Electrolysis-broaching combined machining tool electrodes

A tool electrode, composite machining technology, applied in electric machining equipment, manufacturing tools, metal machining equipment and other directions, can solve problems such as easy to cause short circuit, burn broach and workpiece, etc., achieve low comprehensive cost, avoid corrosion, and novel structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

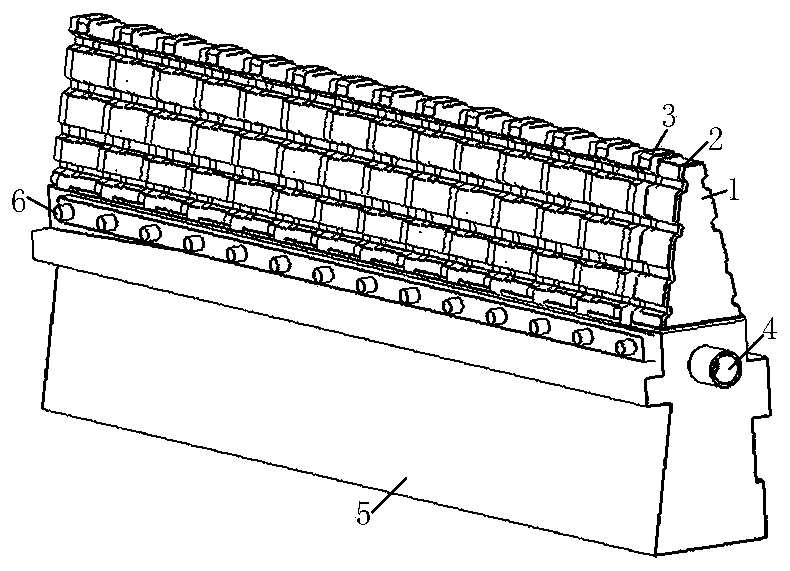

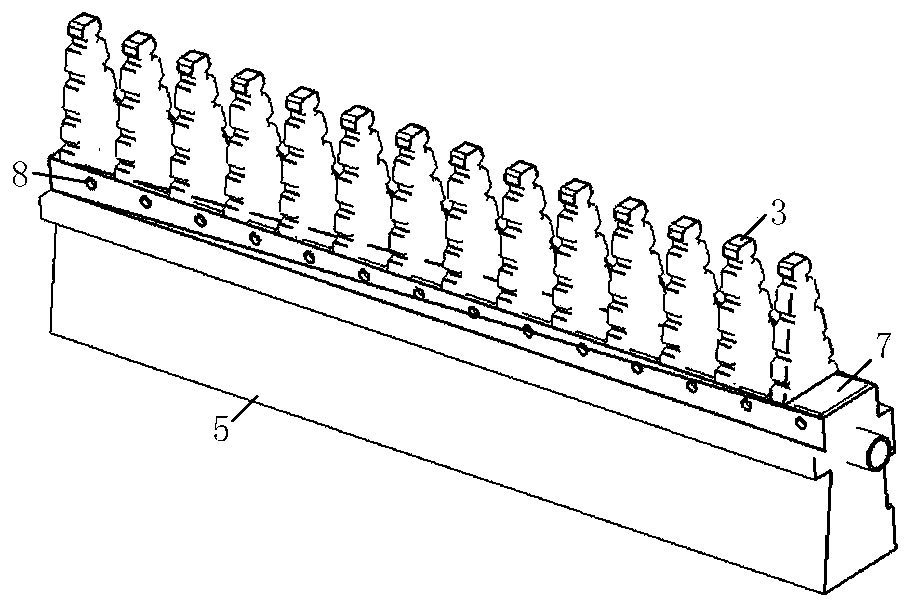

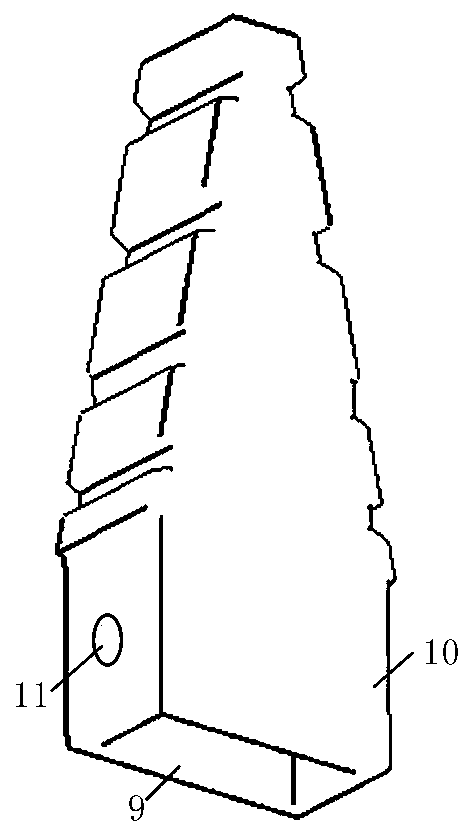

[0023] Such as Figure 1-5 As shown, a tool electrode for electrolysis-broaching composite processing includes a tool electrode composed of an insulating separator 1, a porous metal plate 2, a pull blade 3, an electrolyte water inlet 4, a cutter body 5, a porous metal lead terminal 6, Porous metal plate mounting slot 7, lead wire terminal mounting slot 8, porous metal plate inner flow channel 9, porous metal plate mounting end 10, conductive pin hole 11, knife body electrolyte flow channel insulating layer 12, insulating sleeve 13, conductive The pin 14 and the insulating pad 15 are connected to form; the broaching blade 3 is used to realize mechanical broaching; the porous metal plate 2 is used to realize electrochemical corrosion; the porous metal plate 2 is connected to the cutter body 5 through the porous metal plate mounting groove 7, and Fix by inserting conductive p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com