Additional elevator gallery bridge assembly and installing method thereof

A technology of covered bridges and components, applied in elevators, transportation and packaging, building maintenance and other directions in buildings, can solve the problems of waste materials, low work efficiency, long construction period, etc., to facilitate production and transportation, reduce adverse effects, improve The effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

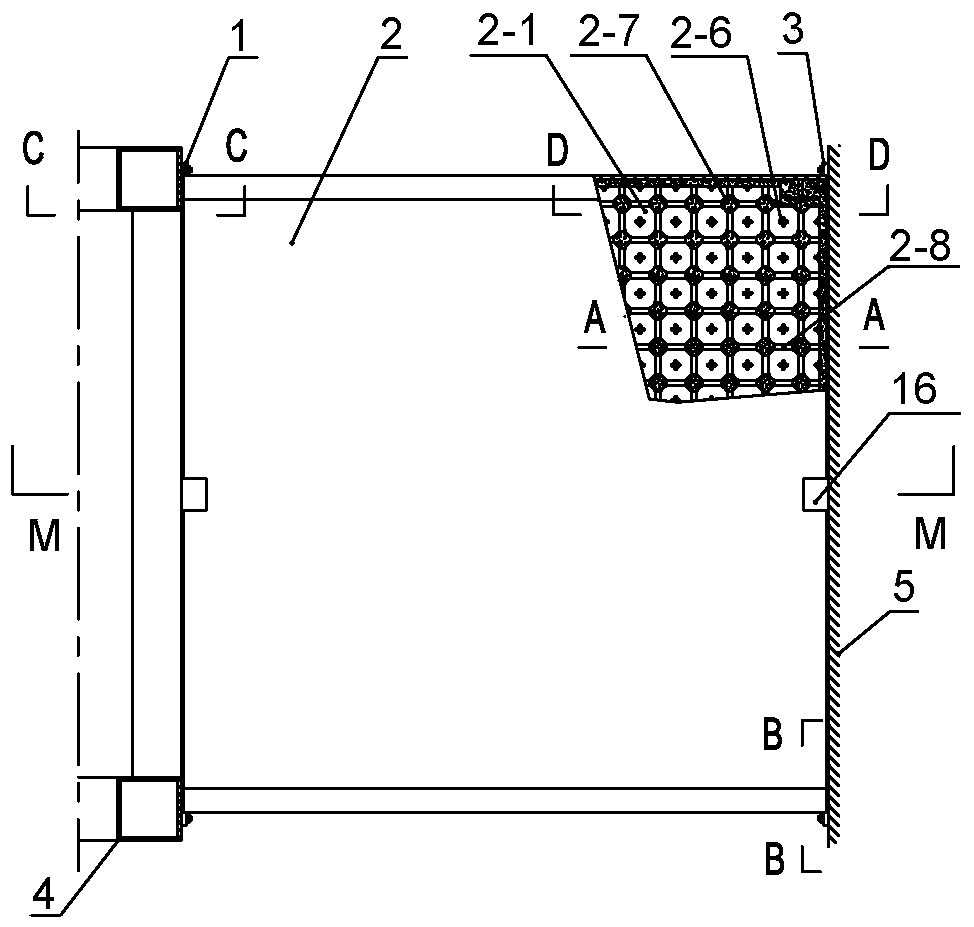

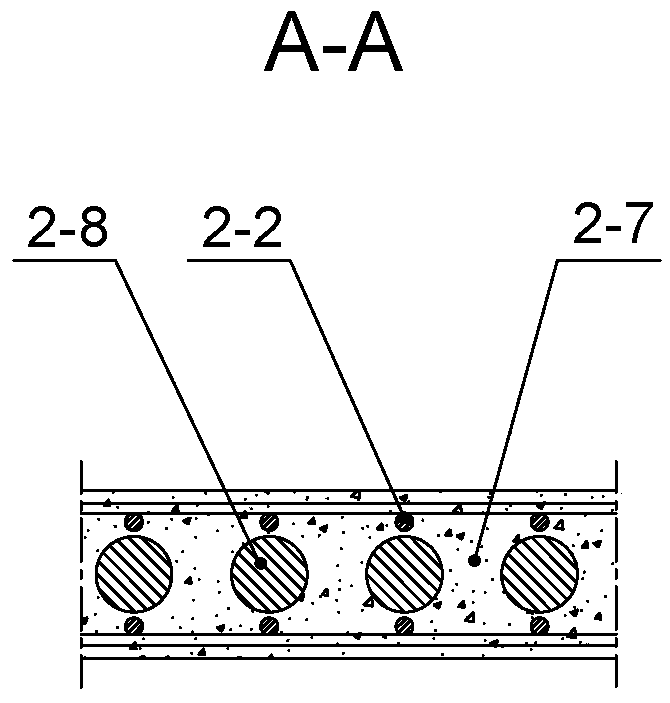

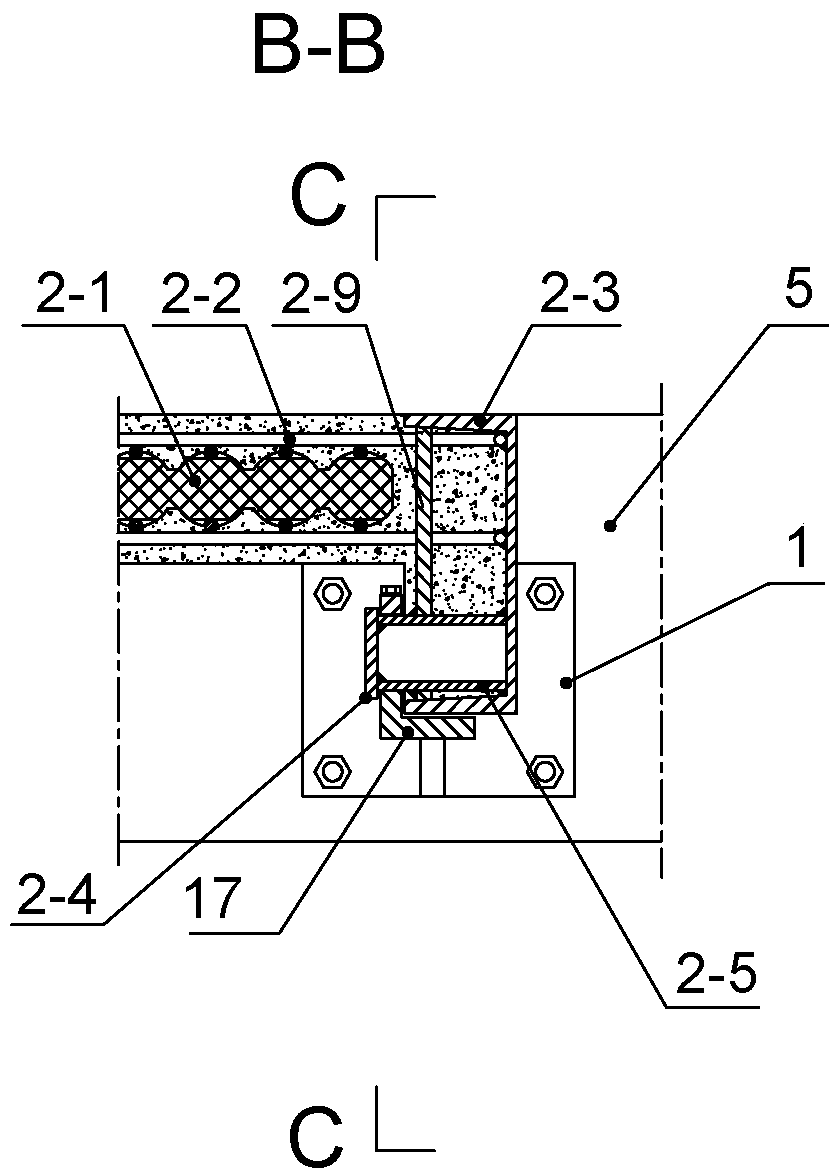

[0039] like Figure 1 to Figure 5 shown.

[0040] An additional elevator corridor bridge assembly includes a shaft support 1, a corridor plate 2, a building support 3 and the like. The corridor slab 2 is a prefabricated reinforced concrete hollow slab, and the two ends of its two sides are respectively provided with load-bearing shafts 2-5; the shaft support 1 is fixed on the elevator shaft 4, and an opening upward The groove I1-1 of the groove I1-1 is provided with a sealing plate I1-2 that matches with it and can close the groove I1-1; the building support 3 is fixed on the building beam 5 of the existing building, and the There is a groove II3-1 with an upward opening, and a sealing plate II3-2 that matches it and can close the groove II is also provided above it; the longitudinal section of the groove I and the longitudinal section of the groove I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com