Processing and forming integration machine based on corrugated paper production

A technology of processing and forming, all-in-one machine, applied in the direction of mechanical processing/deformation, sending objects, thin material processing, etc., can solve the problems of low degree of automation, time-consuming, laborious, high cost, etc., achieve high degree of automation, increase bending resistance, reduce broken The effect of the probability of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

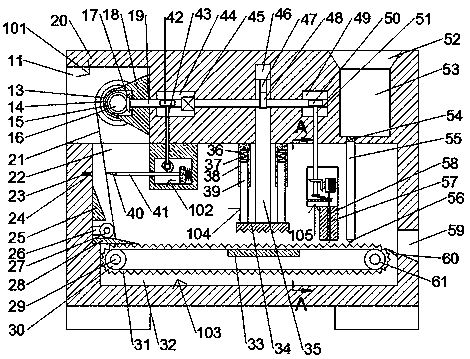

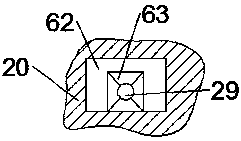

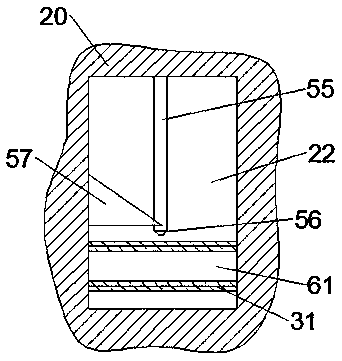

[0020] Combine below Figure 1-5 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0021] refer to Figure 1-5 According to an embodiment of the present invention, a processing and forming machine based on corrugated paper production includes a main body 20, and the main body 20 is provided with a feeding chamber 11 with an opening to the left, and a roller 13 can be installed in the feeding chamber 11 , the outer circumference of the drum 13 is wound with raw pulp paper 21, and the feeding chamber 11 is provided with a control mechanism 101 that can control the rotation of the drum 13 and transport the raw pulp paper 21 downwards. The lower side of the cavity 11 is communicated with a working cavity 22, a fixed body 64 is fixed on the top wall of the working cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com