Feeding auxiliary system for panel cutting and method thereof

An auxiliary system and plate technology, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of time-consuming and labor-intensive, reducing work efficiency, etc., and achieve the effect of improving feeding efficiency, reducing manpower and material resources, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

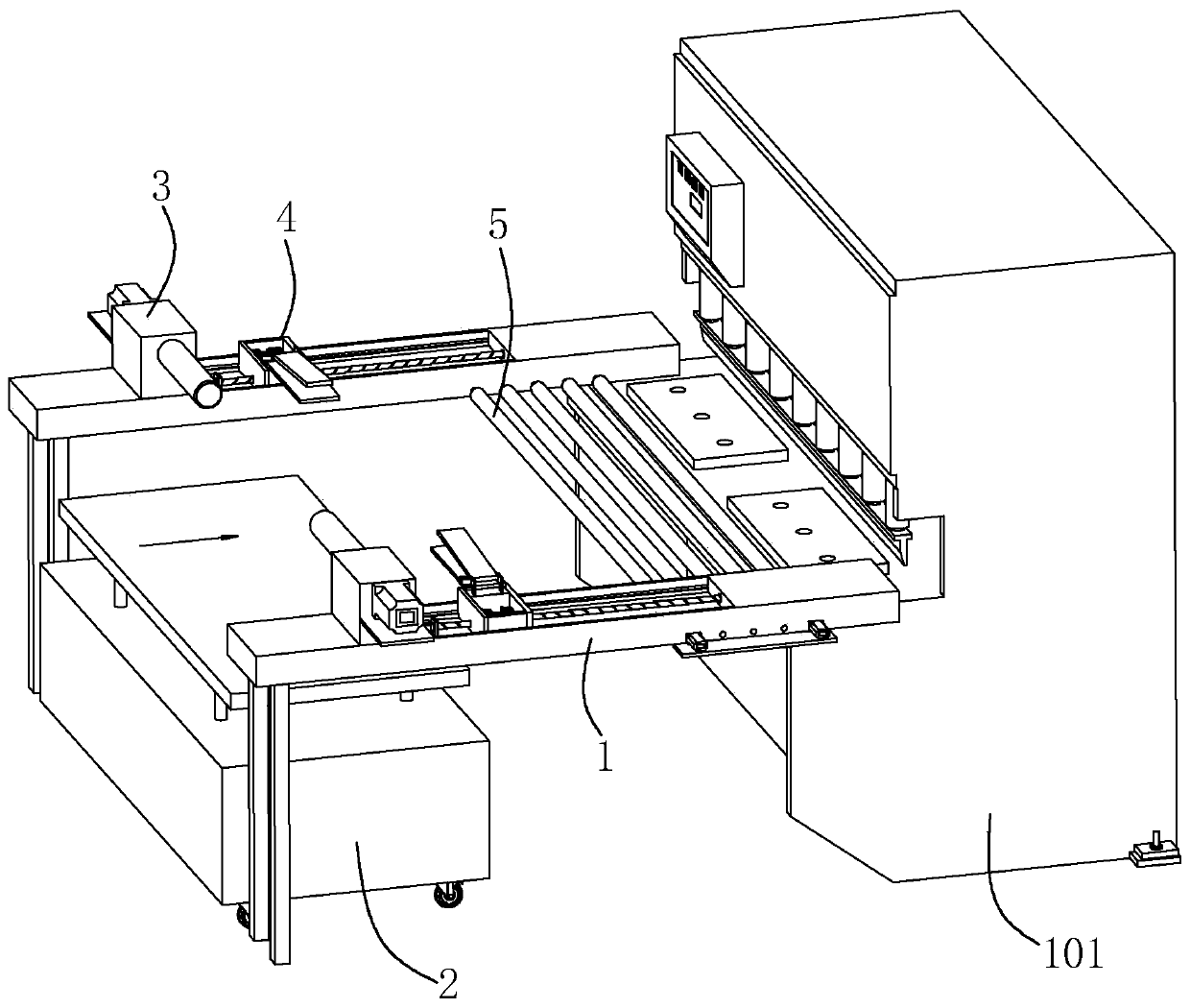

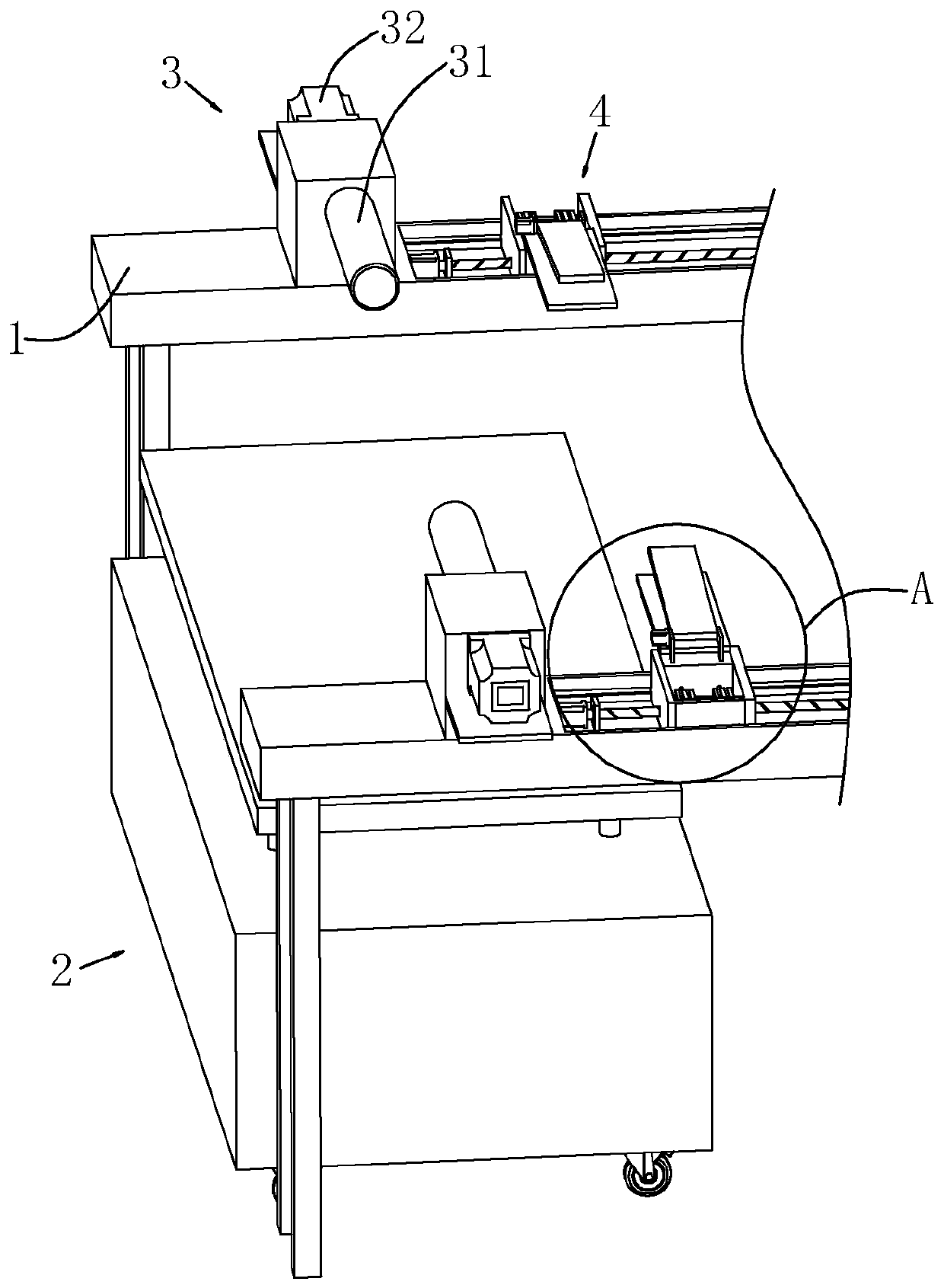

[0048] Such as figure 1 As shown, it is a feeding auxiliary system and method for plate cutting disclosed in the present invention, including a body 101, a lifting device 2, a first conveying device 3, a second conveying device 4, a third conveying device 5 and a frame 1 One end of the frame 1 is fixed on one side of the feed port of the body 101, and the other end extends horizontally away from the body 101. The first conveying device 3, the second conveying device 4 and the third conveying device 5 are all installed on the machine Rack 1; The conveying direction in the present embodiment is as figure 1 indicated by the arrow.

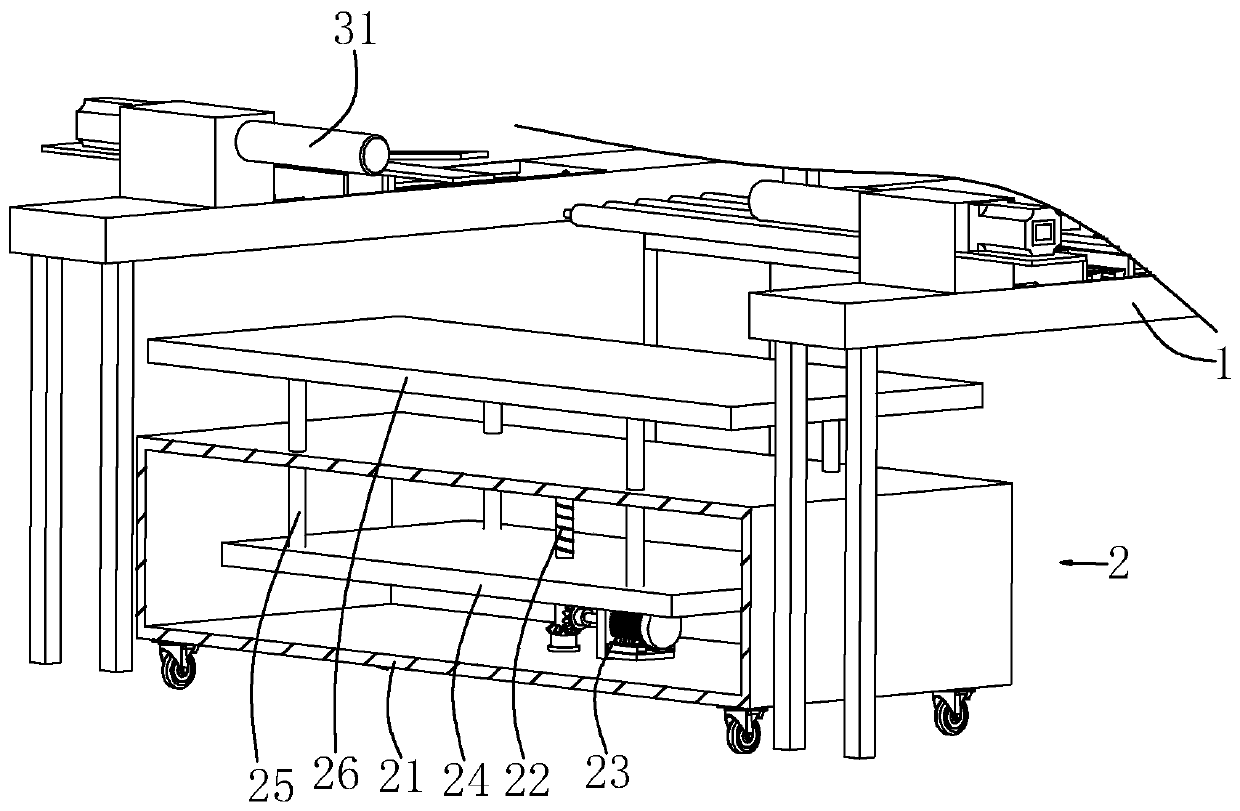

[0049] Such as figure 1 with figure 2 As shown, the lifting device 2 is arranged directly below the end of the frame 1 away from the main body 101, and the lifting device 2 includes a mounting box 21, a first screw rod 22, a first driving member 23, a connecting plate 24, a connecting rod 25 and a receiving plate 26 , the installation box 21 is p...

Embodiment 2

[0059] Such as Figure 7 As shown, the difference from Embodiment 1 is that the lifting device 2 includes a base plate 27, a support plate 28, and two pairs of second drive assemblies 29, and the bottom diagonal of the base plate 27 is provided with rollers with a braking function. The two driving assemblies 29 are mounted on opposite sides of the upper surface of the base plate 27 respectively. Two pairs of the second driving assemblies 29 are piled up and arranged. Two guide grooves 293, two drive blocks 294, two driven blocks 295 and two seventh drive members 296, two first guide grooves 292 are arranged on the side of the bottom plate 27 away from the rollers, the extending direction of the two guide grooves Be located on the same straight line, drive block 294 can be slidably set in the two guide grooves, the seventh drive member 296 is installed at one end in the first guide groove 292, the seventh drive member 296 is a cylinder, and the piston of the cylinder is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com