Centrifugal fan for leaf peeling device

A centrifugal fan and leaf stripping technology, used in harvesters, agricultural machinery and implements, agriculture, etc., can solve problems such as damage to sugarcane stems and failure of leaf stripping, avoid up and down movement, ensure leaf stripping effect, and improve leaf stripping. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

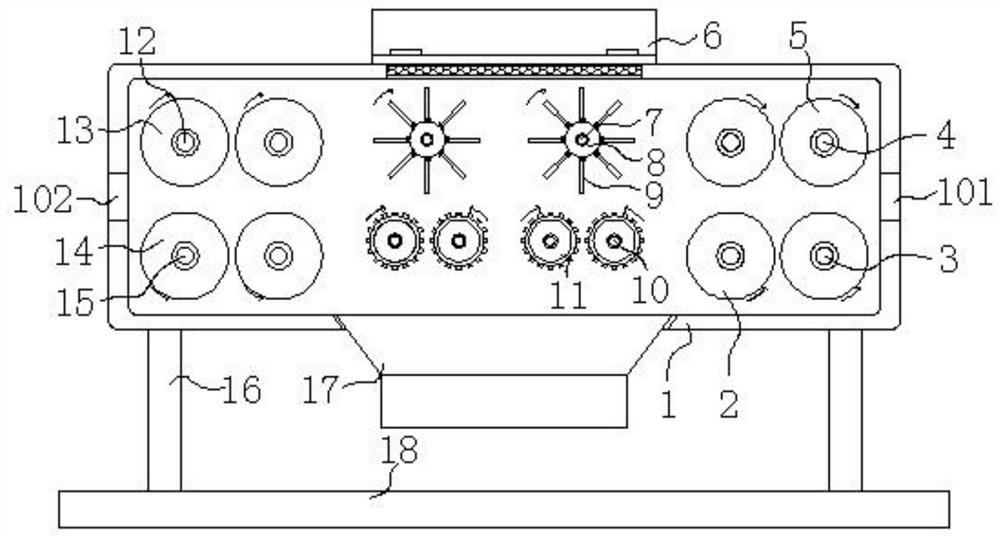

[0024] Embodiment one, with reference to figure 1 , the leaf stripping device of the centrifugal fan, including a leaf stripping box 1, is characterized in that: the stripping box 1 is provided with two fan shafts 7 along the width direction, and the leaf stripping box 1 is located at the bottom of each fan shaft 7. There are two stripping shafts 10, the outer walls of the two stripping shafts 10 are fixedly provided with stripping rollers 11, the both sides of the stripping box 1 are respectively provided with a feed inlet 101 and a discharge port 102, and the stripping box 1 1. The upper feed shaft 4 and the lower feed shaft 3 are respectively embedded from top to bottom near the feed port 101, and the upper feed rollers are respectively sleeved on the outer walls of the upper feed shaft 4 and the lower feed shaft 3. The cylinder 5 and the lower feeding roller 2 are respectively embedded with an upper output shaft 12 and a lower output shaft 15 from top to bottom near the di...

Embodiment 2

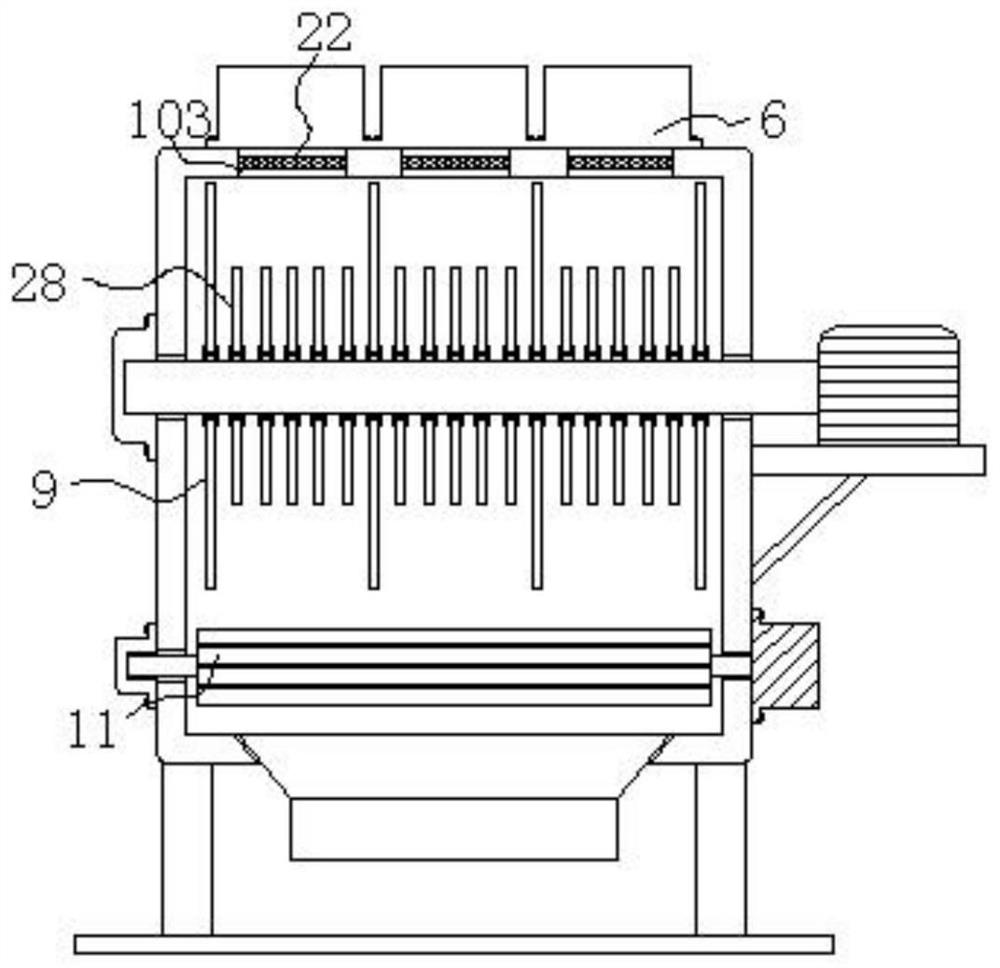

[0025] Embodiment two, refer to figure 2 , image 3 and Figure 5 The outer wall fixing sleeves of the two fan shafts 7 are provided with pusher rollers 8, and the outer walls of the pusher rollers 8 are evenly welded with a plurality of fixed blocks 27, and the short blades 28 are fixed in the plurality of fixed blocks 27 by hexagon socket screws. and the long blades 9, and the short blades 28 and the long blades 9 are alternately distributed along the width direction of the two fan shafts 7, and there are eight short blades 28 and long blades 9 located on the same vertical plane of the two fan shafts 7, And the short blade 28 and the long blade 9 are all made of soft material, and the long blade 9 and the short blade 28 are all made of soft material, which can be made of wear-resistant rubber, so that it can be used as the blade of the blower fan, and avoid the process of stripping the leaves. The sugarcane stem moves up and down to improve the leaf stripping efficiency, ...

Embodiment 3

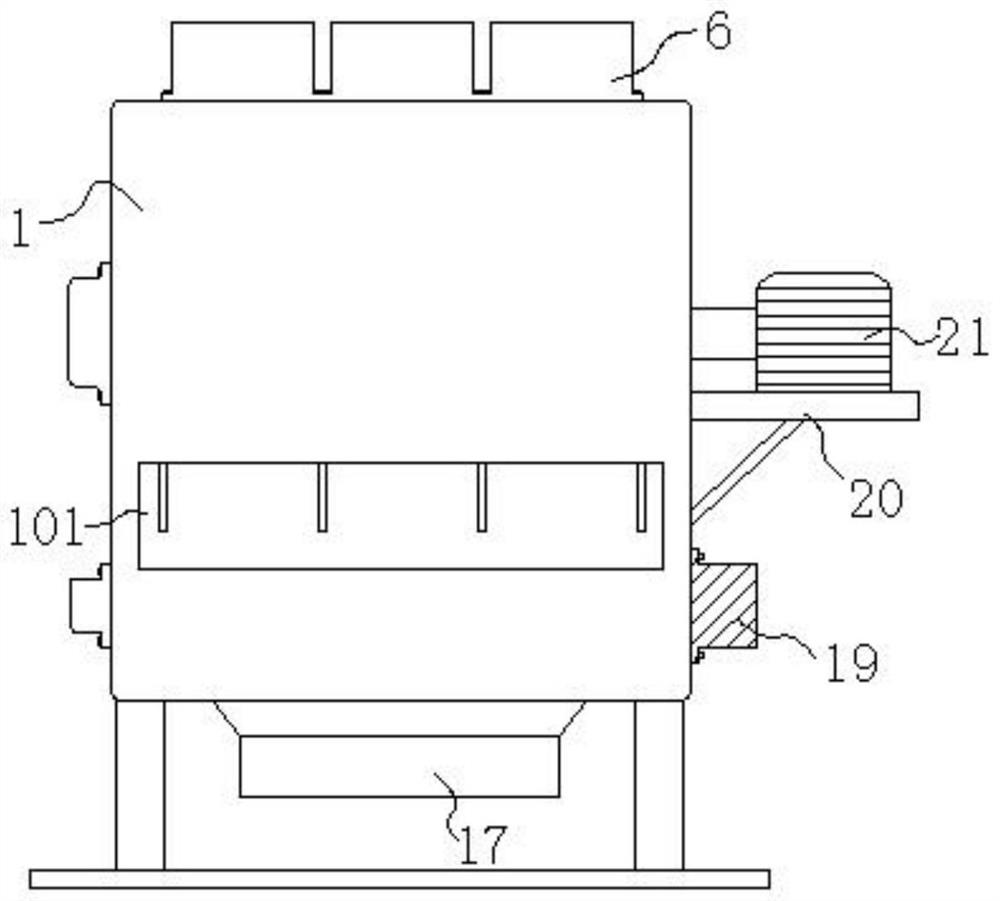

[0026] Embodiment three, refer to figure 1 , image 3 and Figure 4 , one side of the peeling box 1 is welded with a support frame 20, and the top of the support frame 20 is fixed with a plurality of driving motors 21 by bolts, and the output ends of the plurality of driving motors 21 are respectively connected to the two fan shafts 7 and the lower feeding The shaft 3, the upper feeding shaft 4, the upper output shaft 12 and the lower output shaft 15 are rotationally connected, and one side of the leaf stripping box 1 is fixed with two leaf stripping motors 19 by bolts, and the output ends of the two leaf stripping motors 19 are respectively Rotately connected with the stripping shaft 10, the inner wall of the blower box 6 is welded with a support ring block 23, the top of the support ring block 23 is provided with a fixed rod 24, and the fixed rod 24 is fixed with the support ring block 23 by bolts, and the fixed rod The other end of 24 is welded with blower motor 25, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com