Low-dip-angle weak structural surface after-grouting seepage deformation field test method and sample device

A technology of weak structural surface and penetration deformation, applied in measurement devices, preparation of test samples, permeability/surface area analysis, etc., can solve the problems of complex test methods, high input costs, and the reliability of test results cannot be fully recognized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

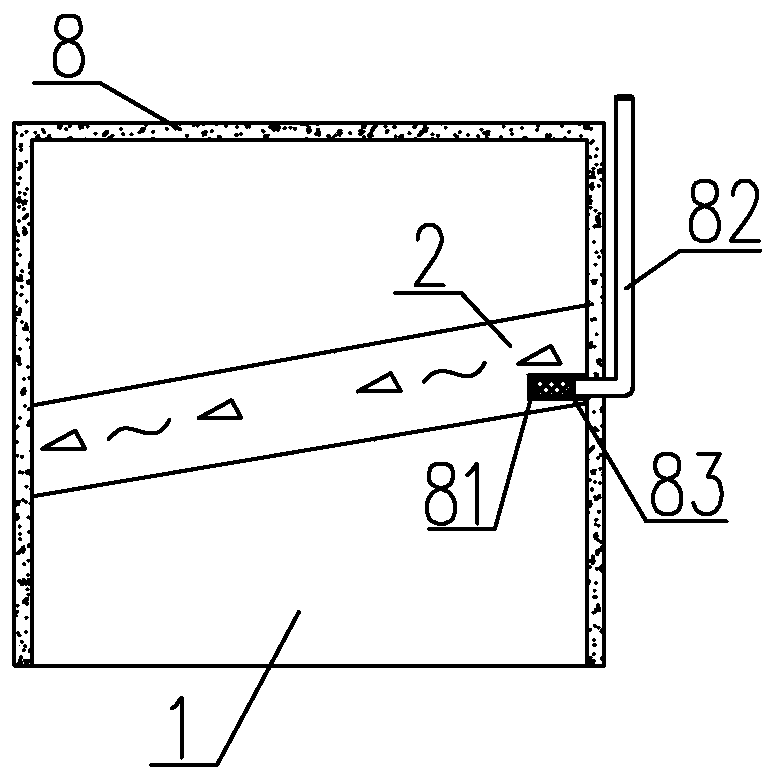

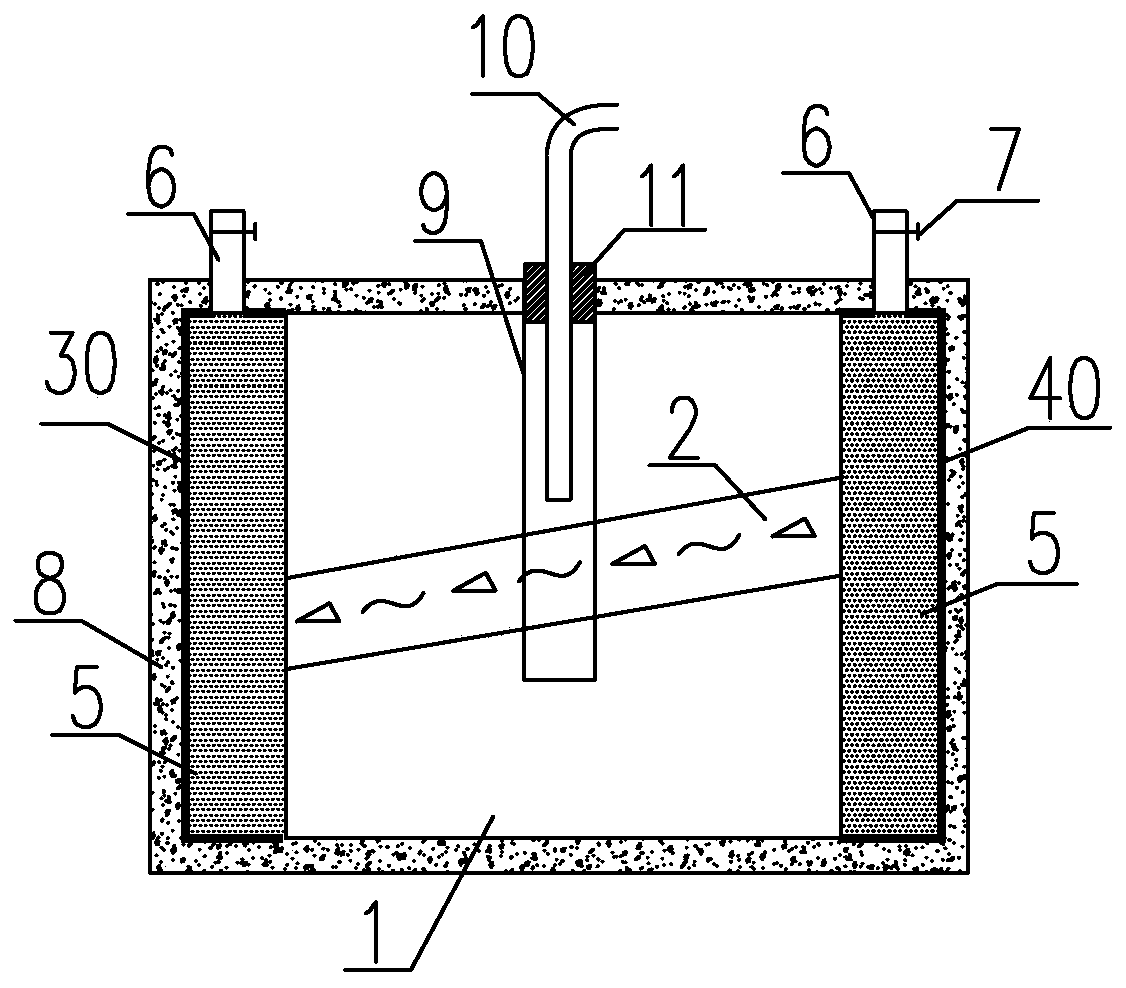

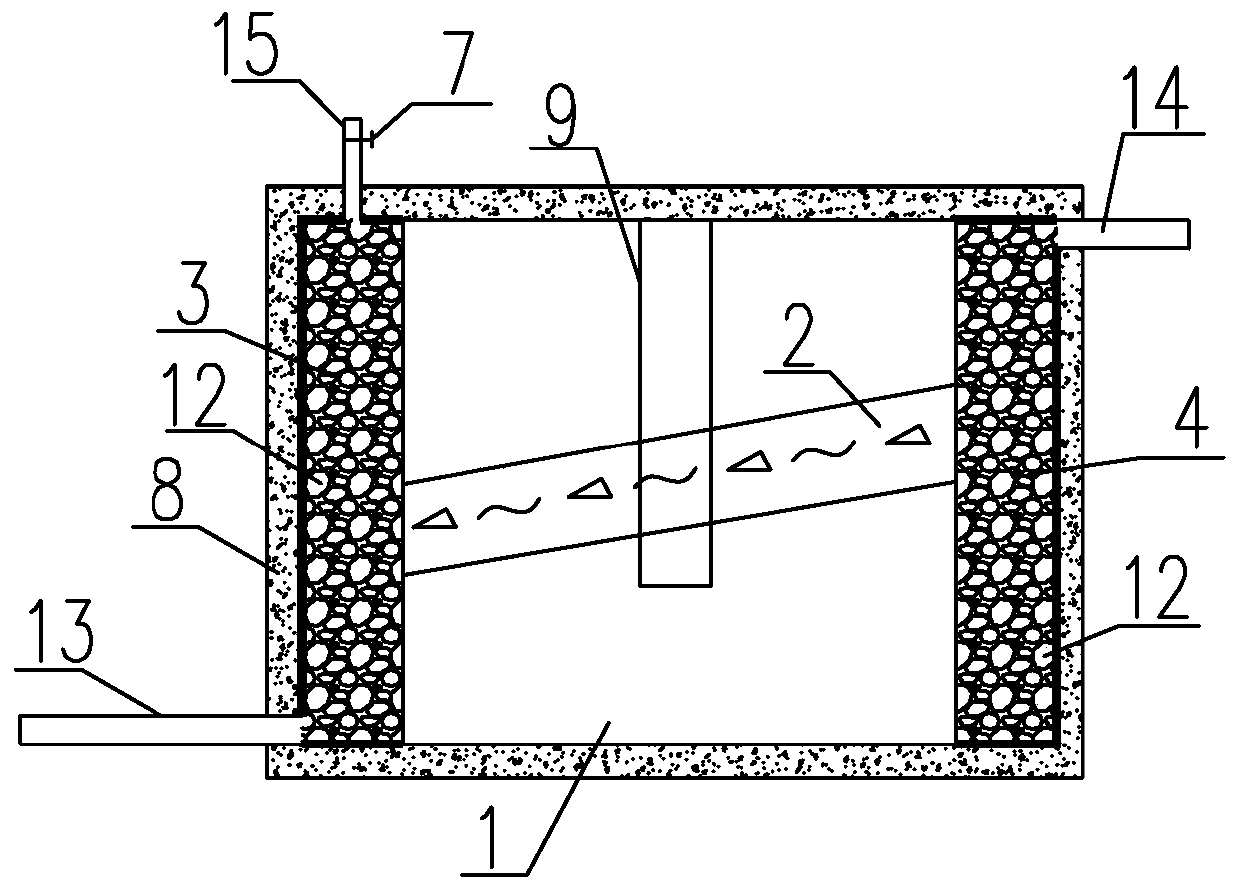

[0045] (1) Test principle

[0046] The test is based on Darcy's law (v=KI), the relationship between the seepage velocity of water in the rock and soil pores is proportional to the hydraulic gradient, and the seepage deformation test is carried out step by step using the equal head method. (See figure 1 ) The water flow in the reservoir is first raised to the rated water head of the pressurized water pump through the pressurization system, and enters the sample at a stable specified water pressure under the control of the pressure regulating and stabilizing system. During the infiltration process, piezometric tubes, sensors and other instruments buried inside the sample timely record the data of inlet / outlet water head, water temperature, water volume and so on. After the first-level pressure test is completed, the osmotic pressure is increased through the pressure regulation and stabilization system, and then the osmotic deformation test under this level of pressure is carri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com