Automobile lamp renovating appliance and self-heating material

A technology for car lights and appliances, which is applied in the field of car light refurbishment appliances and self-heating materials, which can solve the problems of high cost, inconvenient use, and wire and cable entanglement, and achieve the effects of low production cost, cost reduction, and convenient and quick use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

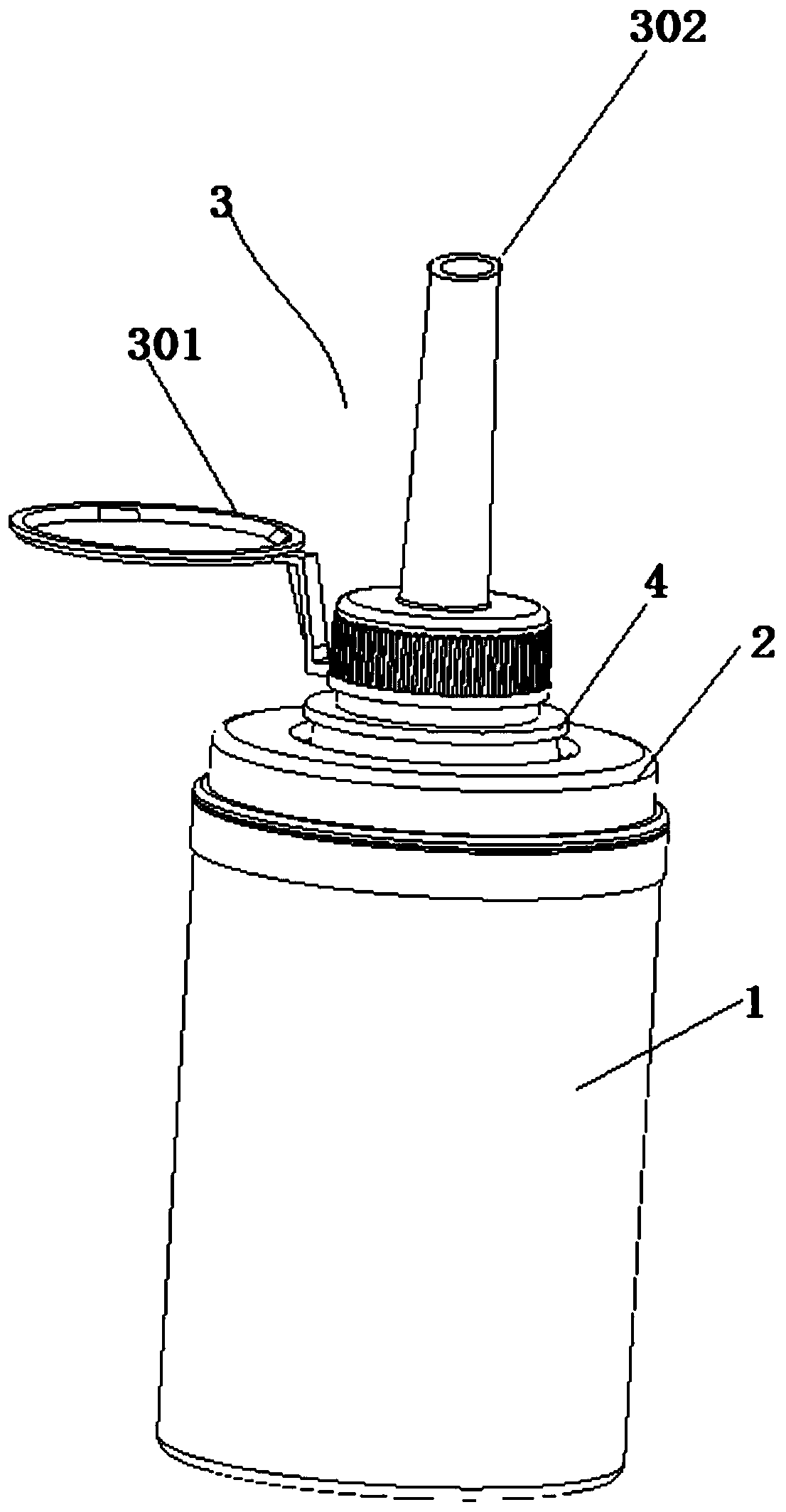

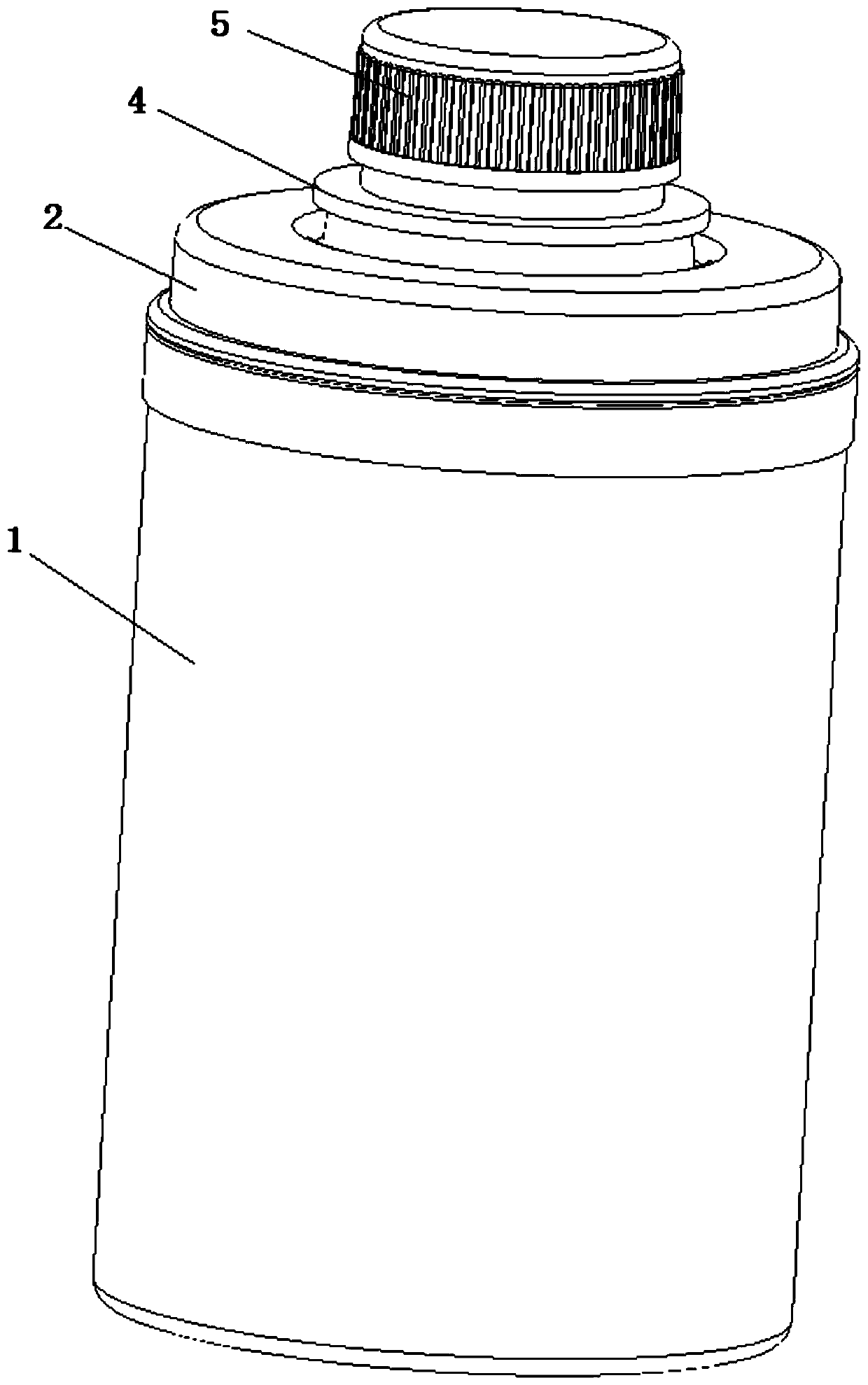

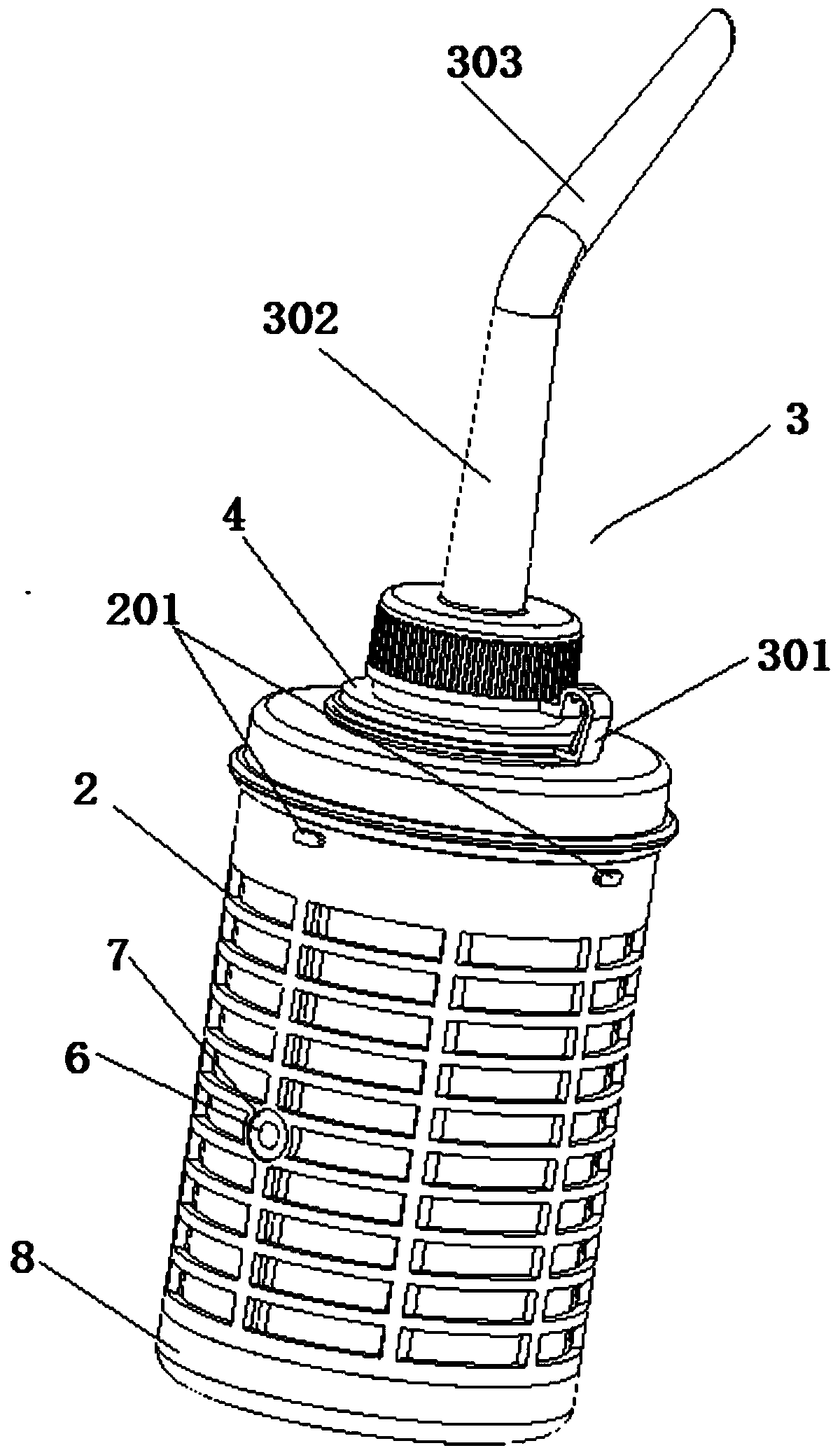

[0033] see figure 1 , image 3 , Figure 7 as well as Figure 10 , the present embodiment provides a car lamp refurbishment appliance, including a pot body 10 and a nozzle 3 connected to the pot body 10, a grille layer 2 is provided outside the pot body 10, and a The heating pack 11, the heating pack 11 can react with the air and heat the kettle body 10, the grille layer 2 is detachably connected with the shell 1, so that the heating pack 11 is isolated from the outside air. The outside of the grid layer 2 is provided with a temperature-sensitive object 6 to identify the heating temperature of the pot body 10. The temperature-sensitive object 6 is made of temperature-sensitive paint. When the temperature of the heating package 11 rises to a certain temperature, the temperature-sensitive object 6 will Under the heating action of 11, it gradually subsides until it disappears, and the temperature-sensitive object 6 is provided with a heat-insulating film 7 to isolate the tempe...

Embodiment 2

[0039] The technical solution of this embodiment provides a self-heating material, which consists of the following components in grams by weight: 58g of reduced iron powder, 8g of wood powder, 5g of activated carbon, 3g of table salt, and 18g of water. This embodiment can be obtained through experimental tests The highest average heating temperature of the second self-heating material is 78.5 degrees Celsius, and the average continuous heating time is 52.8 minutes.

Embodiment 3

[0041] The self-heating material of this embodiment is composed of the following components in grams by weight: 62g of reduced iron powder, 12g of wood powder, 7g of activated carbon, 5g of table salt, and 22g of water. The fever temperature was 75.2 degrees Celsius, and the average duration of fever was 62.4 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com