Offset type semiconductor thermoelectric module adopting hexahedral thermoelectric arms

A technology of thermoelectric module and thermoelectric arm, which is applied in the direction of thermoelectric devices that only use the Peltier or Seebeck effect, can solve the problems of increased electrode loss and increased resistance, and achieve the effect of reducing consumption, reducing impact, and high power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is attached Figure 1-9 The embodiments of the present invention are further described in detail.

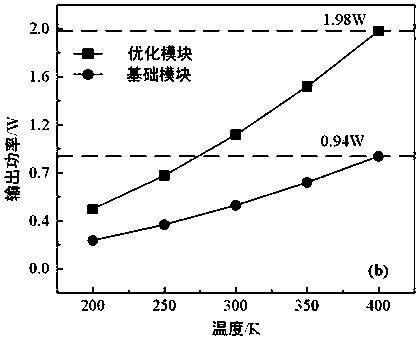

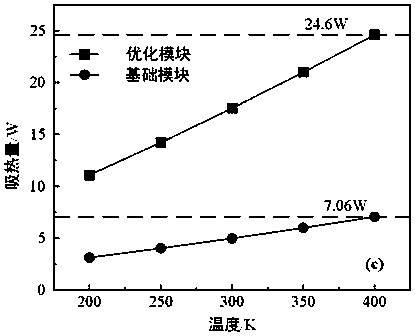

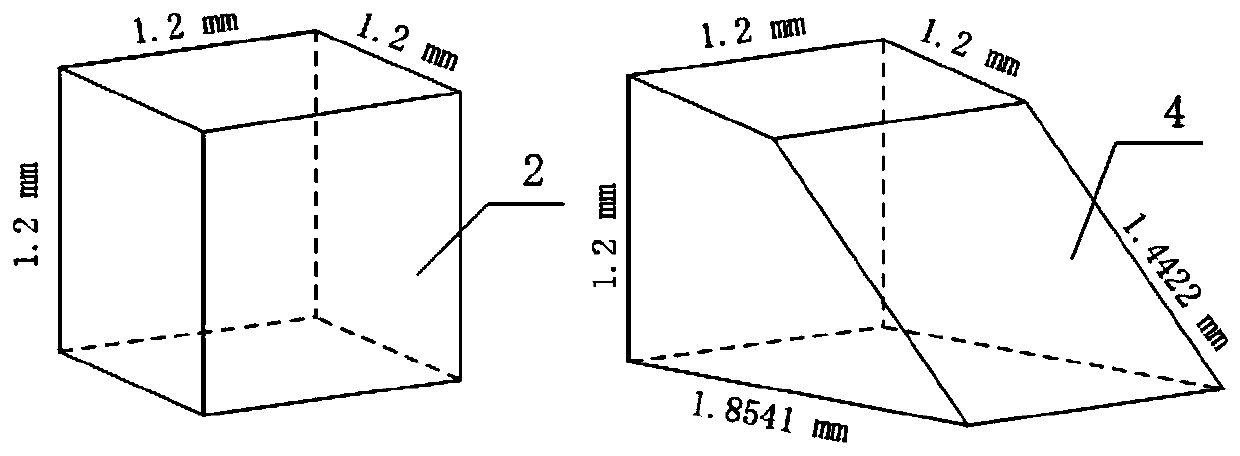

[0024] Through the analysis of the internal current distribution of the thermoelectric arm in the thermoelectric module, it is proved that the thermoelectric arm with the offset hexahedron structure has better thermoelectric performance than the ordinary parallelepiped thermoelectric arm, so based on the above two points, the present invention proposes the use of the offset hexahedron Structural thermoelectric modules.

[0025] The present invention is an offset semiconductor thermoelectric module adopting a hexahedral structure thermoelectric arm, comprising two hexahedral semiconductor thermoelectric arms 2, a copper conductive sheet a1 and a copper conductive sheet b3, wherein the two hexahedral semiconductor thermoelectric arms 2 are symmetrical by The parallel connection is arranged between the two copper conductive sheets a1 and the copper conductive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com