Bin structure and full-automatic LED packing machine thereof

A packaging machine, fully automatic technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of complex structure of LED packaging equipment, undisclosed feeding, and inability to achieve fully automatic processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

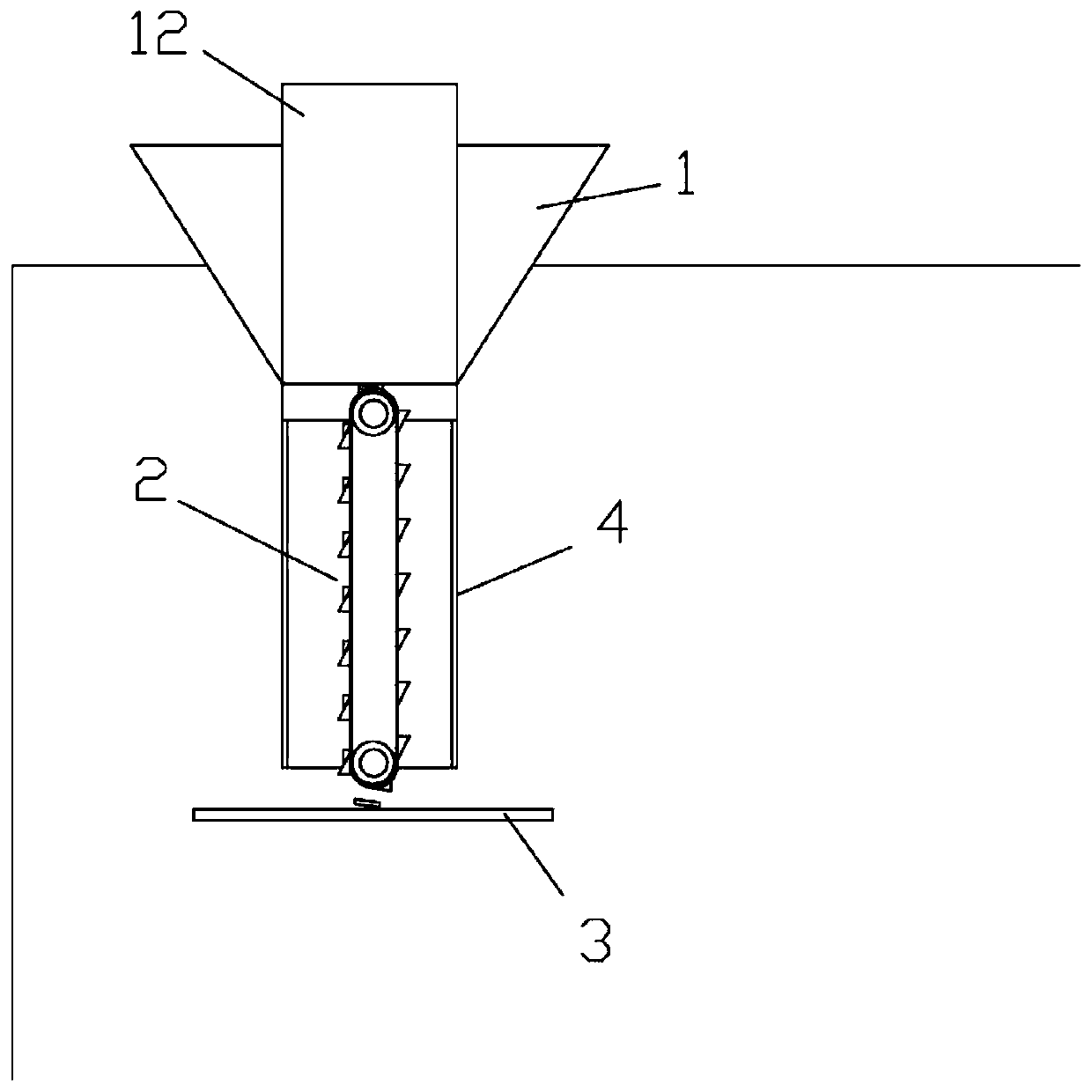

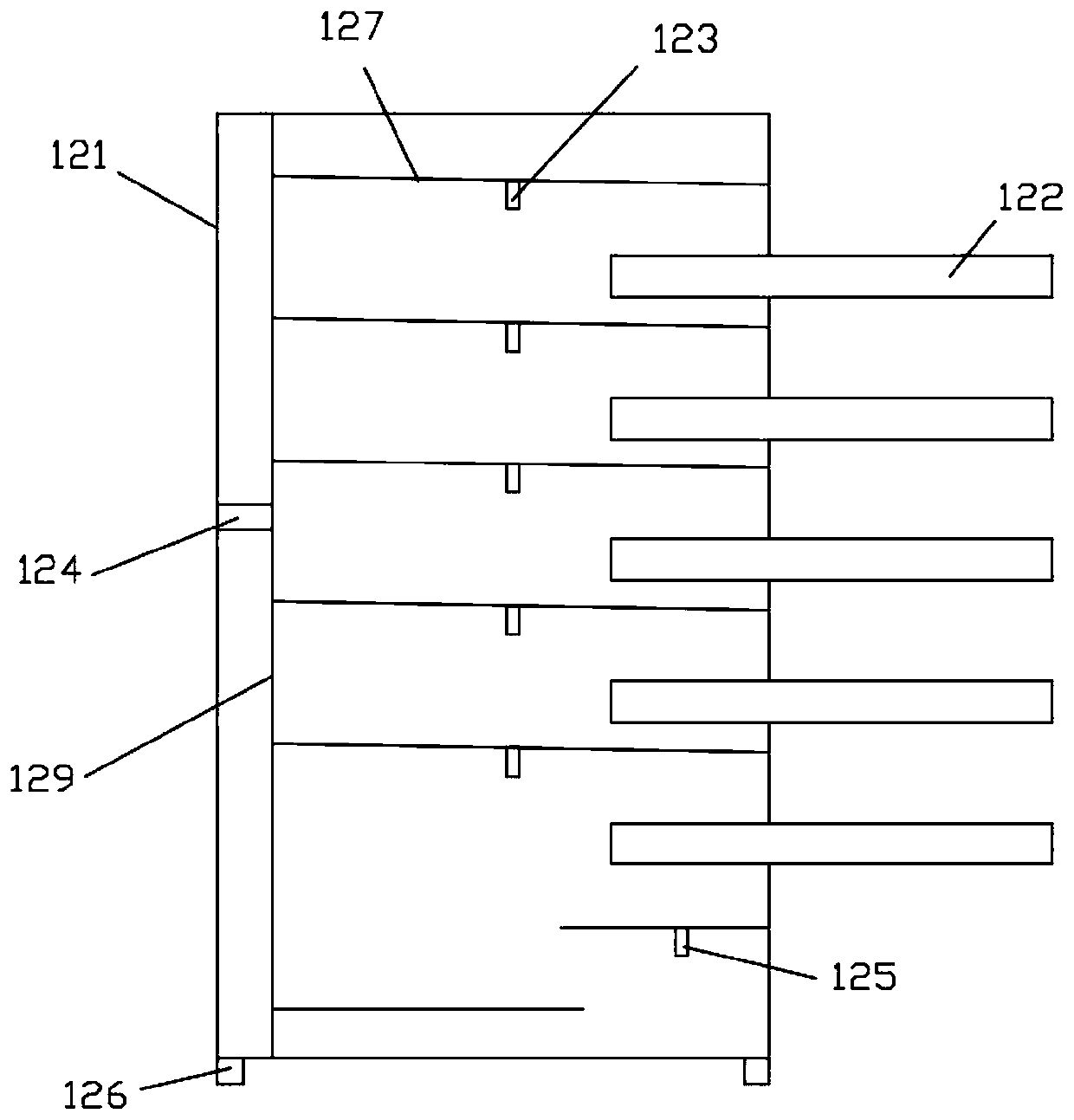

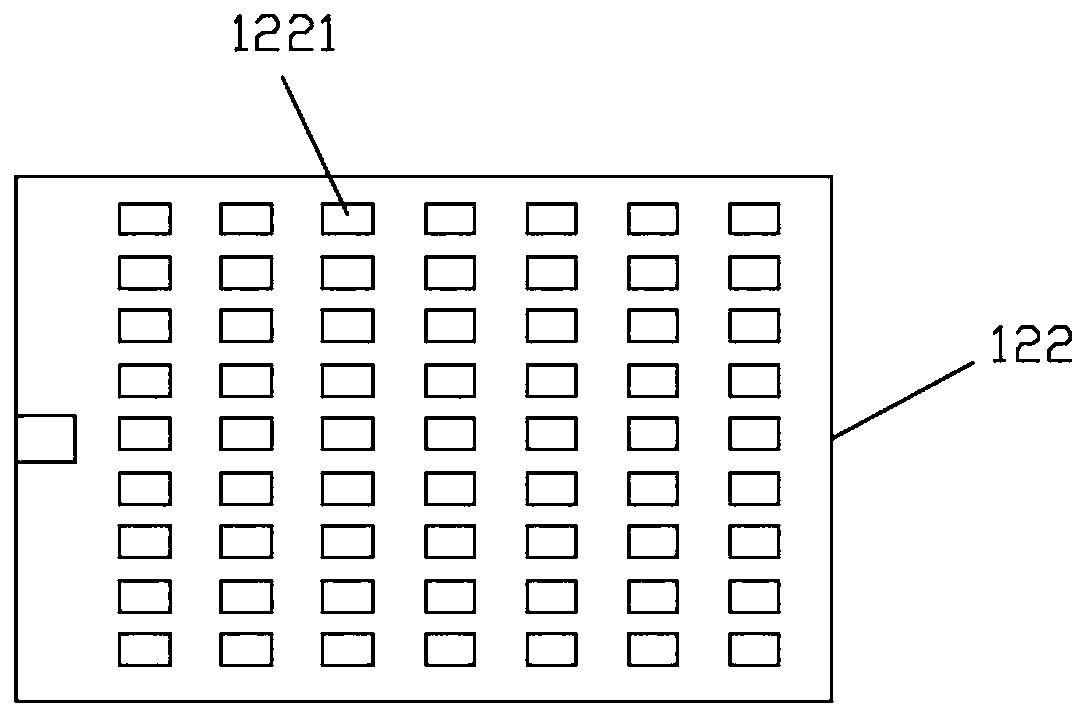

[0029] Please refer to Figure 1-8 As shown, the embodiment of the present invention discloses a fully automatic LED packaging machine, including a feeding mechanism and a silo structure, the silo structure includes a hopper and a material rack 12 arranged in the hopper, and the feeding mechanism It includes a conveying mechanism 2 arranged at the lower part of the hopper 1, and the conveying mechanism 2 includes a feeding belt 21, a driving roller 22 and a driving device. The silo structure of the fully automatic LED encapsulation machine adds the LED chip 100 to the feeding mechanism, and then the feeding mechanism places the LED chip 100 on the placement table 3, and then completes the LED packaging on the placement table 3, Finally, the packaged finished product is obtained.

[0030] The silo structure includes a hopper and a material rack 12 arranged in the hopper, the bottom of the hopper is provided with a discharge port, and the outside of the discharge port is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com