Pipe type automatic three-dimensional warehouse and warehouse-out and in method

A three-dimensional warehouse and pipe technology, applied in the field of three-dimensional warehouse, can solve the problems of high warehouse space requirements, low intelligence and stability, low access efficiency, etc., to achieve real-time monitoring and query, improve space utilization, Realize the effect of digital management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is further described below in conjunction with the accompanying drawings, and the illustrated embodiments and illustrations are used to explain the present invention, but not as a limitation to the present invention.

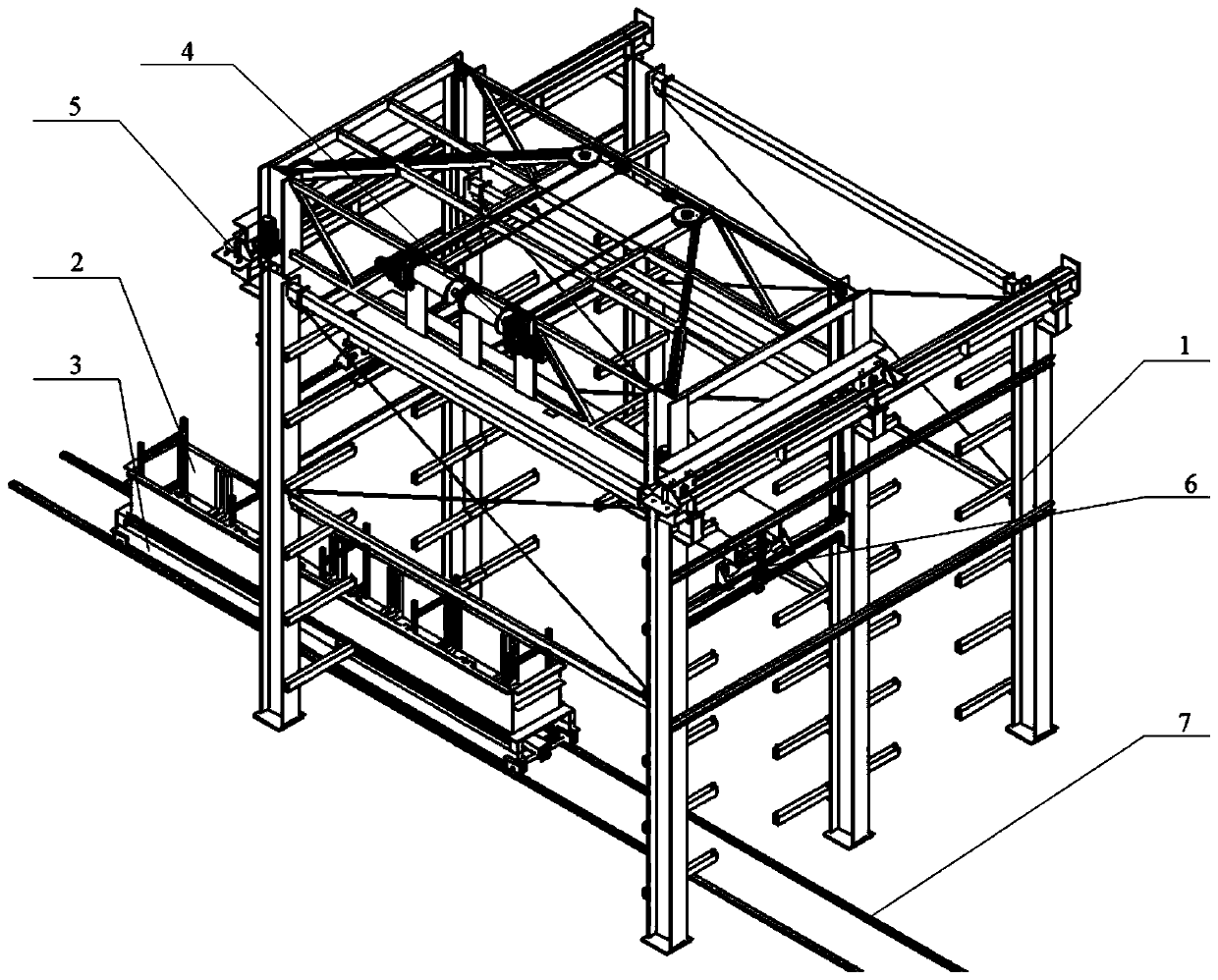

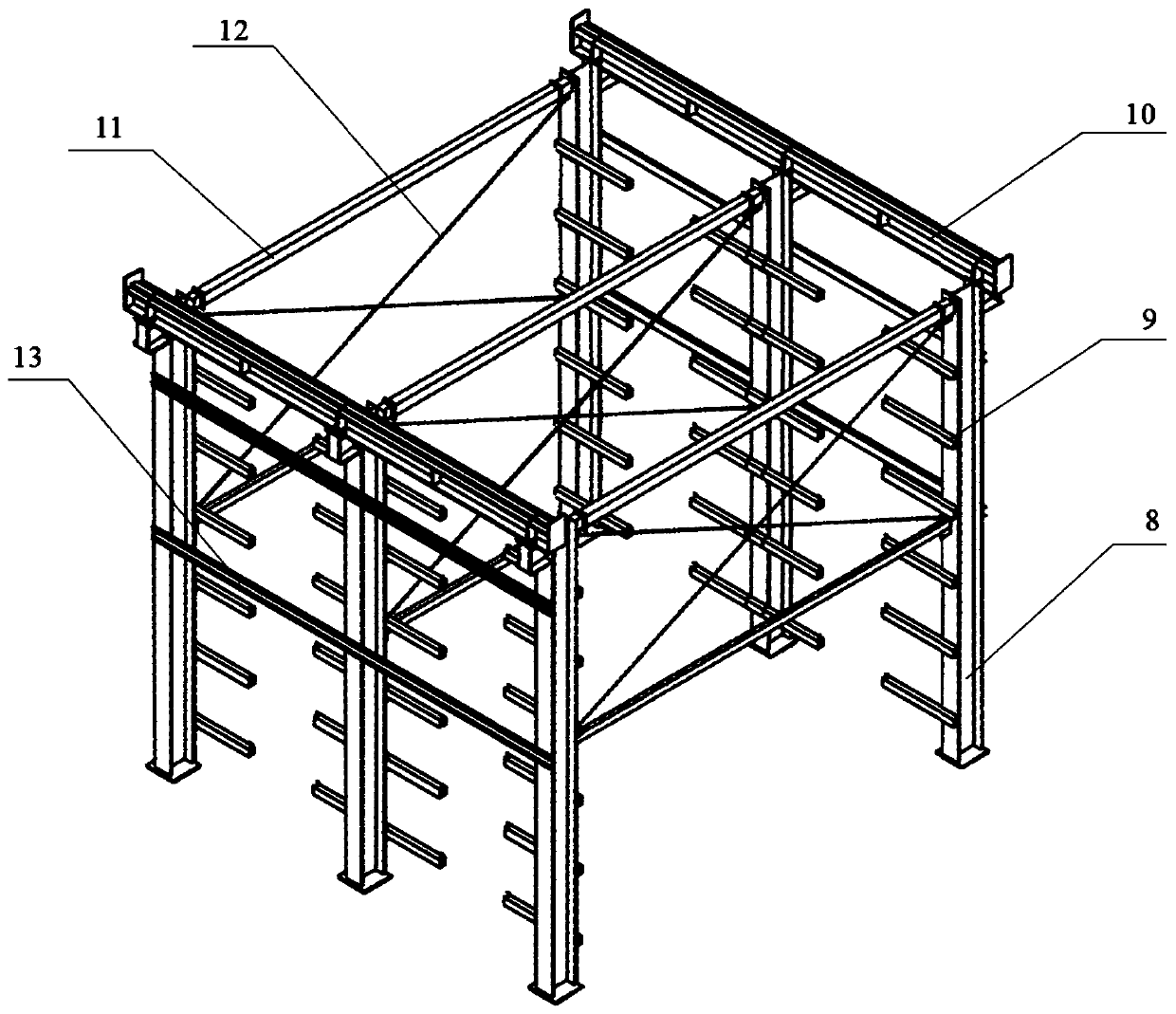

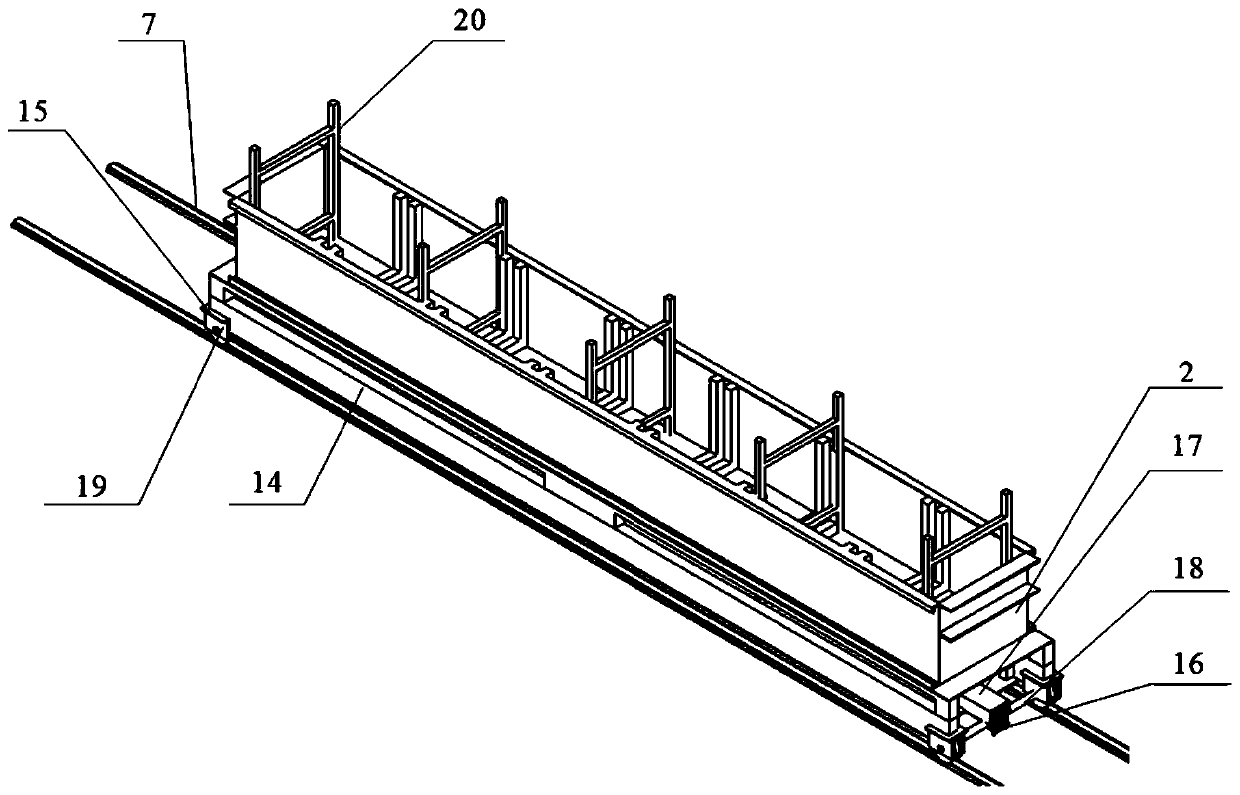

[0039] refer to figure 1 , the pipe automatic three-dimensional warehouse of the present invention includes a shelf 1, a material frame 2, a material frame conveying trolley 3, a lifting mechanism 4, a running mechanism 5, an access mechanism 6, a Y-direction track 7 and an automated warehouse management system.

[0040]Among them, the shelf 1 is a multi-layer structure, using a cantilever shelf, and each layer can place a material frame for the storage of pipes; material frame 2 is used for the storage of pipes, so that the pipes can be fixed and easy to transport; material frame conveying trolley 3 It is used to transport the material frame 2 loaded with pipes to the designated storage location for storage and deliver the material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com