3D printed lighted buoy device and manufacturing method thereof

A 3D printing and light buoy technology, applied in the field of 3D printing, can solve the problems of light buoys that cannot continue to work, high cost, and easy aging, and achieve the effects of reducing the difficulty of transfer, good protection, and reducing aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

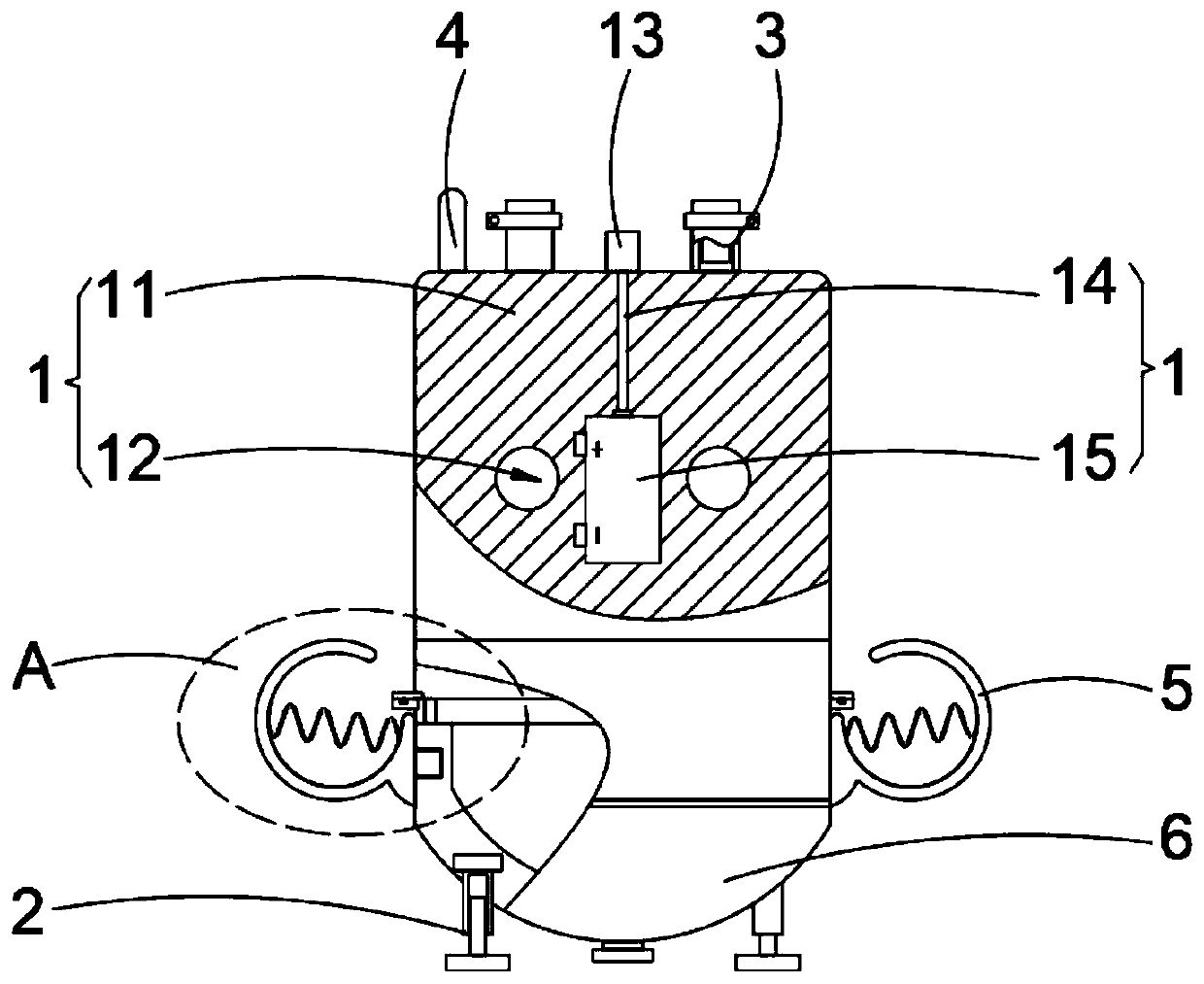

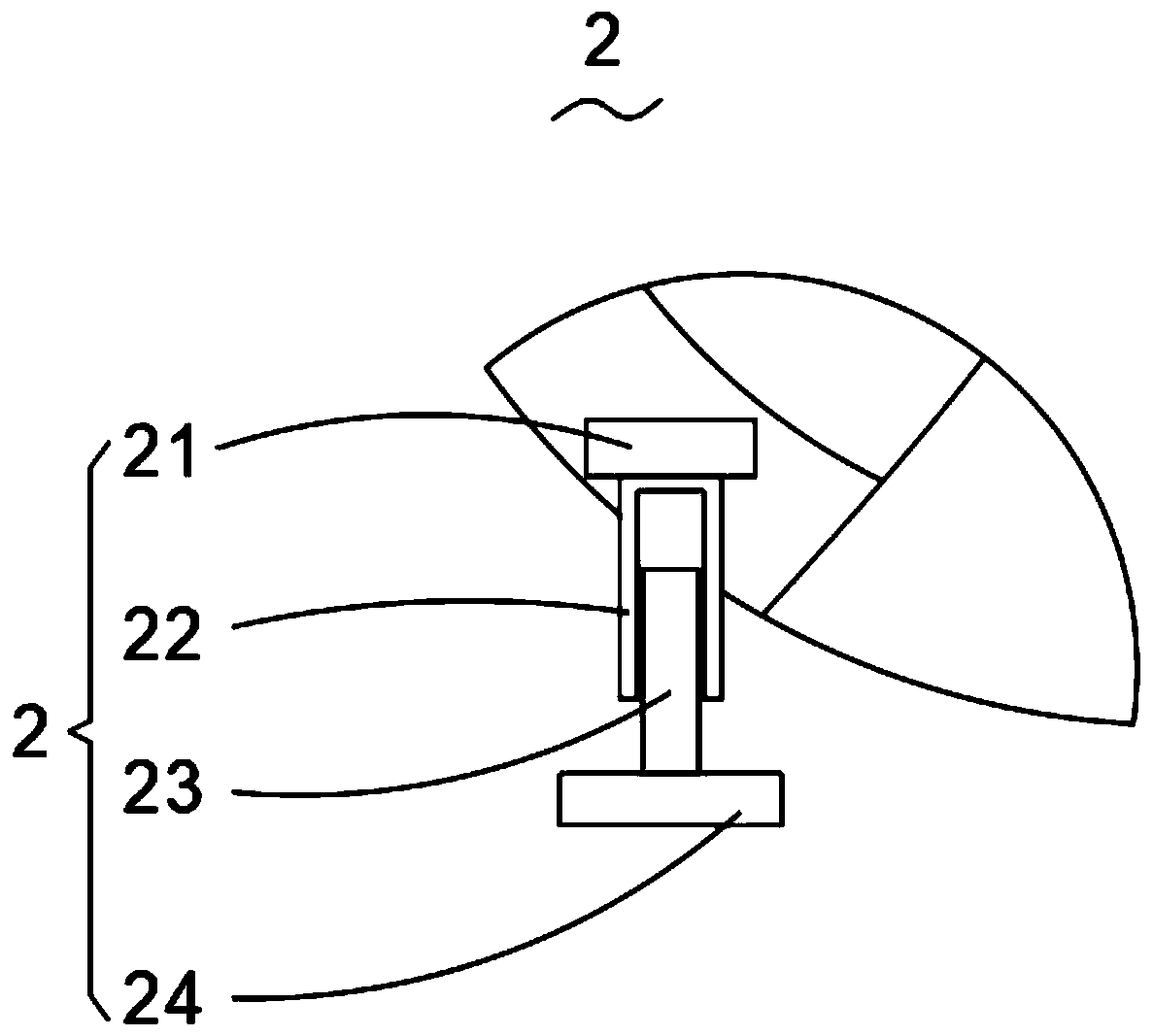

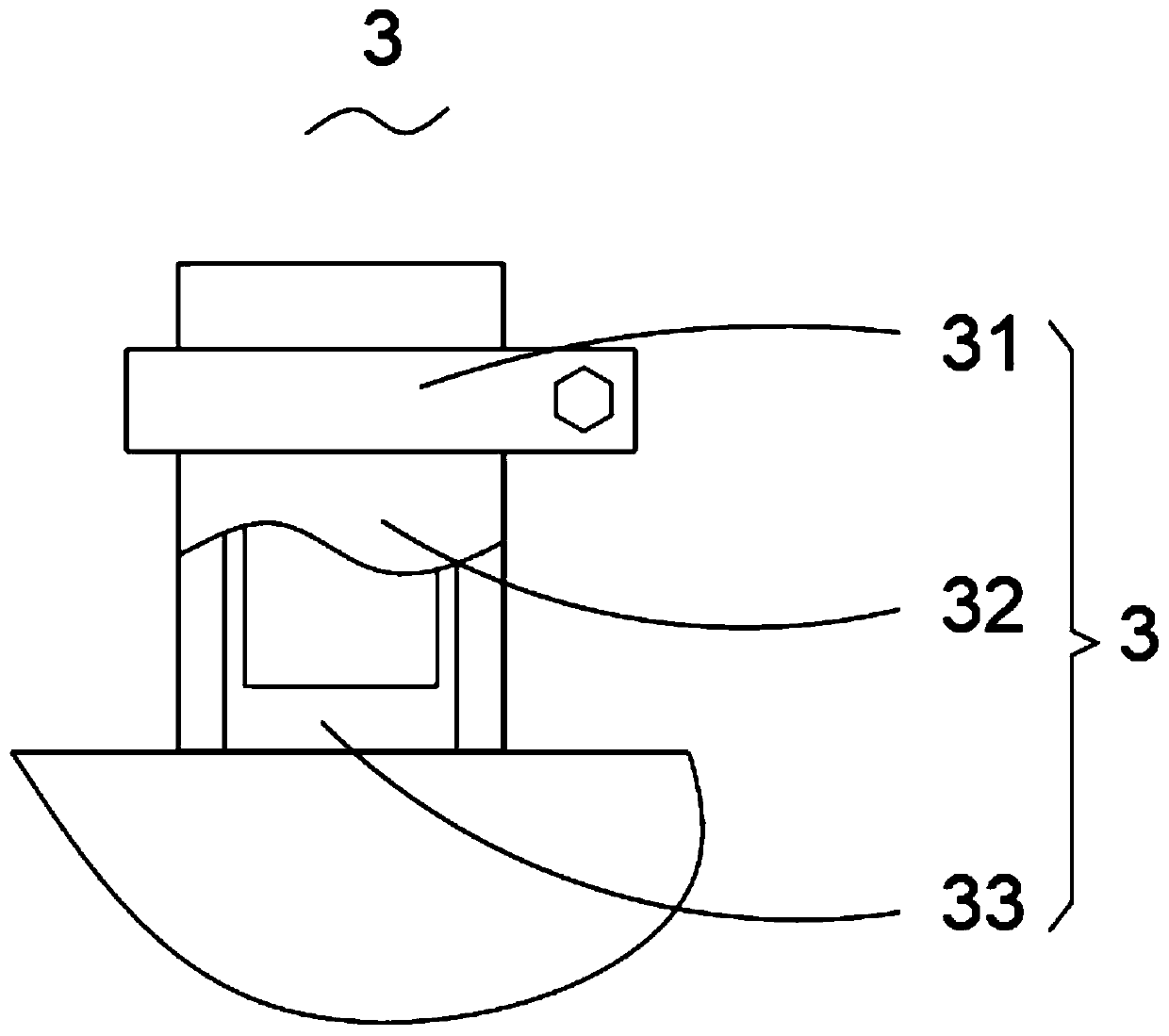

[0031] Please refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 ,in, figure 1 A schematic structural diagram of a preferred embodiment of the device and method for 3D printing light buoys provided by the present invention; figure 2 for figure 1 The structural schematic diagram of the counterweight mechanism shown; image 3 for figure 1 The structural schematic diagram of the reserved bolt hole column mechanism shown; Figure 4 for figure 1 Partial enlarged view of A in the center; Figure 5 for Figure 4Partial enlarged view of B in the center. The 3D printing light buoy device includes: light buoy main body mechanism 1; counterweight mechanism 2, which is connected to the bottom counterweight mechanism 6; reserved bolt hole post mechanism 3, and the reserved bolt hole post The mechanism 3 is connected to the upper surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com