A kind of wire transfer insulation treatment structure for Hall thruster

A technology of Hall thruster and wire transfer, which is applied in the direction of connecting insulation, thrust reverser, using plasma, etc., to achieve the effect of improving reliability and achieving insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

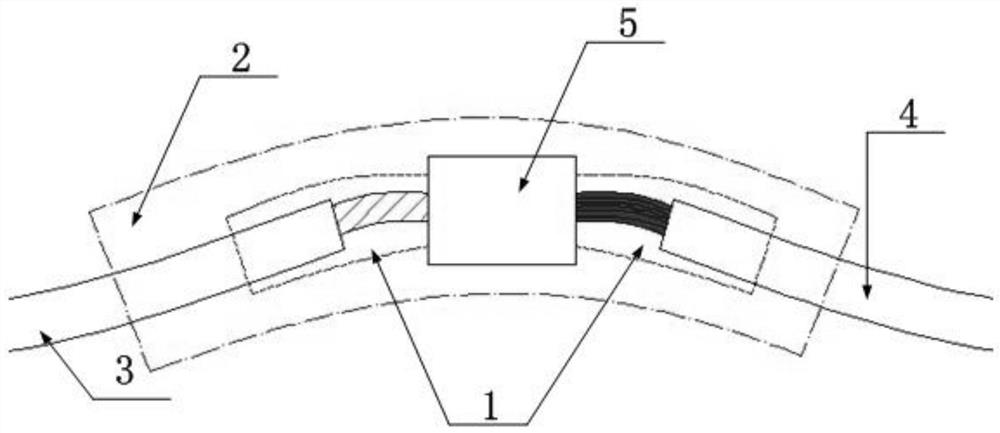

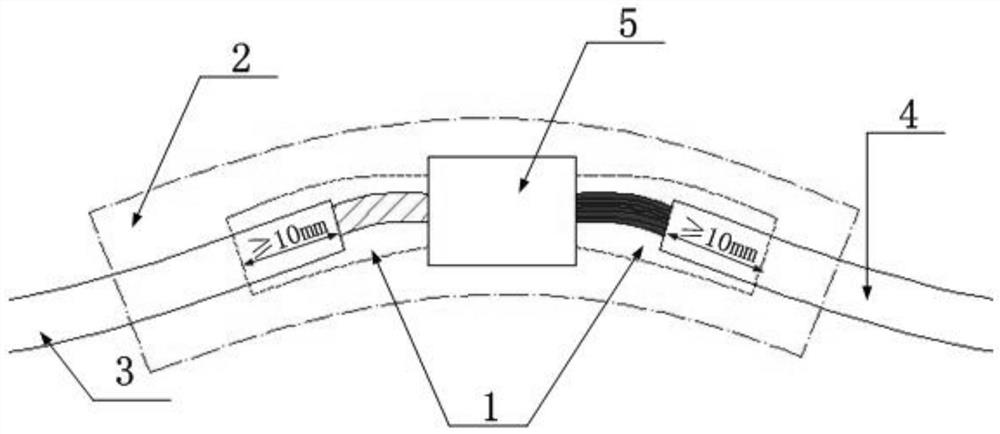

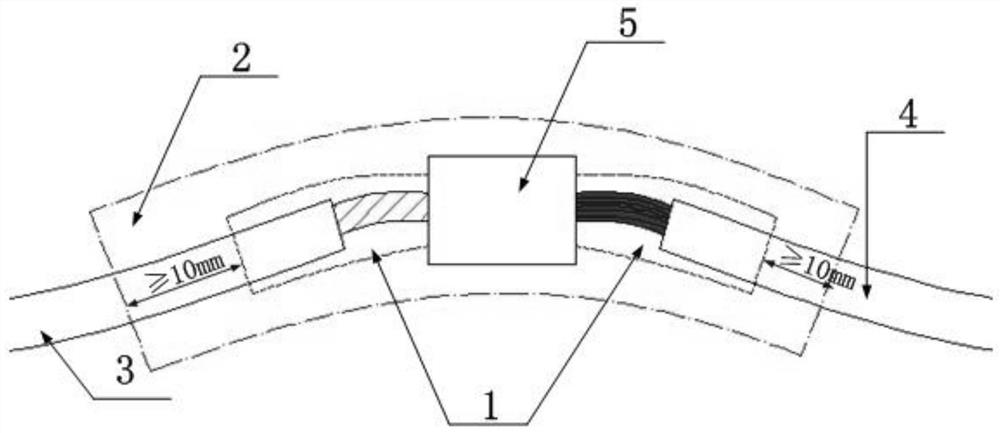

[0030] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0031] The invention provides a wire transfer insulation treatment structure for a Hall thruster. Two kinds of high temperature resistant heat shrinkable tubes with different diameters are used to realize the insulation treatment of the wire transfer point, which is suitable for insulation treatment under high temperature conditions; Thrusters or other occasions that require the conversion of single-strand core wires to multi-strand core wires and the working temperature is high.

[0032] The insulation treatment structure at the wire transfer point of the Hall thruster mainly includes two sections of small-diameter high-temperature-resistant heat-shrinkable tube 1, large-diameter high-temperature-resistant heat-shrinkable tube 2, single-strand wire 3, multi-strand wire 4, and wire welding joint 5; among them, The wire welding head 5 is a cube s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com