Adhesive property representation method and representation device of electrode plate

A technology of bonding properties and electrode sheets, applied in the field of electrode sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

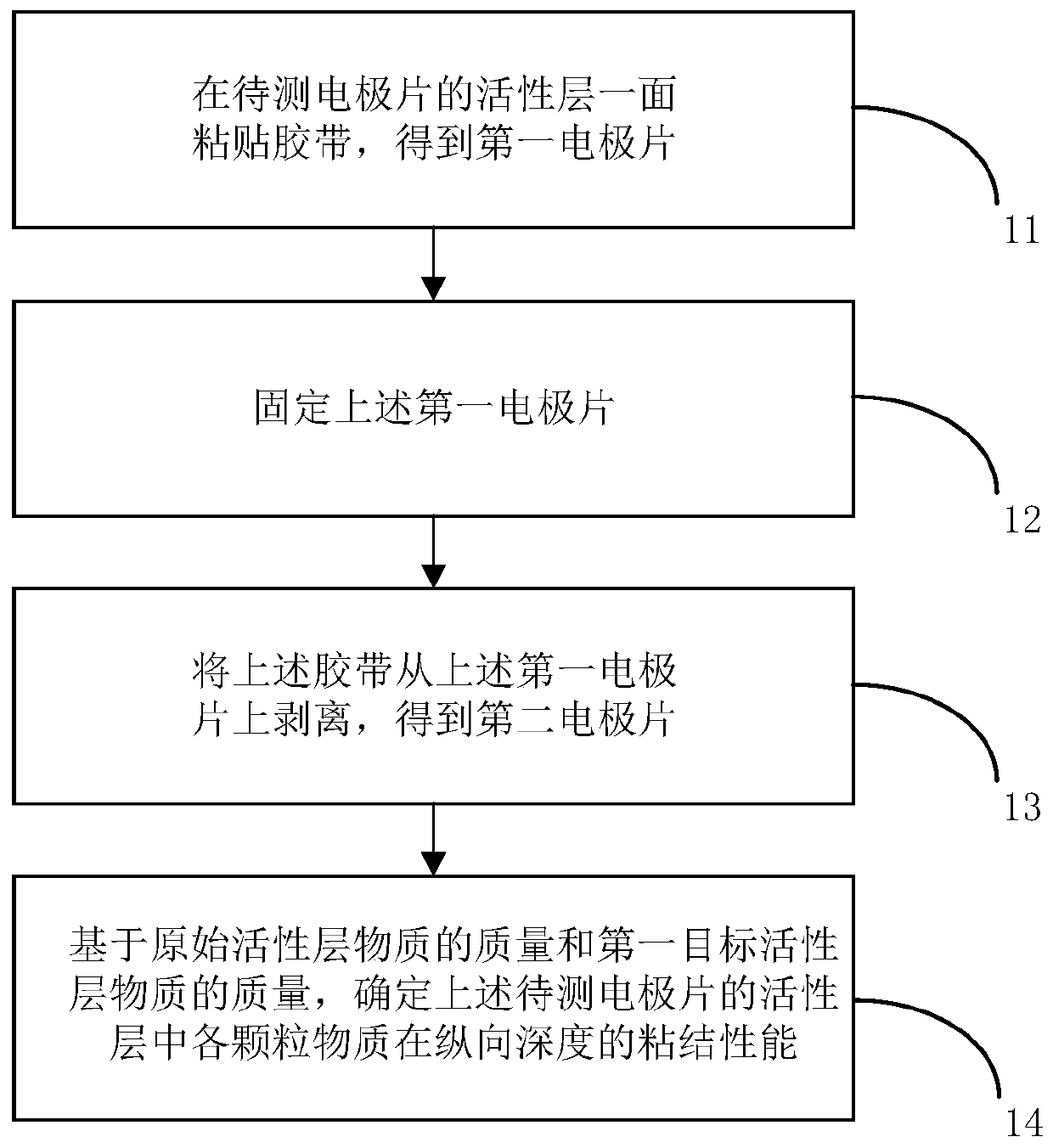

[0042] The embodiment of the present application provides a method for characterizing the bonding performance of electrode sheets, such as figure 1 As shown, the method includes:

[0043] Step 11, sticking an adhesive tape on one side of the active layer of the electrode sheet to be tested to obtain the first electrode sheet;

[0044] Optionally, the width and length of the above-mentioned electrode sheet to be tested are all less than or equal to the above-mentioned adhesive tape, so that one side of the above-mentioned active layer can be completely covered by the above-mentioned adhesive tape, and after the above-mentioned adhesive tape is peeled off, a more accurate measurement of the stripped active layer material is obtained. quality.

[0045] Optionally, the above-mentioned adhesive tape may be a single-sided strong tape or a double-sided strong tape, which is not limited here.

[0046] Optionally, the adhesive tape can be pasted manually or by a machine, which is not...

Embodiment 2

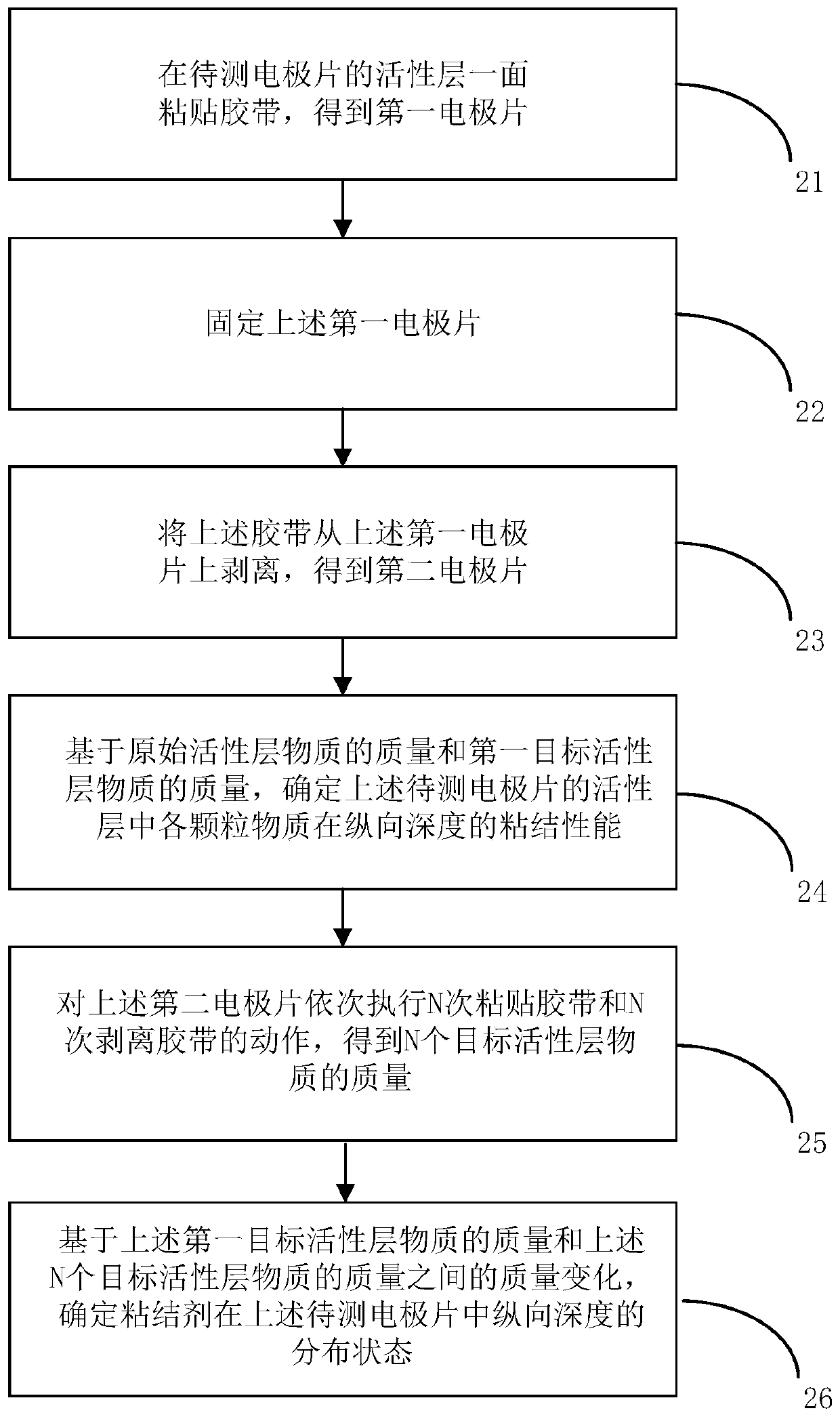

[0103] The embodiment of the present application provides a method for characterizing the bonding performance of electrode sheets, such as figure 2 As shown, the characterization method includes:

[0104] Steps 21-24;

[0105] Among them, steps 21-24 can refer to figure 1 The description in steps 11 to 14 in the illustrated embodiment will not be repeated here.

[0106] Step 25, performing N times of sticking the tape and N times of peeling off the tape on the second electrode sheet in order to obtain the mass of N target active layer substances;

[0107] The above N is greater than or equal to 2;

[0108] Among them, the above N times of sticking the tape can refer to figure 1 For the description in step 11 in the illustrated embodiment, the above N times of stripping the adhesive tape can refer to figure 1 The description in step 13 in the illustrated embodiment will not be repeated here.

[0109] Step 26, based on the mass change between the mass of the first target ...

Embodiment 3

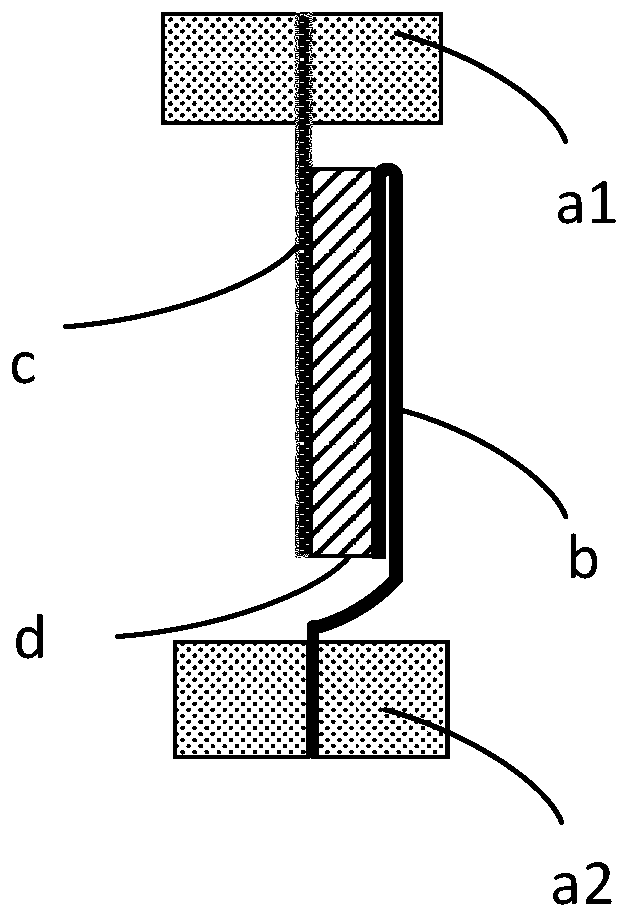

[0125] The embodiment of the present application provides a device for characterizing the bonding performance of electrode sheets, Figure 4 A schematic structural diagram of the characterization device provided by the embodiment of the present application is shown.

[0126] Specifically, see Figure 4 , the characterization device includes a fixation module 41 , a glue pulling module 42 and an analysis module 43 .

[0127] Wherein, the fixing module 41 is used to fix the first electrode sheet, and the above-mentioned first electrode sheet is an electrode sheet to be tested with adhesive tape pasted on one side of the active layer;

[0128] The glue pulling module 42 is used to peel off the above-mentioned adhesive tape from the above-mentioned first electrode sheet to obtain a second electrode sheet;

[0129]The analysis module 43 is used to determine the binding performance of each particle material in the active layer of the electrode sheet to be tested in the longitudina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com