Electromagnetic gun with segmented combination between guide rail and rifling

A technology of electromagnetic guns and guide rails, applied in the field of electromagnetic guns, can solve problems such as the inability to guarantee the flight stability and lethality of projectiles, and achieve the effects of increasing damage capabilities, increasing the range of projectiles, and avoiding the landing of projectile tails

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

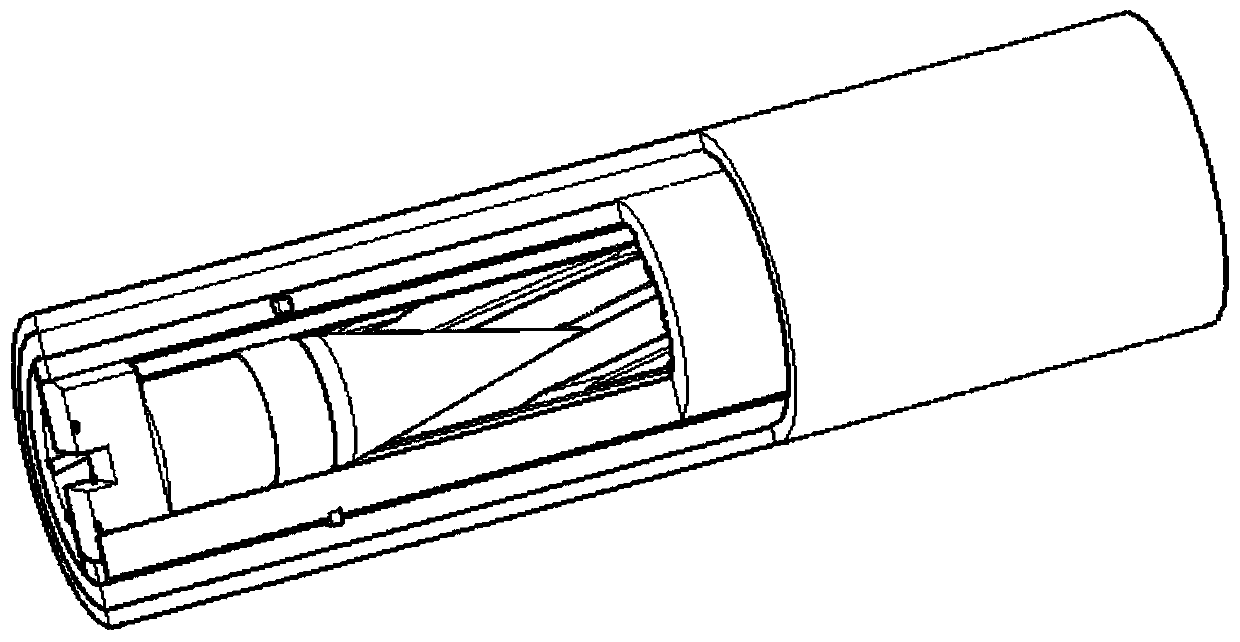

[0038] Such as Figure 1-10 As shown, a new structure of the railgun barrel enables the projectile to obtain rotational acceleration while obtaining linear acceleration in the bore, so that the projectile obtains greater rotational stability after being ejected from the muzzle, and increases the hit rate and damage capability of the projectile. The components of the structure mainly include the first rifled bore 3, the second rifled bore 4, the first electromagnetic guide rail 5, the second electromagnetic guide rail 6, the first insulating strip 9, the second insulating strip 10, the third insulating strip 11, the fourth Insulating strip 12, C-shaped shell stabilizing armature 8, bullet belt shell 7, stainless steel body tube 1, epoxy resin casting pre-tightening body, left front upper lock shaft, right front upper lock shaft, left rear upper lock shaft, right rear upper lock Shaft, Left Front Bottom Lock, Right Front Bottom Lock, Left Rear Bottom Lock, Right Rear Bottom Lock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com