Electric-attraction type dispensing equipment and control method thereof

A control method and dispensing technology, which are used in liquid spraying equipment, electrostatic spraying devices, spraying devices, etc., can solve the problem of difficulty in ensuring the size, weight and offset of the dispensing fluid, difficulty in ensuring the yield, and difficulty in precise glue control. Accurate positioning and other problems, to achieve the effect of fast dispensing rate, precise glue control, and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the examples, and the contents mentioned in the embodiments are not intended to limit the present invention.

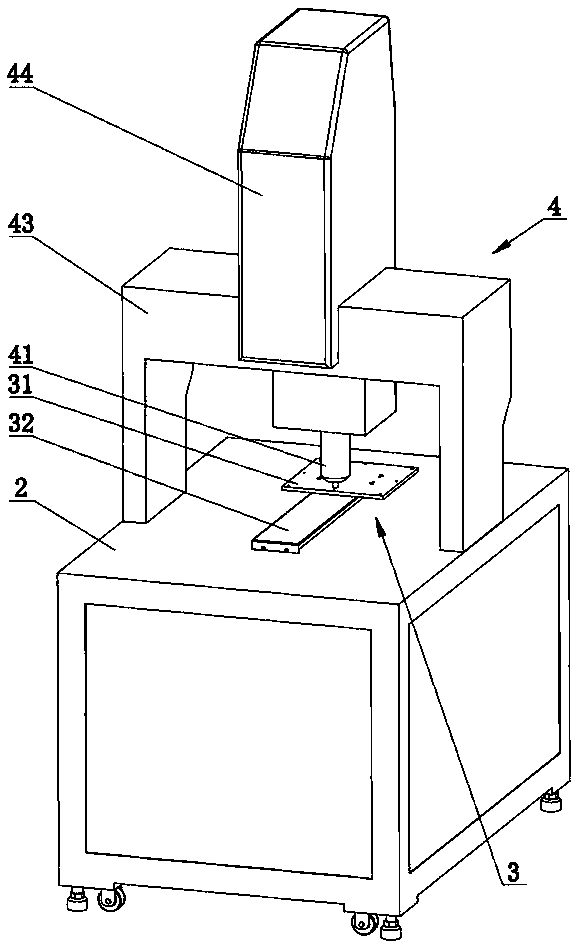

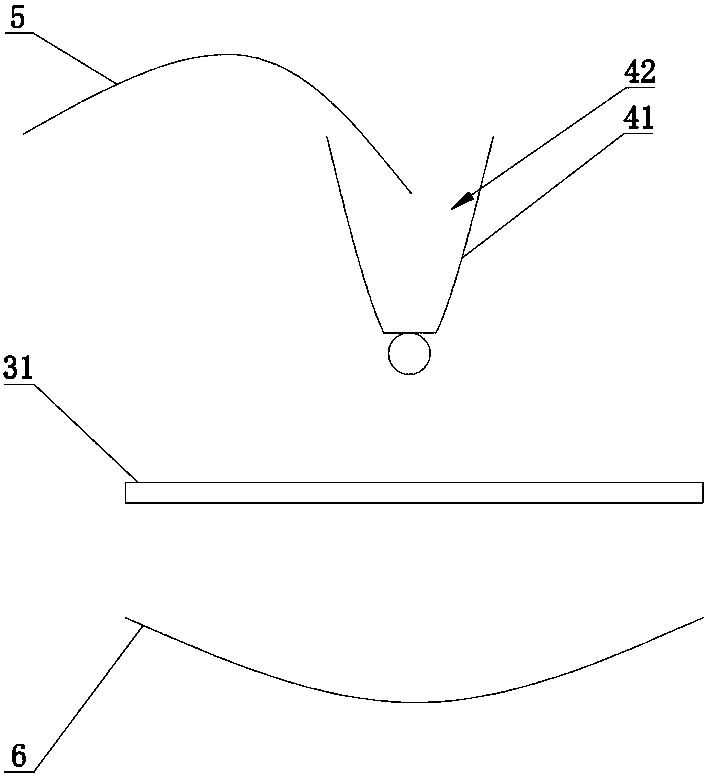

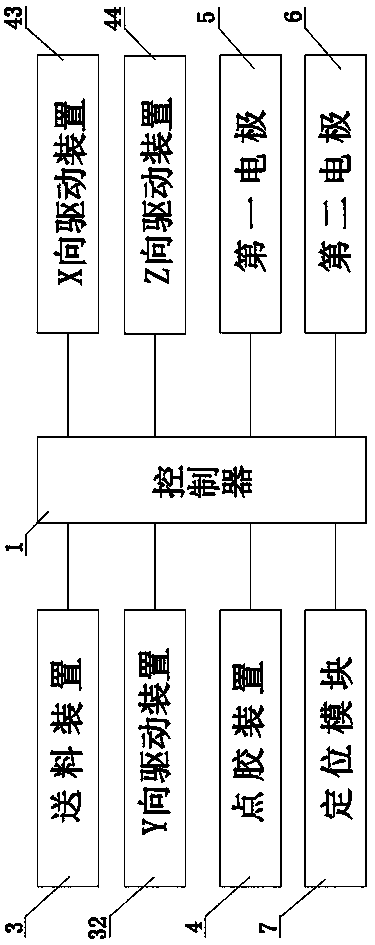

[0025] Such as Figure 1 to Figure 3 As shown, an electric suction dispensing equipment includes a controller 1, a frame 2, a feeding device 3 arranged on the frame 2, and a fluid quantitative output device 4 located above the feeding device 3. The fluid quantitative output device 4 Comprising a dispensing head 41 located on the feeding device 3 and a glue chamber 42 set inside the dispensing head 41 for accommodating fluid, the feeding device 3 and the fluid quantitative output device 4 are electrically connected to the controller 1, and Including a first electrode 5 and a second electrode 6 with opposite polarities and electrically connected to the controller 1, one end of the first electrode 5 is electrically connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com