Well and layer selection method for pouring measure of large-scale flooding solution into thin and poor layer water-injection well of sandstone reservoir

A technology for thin and poor oil layers and sandstone reservoirs, applied in the field of oilfield development, can solve the problems of insufficient formation energy in oil layers, poor water injection capacity of thin and poor layers, poor seepage capacity of thin and poor layers, etc. The effect of improving water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The present invention will be further described in conjunction with the Xing 13-10-Xie 117 well in the Xingshugang Oilfield of the Daqing Oilfield.

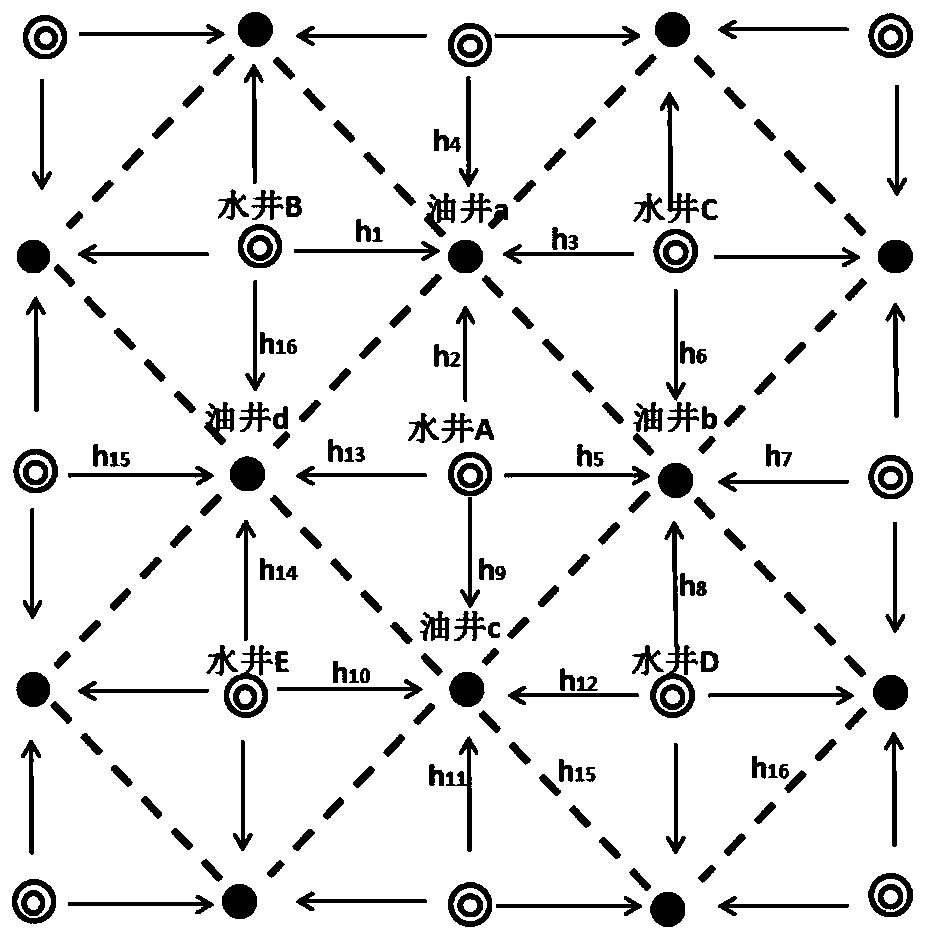

[0027] (1) Optimizing the target well

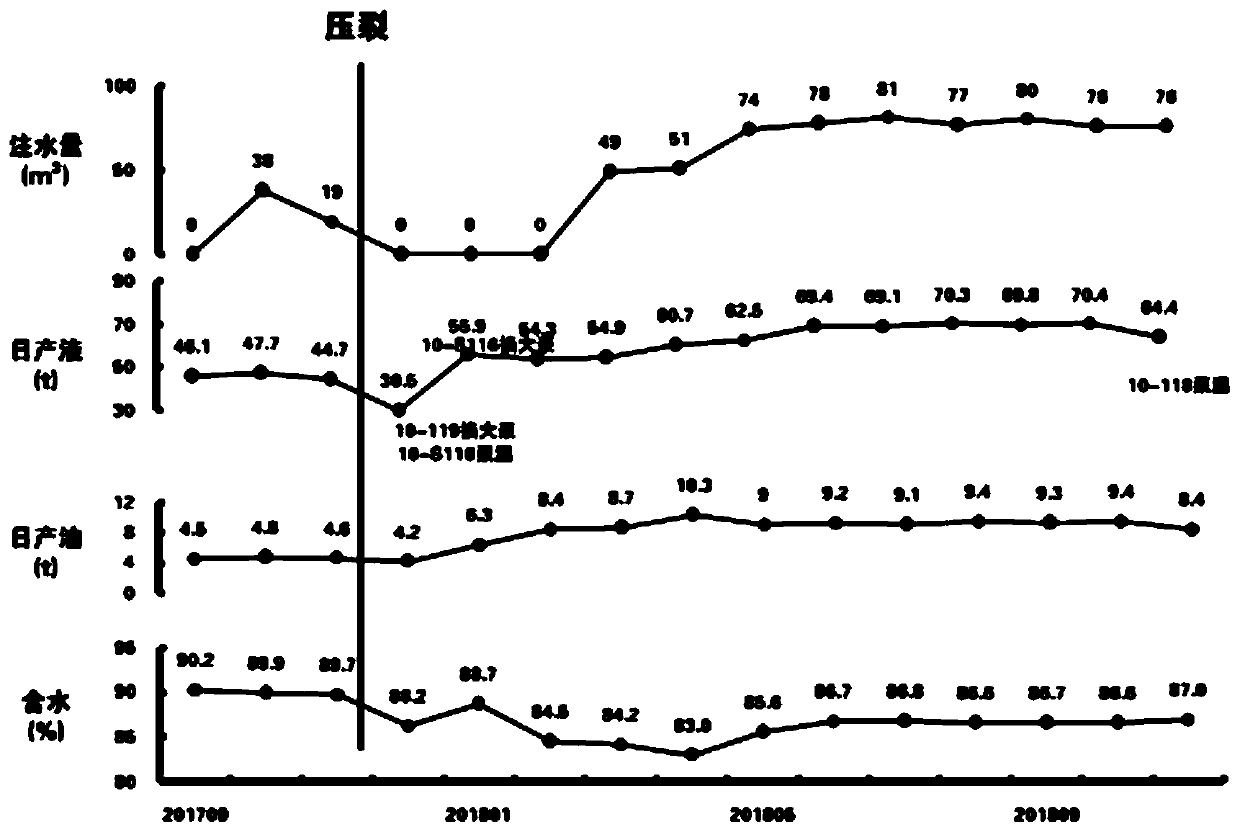

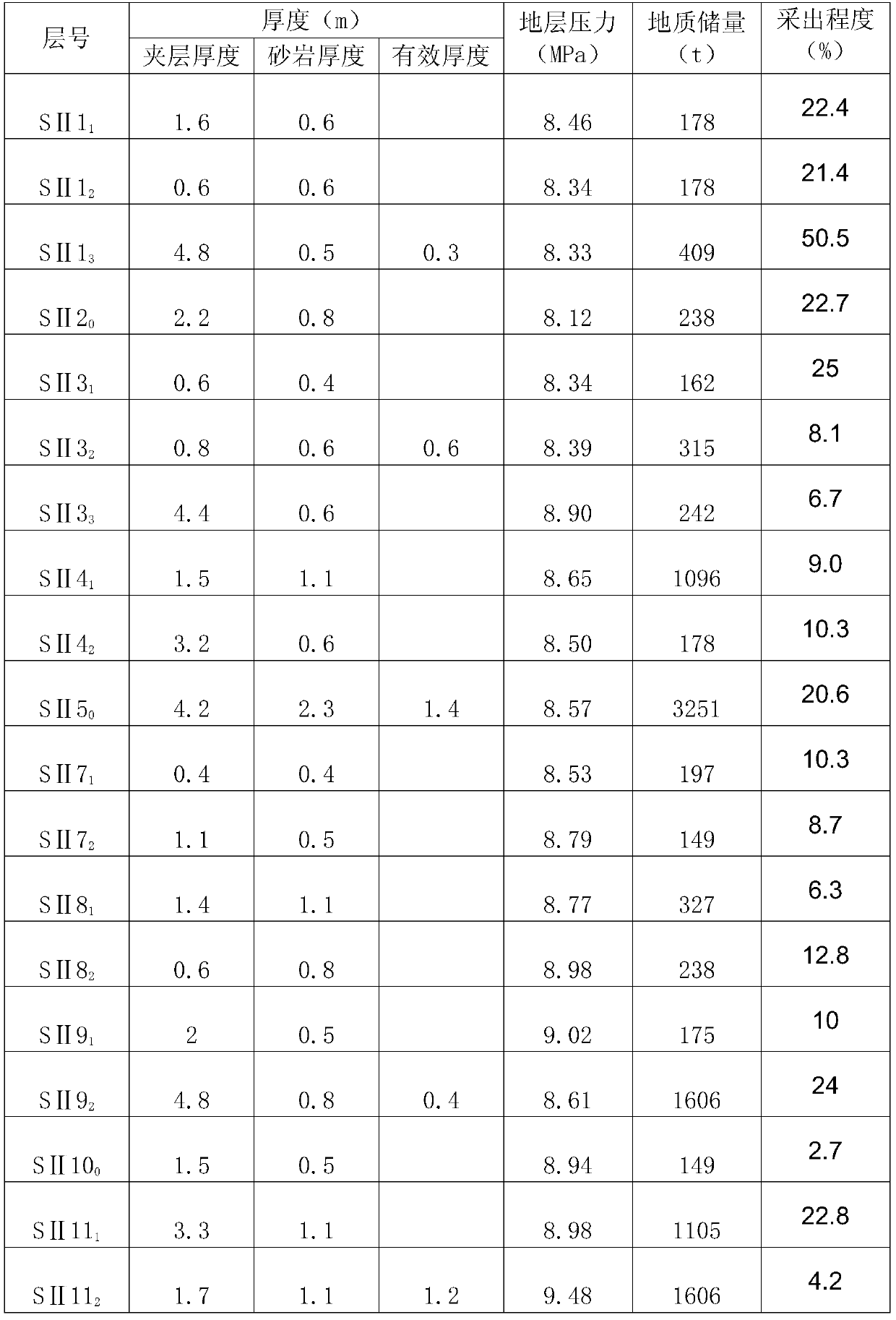

[0028] Well Xing 13-10-Xie 117 is a secondary intensification water injection well in the transition zone of the Xing 13 area. It is connected to 4 oil production wells around it, and the injection-production relationship is perfect. Initial daily injection 41m 3 , due to poor mining targets and large injection-production well spacing (minimum 156m), water absorption gradually becomes worse after injection. Four oil wells Xing 13-10-Ding 116, Xing 13-Ding 1-116, Xing 13-10-119 and Xing 13-Ding 1-118 are connected around the water well Xing 13-10-Ding 117, according to the injection-production ratio balance method , the cumulative injection volume of water well Xing 13-10-Xiang 117 is less than the cumulative liquid production volume obtained by supplying water to the surrounding fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com