Molten iron slagging-off detection method based on lightweight convolutional neural network

A technology of convolutional neural network and detection method, which is applied in the field of molten iron slag detection based on lightweight convolutional neural network, can solve the problems of unsatisfactory recognition accuracy and precision, and avoid manual participation in harsh and complex environments. Anti-jamming ability and effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

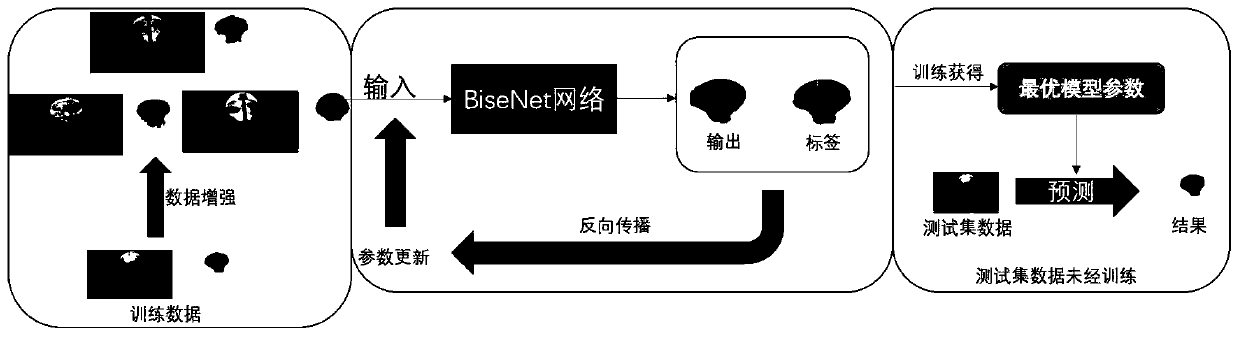

[0038] This embodiment provides a method for detecting molten iron slag based on a lightweight convolutional neural network. First, a video is collected from the actual industrial site of molten iron slag extraction, and enough pictures are extracted from it to make a data set, including 300 original images. Then, under the guidance of experienced workers, manually label these pictures to obtain the corresponding label data. Then, according to the principle of deep learning to classify each pixel of the image, the data set is trained using the lightweight network model BiseNet (Bilateral Segmentation Network for Real-time Semantic Segmentation).

[0039] BiseNet contains two paths, Spatial Path and Context Path, among which Spatial Path can preserve the spatial scale of the original input image and encode rich spatial information. Spatial Path consists of three layers, each layer contains a convolution with a stride of 2, followed by batch normalization and ReLU activation fun...

no. 2 example

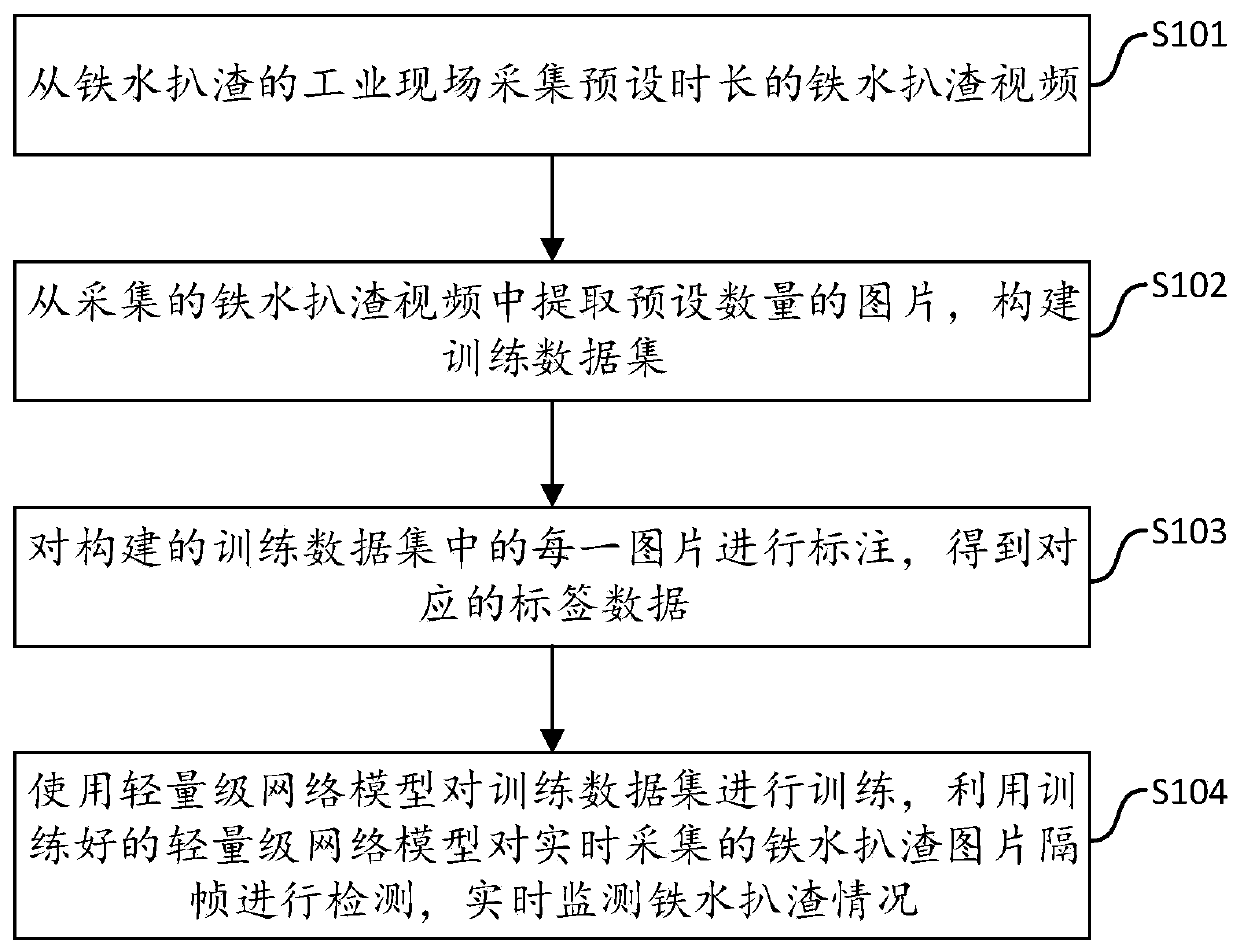

[0052] This embodiment provides a method for detecting hot metal slag scraping based on a lightweight convolutional neural network, including:

[0053] 1. Collect a 3200s video of molten iron slag removal from the actual industrial site of molten iron slag removal through an industrial camera; among them, the video resolution is 1920x1080, and the frame rate is 25 frames per second;

[0054] 2. Take one frame every 8 seconds from the collected molten iron slag removal video, and get 400 original images; divide the obtained original images into training data set and test data set according to the ratio of 3:1; among them, the training data set Under the guidance of experienced people, use PhotoShop to manually annotate the 300 pictures at the pixel level. These 300 pictures are used as the training data set, and the remaining 100 pictures are used as the test data set;

[0055] 3. During training, through random up-down flip, random left-right flip, and random size cropping, da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com