Long-stroke lead screw movable auxiliary supporting mechanism

A technology of auxiliary support and support mechanism, which is applied in the direction of mechanical equipment, transmission devices, belts/chains/gears, etc., and can solve problems such as the inability of the nut to move and the inability to use long screw supports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

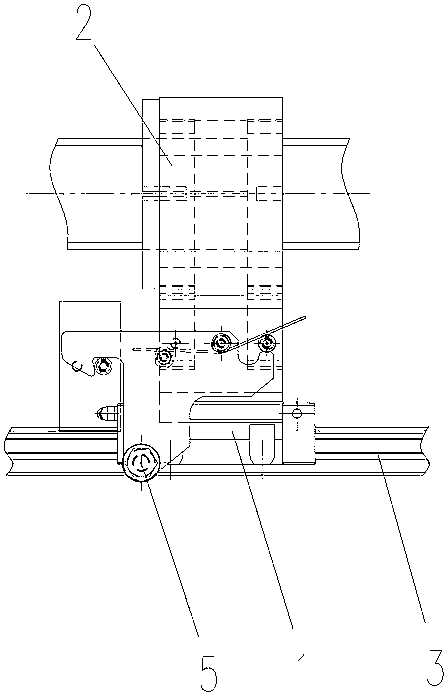

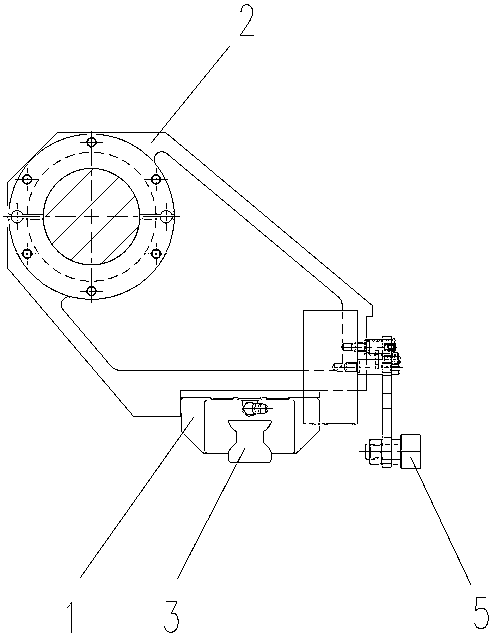

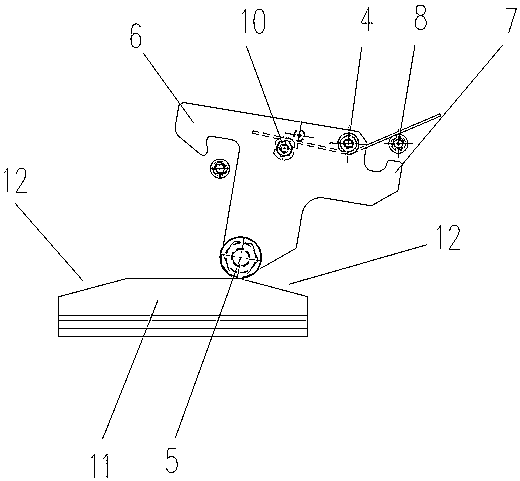

[0014] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as figure 1 , figure 2 , image 3 , Figure 4 Shown: a long-stroke lead screw movable auxiliary support mechanism, which includes a sliding seat 1, a lead screw support sleeve 2 is fixedly connected above the slide seat 1, and the side of the lead screw support sleeve 2 is also provided with a connection decoupling mechanism, the sliding seat 1 is slidably connected to the slide rail 3,

[0015] The connection and decoupling mechanism is connected to the lead screw support sleeve 2 through the rotation of the rotating shaft 4, the bottom of which is provided with a roller 5, one end of the top of the connection and decoupling mechanism is provided with a connection hook 6, and the other end is provided with a limit portion 7, and the connection hook One side of 6 is provided with a connecting hook slope, the rotating shaft 4 is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com