Bobbin replacing mechanism for winder

A winding machine and bobbin yarn technology, which is applied in the field of bobbin changing mechanism for winding machines, can solve the problems of high price, complicated structure, and high labor intensity, and achieve the effects of low manufacturing cost, simple overall structure, and convenient operation for workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

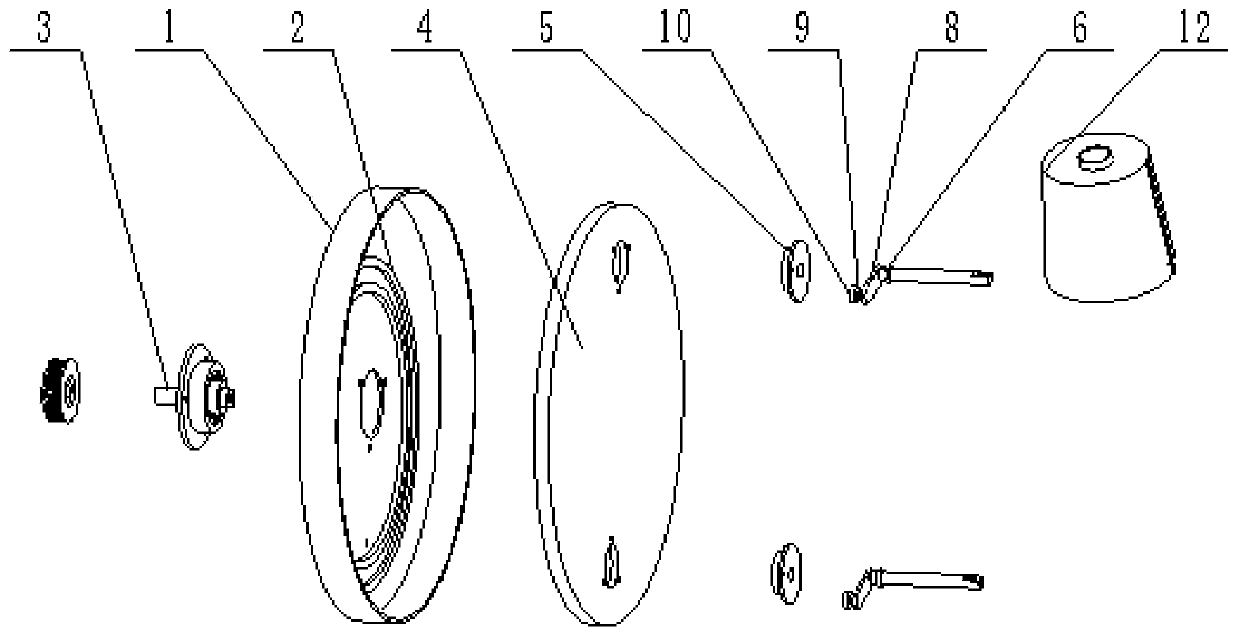

[0016] Example 1 as figure 1 As shown, a bobbin changing mechanism for a winding machine includes a vertically fixed disc-shaped track disc 1, and two concentric tracks 2 are fixed inside the track disc 1, and the outer track 2 and the track disc 1 The bottom of the inner wall is tangent, and the center of the orbital disk 1 is rotated by a bearing to provide a main shaft 3. The main shaft 3 is located on the side of the orbital disk 1 where the track 2 is provided. A turntable 4 is fixed on the side. A through hole is installed, and a support seat 5 is embedded in the through hole on the turntable 4 .

[0017] A mounting hole is provided in the support seat 5, and a bobbin lifting rod 6 is arranged in the mounting hole of the supporting seat 5. The end of the bobbin lifting rod 6 close to the track disk 1 is provided with a driving part 8 arranged perpendicularly thereto, and the driving part 8 is far away from the One end of the bobbin picker bar 6 is fixedly provided with ...

Embodiment 2

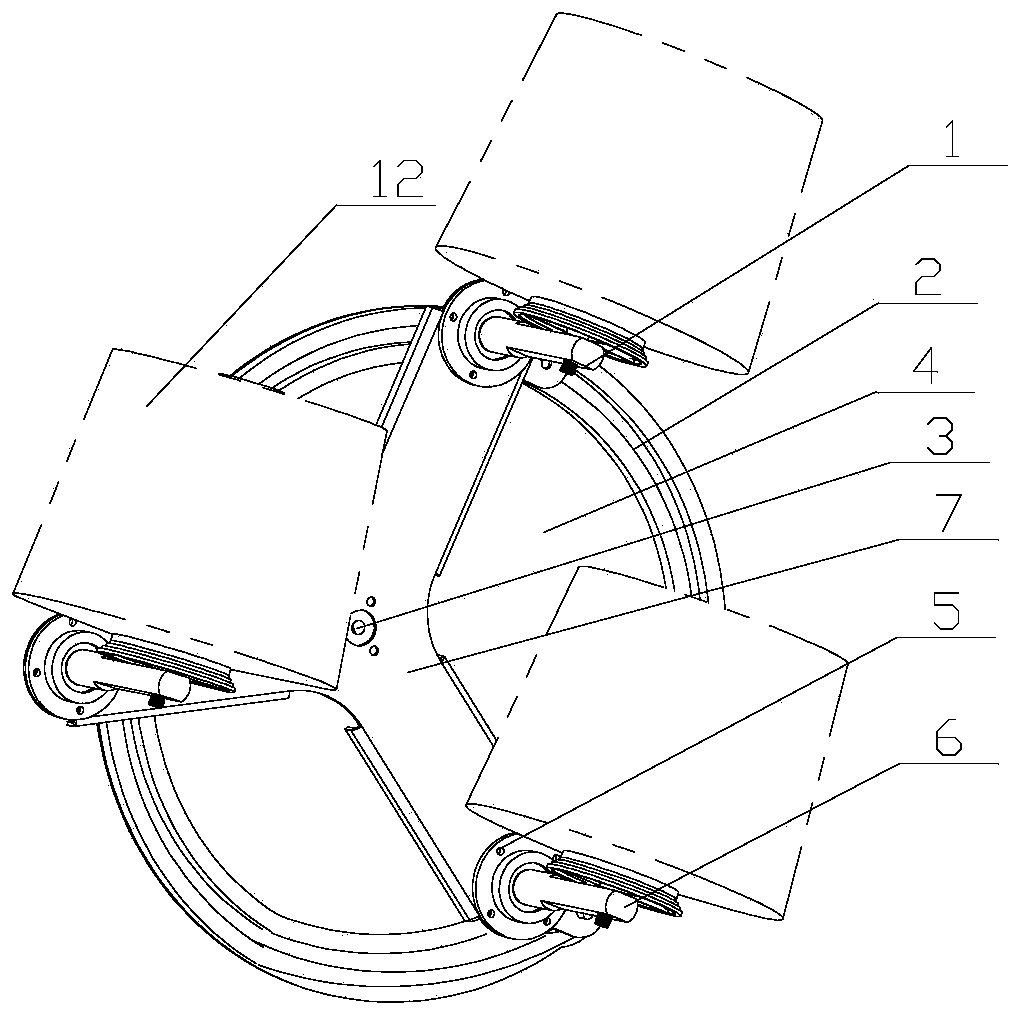

[0019] Embodiment 2 provides a bobbin changing mechanism for a bobbin winder, the whole is roughly the same as that of Embodiment 1, the difference is that figure 2 As shown, three installation through holes are evenly distributed around the circumference of the main shaft 3 on the turntable 4 . In addition, the turntable 4 is provided with a reinforcing plate 7 on one side of the track 2 , and the reinforcing plate 7 is provided with avoidance through holes corresponding to the positions of the support seats 5 and the main shaft 3 .

[0020] When working: the worker vertically loads the bobbin yarn on the installation rod 11 located on the upper side of the turntable 4, the power device drives the turntable 4 to rotate through the main shaft 3, and the turntable 4 drives the bobbin lifting rod 6 and sliding The block 8 slides along the track 2, because the distance between the installation through hole and the top end of the track 2 when the installation through hole on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com