Production process of weather-resistant plastic woven bag

A plastic woven bag and production process technology, applied in the field of plastic woven bags, can solve the problems of affecting the use effect, poor structural strength, poor weather resistance, etc., and achieve good storage capacity, improved oxidation resistance, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

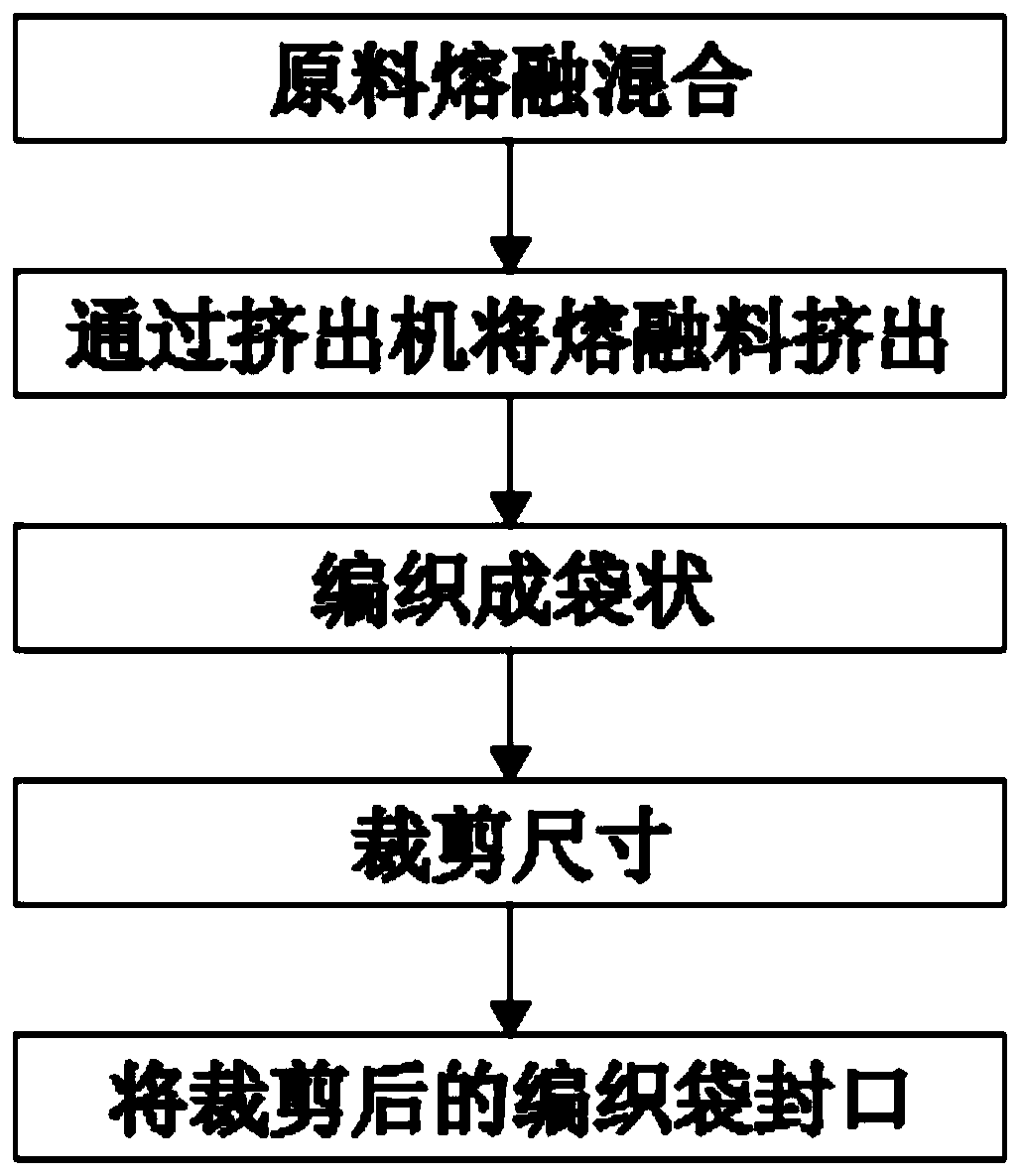

[0035] The specific steps of the production process of the weather-resistant plastic woven bag are as follows:

[0036] S1: Melting and mixing of raw materials: The raw materials of weather-resistant plastic woven bags are PE, PP, PP resin antioxidants, ultraviolet absorbers and polyamine antioxidants, and PE, PP, PP resin antioxidants, ultraviolet absorbers and The polyamine antioxidant-reductive agent according to the mass proportion is: PE30kg, PP30kg, PP resin antioxidant 3kg, ultraviolet absorber 3kg and polyamine antioxidant-reductive agent 3kg, PE, PP, PP resin antioxidant, ultraviolet The absorbent and polyamine antioxidant-reductive agent are injected into the heating melting furnace, so that PE, PP, PP resin antioxidant, ultraviolet absorber and polyamine antioxidant-reductive agent are heated and melted, and the PE, PP, PP The resin antioxidant, ultraviolet absorber and polyamine antioxidant-reductive agent are stirred and mixed, so that the raw materials are homoge...

Embodiment 2

[0042] The specific steps of the production process of the weather-resistant plastic woven bag are as follows:

[0043] S1: Melting and mixing of raw materials: The raw materials of weather-resistant plastic woven bags are PE, PP, PP resin antioxidants, ultraviolet absorbers and polyamine antioxidant-reductive agents, and PE, PP, PP resin antioxidants, ultraviolet absorbers and The polyamine antioxidant-reductive agents according to the mass proportion are: PE32kg, PP32kg, PP resin antioxidant 4kg, ultraviolet absorber 4kg and polyamine antioxidant-reductive agent 4kg, PE, PP, PP resin antioxidant, ultraviolet The absorbent and polyamine antioxidant-reductive agent are injected into the heating melting furnace, so that PE, PP, PP resin antioxidant, ultraviolet absorber and polyamine antioxidant-reductive agent are heated and melted, and the stirring equipment is used to mix PE, PP, PP The resin antioxidant, ultraviolet absorber and polyamine antioxidant-reductive agent are sti...

Embodiment 3

[0049] The specific steps of the production process of the weather-resistant plastic woven bag are as follows:

[0050] S1: Melting and mixing of raw materials: The raw materials of weather-resistant plastic woven bags are PE, PP, PP resin antioxidants, ultraviolet absorbers and polyamine antioxidant-reductive agents, and PE, PP, PP resin antioxidants, ultraviolet absorbers and The polyamine antioxidant and reduction agents are as follows according to the mass proportion: PE34kg, PP34kg, PP resin antioxidant 5kg, ultraviolet absorber 5kg and polyamine antioxidant and reduction agent 5kg, PE, PP, PP resin antioxidant, ultraviolet The absorbent and polyamine antioxidant-reductive agent are injected into the heating melting furnace, so that PE, PP, PP resin antioxidant, ultraviolet absorber and polyamine antioxidant-reductive agent are heated and melted, and the stirring equipment is used to mix PE, PP, PP The resin antioxidant, ultraviolet absorber and polyamine antioxidant-redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com