Method of improving reliability of flash memory

A memory and reliability technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of semiconductor wafer 10 over-polishing, good rate decline, high cost, etc., to improve random bit failures and improve product reliability The effect of sex and process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

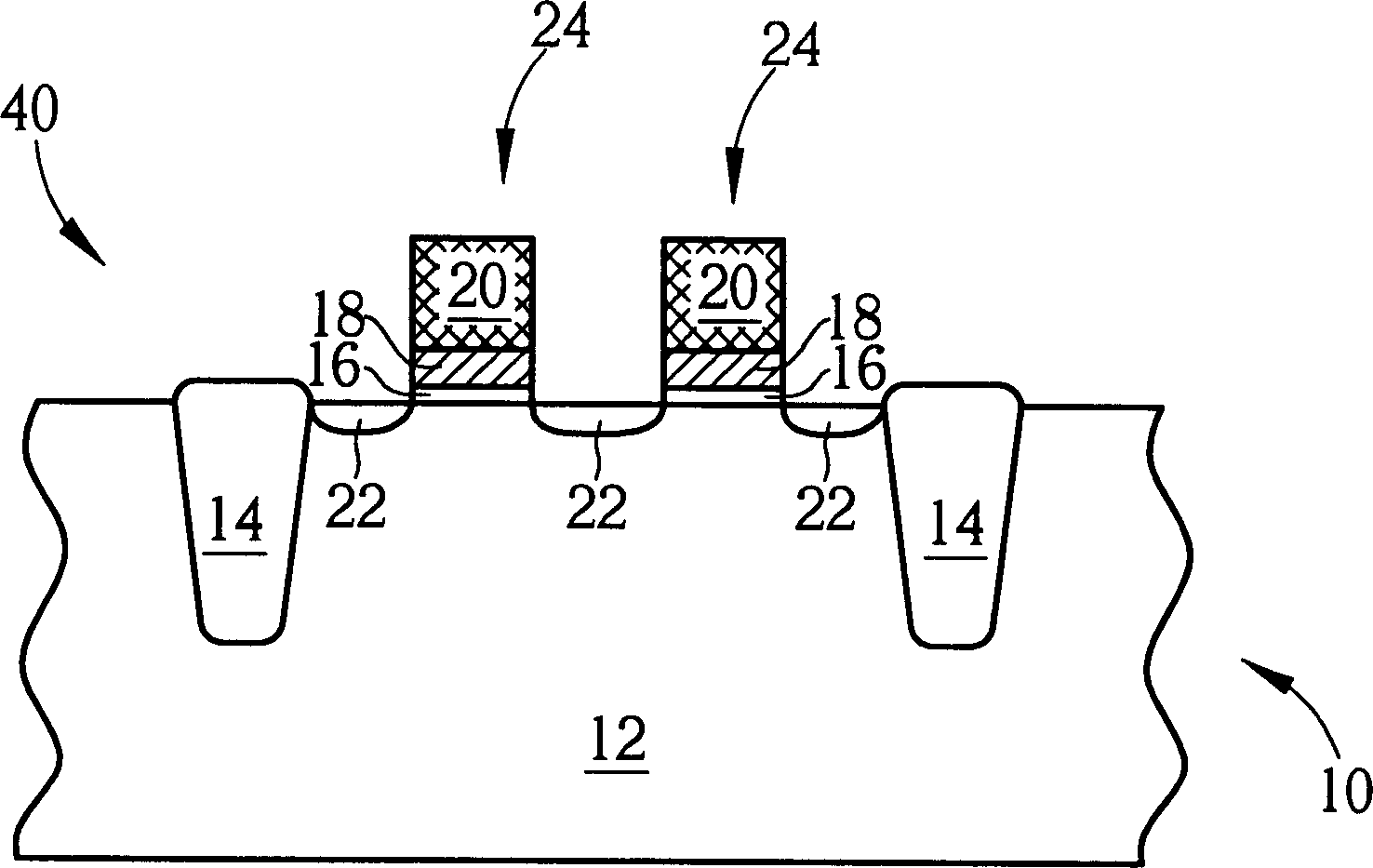

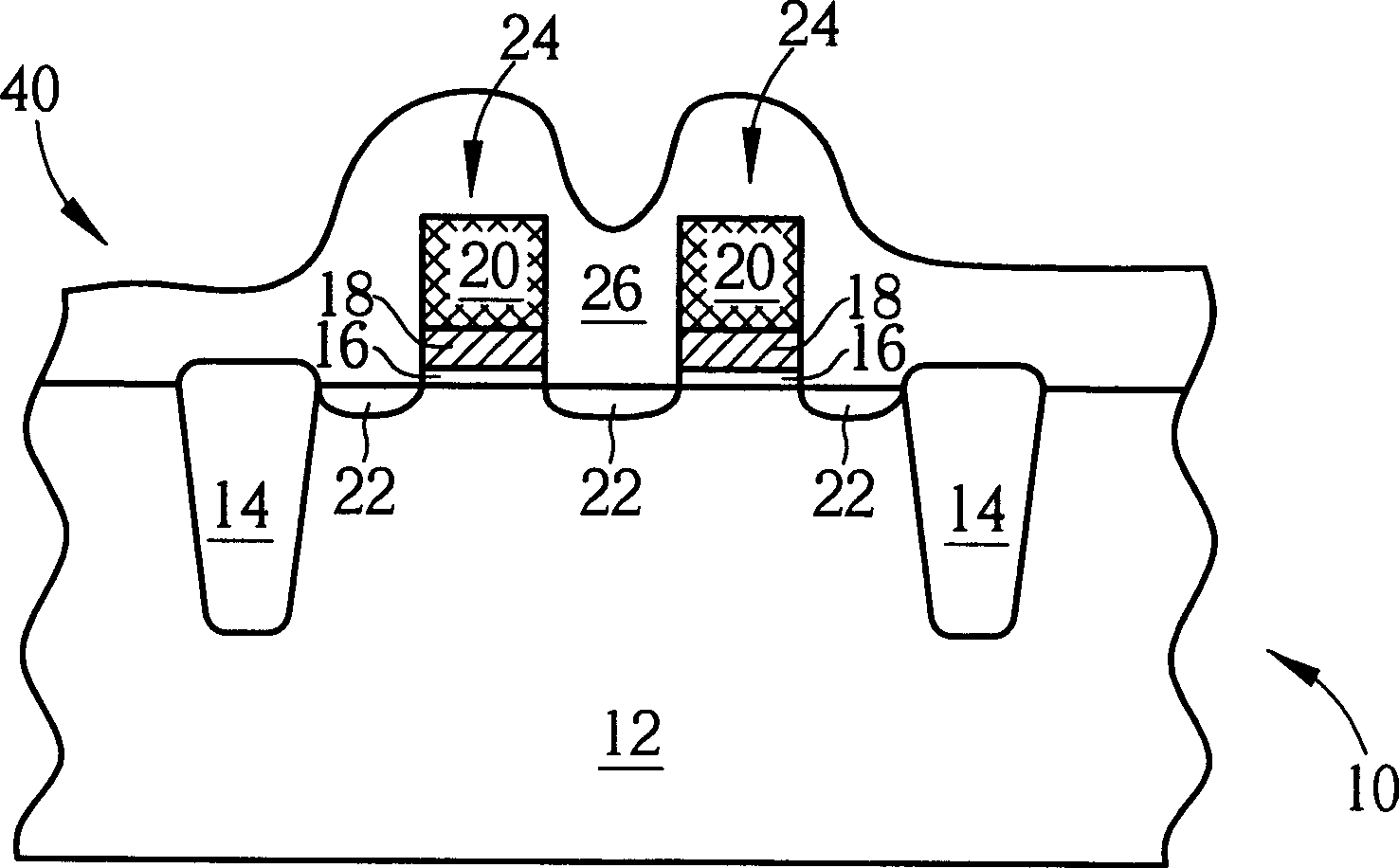

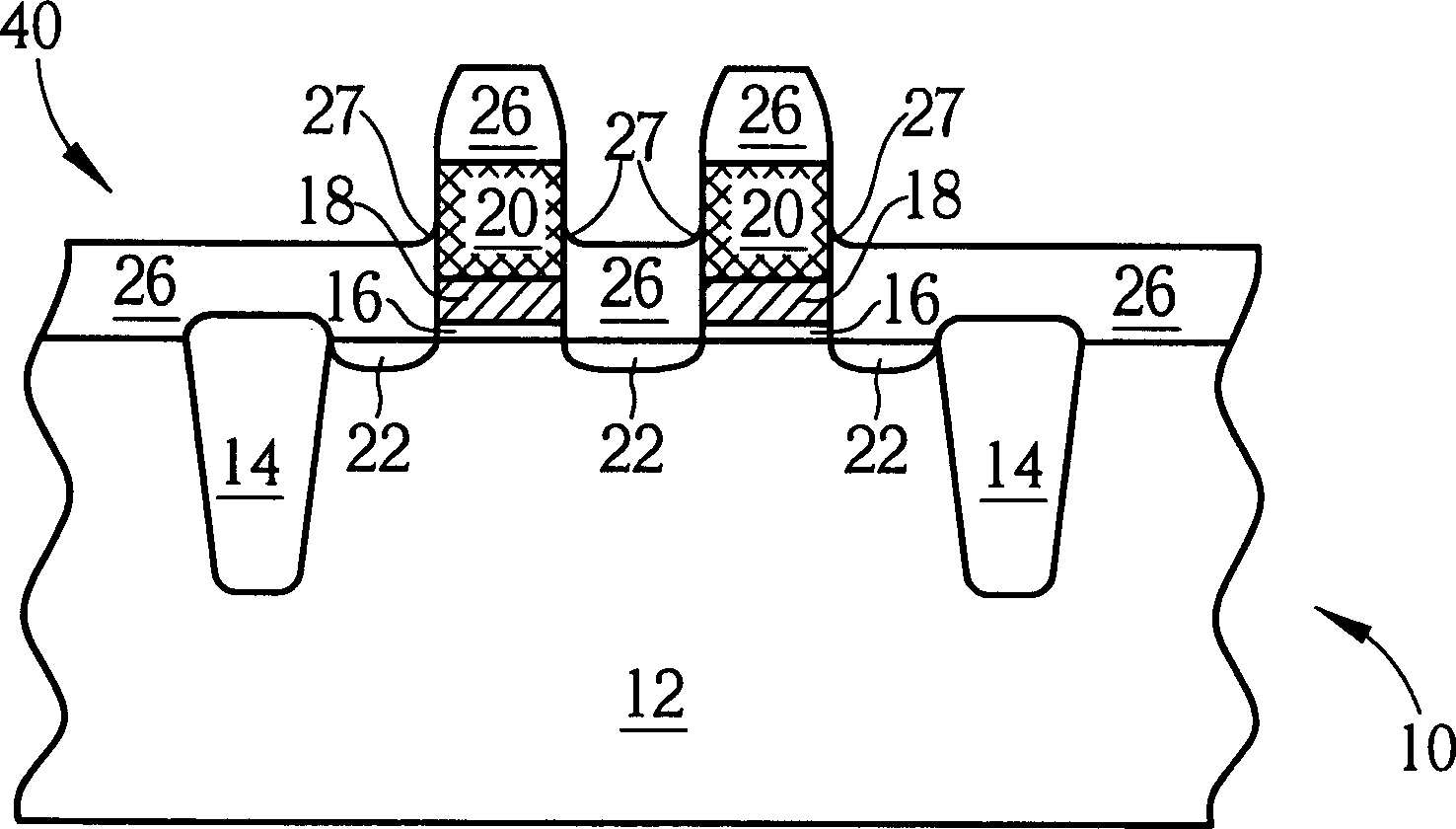

[0033] Please refer to Figure 8 to Figure 12 , Figure 8 to Figure 12 It is a schematic cross-sectional view of fabricating a high-reliability flash memory unit in a preferred embodiment of the method of the present invention. For the convenience of describing the present invention, Figure 8 to Figure 12 Only a part of the flash memory area relevant to the method of the present invention is shown. In the preferred embodiment of the method of the present invention, a dual-bit flash memory unit 110 is taken as an example for illustration. First, if Figure 8As shown, the semiconductor wafer 80 includes a silicon substrate 82, an active area (active area) isolated by a shallow trench isolation (shallow trench isolation, STI) region 84 is provided on the silicon substrate 82, and two gates Structure 94 is provided in the active area. The gate structure 94 has a gate oxide layer or tunnel oxide layer 86 on the surface of the silicon substrate 82, a polysilicon layer or PL1 l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com