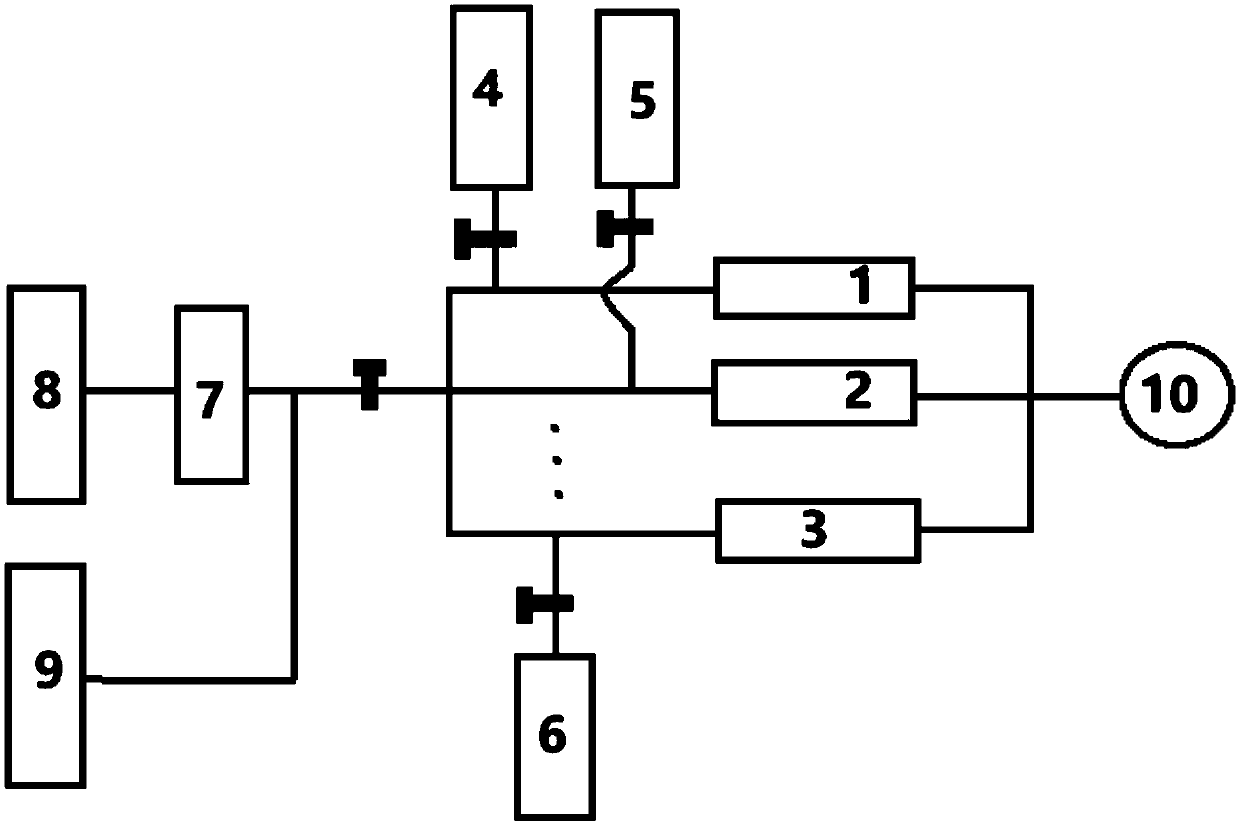

Acid fracturing method of multiple acid injecting systems at deep carbonate rock formation

A technology of carbonate rock and injection system, which is applied in acid fracturing of multiple acid injection systems in deep carbonate rock formations, acid fracturing stimulation operations in deep carbonate rock reservoirs, and can solve the problem of large construction workload and risks To achieve the effect of enhancing the degree of non-uniform etching, increasing the effective production cycle, and improving the conductivity of acid-etched cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0082] (1) Evaluation of key reservoir parameters

[0083] Based on the data of well logging, mud logging and core laboratory testing, etc., the vertical and horizontal distribution characteristics, lithology and whole-rock mineral components, physical properties, rock mechanical parameters and three-dimensional in-situ stress characteristics of the reservoir were evaluated. Cave development characteristics, temperature and pressure.

[0084] (2) Determination of horizontal wellbore trajectory

[0085] Using fine seismic interpretation technology to judge the position of the fracture-cavity system, especially the large-cavity system, and control the wellbore trajectory at the top 50m of each large cave. The length of the drilled horizontal wellbore is 850m.

[0086] (3) Determination of completion mode and partial pressure mode

[0087] Open hole completion and open hole sliding sleeve staged fracturing are adopted.

[0088] (4) Establishment of oil and gas reservoir geolo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com