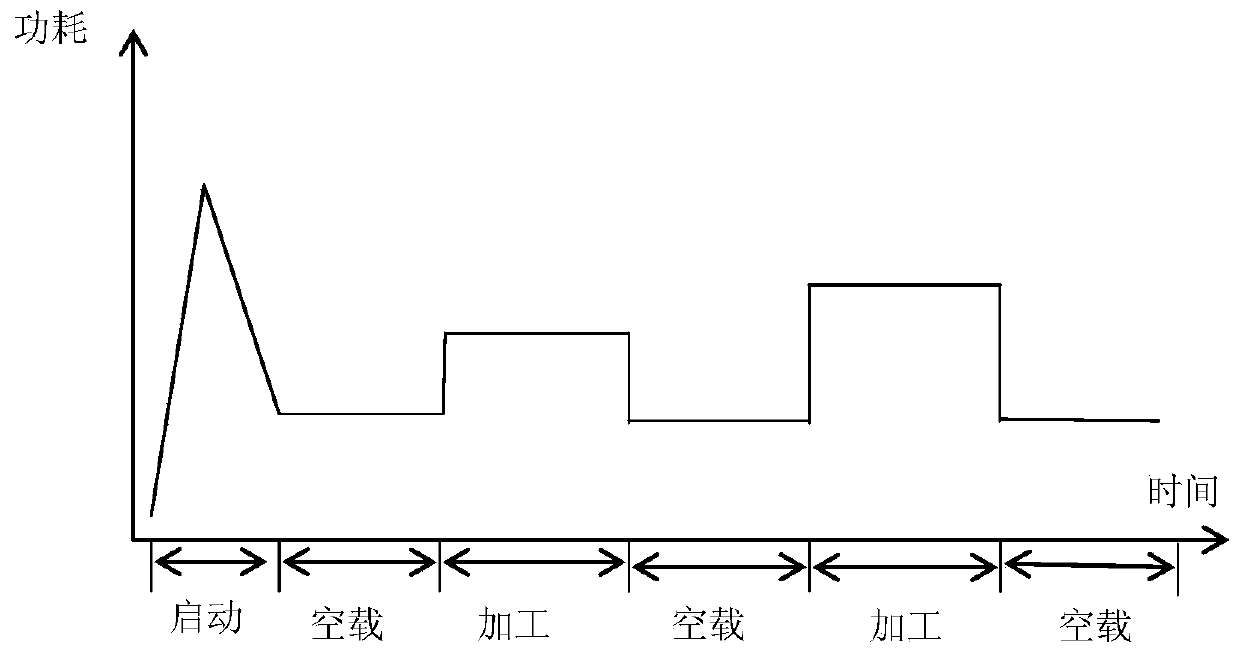

[0057] The initial data is obtained through data input, and the required parameters include: the number of processed workpieces n, the number of processing machines and equipment m, process constraints, and the power consumption E of the equipment production process.

[0058] Step 2. Based on the energy consumption model of the production workshop, adopt the Pareto multi-objective optimization method and equipment load balancing strategy, use the bat algorithm to design a green scheduling algorithm, calculate the static scheduling scheme, and execute the scheduling scheme.

[0059] Step 2.1: Set algorithm parameters.

[0060] Parameters related to the production process: the number of workpieces n; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com