High-bearing coal mining machine walking system

A traveling system and shearer technology, which is applied to slitting machinery, earth-moving drilling, propulsion, etc., can solve the problem of increasing the logarithm of the meshing between the teeth of the traveling wheel and the pin rail, and does not solve the problem of the horizontal deflection angle of the traveling wheel and the pin row. Difficulties in segmented production and manufacturing, to avoid tooth chipping, avoid edge effects, and improve bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

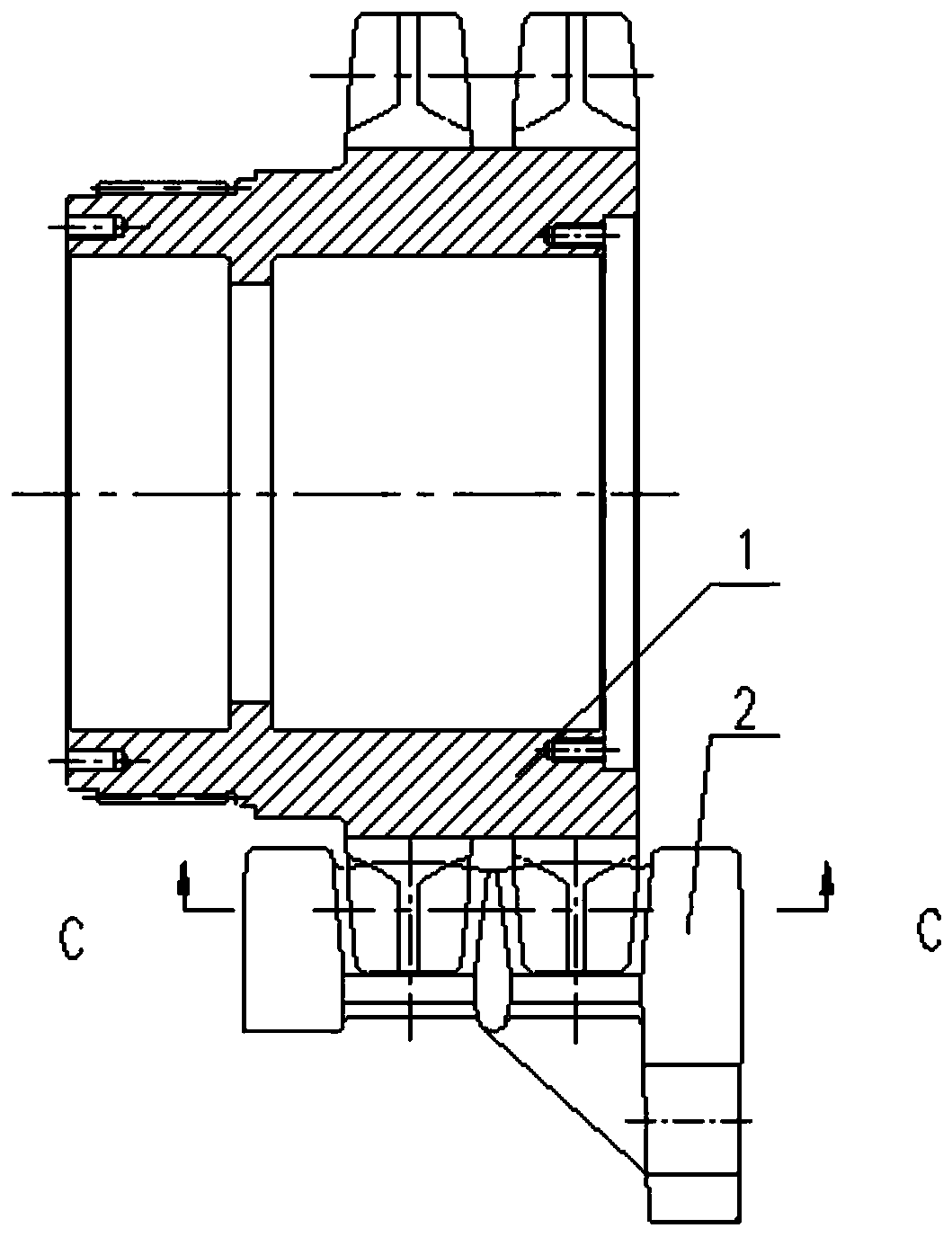

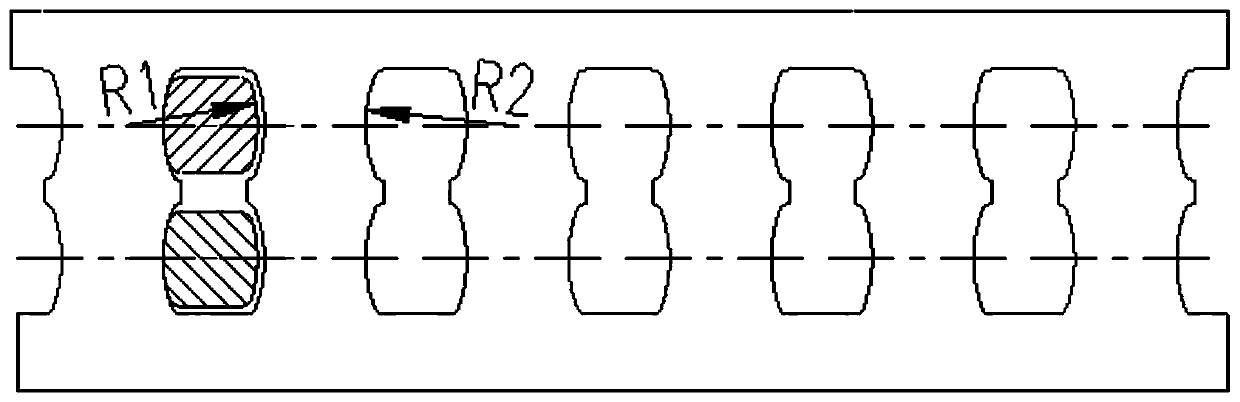

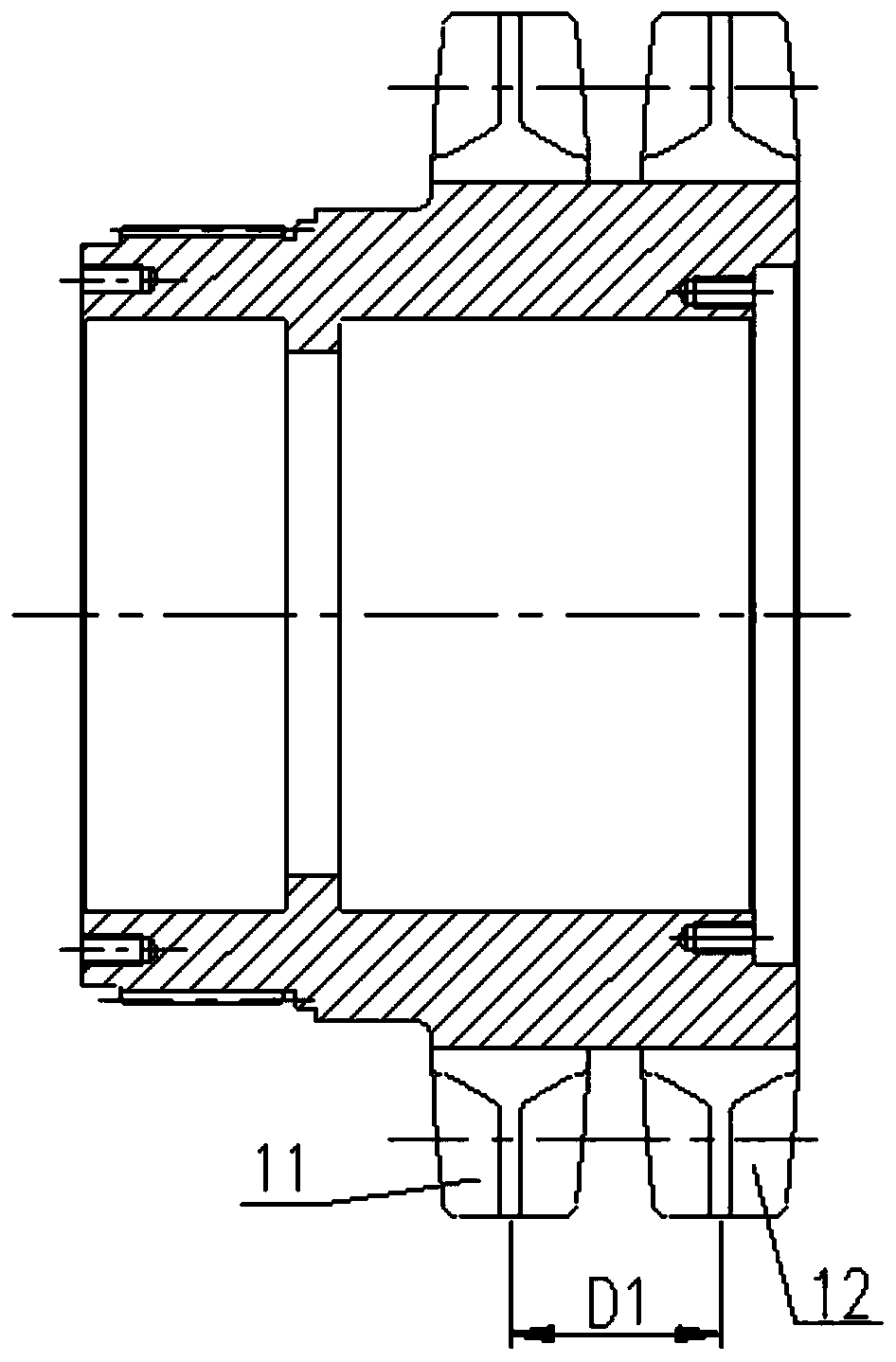

[0025] The invention discloses a walking system of a high-load shearer (referred to as the walking system), such as Figure 1-6 As shown, it includes the intermeshing traveling wheel 1 and the pin row 2, the pin row is fixed on the scraper machine along the length direction of the working face, and the traveling wheel meshes bidirectionally along the pin row to drive the shearer to reciprocate along the working face. The walking wheel is provided with double-row teeth 11 and 12, and the double-row teeth are processed on the same gear blank. The structural parameters of the double-row teeth are such as the number of teeth, modulus, diameter of addendum circle, and tooth profile Same shape, same phase. The tooth surfaces on both sides of each tooth are convex and symmetrical in the tooth thickness direction. The pin rows are provided with double rows of tooth grooves, and the structural parameters of the double rows of tooth grooves are the same and the phases are consistent. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com