Waste material collection and treatment device for metal machining

A waste collection and processing device technology, applied in grain processing, manufacturing tools, cleaning methods and utensils, etc., can solve the problems of oil stains, large storage space, unfavorable use, etc., and achieve the effect of saving water resources and saving storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

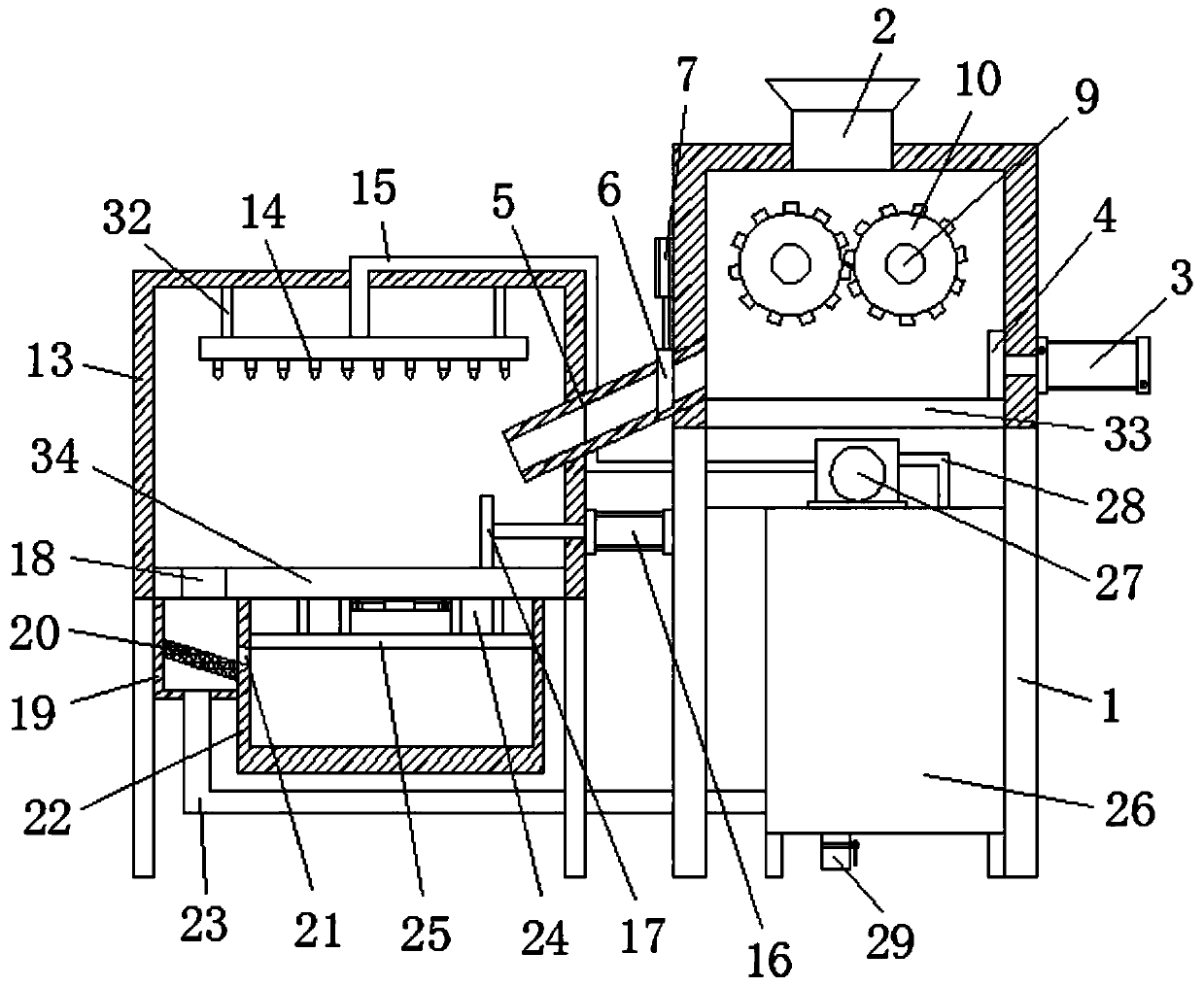

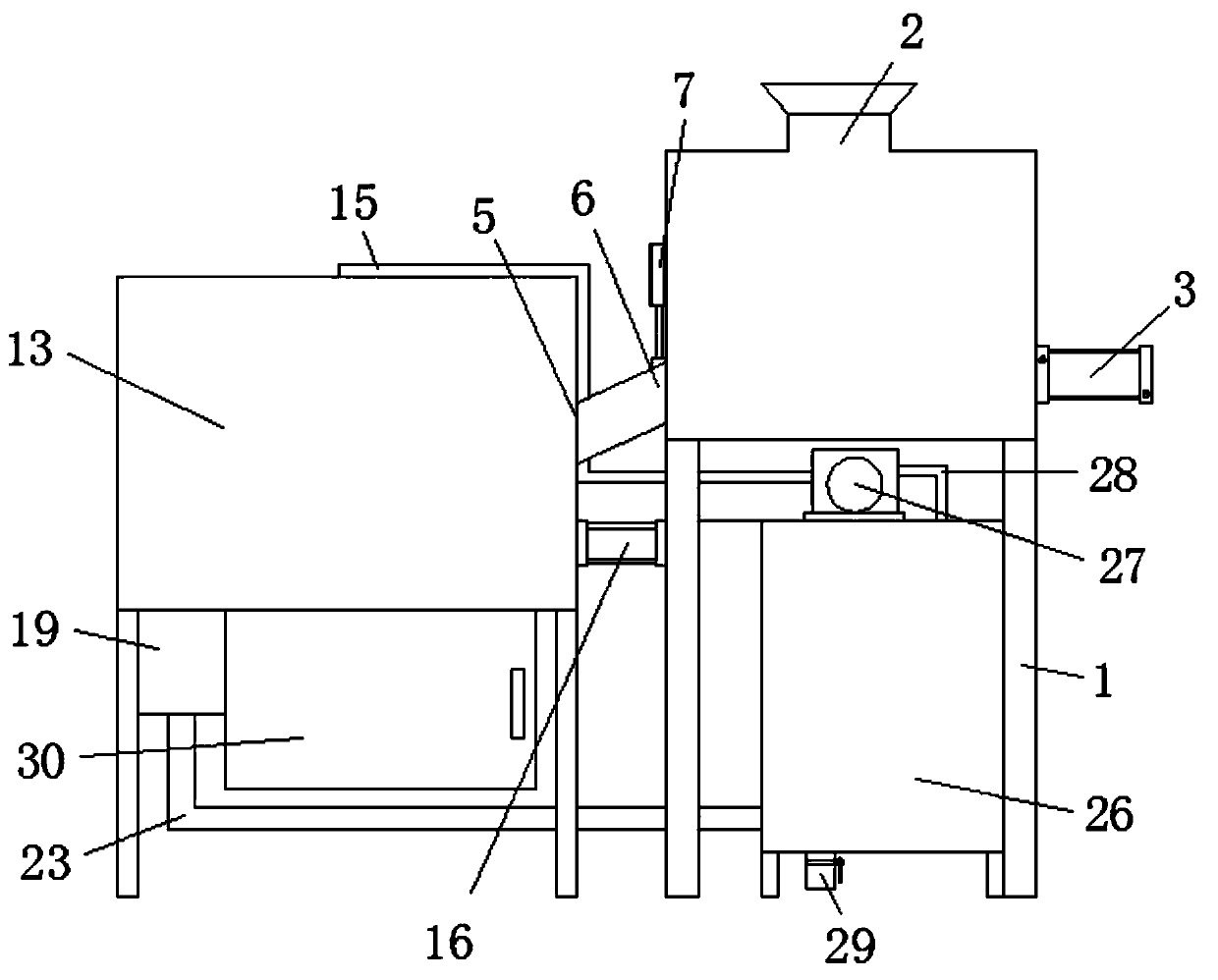

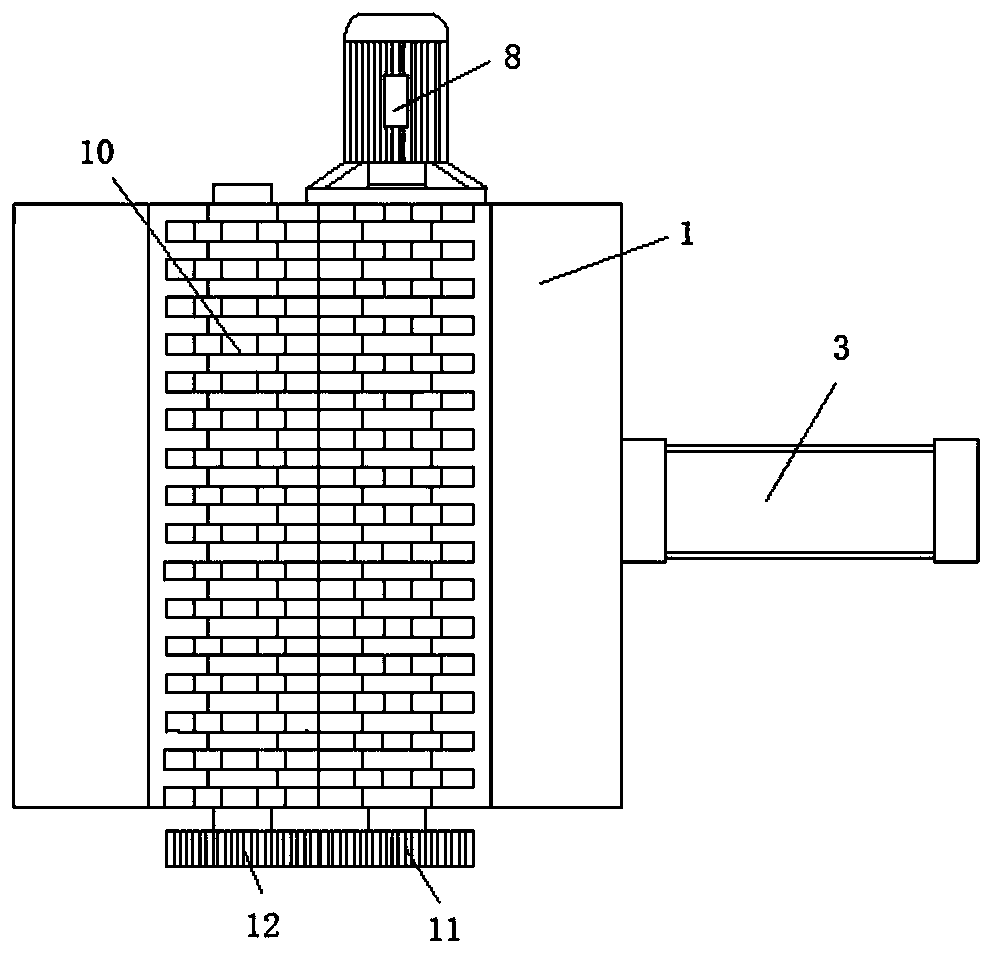

[0030] see Figure 1-4, the present embodiment provides a metal processing waste collection and processing device, including a crushing box 1 and a cleaning box 13, the output end of the crushing box 1 is fixedly connected with the input end of the cleaning box 13, and the crushing box 1 The middle part of the upper end of the upper end is fixedly connected with the feeding port 2, the inner middle part of the crushing box 1 is fixedly connected with the first partition 33, and one side of the crushing box 1 corresponding to the position of the first partition 33 is fixedly connected with the first Cylinder 3, the piston rod of the first cylinder 3 traverses through the crushing box 1 and is fixedly connected with a first push plate 4, and the inside of the crushing box 1 is fixedly connected with two drive shafts 9, and the crushing box 1 A motor 8 is fixedly connected to the rear surface of the motor 8, and the output end of the motor 8 is fixedly connected to one of the tra...

Embodiment 2

[0034] see Figure 1-4 , made a further improvement on the basis of Example 1: the inside of the filter box 19 is obliquely fixedly connected with a first filter screen 20, and the inclination angle of the first filter screen 20 is 25°, the first The upper surface of the filter screen 20 is fixedly connected with a slide plate, and the slide plate is provided with several through holes, which facilitate the sliding of waste fragments to the inside of the collection box 22, and are also convenient for the discharge of sewage after cleaning. The inside of the water tank 26 The second filter screen 31 is fixedly connected, and the bottom end of the water tank 26 is fixedly connected with a sewage discharge pipe 29 corresponding to the side of the second filter screen 31, and the sewage discharge pipe 29 runs through the water tank 26 transversely. A control valve is fixedly connected to the pipe 29, which is convenient for discharging or replacing the sewage inside the water tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com