Polyester filament fabric printing and dyeing equipment

A technology of printing and dyeing equipment and polyester filament, which is applied in the field of textile processing, can solve the problems of complicated structure of printing and dyeing machine, complicated control of printing and dyeing machine, lack of linkage, etc., and achieve the effect of prolonging time, easy control, and reducing the number of installations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on the specific embodiments and in conjunction with the accompanying drawings.

[0033] In the current textile processing field, it is often necessary to print and dye large quantities of cloth. Printing and dyeing operations are generally carried out using printing and dyeing machines. Existing printing and dyeing machines have multiple moving parts, each of which needs to be equipped with a power source, resulting in a complex structure of the printing and dyeing machine, and the independent operation of each moving part, lack of linkage, resulting in cumbersome control of the printing and dyeing machine.

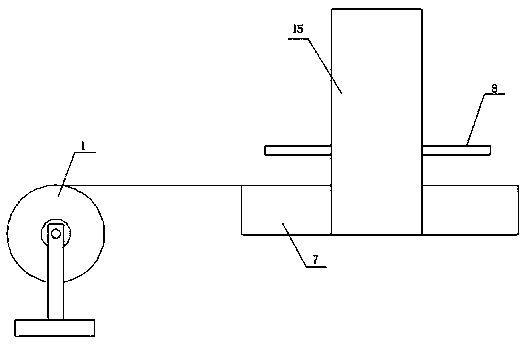

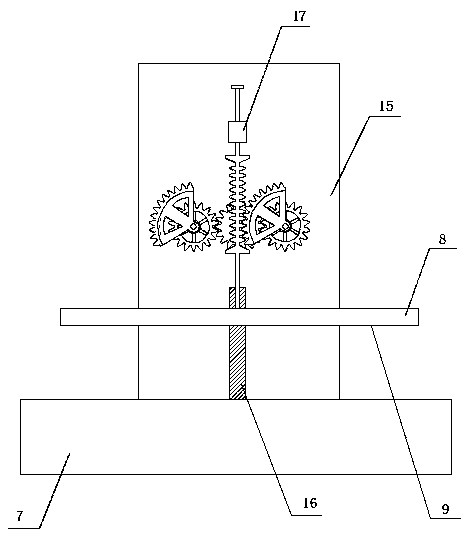

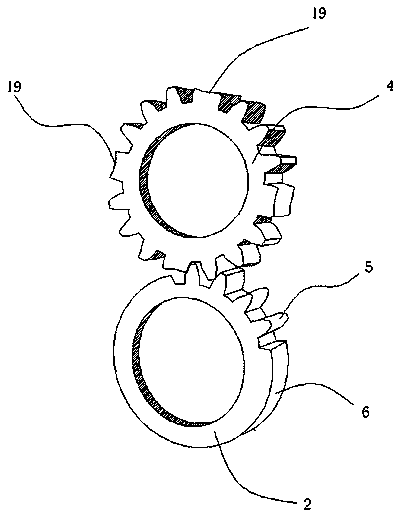

[0034] For this reason, see Figure 1~6 , Figure 8, the first embodiment of the present invention provides a polyester filament fabric printing and dyeing equipment, including a feeding mechanism, a printing and dye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com