Making process of image-transmitting soft fiber tow

A manufacturing method and image transmission beam technology, which is applied in the direction of optical fiber bundles, can solve the problems of difficult manufacturing and easy broken wires, and achieve the effects of reducing the broken wire rate, improving resolution, and increasing light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] In this embodiment, 271 (the specific number should be selected according to the cross-sectional size and resolution of the image beam, but at least 90) whose outer surface is 0.8mm in diameter is soluble glass, the middle is low refractive index glass, and the inner core is high Refractive index glass, a single fiber material with a length of 500mm is arranged into a composite fiber rod with a regular hexagonal cross-section, which is bound and bound; the above composite fiber rod is drawn into a composite fiber filament with a diameter of 0.8mm by a wire drawing machine; the above drawn The formed composite fiber filaments of the same specification are arranged into a composite fiber rod with a diameter of 25 mm; the two ends of the composite fiber rod are partially fused at high temperature to form a cone; the two ends of the composite fiber rod are protected with acid-resistant rubber, and the middle The unfused composite fiber rods were placed in 10% HNO by weight ...

Embodiment 2

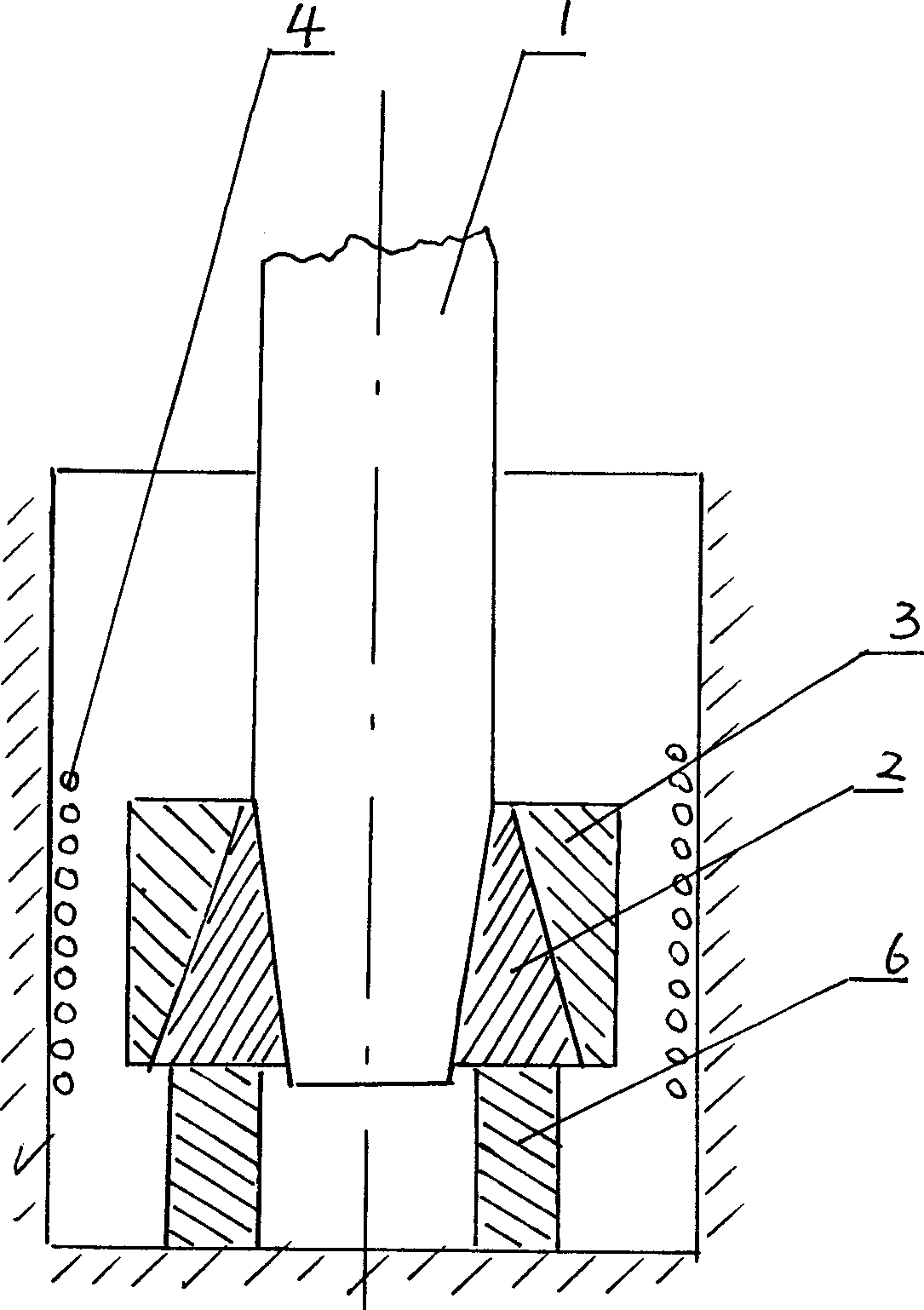

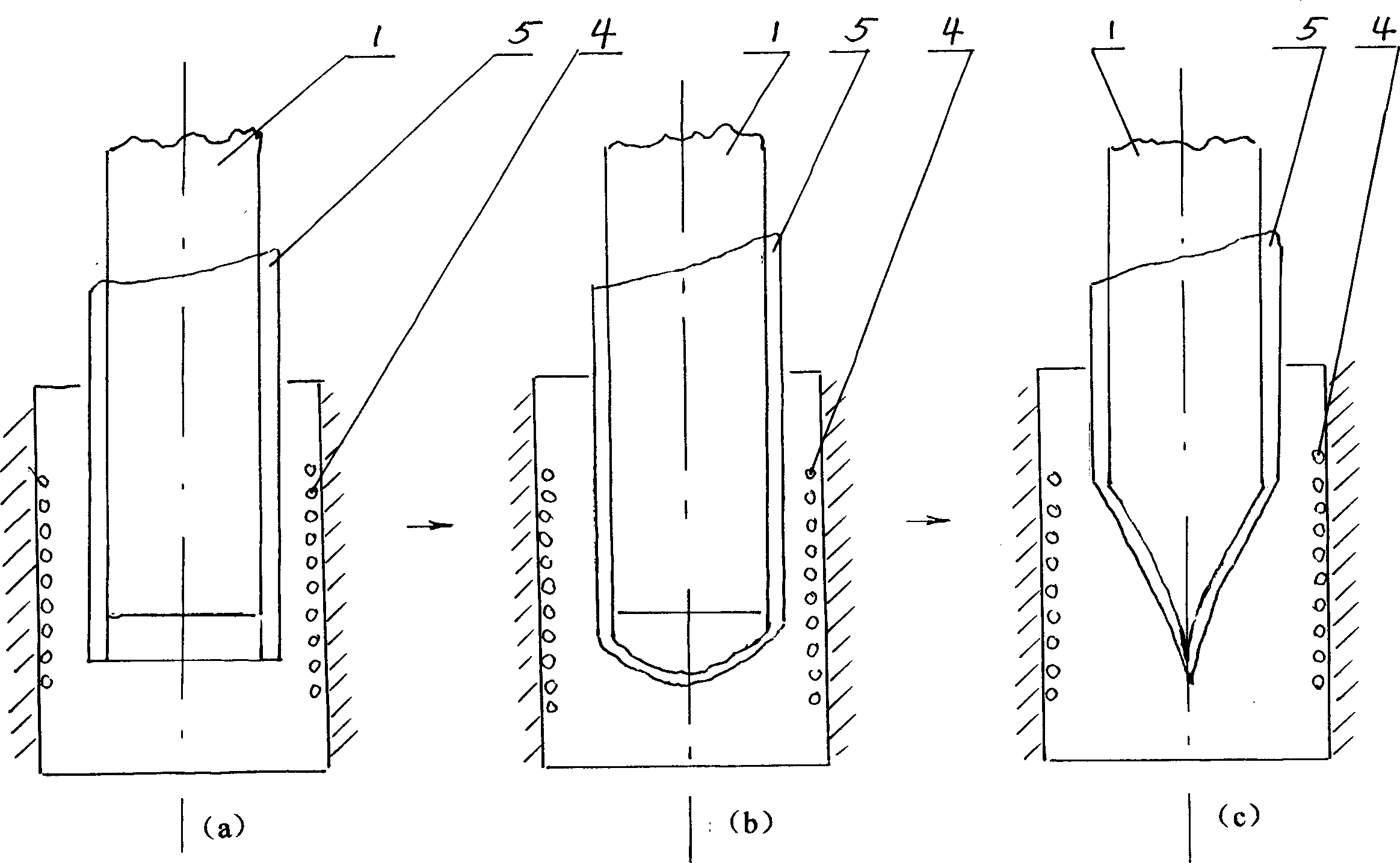

[0020] The method of locally fusing the two ends of the composite fiber rod at high temperature to form a cone as described in Example 1 can use figure 1 As shown, the end of the composite fiber rod 1 is placed in the heating furnace 4 , the end of the composite fiber rod 1 is covered with a briquetting block 2 and a pressure ring 3 , and a pad 6 is provided under the briquetting block 2 . During processing, the end of the composite fiber rod 1 and the briquetting block 2 are locally heated, and then the pressure ring 3 tightens the briquetting block 2 placed on the pad 6 by adding force, so that the end of the composite fiber rod 1 Form a cone, then cool down slowly to relieve stress.

Embodiment 3

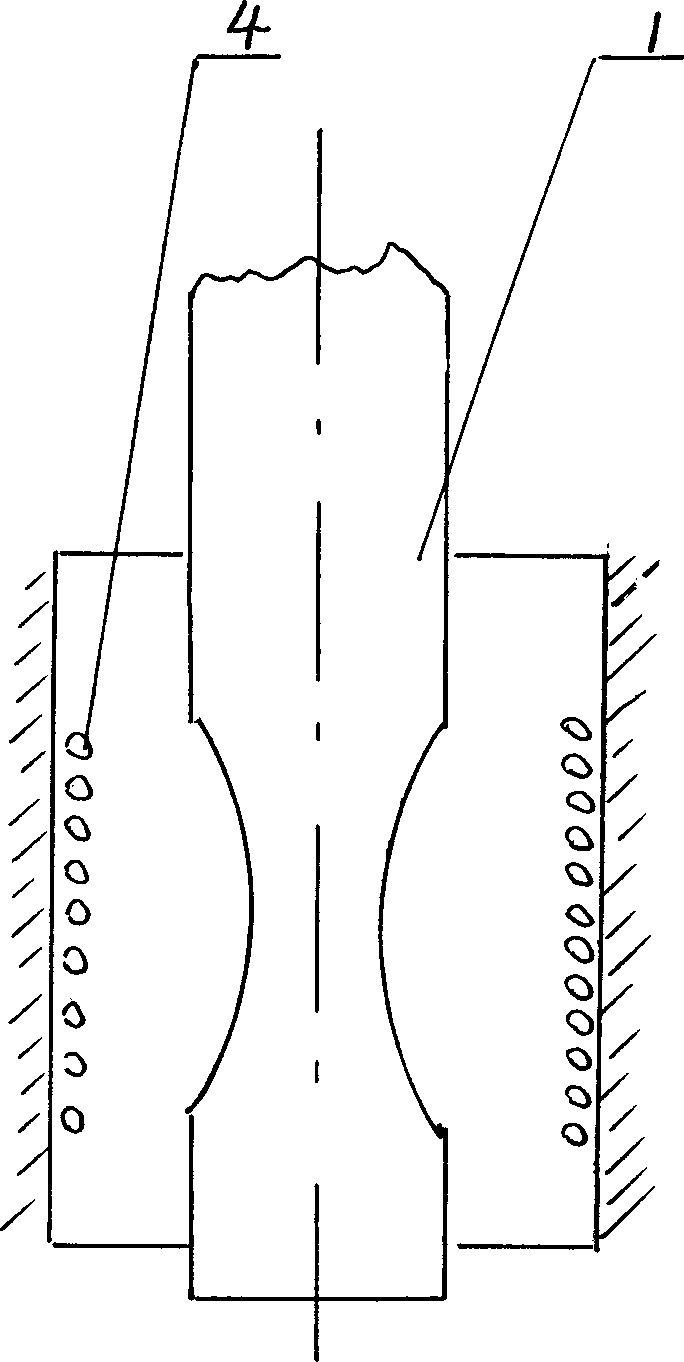

[0022] The method of locally fusing the two ends of the composite fiber rod at high temperature to form a cone as described in Example 1 can use figure 2 As shown, the end of the composite fiber rod 1 passes through the center of the hearth of the heating furnace 4 to start heating. When the temperature is higher than the softening temperature of the fiber (about 20-50°C), the fiber filament begins to soften, and the end of the composite fiber rod Under the action of gravity, the end of the composite fiber rod in the high temperature section is elongated to form a cone, and then the temperature is slowly lowered to eliminate the stress.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com