Processing method for forming positive electrode end surface of circular lithium battery

A processing method and technology of lithium batteries, which are applied in battery assembly machines, secondary battery manufacturing, battery pack components, etc., can solve the problem that the top of the battery is not flat enough, and cannot meet the technical requirements of round lithium-ion batteries, etc. problem, to improve safety and solve the effect of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

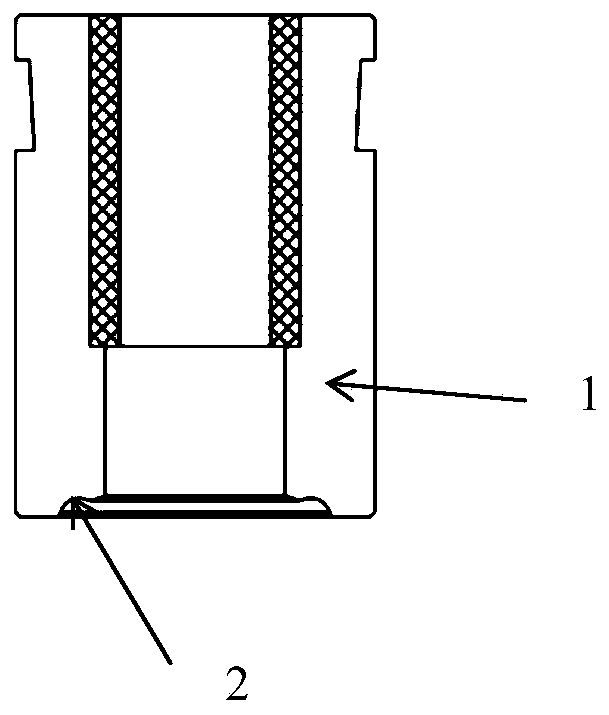

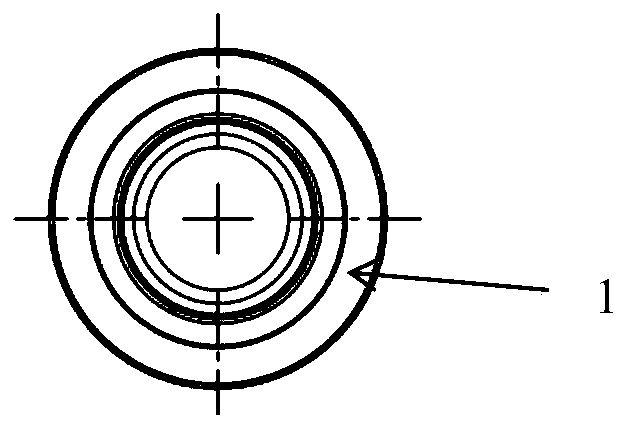

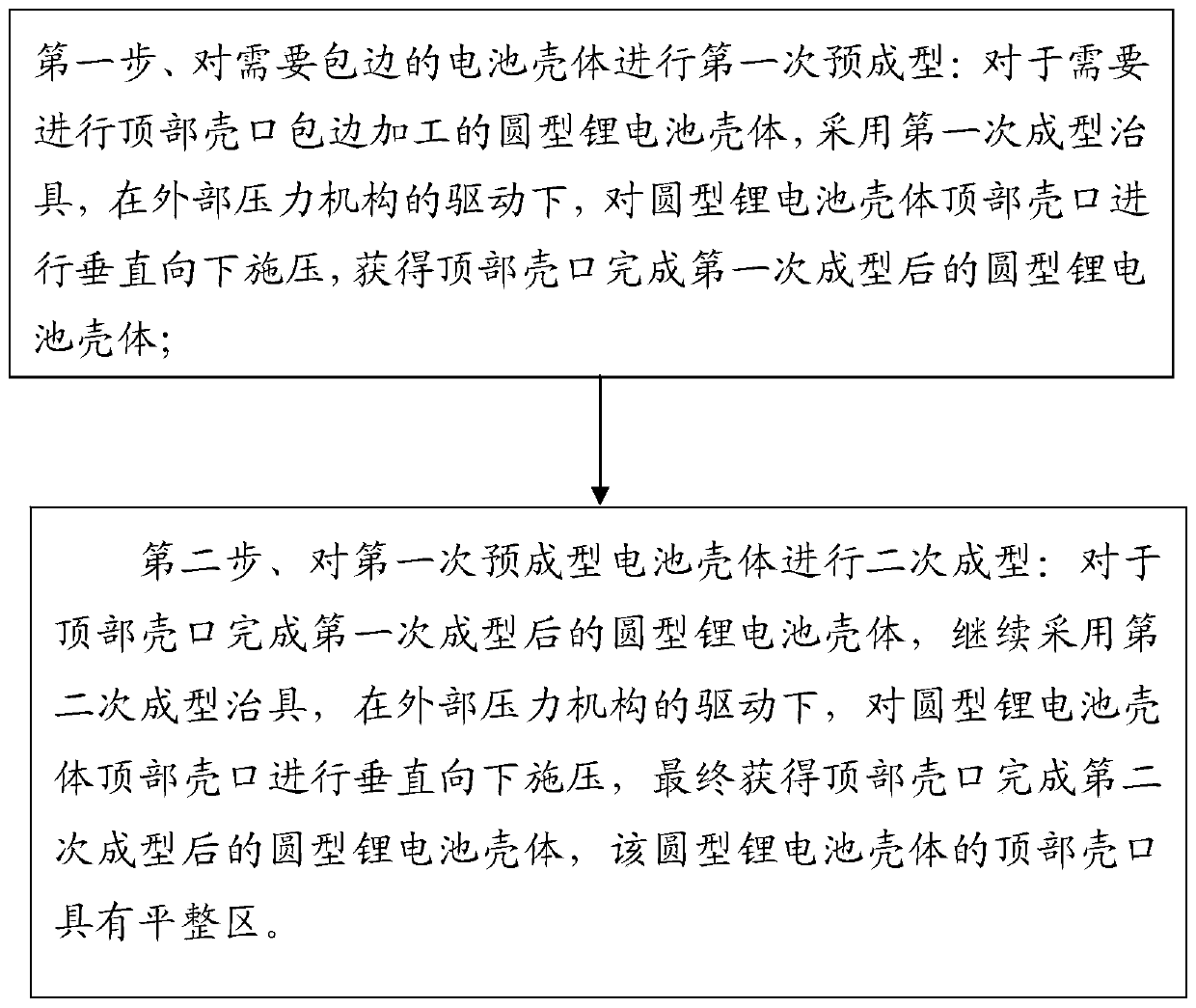

[0045] see Figure 3 to Figure 14 , the invention provides a processing method for forming the positive end surface of a circular lithium battery, comprising the following steps:

[0046] The first step is to perform the first pre-forming of the battery case that needs to be edge-wrapped: for the round lithium battery case that needs to be edge-wrapped at the top shell mouth, the first-time forming fixture is used, driven by the external pressure mechanism Next, apply vertical downward pressure on the top shell opening of the round lithium battery case to obtain the round lithium battery case after the first molding of the top shell opening;

[0047] In the first step, for specific implementation, see Figure 4 , Figure 5As shown, the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com