Trackless self-propelled platform truck for maintaining subway tunnel

A self-propelled, platform vehicle technology, applied in tunnels, motor vehicles, transportation and packaging, etc., can solve problems such as inconvenient operation, falling blocks, segment cracking, etc., and achieve the effect of convenient adjustment, simple structure and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

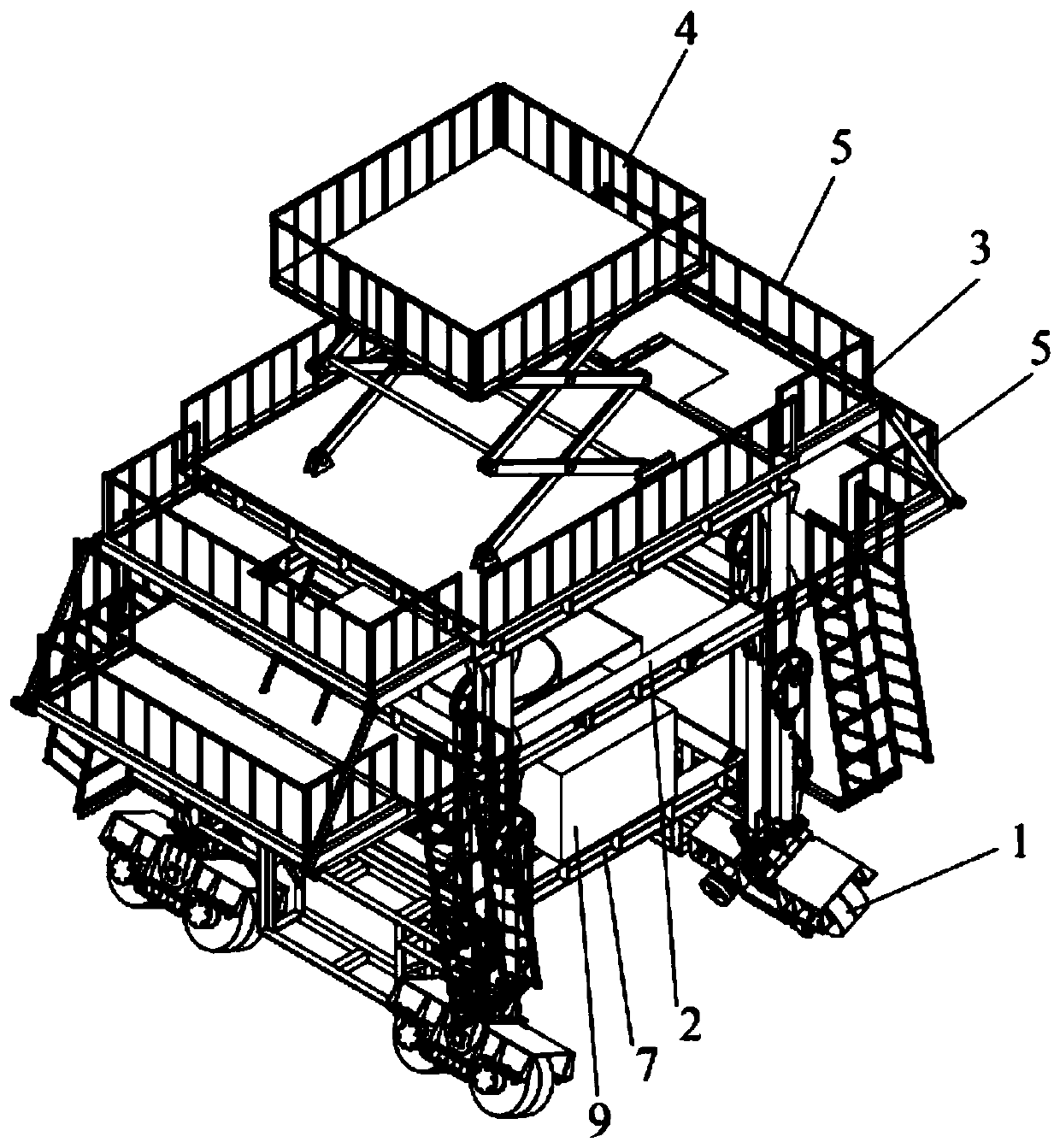

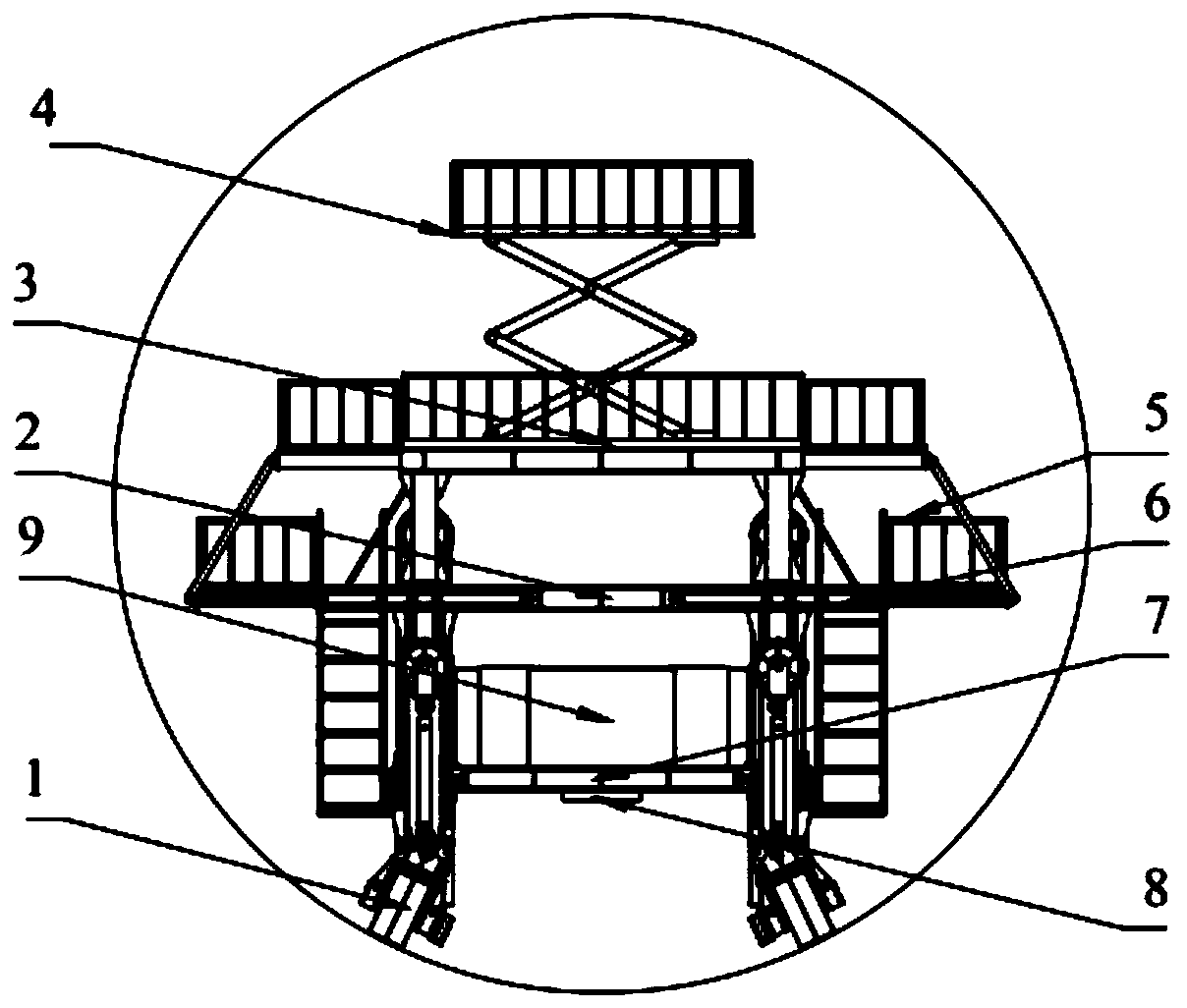

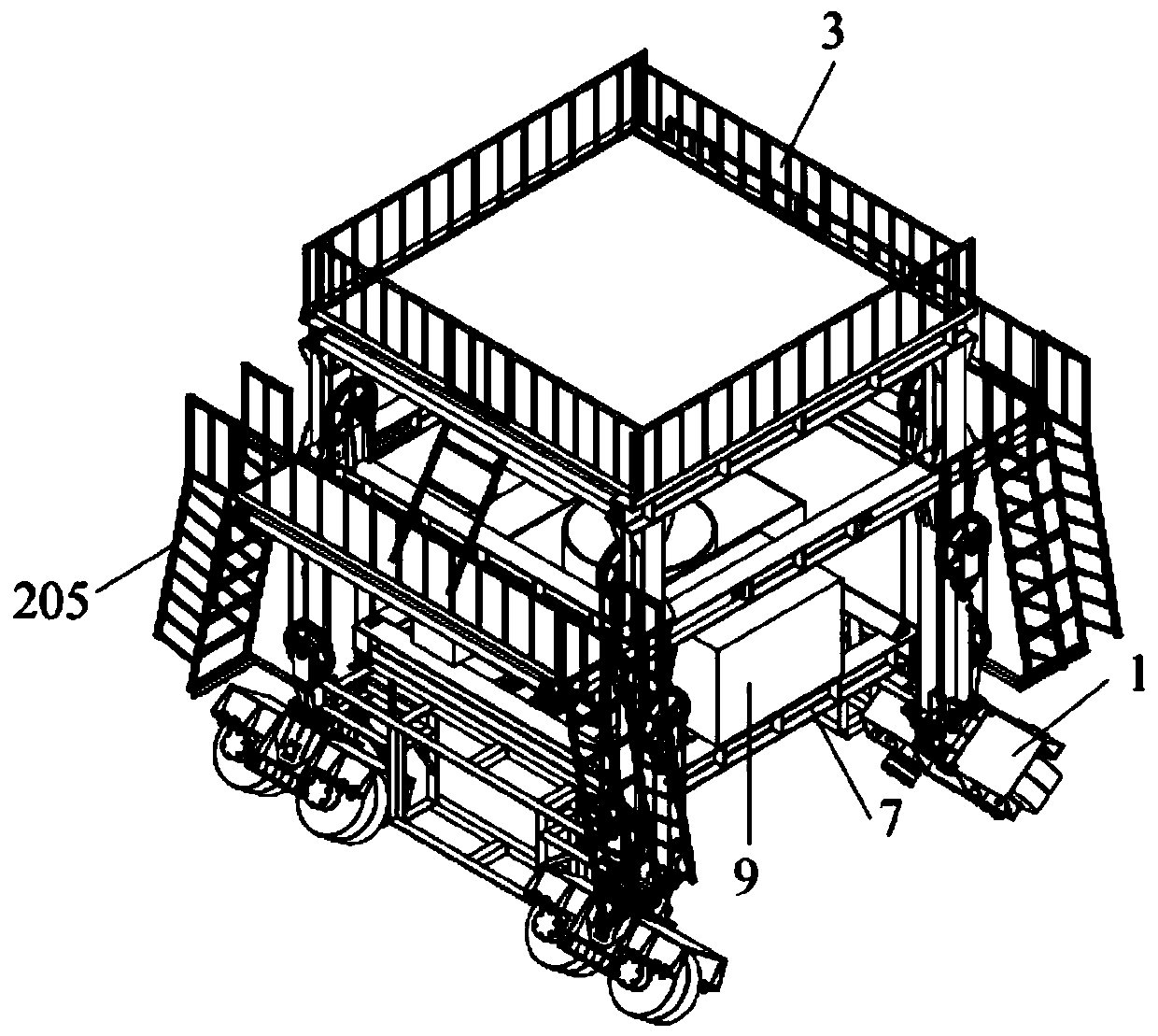

[0040] refer to Figure 1-17 , the present invention provides a technical solution:

[0041] Please refer to Figure 1-6 , a trackless self-propelled platform vehicle for subway tunnel maintenance, including a mechanical system, a control system, a hydraulic system and a power supply system, the mechanical system includes a traveling device 1, a main bearing platform 2, a fixed operating platform 3, and a lifting operating platform 4. Telescopic work platform 5, support device 6, vehicle-mounted equipment platform 7 and centering mechanism 8, the walking device 1, main carrying platform 2, fixed working platform 3 and lifting working platform 4 are connected in sequence, and the main carrying platform 2 Both ends of the fixed work platform 3 are slidably connected with a telescopic work platform 5, the support device 6 is connected with the telescopic work platform 5, the vehicle-mounted equipment platform 7 is used to place the vehicle-mounted equipment, and the self-alignin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com