Novel cornea shaping lens and production method thereof

An orthokeratology lens and a new type of technology, applied in the field of ophthalmic optics, can solve the problems affecting the correction effect of the orthokeratology lens, the deviation of the orthokeratology lens, foreign body sensation, etc. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

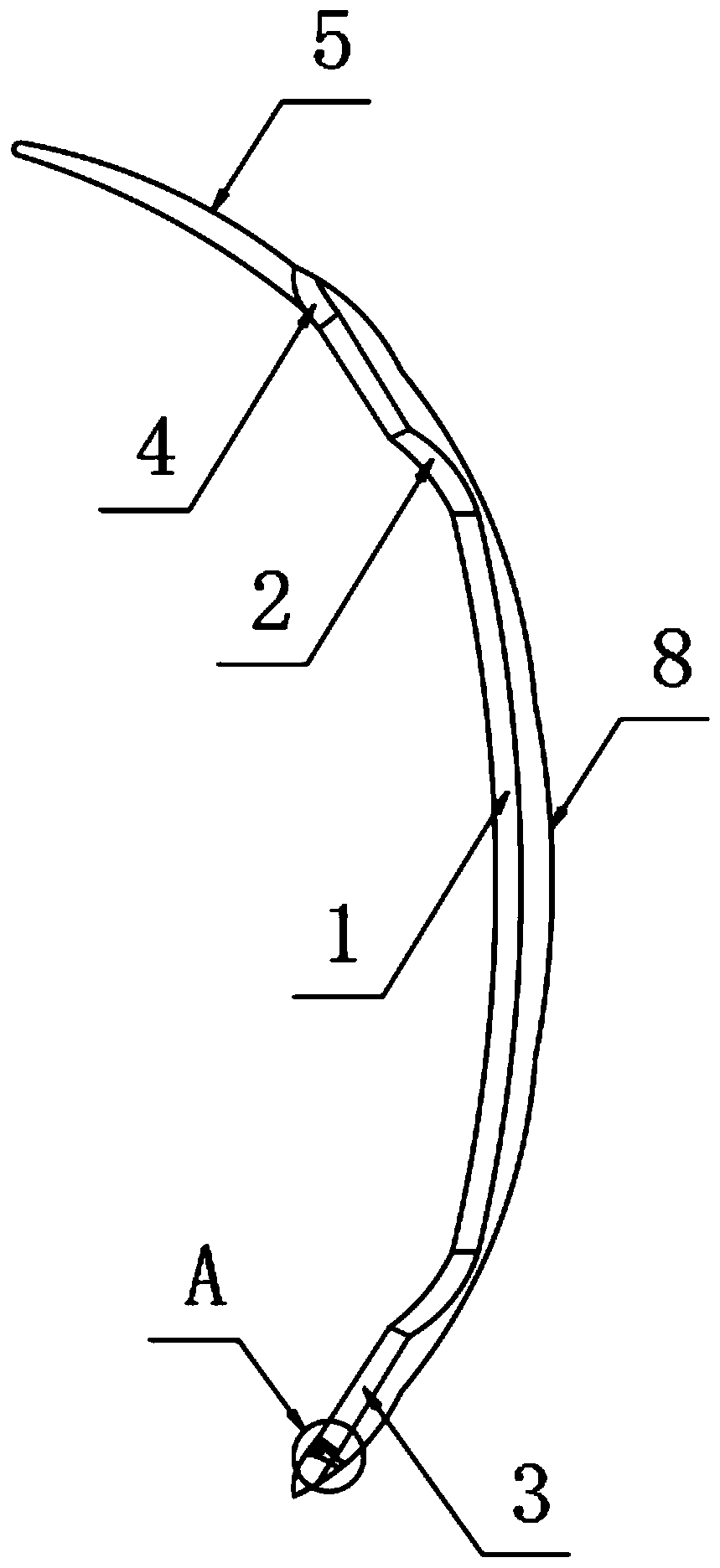

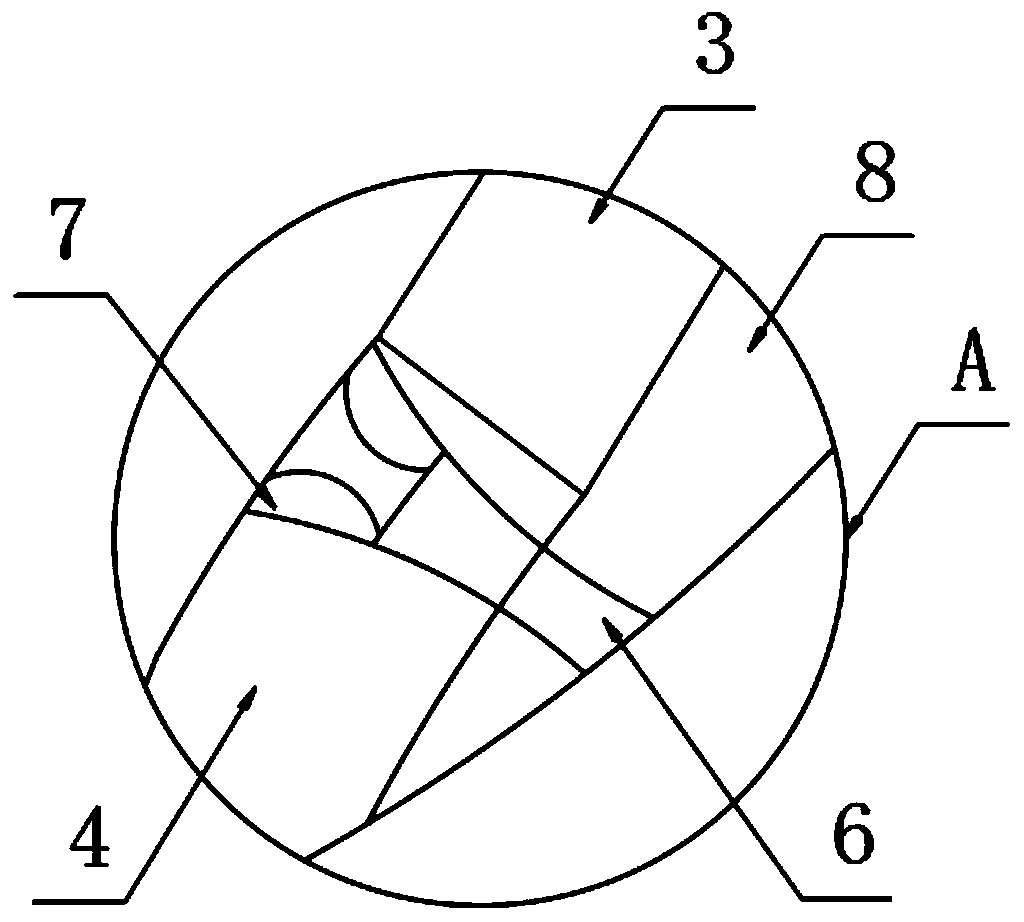

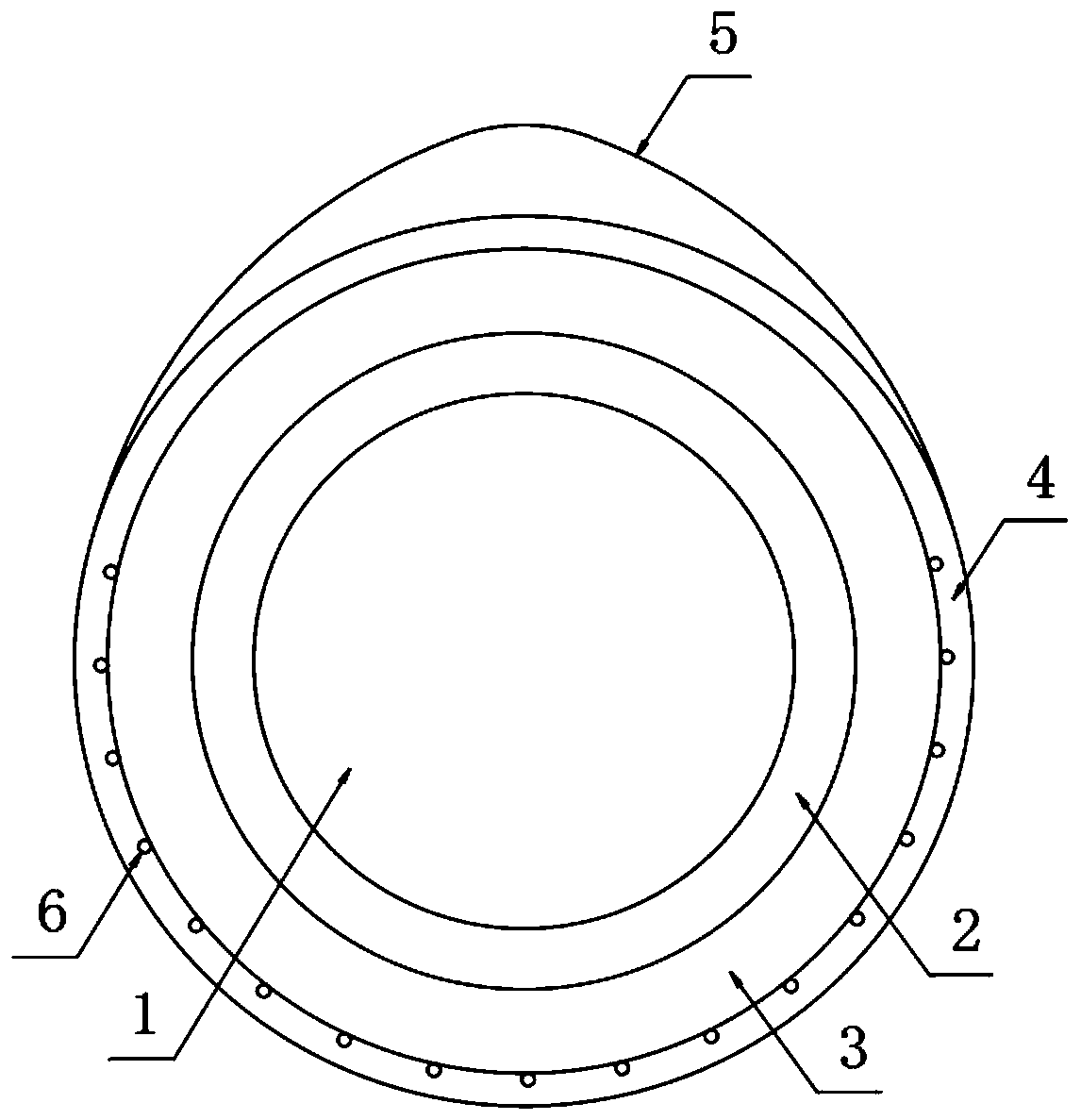

[0035] The present invention provides such Figure 1-3 A new type of orthokeratology lens shown includes a base arc 1 for flattening the front surface of the cornea, and an inversion arc 2 for providing tear storage space and negative pressure is provided on the outside of the base arc 1 , The outer side of the inversion arc area 2 is provided with a positioning arc area 3 for helping the lens to be positioned on the cornea, and the outer side of the positioning arc area 3 is provided with a peripheral arc area 4 for allowing tears to circulate under the lens. The top of 4 is provided with a guide area 5, and a plurality of circulation holes 6 are formed through the peripheral arc area 4, and a protective ring 7 is fixed inside the circulation hole 6, and the base arc area 1, reverse arc area 2, A reinforcement layer 8 is provided on the front side of the positioning arc 3 and the peripheral arc 4 .

[0036] It can be seen from the above-mentioned embodiments that the present...

Embodiment 2

[0038] Further, in the above-mentioned embodiment 1, the base arc area 1, the reverse arc area 2, the positioning arc area 3, the peripheral arc area 4, the guide area 5, the circulation hole 6, the protection ring 7 and the reinforcement layer 8 are integrally formed , in order to reduce the manufacturing difficulty.

[0039] Further, in the above-mentioned embodiment 1, the base arc area 1, the reverse arc area 2, the positioning arc area 3, the peripheral arc area 4, the guide area 5, the circulation hole 6, the protection ring 7 and the reinforcement layer 8 are all composed of Made of Boston EM, Boston EM is a high oxygen permeability polymer material, which is professionally used in the production of orthokeratology lenses.

[0040] Further, in the above-mentioned embodiment 1, the center thickness of the base arc region 1 is 0.10-0.13 mm.

[0041] Further, in the above-mentioned embodiment 1, the top end of the guide area 5 is set as an arc surface, so that the end of ...

Embodiment 3

[0045] The present invention also provides Figure 4-6 A kind of novel orthokeratology lens manufacturing method shown, specifically comprises the following steps:

[0046]Step 1. Prepare manufacturing equipment and molds: the manufacturing equipment includes a bottom plate 9, a cylinder 20 is fixed on the top of the bottom plate 9, a bearing plate 10 is fixed on the top of the cylinder 20, and a middle part is fixed on the top of the bearing plate 10 Spacer plate 11 and both sides spacer plate 12, described both sides spacer plate 12 is located at middle part spacer plate 11 both sides, is provided with molding die 14 between described middle part spacer plate 11 and both sides spacer plate 12, and described forming mold 14 The top is fixedly provided with a cover plate 13, the top of the cover plate 13 is fixedly provided with a connecting rod 15 and the bottom is fixedly provided with a guide rod 18, the top of the connecting rod 15 is fixedly provided with a crossbeam 16, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com