OCA film encapsulation process for a display module

A display module and thin film packaging technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of low production efficiency, difficult to meet production needs, and high equipment, so as to improve the packaging effect, meet production needs, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0035] The first embodiment provided by the present invention is an OCA film packaging process for a display module, which includes the following steps:

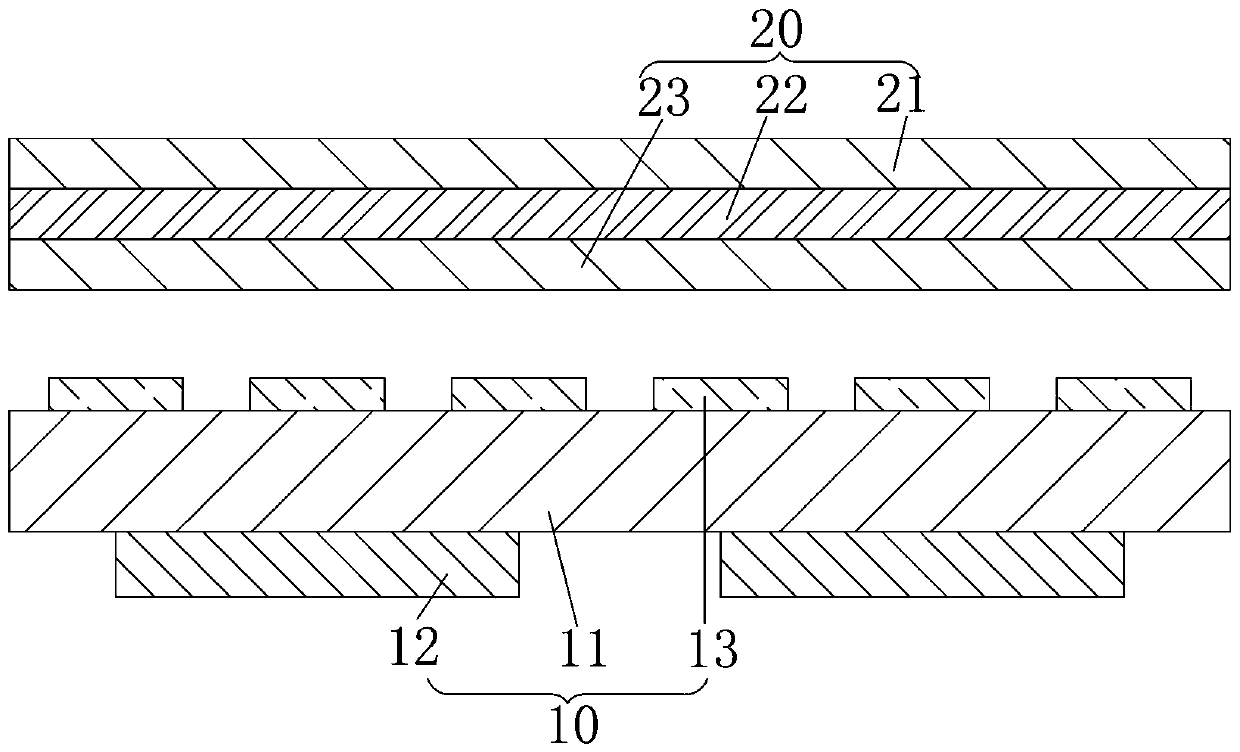

[0036] (1) if figure 1 As shown, a display module 10 is provided, and the display module 10 includes a display substrate 11, a driver IC 12 and an LED chip 13; a plurality of driver ICs 12 are mounted on the bottom surface of the display substrate 11, and a plurality of LED chips 13 are mounted on the display substrate 11 top surface. Wherein, the display substrate 11 is a rigid printed circuit board.

[0037] (2) if figure 1 As shown, an OCA optical adhesive 20 is provided, and the OCA optical adhesive 20 includes an upper release film 21 , an optical adhesive 22 and a lower release film 23 that are laminated sequentially from top to bottom. Wherein, the optical colloid 22 is acrylic and transparent colloid.

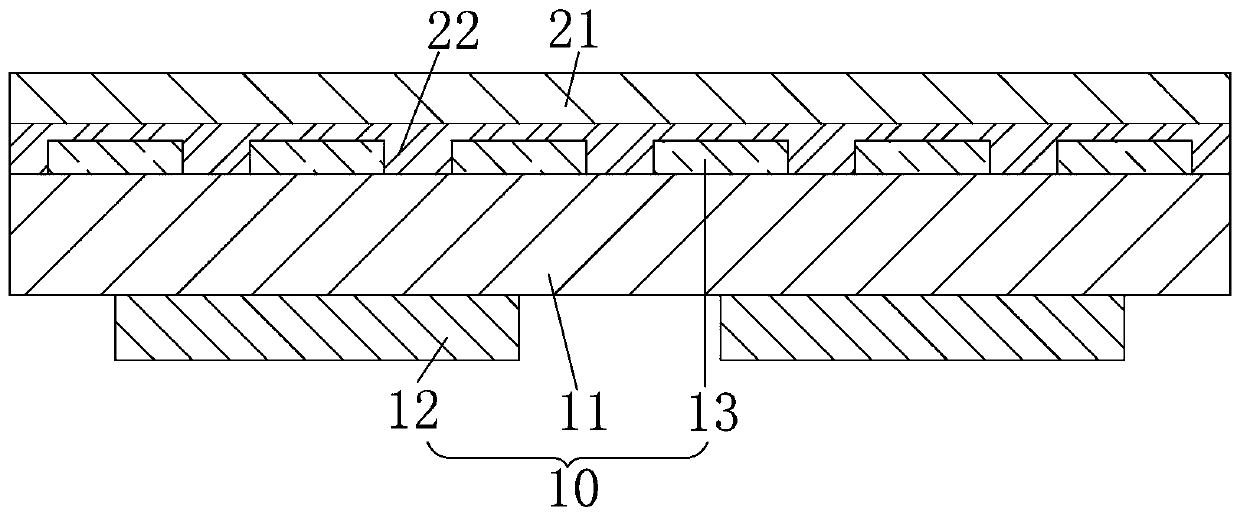

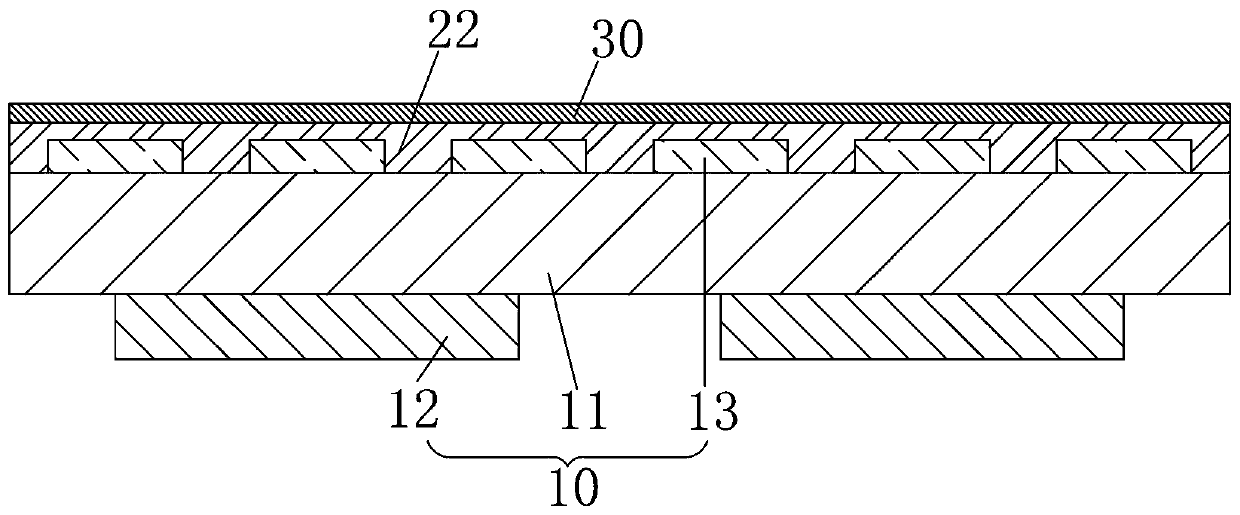

[0038] (3) Tear off the lower release film 23, and attach the bottom surface of the optical colloid 22 to the t...

no. 2 example

[0042] The second embodiment provided by the present invention is an OCA film packaging process for a display module, which includes the following steps:

[0043] (1) if figure 1 As shown, a display module 10 is provided, and the display module 10 includes a display substrate 11, a driver IC 12 and an LED chip 13; a plurality of driver ICs 12 are mounted on the bottom surface of the display substrate 11, and a plurality of LED chips 13 are mounted on the display substrate 11 top surface. Wherein, the display substrate 11 is a rigid printed circuit board.

[0044] (2) if figure 1 As shown, an OCA optical adhesive 20 is provided, and the OCA optical adhesive 20 includes an upper release film 21 , an optical adhesive 22 and a lower release film 23 that are laminated sequentially from top to bottom. Wherein, the optical colloid 22 is acrylic and transparent colloid.

[0045] (3) Tear off the lower release film 23, and attach the bottom surface of the optical colloid 22 to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com