Unmanned logistics vehicle control system with optimized walking path and control method thereof

A path optimization and control system technology, applied in conveyor control devices, conveyor objects, conveyors, etc., can solve the problems of low work efficiency, high cost, poor stability, etc., to reduce operating costs, improve production efficiency, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

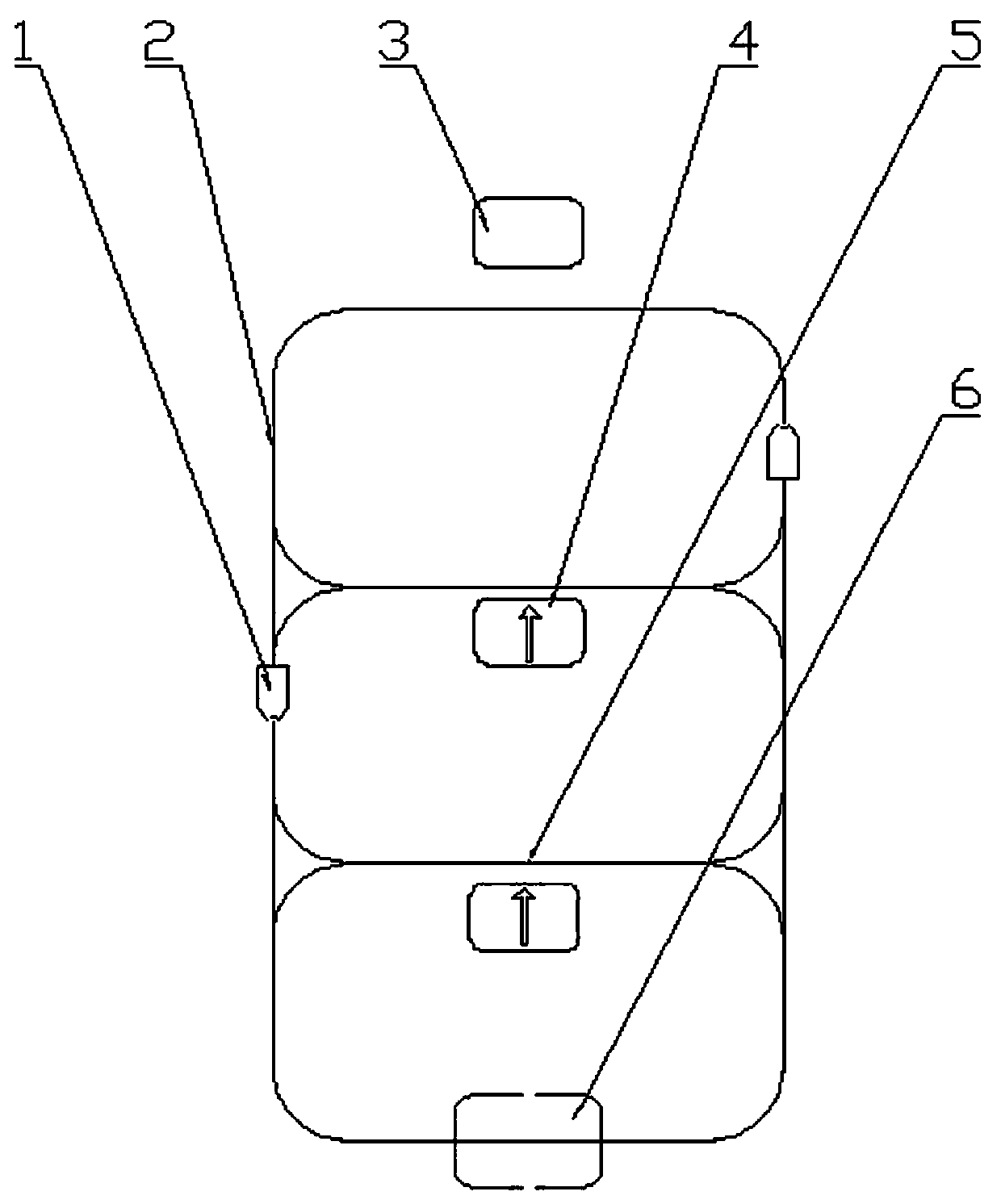

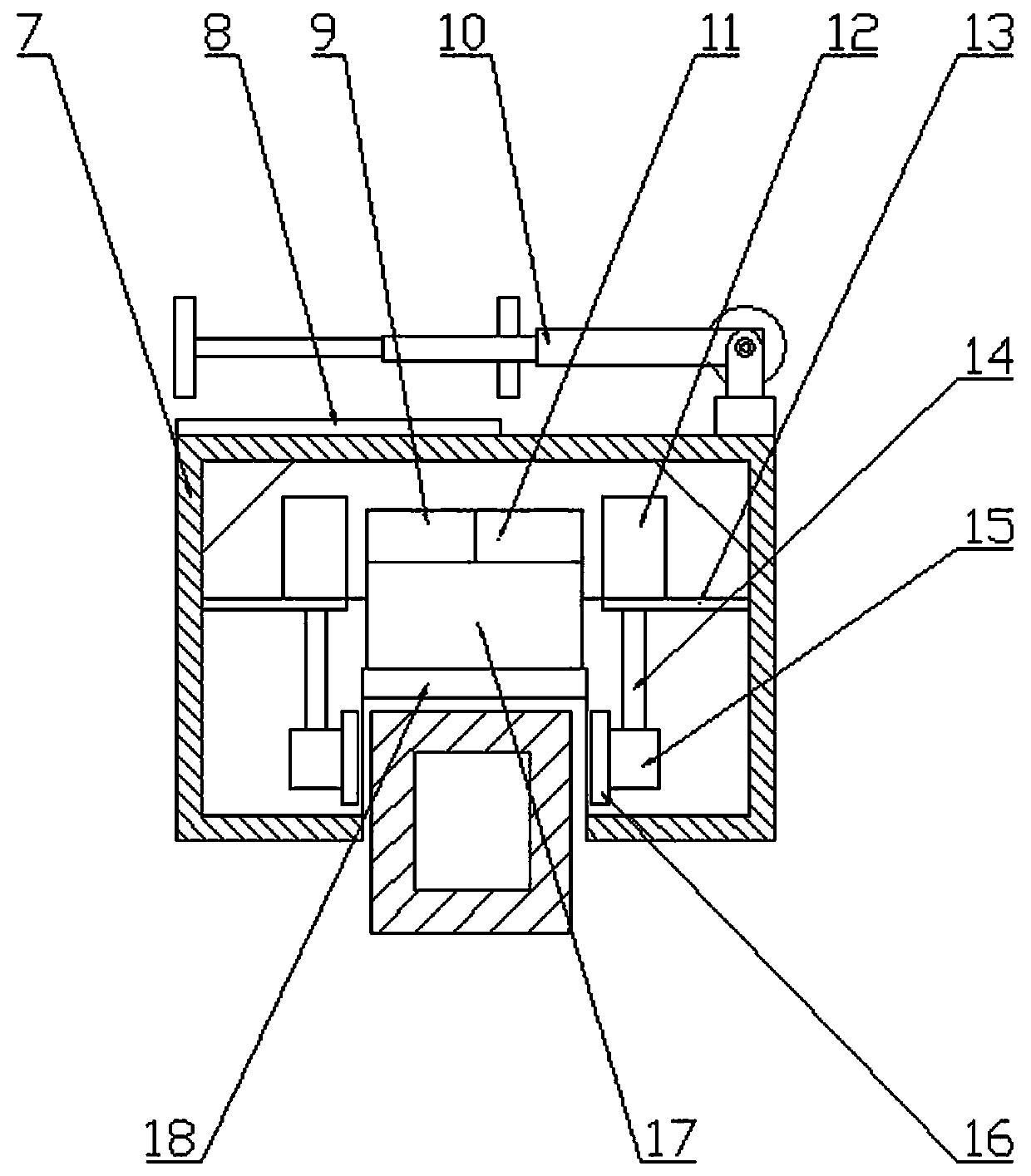

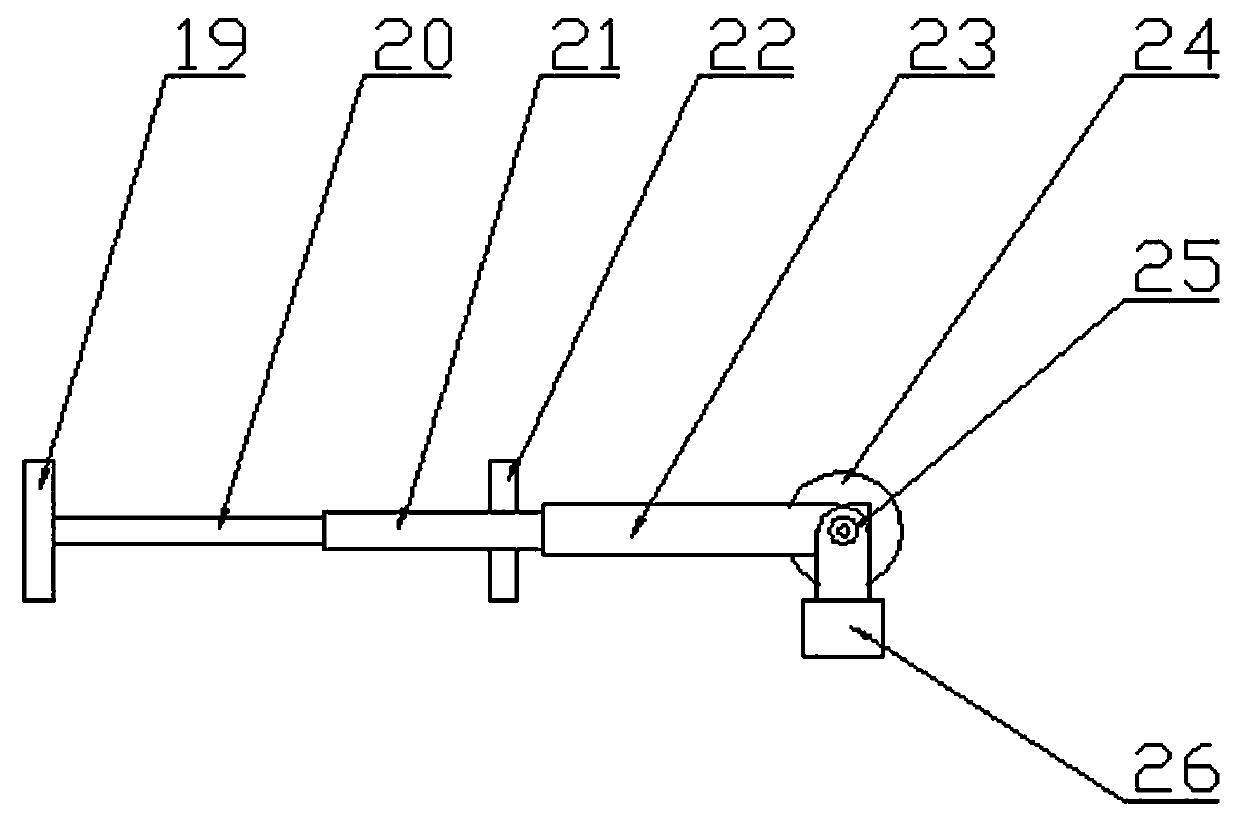

[0030] Example: such as Figure 1-4 As shown, an unmanned logistics vehicle control system with an optimized walking path includes a running track 2, which is provided with two horizontal tracks 5 connected in an arc shape to the running track 2, and the running track 2 and the horizontal track 5 There are two unmanned logistics vehicles 1 on each side, an unloading station 3 on one side of the running track 2, a loading station 6 on the other side of the running track 2, and two horizontal and horizontal Tracks 5 are equally spaced and parallel to the loading stations 4 . The loading station 4 includes a loading shelf 28. The loading shelf 28 is provided with a cargo weight sensor II 30 nestedly connected with the loading shelf 28. One end of the cargo weight sensor II 30 is provided with an infrared emitter fixed with a bolt perpendicular to the end face of the loading shelf 28. 27. The other end of the cargo weight sensor II 30 is provided with an infrared receiver 32 fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com