Combustion detecting method and device and cooking equipment

A detection method and technology of a detection device are applied in the fields of cooking equipment, combustion detection method and device, which can solve the problems of inaccurate detection results, high solution cost, slow response speed, etc., and achieve good judgment effect, long service life and low price. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The combustion detection method and device of the present invention are mainly used in cooking equipment, especially for cooking equipment such as microwave ovens and steam ovens. However, the inventive concept of the present invention is not limited to these cooking equipment, and can also be used in other cooking equipment. In equipment, it is used to detect whether there is a burning phenomenon. The microwave oven is used as an example below.

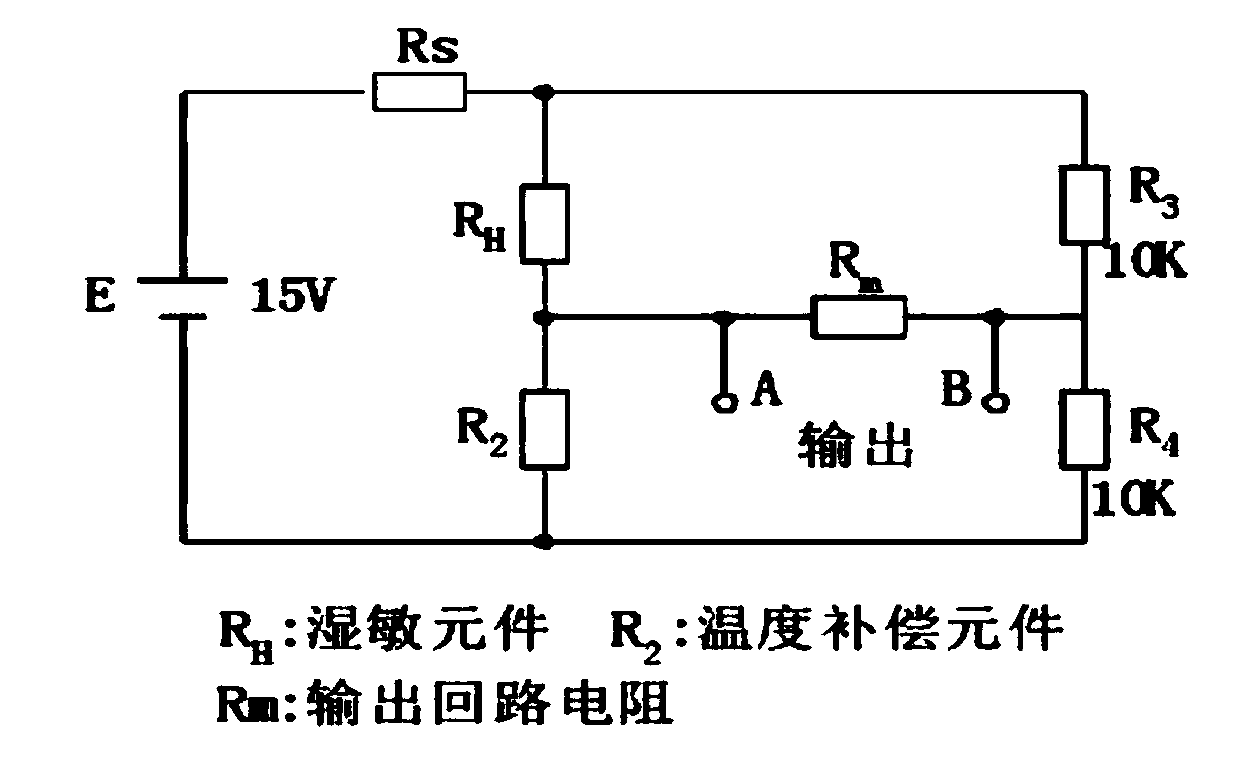

[0033] At present, the humidity sensor used in microwave ovens is a thermistor absolute humidity sensor. The sensor is composed of two thermistors, one of which is sealed in a closed environment of dry air as a compensation resistor R 2 , another openness as the humidity sensing resistor R H , constituted as figure 1 As shown in the bridge, since the thermal conductivity of water vapor is greater than that of air, the thermal conductivity of air changes with humidity, which causes the impedance of the humidity sensing elemen...

Embodiment 2

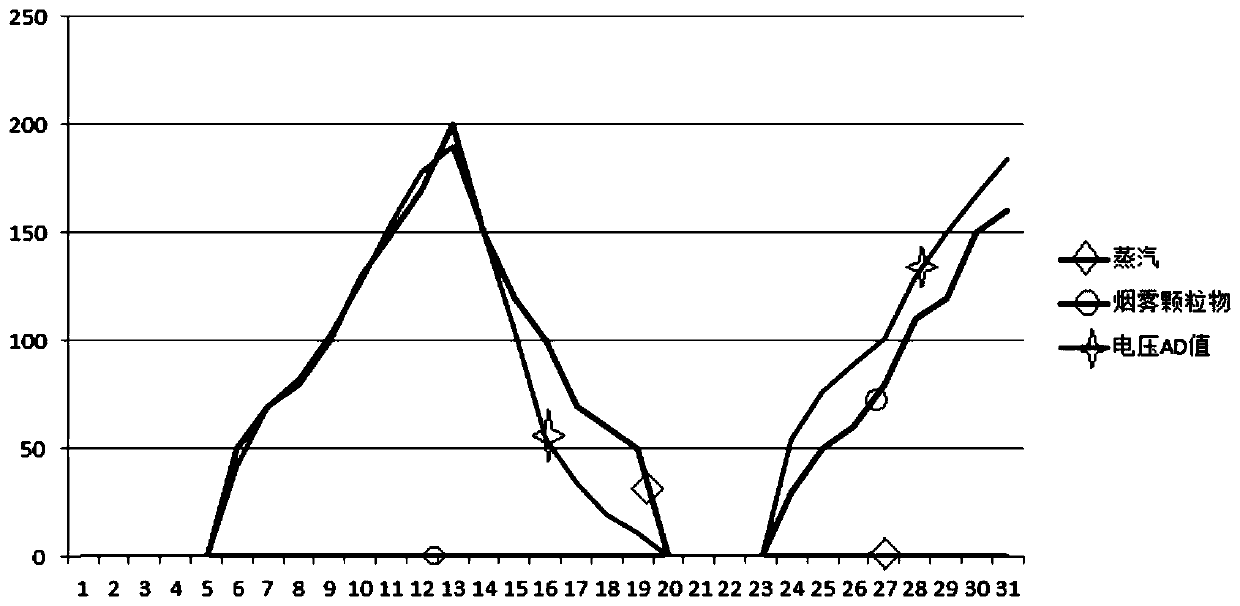

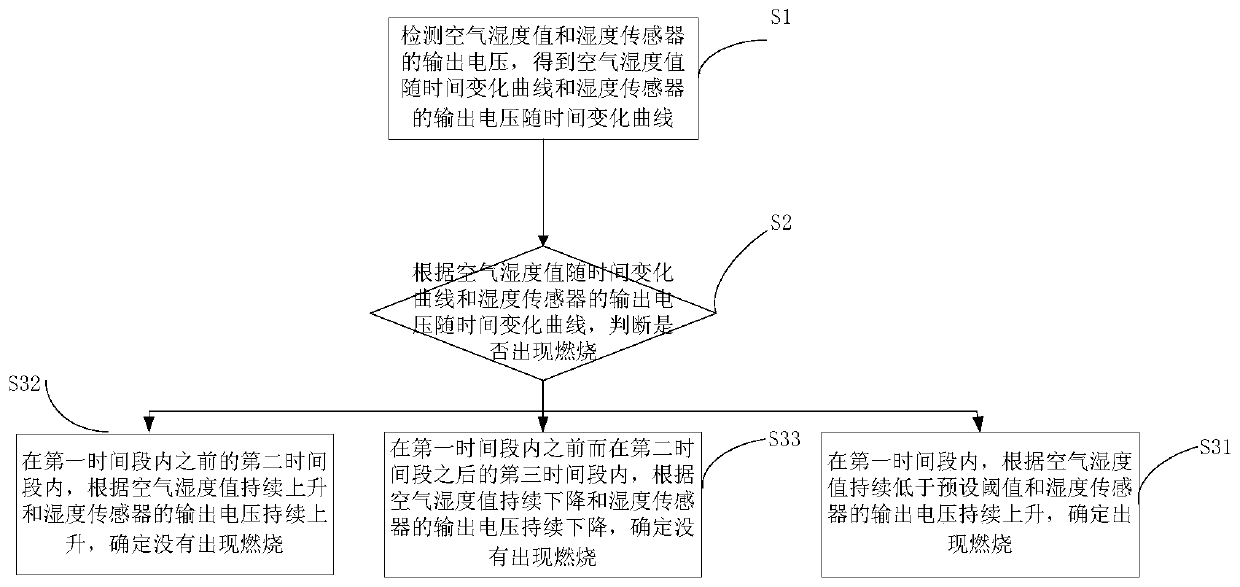

[0040] Such as image 3 As shown, this embodiment relates to a combustion detection method for cooking equipment, preferably for microwave ovens, comprising the following steps:

[0041] S1. Detect the air humidity value and the output voltage of the humidity sensor, and obtain the curve of the air humidity value versus time and the output voltage of the humidity sensor versus time; the humidity sensor is a thermistor absolute humidity sensor, including a compensation resistor and a humidity sensor resistance. The output voltage of the humidity sensor is the voltage value at both ends of the output loop resistance of the humidity sensor.

[0042] S2. According to the time-varying curve of the air humidity value and the time-varying curve of the output voltage of the humidity sensor, determine whether combustion occurs. According to the different situations of the two curves, it can be judged whether there is combustion. Here are three possible scenarios:

[0043] S31. Duri...

Embodiment 3

[0048] Such as Figure 4 As shown, the present embodiment relates to a combustion detection device 100 for cooking equipment, preferably for a microwave oven, comprising:

[0049] The detection module 101 is used to detect the air humidity value and the output voltage of the humidity sensor, and obtain the air humidity value versus time curve and the output voltage of the humidity sensor versus time; the humidity sensor is a thermistor absolute humidity sensor, including a compensation resistor and a moisture sensing resistor. The output voltage of the humidity sensor is the voltage value at both ends of the output loop resistance of the humidity sensor.

[0050] The judging module 102 is configured to judge whether combustion occurs according to the time-varying curve of the air humidity value and the time-varying curve of the output voltage of the humidity sensor.

[0051] During the first time period, according to the fact that the air humidity value is continuously lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com