Transverse blind test scanning device for leakage of fuel gas buried pipeline

A scanning device, buried technology, applied to the measuring device, by detecting the appearance of fluid at the leakage point, the direction of the pipeline system, etc., it can solve the problems of non-adjustable laser emission angle, inability to detect sidewalks, small detection range, etc., to improve detection The effect of range and detection efficiency, avoiding inflexible blind detection methods, and reducing the risk of casualties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

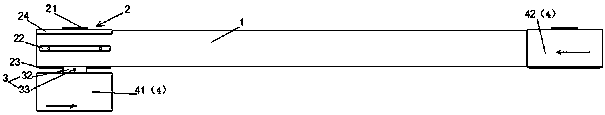

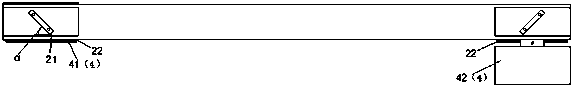

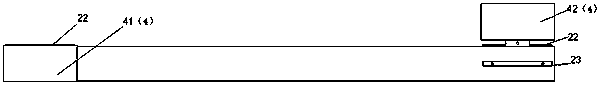

[0052] Example 1: See Figure 1-7 The shown horizontal blind detection and scanning device for buried gas pipeline leakage includes a bracket 1 and a laser detector body 4, the laser detector body 4 is arranged on both sides of the bracket 1, the bracket 1 is a round aluminum tube bracket, and the laser detector body 4 Including laser detector body one 41 and laser detector body two 42, the angle between laser detector body one 41 and bracket 1 is 0-45 degrees, and the angle between laser detector body two 42 and bracket 1 is 0-45 degrees The bracket 1 and the laser telemeter body 4 are connected through a quick release clamp assembly 3 . The bracket 1 is used to connect the laser detector body 4, and the laser detector body 4 is controlled below 50cm from the ground. Laser detection can be emitted in one direction or left and right, and the horizontal angle of laser emission can be adjusted. Only one set of laser detector body and the aluminum tube of the bracket form an ang...

Embodiment 2

[0072]Embodiment 2: A horizontal blind detection and scanning device for buried gas pipeline leakage, including a bracket 1 and a laser telemeter body 4, including a bracket 1 and a laser detector body 4, and a laser detector body 4 and a bracket 1 are arranged on both sides of the bracket 1 It is a circular aluminum tube bracket, and the laser detector body 4 includes a laser detector body 1 41 and a laser detector body 2 42, the angle between the laser detector body 1 41 and the bracket 1 is 0-45 degrees, and the laser detector body 2 The angle between 42 and the bracket 1 is 0-45 degrees, the bracket 1 and the laser telemeter body 4 are connected through the ball table assembly 5, preferably the bottom of the bracket 1 is fixedly connected with the lower aluminum alloy connector 50, and the lower aluminum alloy connector 50 The cross-section is "Π", the lower aluminum alloy connector 50 is consistent with the structure of the aluminum alloy connector 24, the billiard table a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com