Mounting structure for sound absorption unit plates of fully-enclosed sound barrier for high speed railway

A technology for high-speed railways and unit panels, applied in noise absorbing devices, buildings, etc., can solve the problems of cumbersome connections, high steel consumption, and easy damage, and achieve simple overall structure, lower utilization rates, and avoid excessive collisions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

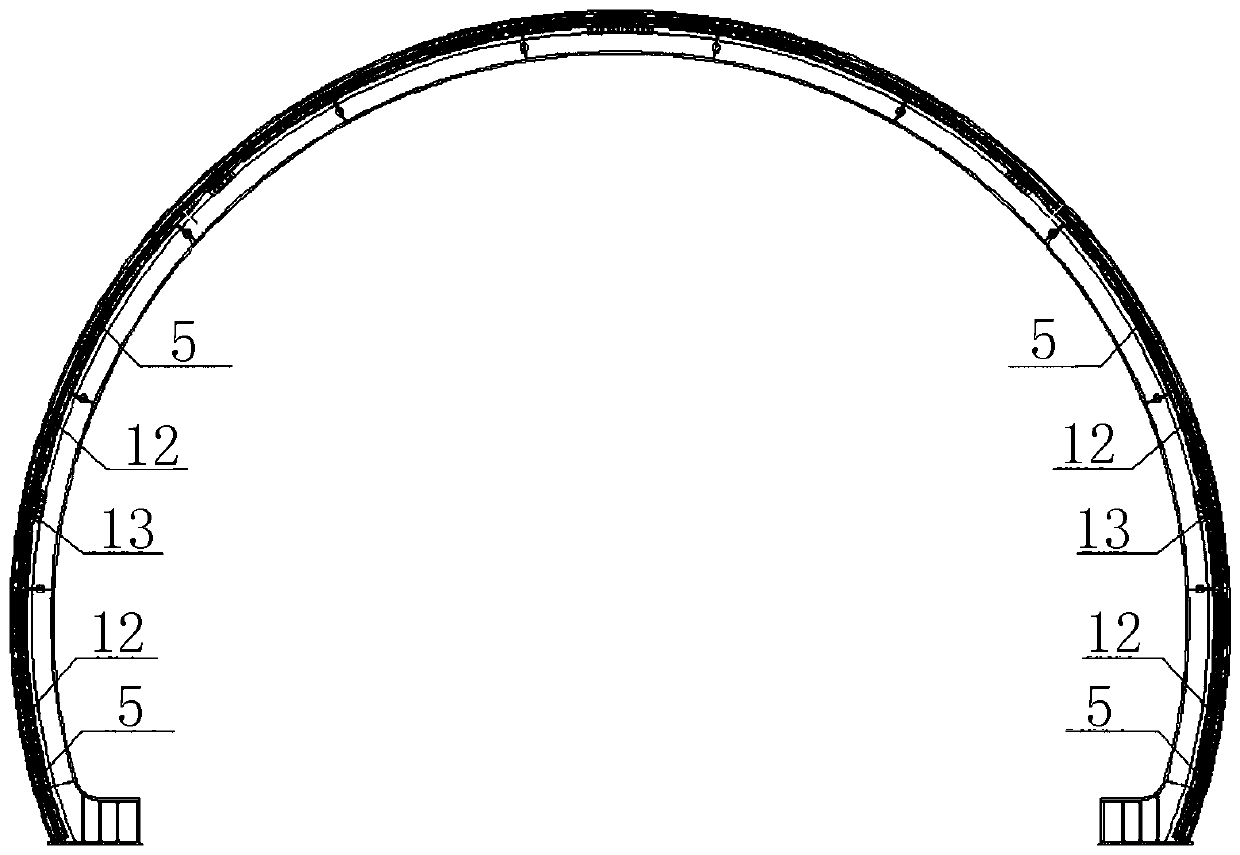

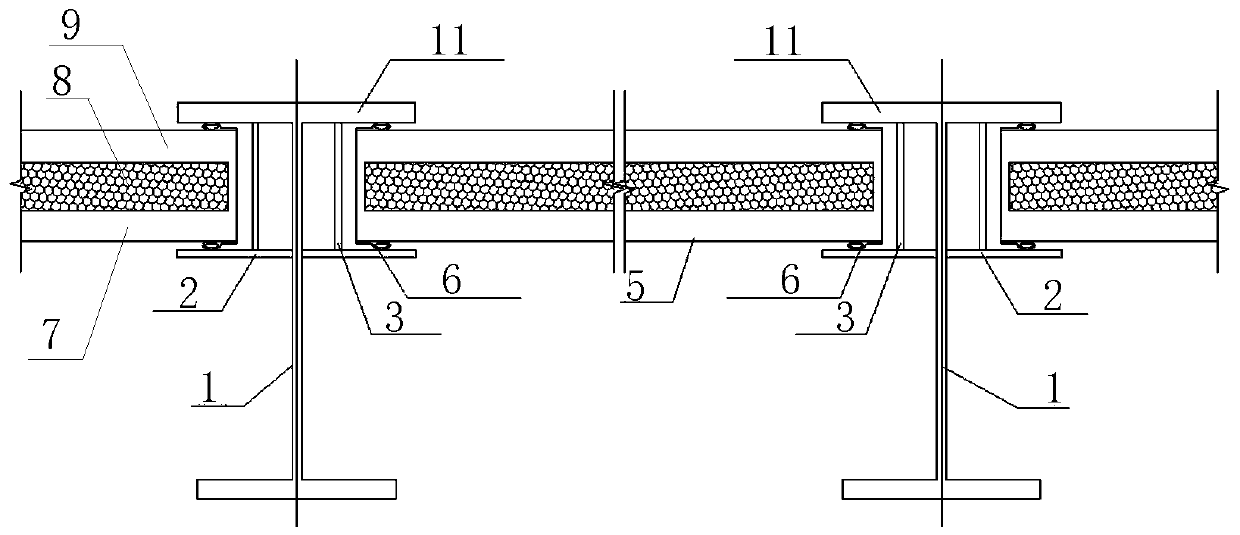

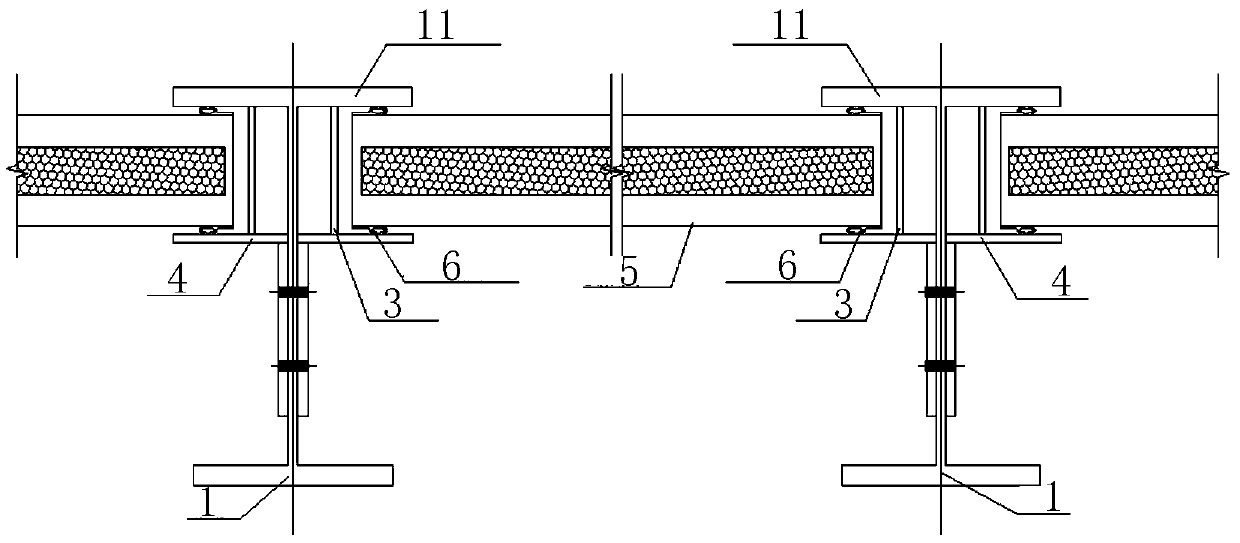

[0028] See attached figure 1 , is a fully enclosed sound barrier project, which is assembled from multiple curved H-shaped steel beams with the same structure (clear span 12.08m, height 9.4m), steel tie rods, double limb angle braces and sound-absorbing unit panels 5 , steel beam 1 has a net span of 12.08m, a sag height of 9.4m, the section height of arc steel beam 1 is 500mm, and the width is 300mm; The 140mm cavity card slot between the edge, the fixed baffle 2 and the limit baffle 3, the sound-absorbing unit plate 5 is inserted into the internode of the steel beam 1 as a whole by using the movable baffle 4 in the neutral position, relying on the EPDM strip 6 The design avoids direct contact between the shell of the sound-absorbing unit plate 5 and the steel beam 1, and it is easy to be damaged due to movement under wind pressure.

[0029] The sound-absorbing unit board 5 is composed of a panel 7, glass wool 8 and a back board 9. The upper and lower ends of the sound-absorb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com