Track fastener fastener looseness detection method adopting depth image

A depth image and track fastener technology, applied in image enhancement, image analysis, image data processing, etc., can solve the problems of poor precision, limited scope of application, low efficiency, etc., and achieve the goal of improving reliability and reducing the accuracy of depth measurement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

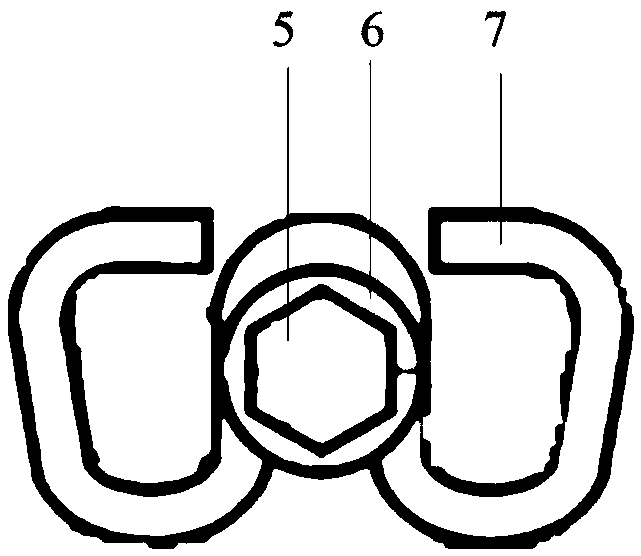

[0053] This embodiment takes image 3 The illustrated hexagonal bolt is used as an example for explanation.

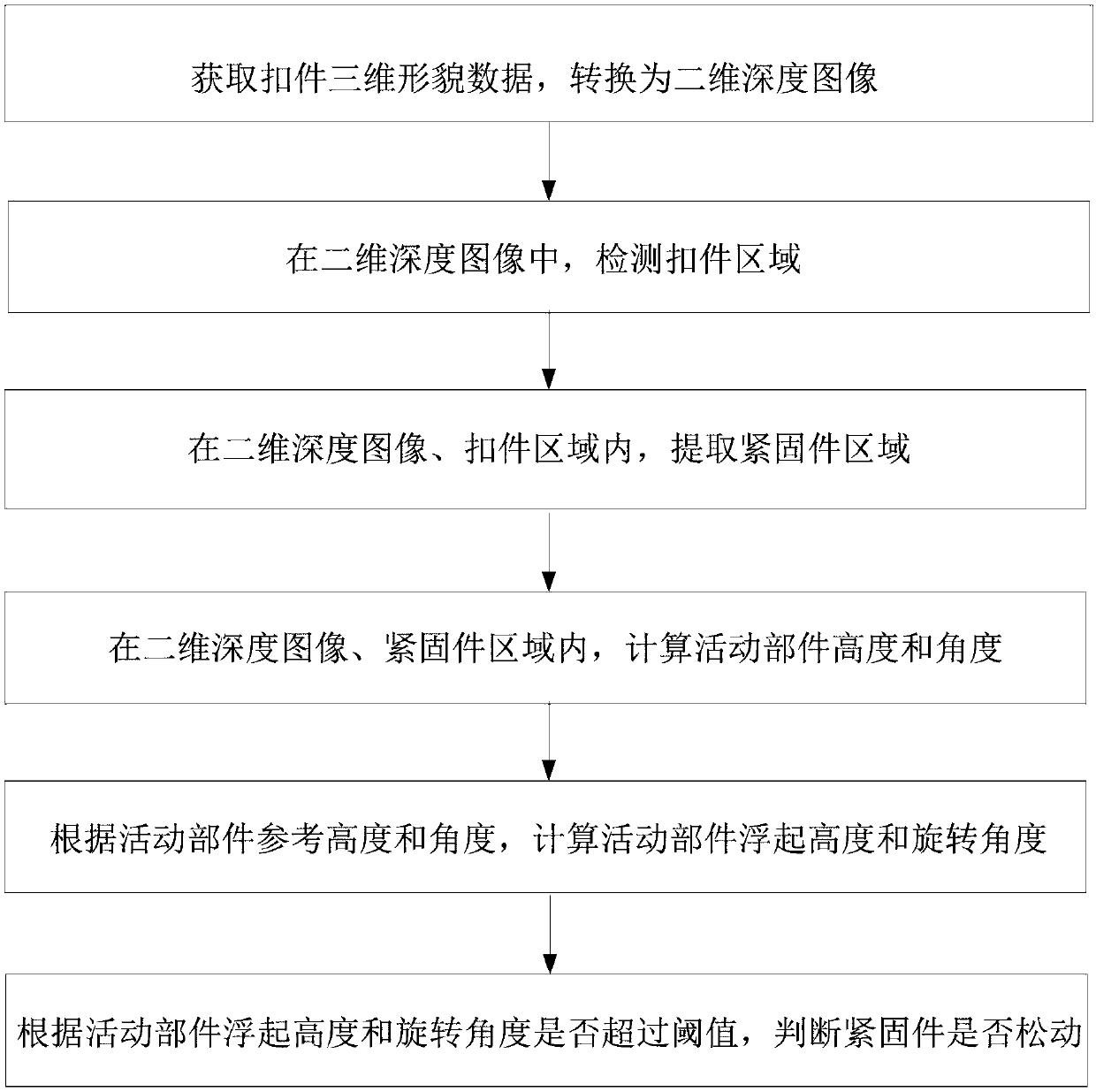

[0054] Step 1: Use the 3D imaging system to obtain the 3D shape data of the rail fastener, and use the track plane as the horizontal reference plane to convert the 3D shape data into a 2D depth image.

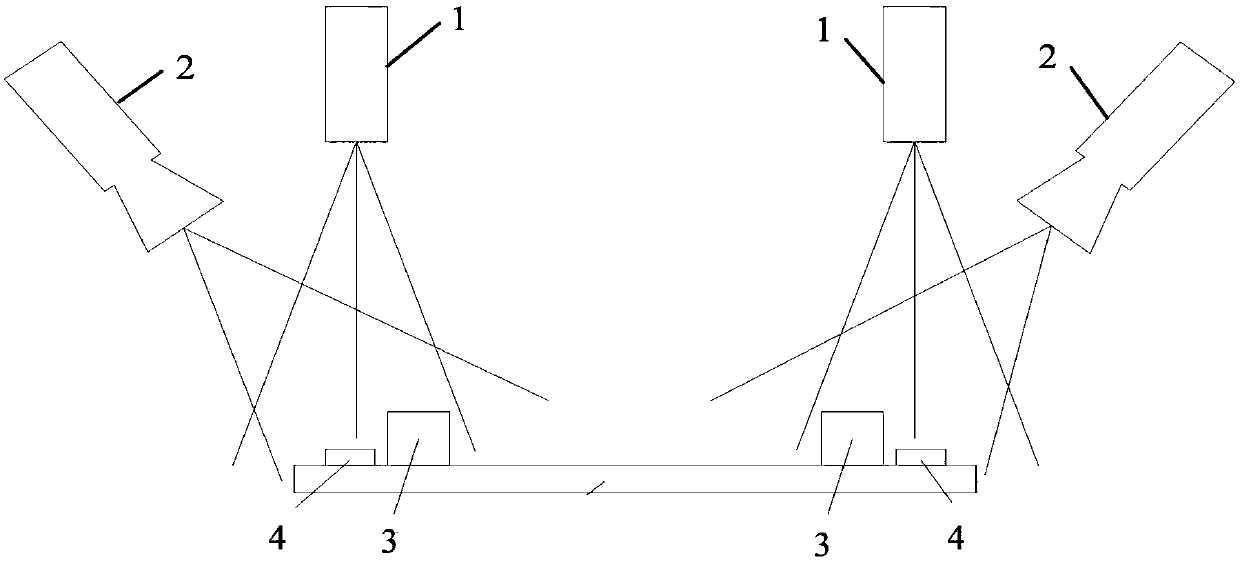

[0055] use figure 2 The shown line structured light scanning 3D imaging system acquires 3D shape data of rail fasteners. Such as figure 2 As shown, the line-structured light scanning 3D imaging system includes a line-structured light projector 1 and an area array camera 2, the positions and angles of the line-structured light projector 1 and the area array camera 2 remain fixed, and the line-structured light projector 1 generates a line structure The light sheet light is projected onto the fastener 4 perpendicular to the rail 3, forming a section profile on the surface of the fastener 4, and the section profile is photographed by the area array camera 2, and the di...

Embodiment 2

[0068] The difference from Embodiment 1 is that in step a-4-2, the average or median value of the depth image pixels in the region R is calculated, or the regular polygon is fitted to the non-zero elements in the region R, and the regular polygon or the regular polygon is extracted. The mean or median value of the depth image pixels within the area of the inscribed circle of the polygon, as the bolt height h′ c , the regular polygon is a regular hexagon.

Embodiment 3

[0070] The difference from Example 1 is that for Figure 4 The quadrilateral bolts shown are processed, and the regular polygon is a square.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com